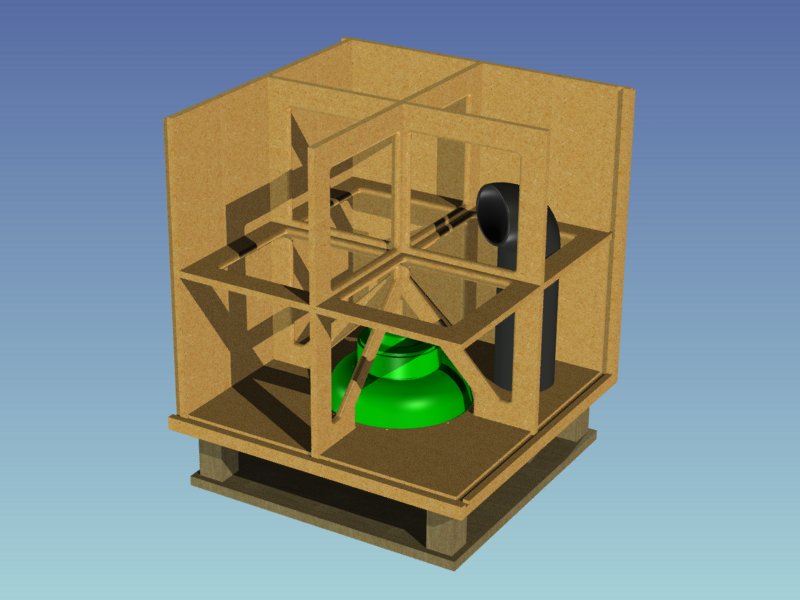

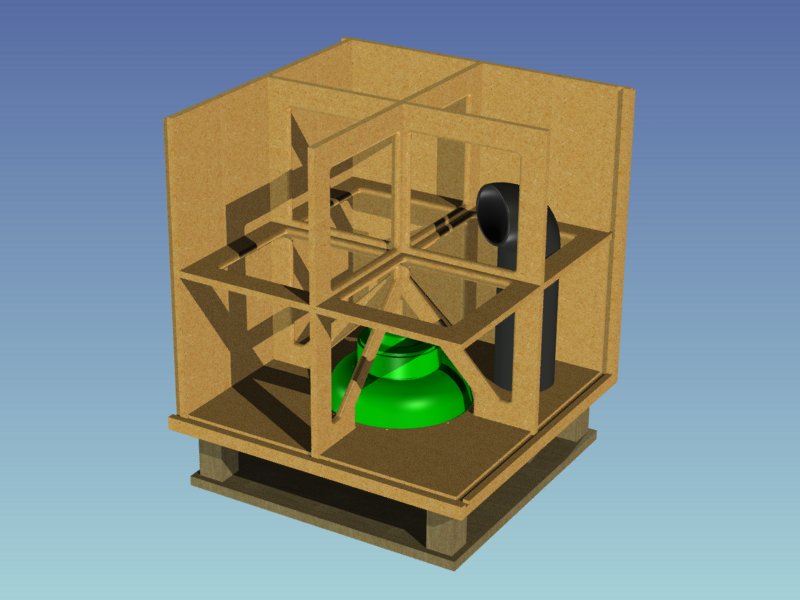

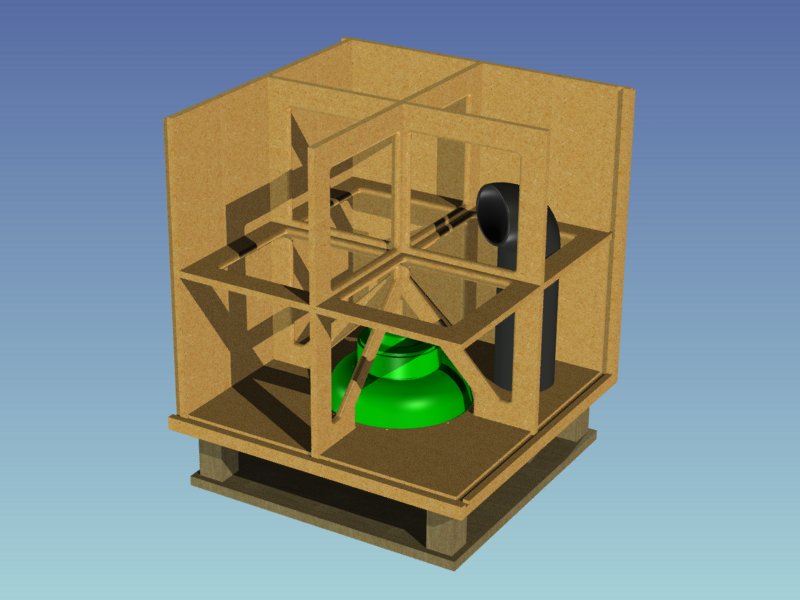

I have a 16.5"x16.5"x16.5" sealed enclosure for a single 12" driver. I'll be pumping a fair bit of power into it considering I'm running a Linkwitz Transform to boost output to be flat to nearly 20Hz. I've used 1" MDF panels, and I'm wondering how much to brace the internals. I've got enough extra MDF to do some extensive cross bracing similar to this setup:

NOTE: This is NOT my subwoofer. Mine is sealed.

Is this overkill or necessary. I can do any amount in between as well. Is a dowel enough or do I need something extensive like this?

NOTE: This is NOT my subwoofer. Mine is sealed.

Is this overkill or necessary. I can do any amount in between as well. Is a dowel enough or do I need something extensive like this?

Last edited:

Oops. I meant 16.5"x16.5"x16.5". Fixed in original post.the pic is just about right

how do you fit a 12" driver in a 16.5inch^3 box? that's like 2.7" x 2.7" x 2.7"

Where are you getting an 8x8 area? I don't really understand.yeah, i figured. bracing like the picture will be good in a 16" cubed box the small 8"x8" open panel area will only vibrate at frequencies well above the output of the driver.

take a 16" square and cut it into 4 sections like in the picture above. each open area (undamped) will be 8" by 8" the resonance of a 8"diameter circle (to calculate resonance you have to think in circles that will fit in a space) is right around ~1041Hz well above the frequency range of the driver.

take a 16" square and cut it into 4 sections like in the picture above. each open area (undamped) will be 8" by 8" the resonance of a 8"diameter circle (to calculate resonance you have to think in circles that will fit in a space) is right around ~1041Hz well above the frequency range of the driver.

Try using 2x4 solid lumber (non-finger jointed wall studs) for bracing - it's much stiffer than MDF, or locate the window-pane bracing off-center by at least an inch or two to sub-divide the panels into uneven areas.

INOTE: This is NOT my subwoofer. Mine is sealed.

That's way overkill. It will only rob you of efficiency (due to lowered box volume) and make the sub heavier than necessary. So sonic or practical benefit.

For a sub that size in 1" MDF, you don't need anything more than maybe a dowel connecting the side walls. Depending on the size of your driver's motor, you may also want a shelf brace to support it.

That's way overkill. It will only rob you of efficiency (due to lowered box volume) and make the sub heavier than necessary. So sonic or practical benefit.

For a sub that size in 1" MDF, you don't need anything more than maybe a dowel connecting the side walls. Depending on the size of your driver's motor, you may also want a shelf brace to support it.

Are you saying for a sub the size in the picture or for my sub? I just finished routing everything and I'm contemplating whether or not to brace at all. 1" MDF is rigid as hell and I don't think it's going to go anywhere, even at <20Hz. A dowel just seems so cheap, though.

at 20Hz it won't move at all at 62.5, 125, 250, 500Hz it will ring like a bell. you have to think about harmonics. what crossover point are you going to use?

I haven't measured the response of the mains, but it'll probably be 120Hz or lower, more than likely closer to 100. Will it really ring like that?

I haven't measured the response of the mains, but it'll probably be 120Hz or lower, more than likely closer to 100. Will it really ring like that?

clamp one of the cut panels on the edges, hold the clamp bar and tap it with a mallet, you will hear it's resonance frequency.

Is that better than a shelf brace? And I presume the 1" side would be up against the wall (making a sort of T shape)?

better... there is a point of diminishing returns with bracing, depends on the energies involved. Good enough, probably.

yes, a T shape.

Are you saying for a sub the size in the picture or for my sub? I just finished routing everything and I'm contemplating whether or not to brace at all. 1" MDF is rigid as hell and I don't think it's going to go anywhere, even at <20Hz. A dowel just seems so cheap, though.

Your bracing scheme would probably be fairly difficult to assemble.

What I would probably do:

two square braces like you have at the 1/3 and 2/3 points

On the sides that aren't braced by the square braces, put ribs that are ~3x thickness near the 1/3 and 2/3 points.

Ron is hinting at something here...

Given the braces shown in the picture, there is a more effective way to use them. Take the horizontal brace and reorient it parallel to one of the other 2. Space the 2 in the same direction at about 1/3 & 2/3rds but not exactly. The 3 subpanels should be unequal.

The 3rd brace can be left as is, but should not be dead centre.

Braced as shown you will have 20 8x8 panels that would all resonant in sympathy with one another (if your sub was producing sufficient energy at that frequency to excite the resonance (unlikely)).

Note that MDF makes poor braces (and also that 1" MDF is about the equivalent of 5/8" quality ply but with more energy storage).

dave

Given the braces shown in the picture, there is a more effective way to use them. Take the horizontal brace and reorient it parallel to one of the other 2. Space the 2 in the same direction at about 1/3 & 2/3rds but not exactly. The 3 subpanels should be unequal.

The 3rd brace can be left as is, but should not be dead centre.

Braced as shown you will have 20 8x8 panels that would all resonant in sympathy with one another (if your sub was producing sufficient energy at that frequency to excite the resonance (unlikely)).

Note that MDF makes poor braces (and also that 1" MDF is about the equivalent of 5/8" quality ply but with more energy storage).

dave

Are you saying for a sub the size in the picture or for my sub?

Both.

I just finished routing everything and I'm contemplating whether or not to brace at all. 1" MDF is rigid as hell and I don't think it's going to go anywhere, even at <20Hz.

Probably not worth the effort. I have one brace in my new main sub (65L cabinet, Aurasound NS12-794-4A), which is made from thinner material than your sub. And it's fine.

A dowel just seems so cheap, though.

I'd rather something be cheap and effective (especially when it's invisible) than expensive and pointless. But perhaps that's just me.

And not very effective.

dave

Why? If the two opposite sides of the box are drilled for the single dowel, and it's glued in place, then it should be plenty strong, depending on dowel diameter since the wood will be in tension which is the strongest aspect.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- How much bracing is necessary?