Just a little sidenote .. If you're to build the THAM12 with PD.12SB30 you have to make the cabinet a couple of mm. wider.

I made the mistake to not look properly on the driver measurements, so i missed that it is actually a few mm. wider instead of a few mm. narrower. So i had to take 1,5mm of each side of the driver 🙄

Well .. I guess you learn every day.

I made the mistake to not look properly on the driver measurements, so i missed that it is actually a few mm. wider instead of a few mm. narrower. So i had to take 1,5mm of each side of the driver 🙄

Well .. I guess you learn every day.

Hi all!

What if we mount driver from inside the throat? Of course. with magnet in mouth and removable bottom panel. It seems closer to hornresp model if done that way IMHO.

Best regards

Vladimir

What if we mount driver from inside the throat? Of course. with magnet in mouth and removable bottom panel. It seems closer to hornresp model if done that way IMHO.

Best regards

Vladimir

Hi Fladot,

I think that would be interesting. You would probably need a removable bottom panel (or a removable mounting board to mount board plus driver from the mouth openin), and a disc (or two) for the remaining cone correction:

Regards,

I recommended AGAINST doing this (removable bottom panel) in post #77. That first section of the horn needs to be properly braced, and making that panel removable makes it more difficult to implement proper bracing.

Hi Fladot,

I think that would be interesting. You would probably need a removable bottom panel (or a removable mounting board to mount board plus driver from the mouth openin), and a disc (or two) for the remaining cone correction:

Regards,

Thanks tb46,

as for cone correction: is it from side to side or it's in a disc form, following the cone shape in 3D?

Vladimir

Hi Brian,

Yes, removable bottom panel does complicate things a bit, but properly implemented can improve rigidity of that section in my opinion. By the way, we have that situation at FL horns.

Regards,

Vladimir

Yes, removable bottom panel does complicate things a bit, but properly implemented can improve rigidity of that section in my opinion. By the way, we have that situation at FL horns.

Regards,

Vladimir

Hi Fladot,

Post #125: "...is it from side to side or it's in a disc form..."

That would be your choice, obviously you'd have to adjust the size accordingly. The sketch in Post #123 shows it in disc form.

Brian is correct, the bracing would have to be taking into account too, and not just for stability, but also for volume/area.

Regards,

Post #125: "...is it from side to side or it's in a disc form..."

That would be your choice, obviously you'd have to adjust the size accordingly. The sketch in Post #123 shows it in disc form.

Brian is correct, the bracing would have to be taking into account too, and not just for stability, but also for volume/area.

Regards,

Hi Brian,

Yes, removable bottom panel does complicate things a bit, but properly implemented can improve rigidity of that section in my opinion. By the way, we have that situation at FL horns.

Regards,

Vladimir

Having actually done it for a TH that's a very close relative of the THAM 12, my advice is DO NOT DO IT. Proper crossbracing between the driver panel and external panel in that section is VERY important, and it WILL be compromised if you make that panel removable to allow the driver to be inserted from that side.

It's a mechanical challenge.

Everything is possible but this depends on the builder's technical knowledge and handiness.

I have seen proof that Russians are very handy and good at thinking 'outside the box', on the internet. 🙂

shields up....

Everything is possible but this depends on the builder's technical knowledge and handiness.

I have seen proof that Russians are very handy and good at thinking 'outside the box', on the internet. 🙂

shields up....

I have seen proof that Russians are very handy and good at thinking 'outside the box', on the internet. 🙂

shields up....

I'm not sure I understand but I hope it's pun intended. 🙂

I have Russian name but I come from country of famous Novak Djoković.😉

Regards,

Vladimir

Hi korrnylike,Djim or Tb46

Can some please post a drawing and measurement of the cone correction for the b&c 12PS100 driver.

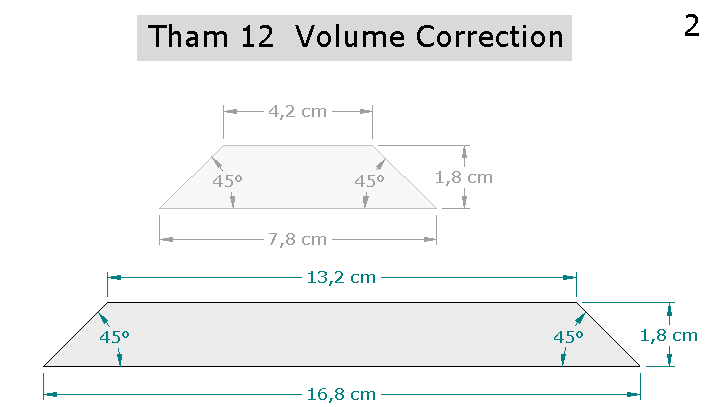

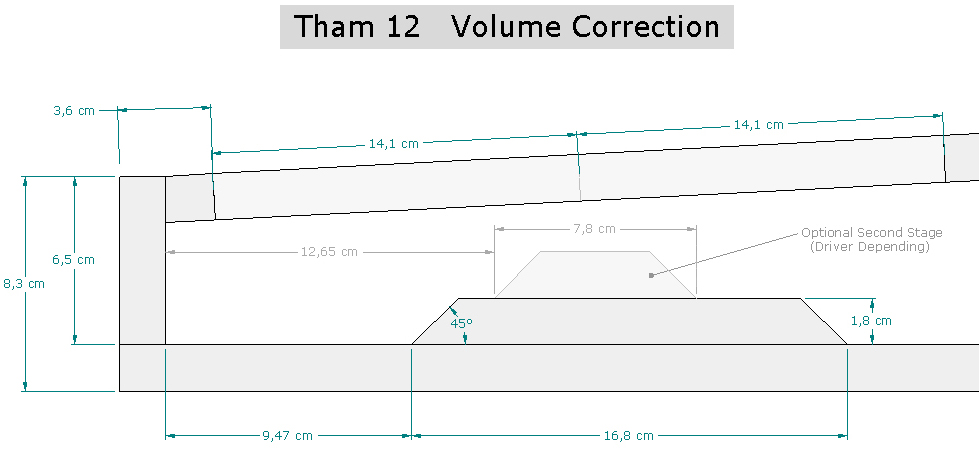

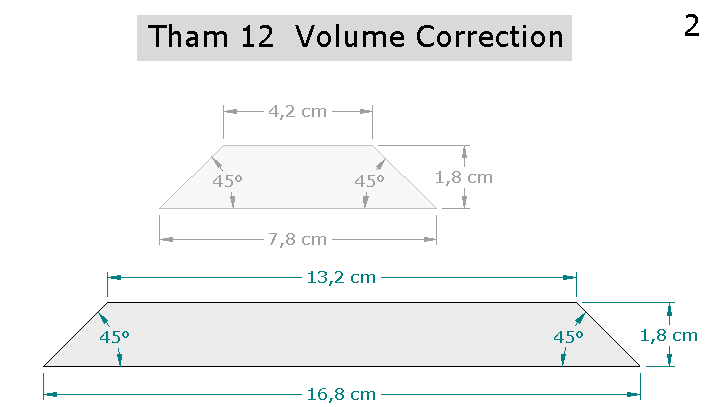

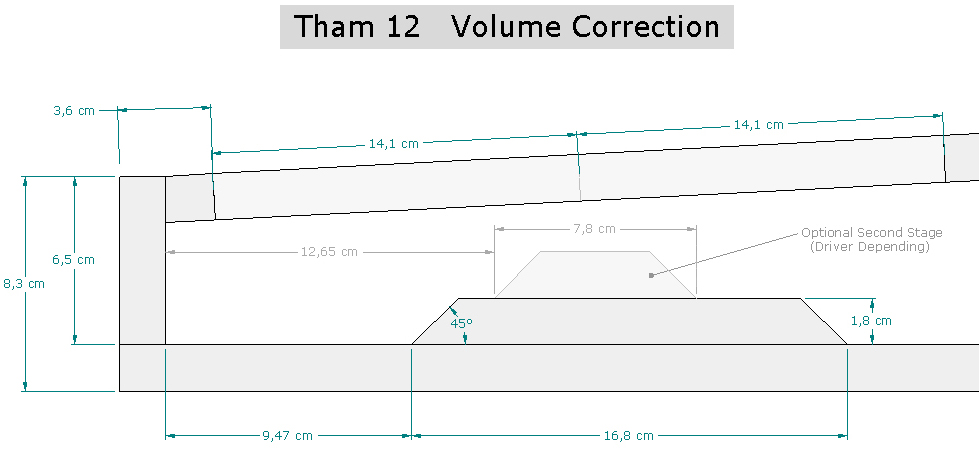

Sorry for the delay but here you have the drawings (in scale this time😉) for the Tham 12.

The 'first stage' is meant for majority of drivers that work in the Tham12 and could be seen as a general design correction. The second stage is more specific with the 12PS100 driver in mind.

With any Volume Correction I always advice to test it first (at high levels) before final assembly, just to make sure.

Last edited:

Hmm .. Maybe i will have to try out this cone-correction thing. A shame i finished my 2 cabs before looking further into this.

Anyway .. Here is a shot of my newly (yesterday) finished THAM12s

Have only had a couple of minutes to play around with them, but the sound quality is absolutely great! I will have to play a little more around with the crossover frequency before giving them a proper beating, as i think i might had it too low, making the cone move a little to much for my taste. Having a gig on saturday with plenty of playtime, so looking forward to mess around with them 🙂

Anyway .. Here is a shot of my newly (yesterday) finished THAM12s

An externally hosted image should be here but it was not working when we last tested it.

Have only had a couple of minutes to play around with them, but the sound quality is absolutely great! I will have to play a little more around with the crossover frequency before giving them a proper beating, as i think i might had it too low, making the cone move a little to much for my taste. Having a gig on saturday with plenty of playtime, so looking forward to mess around with them 🙂

Hi Chaps,Hmm .. Maybe i will have to try out this cone-correction thing. A shame i finished my 2 cabs before looking further into this. Anyway .. Here is a shot of my newly (yesterday) finished THAM12s

Of course this is a much smaller 'crampy' space than a TH18 but if you cut the correction in half, you should be able to mount them trough the driver cut-out.

Very nice build btw!

Hi Chaps,

Of course this is a much smaller 'crampy' space than a TH18 but if you cut the correction in half, you should be able to mount them trough the driver cut-out.

Very nice build btw!

Yes i think i should be able to squeeze it in there. It will have to be cut in half anyway because of a bracing along the middle underneath the driver. Should be worth a try.

And thanks 🙂

I'll will draw another correction in the next few days when used with the centre brace cause it needs a small adjustment for that.

I'll will draw another correction in the next few days when used with the centre brace cause it needs a small adjustment for that.

That would be great!

Hmm .. Maybe i will have to try out this cone-correction thing. A shame i finished my 2 cabs before looking further into this.

Anyway .. Here is a shot of my newly (yesterday) finished THAM12s

An externally hosted image should be here but it was not working when we last tested it.

Have only had a couple of minutes to play around with them, but the sound quality is absolutely great! I will have to play a little more around with the crossover frequency before giving them a proper beating, as i think i might had it too low, making the cone move a little to much for my taste. Having a gig on saturday with plenty of playtime, so looking forward to mess around with them 🙂

They look great. Do you have any measurements, or even simply comments regarding their performance? Also, if it's not too much trouble, I'd love to know what drivers, handles, and connectors you used as well as any particular issues that you might have had during construction?

I love the stacking feet, I presume that they have been routed so that they can be stacked in either dimension?

I'd love to see more pictures, either build shots, or side/rear shots, if you have them.

At the risk of pushing my luck, have you weighed them?

As I say, they look great, you appear to know what you're doing and it would be great to hear field reports from people who have actually used them. I've seen plenty of discussion about MTH30 builds, and, of course, this thread has a lot of discussion of the THAM12 design, but I've seen very little about actual THAM12 builds.

tnx,

gs

Hi korrnylike,

Sorry for the delay but here you have the drawings (in scale this time😉) for the Tham 12.

The 'first stage' is meant for majority of drivers that work in the Tham12 and could be seen as a general design correction. The second stage is more specific with the 12PS100 driver in mind.

With any Volume Correction I always advice to test it first (at high levels) before final assembly, just to make sure.

Djim thanks for the drawing.

The driver will be arriving today.

Hi kornnylike,

It would still be great to get the driver/cone dimensions.

Regards,

What area of the cone do you want me to measure.

- Home

- Loudspeakers

- Subwoofers

- MTH30 Questions : Complete Noob!