From just calculating it and due to having both a sub and woofer at some separation with the mic biased a little high, I'm thinking both the ~180? and ~220? Hz notches are floor bounce.

GM

GM

Thank you all for your comments and suggestions.

I will make new measurements separately for each driver.

The XO is with 24db so is that common that you need to reverse the leads on the tweeter? I know that its common for 12db.

I will also try to adjust the hight og the mic.

If I should dial in a delay, it would be calculating the distance between both drivers voice coils?

There is a 6.2ms delay on the whole top to allign with the sub.

Best, Andy

I will make new measurements separately for each driver.

The XO is with 24db so is that common that you need to reverse the leads on the tweeter? I know that its common for 12db.

I will also try to adjust the hight og the mic.

If I should dial in a delay, it would be calculating the distance between both drivers voice coils?

There is a 6.2ms delay on the whole top to allign with the sub.

Best, Andy

second round measurments

I was able to do some more measuring and wanted to share.

The setup is the same as before, but levels have changed, since I don't have a SPL meter.

REW with a DBX RTA mic and a not validated calibration file I found with google. External calibrated Yamaha Steinberg soundcard, DBX DRPA+ setup with LOW: HP 30hz/24db, MID: HP 100hz/12db, LP 1.12khz/24db HIGH: HP 1.4khz/24db. MID and HIGH has a 6.2ms delay to allign with the sub. The mic is 4meters from the speaker and 1.6 meters high, pointing directly to the horn.

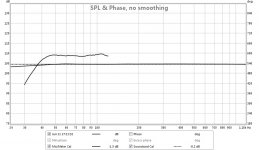

Before:

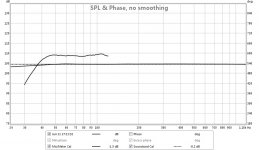

After:

In the after I reversed the leads on the horn, which I think helped removing quite a few dips in the mid area.

These are only frequency measurements, so no THD, Phase etc. so far.

I did actually made an attempt to make SPL measurements with the XTA mic, John Reekie method of making SPL measurements without SLM but I am not able to read and verify the results.

The measurement below ended up being a 10volt measurement, I think because I made some initial SPL calibration settings with a headroom first being to small for a 2.83v input(clipping) and then making a headroom to big(+20db), which called for the high output?

The mic is 4 meters from the sub and 1.6 meters above ground and the 10 volts is measured by plugging in an extra speaker cable in the bag of the sub(parallel) and attach a Voltmeter at the end of that cable.

Input is very welcome.

I am planning on doing more measurments i.e. I want to make sure that the metal grill, which has 47% airflow has no negative impact. And later excursion vs. Cone correction testing etc.

Let me know if you have ideas, also on good maesurement practice.

Best, Andy

I was able to do some more measuring and wanted to share.

The setup is the same as before, but levels have changed, since I don't have a SPL meter.

REW with a DBX RTA mic and a not validated calibration file I found with google. External calibrated Yamaha Steinberg soundcard, DBX DRPA+ setup with LOW: HP 30hz/24db, MID: HP 100hz/12db, LP 1.12khz/24db HIGH: HP 1.4khz/24db. MID and HIGH has a 6.2ms delay to allign with the sub. The mic is 4meters from the speaker and 1.6 meters high, pointing directly to the horn.

Before:

After:

In the after I reversed the leads on the horn, which I think helped removing quite a few dips in the mid area.

These are only frequency measurements, so no THD, Phase etc. so far.

I did actually made an attempt to make SPL measurements with the XTA mic, John Reekie method of making SPL measurements without SLM but I am not able to read and verify the results.

The measurement below ended up being a 10volt measurement, I think because I made some initial SPL calibration settings with a headroom first being to small for a 2.83v input(clipping) and then making a headroom to big(+20db), which called for the high output?

The mic is 4 meters from the sub and 1.6 meters above ground and the 10 volts is measured by plugging in an extra speaker cable in the bag of the sub(parallel) and attach a Voltmeter at the end of that cable.

Input is very welcome.

I am planning on doing more measurments i.e. I want to make sure that the metal grill, which has 47% airflow has no negative impact. And later excursion vs. Cone correction testing etc.

Let me know if you have ideas, also on good maesurement practice.

Best, Andy

Andy,

Your second round measurement looks very good - nice job. The 150 Hz dip looks to deep and sharp to be a floor bounce cancellation. It is probably too narrow to be noticeable but again I was hoping to see traces from each individual driver to debug this. You said that you have not made HD measurements but you have. In REW all measurements automatically generate HD data - just click on HD tab at the top and select harmonics of interest. It is helpful to see first 5 harmonics.

Thanks for sharing. It must sound quite good as it is.

Your second round measurement looks very good - nice job. The 150 Hz dip looks to deep and sharp to be a floor bounce cancellation. It is probably too narrow to be noticeable but again I was hoping to see traces from each individual driver to debug this. You said that you have not made HD measurements but you have. In REW all measurements automatically generate HD data - just click on HD tab at the top and select harmonics of interest. It is helpful to see first 5 harmonics.

Thanks for sharing. It must sound quite good as it is.

xrk971,

Correction: The LowMid XO is 12db both flanks and not 24db HP.

Thank you for comments and info.

I have the separate measurements for LowMid and Horn:

LowMid: (HP100hz/12db and LP 1.12Khz/12 db)

Horn: (HP 1.4Khz/24db -7db)

Old measurement of TH-18 Sub:

Can't seem to find the HD tab as you mention. I am using REW ver.5 buil 2142.

/ Andy

Correction: The LowMid XO is 12db both flanks and not 24db HP.

Thank you for comments and info.

I have the separate measurements for LowMid and Horn:

LowMid: (HP100hz/12db and LP 1.12Khz/12 db)

Horn: (HP 1.4Khz/24db -7db)

Old measurement of TH-18 Sub:

Can't seem to find the HD tab as you mention. I am using REW ver.5 buil 2142.

/ Andy

After:

View attachment 423112

In the after I reversed the leads on the horn, which I think helped removing quite a few dips in the mid area.

What LP filter are you using on the TH?

Brian,What LP filter are you using on the TH?

In post 1664 Andy writes the HP is 30 Hz 24 dB, unspecified filter (BW would have almost no affect on response at 30 Hz, LR would have a little ) but the measured response rolls off below 45 Hz, around 10 Hz higher than the few Xoc1-TH18s measurements seen previously.

Art

Brian,

In post 1664 Andy writes the HP is 30 Hz 24 dB, unspecified filter (BW would have almost no affect on response at 30 Hz, LR would have a little ) but the measured response rolls off below 45 Hz, around 10 Hz higher than the few Xoc1-TH18s measurements seen previously.

Art

That's the HP filter. I was asking about the LP filter. I'm assuming that he's not running it full range above that 30 Hz HP filter.

FWIW that dip around 125hz is phase related. Your woofer should 180* from both the mid and tweeter. The response could be better if you didn't mix/match the LR2/4 filters. When you get the drivers in phase a-5db dip happens around 1khz. It's gradual from 125hz. Then you get a 3db peak @2.5khz ramped from 1khz.

Have you got any other xo filter type options?

The second image is an approximation of the response using the settings you posted. No EQ., no delay, no frequency/xo optimization. ... pretty ugly.

Unless the drivers are compensation for the holes in response this has to be tough to listen to.

Have you got any other xo filter type options?

The second image is an approximation of the response using the settings you posted. No EQ., no delay, no frequency/xo optimization. ... pretty ugly.

Unless the drivers are compensation for the holes in response this has to be tough to listen to.

Attachments

Last edited:

Thank you all for your inputs,

I was having a good time yesterday playing around with measurements and making adjustments on the DSP.

Chrapladm:

Yes I am using b&c18sw100 driver in the subs. The one I was doing the measurments on is the latest of four built and is the version one of Xoc's design with cone correction from Djim. I think the low end will be better after some time, - that is my experience with the others that I built.

Puppet:

I ended up using 24db on both flanks where the LowMid and Horn(tweeter) meets: LowMid: LP 1.33Khz/24db LR and Horn: HP 1.4kzh/24db LR.

Thank your for your input.

What is the prg. that you are using to predict crossovers?

Going from 12 to 24db on the LowMid:

wg_ski:

Thank you for your sugestion on adding delays. This turned out to be quite a learning experience.

Delaying the sub:

I found that the 6.2ms that I dialed in wasn't correct, so I changed that to 8.98ms, which had a very nice impact on the measurments on the 70-150hz area.

I see now that this delay should always be considered every time you change the positioning the subs ie. at the venues.

Before/after delay on Sub:

Delaying LowMid to match the Horn(tweeter):

The horn(tweeter) is 20cm deep, so according to my calculation that comes to around 0,589ms delay at the mouth as a starting point. The LowMid being a conventional cone I thought it would take a bit less delay, but I ended up with the best results with 0,65ms delay on the LowMid.

I put the wiring of the Horn(tweeter) from reversed leads back to 0 degrees phasing.

After dialing in all the delays:

Can someone tell be how you measure the -3db point on the Sub?

The last picture is an attempt to measure SPL with 2.83 volts 1m.

It is done with a SPL calibrated(John Reek mehod) DBX RTA mic, so not a validated response.

The sub only has not been played at high volumes, so that could be the reason for the early drop in the low end? I used that Sub because I wanted to test if my grills with 47% airflow was having a impact on the sound,- which it didn't at low volumes.

SPL on Sub - with HP 30hz/24db:

Thank you all again for your kind inputs

/ Andy

I was having a good time yesterday playing around with measurements and making adjustments on the DSP.

Chrapladm:

Yes I am using b&c18sw100 driver in the subs. The one I was doing the measurments on is the latest of four built and is the version one of Xoc's design with cone correction from Djim. I think the low end will be better after some time, - that is my experience with the others that I built.

Puppet:

I ended up using 24db on both flanks where the LowMid and Horn(tweeter) meets: LowMid: LP 1.33Khz/24db LR and Horn: HP 1.4kzh/24db LR.

Thank your for your input.

What is the prg. that you are using to predict crossovers?

Going from 12 to 24db on the LowMid:

wg_ski:

Thank you for your sugestion on adding delays. This turned out to be quite a learning experience.

Delaying the sub:

I found that the 6.2ms that I dialed in wasn't correct, so I changed that to 8.98ms, which had a very nice impact on the measurments on the 70-150hz area.

I see now that this delay should always be considered every time you change the positioning the subs ie. at the venues.

Before/after delay on Sub:

Delaying LowMid to match the Horn(tweeter):

The horn(tweeter) is 20cm deep, so according to my calculation that comes to around 0,589ms delay at the mouth as a starting point. The LowMid being a conventional cone I thought it would take a bit less delay, but I ended up with the best results with 0,65ms delay on the LowMid.

I put the wiring of the Horn(tweeter) from reversed leads back to 0 degrees phasing.

After dialing in all the delays:

Can someone tell be how you measure the -3db point on the Sub?

The last picture is an attempt to measure SPL with 2.83 volts 1m.

It is done with a SPL calibrated(John Reek mehod) DBX RTA mic, so not a validated response.

The sub only has not been played at high volumes, so that could be the reason for the early drop in the low end? I used that Sub because I wanted to test if my grills with 47% airflow was having a impact on the sound,- which it didn't at low volumes.

SPL on Sub - with HP 30hz/24db:

Thank you all again for your kind inputs

/ Andy

my latest project with ucd class d amp in bridge mode . xoc1 your cabinet rocs 😎😎

😎😎

😎😎

😎😎Attachments

-

DSC03333.JPG83.3 KB · Views: 377

DSC03333.JPG83.3 KB · Views: 377 -

DSC03351.JPG122.3 KB · Views: 324

DSC03351.JPG122.3 KB · Views: 324 -

DSC03344.JPG186.1 KB · Views: 337

DSC03344.JPG186.1 KB · Views: 337 -

DSC03316.JPG96.8 KB · Views: 295

DSC03316.JPG96.8 KB · Views: 295 -

DSC03308.JPG61.7 KB · Views: 300

DSC03308.JPG61.7 KB · Views: 300 -

DSC03309.JPG71.4 KB · Views: 302

DSC03309.JPG71.4 KB · Views: 302 -

DSC03300.JPG84.8 KB · Views: 843

DSC03300.JPG84.8 KB · Views: 843 -

DSC03299.JPG115.5 KB · Views: 866

DSC03299.JPG115.5 KB · Views: 866 -

DSC03298.JPG118.6 KB · Views: 879

DSC03298.JPG118.6 KB · Views: 879 -

DSC03331.JPG74.5 KB · Views: 349

DSC03331.JPG74.5 KB · Views: 349

Last edited:

Minor empirical note.

If your DSP software supports it, no big problem using different crossover points upper and lower drivers, if that makes the empirical results, by mic and by ear, are better. You can't take theory that seriously. No kidding.

Likewise, even if your DSP has an input for air temperature (as on my Behringer DSP) and you try to measure driver location to a millimeter (which of course you really can't do), still you can use whatever time delay works nicest regardless.

I'm new at this DSP stuff, but that's my experience.

Nice to be dealing with a single box and out of doors. In my music room, the dipole ESL mid-ranges, corner bass horn, mid-wall sub-sub, and separately boxed ESL tweeters make tuning like a visit to the fun-house and even setting electrical polarity is mostly an esthetic ear issue. But highly rewarding indeed. Working with a DSP compared to my previous analog adjustable crossover makes freq adjustments jet-propelled and adds time-alignment possibilities.

Ben

If your DSP software supports it, no big problem using different crossover points upper and lower drivers, if that makes the empirical results, by mic and by ear, are better. You can't take theory that seriously. No kidding.

Likewise, even if your DSP has an input for air temperature (as on my Behringer DSP) and you try to measure driver location to a millimeter (which of course you really can't do), still you can use whatever time delay works nicest regardless.

I'm new at this DSP stuff, but that's my experience.

Nice to be dealing with a single box and out of doors. In my music room, the dipole ESL mid-ranges, corner bass horn, mid-wall sub-sub, and separately boxed ESL tweeters make tuning like a visit to the fun-house and even setting electrical polarity is mostly an esthetic ear issue. But highly rewarding indeed. Working with a DSP compared to my previous analog adjustable crossover makes freq adjustments jet-propelled and adds time-alignment possibilities.

Ben

Last edited:

Delaying the sub:

I found that the 6.2ms that I dialed in wasn't correct, so I changed that to 8.98ms, which had a very nice impact on the measurments on the 70-150hz area.

I see now that this delay should always be considered every time you change the positioning the subs ie. at the venues.

Before/after delay on Sub:

View attachment 423456

/ Andy

Absolutely. Also, take note of where you stand (or place the mic) vs what frequencies are playing - delay will change the position of certain frequency sweet spots.

--Example: you can adjust the subwoofer delay to increase (aka move) 40Hz in the center of the dancefloor, yet you'll notice a different frequency (maybe 80Hz, for this example) decrease. But, that 80Hz may have increased a few steps back. Change the delay to have 80Hz strong in the middle and 40Hz will decrease there and increase a few steps back (where 80Hz was solid).

I typically (when I have time) set the delay for the subs first, then delay the tops to align them with the subs (at the xover freq). If I delay the subs to the tops, I may not achieve the desired response from the subs on the dancefloor (or wherever I want said response).

Glad you're having fun with your new toys 🙂

CRESCENDO,

Thanks,

I tried what you said and moved around while playing with delay on the tops. It doesn't actually make things less complicated but good learning.

Delaying subs first you say, so that would be between the subs?

Have you reversed the leads to the th subs?

I tried reversing the sub in a setup where the sub was 4meters from the center of the tops.

With a cross over at 100 hz the bass blends in better. But apperently there is no wrong or right reversing the subs or not. I read somewhere that Danley has plus lead to plus on the driver in the Th-118.

Where do you cross your subs?

/ Andy

Thanks,

I tried what you said and moved around while playing with delay on the tops. It doesn't actually make things less complicated but good learning.

Delaying subs first you say, so that would be between the subs?

Have you reversed the leads to the th subs?

I tried reversing the sub in a setup where the sub was 4meters from the center of the tops.

With a cross over at 100 hz the bass blends in better. But apperently there is no wrong or right reversing the subs or not. I read somewhere that Danley has plus lead to plus on the driver in the Th-118.

Where do you cross your subs?

/ Andy

I am always searching for value and dont know the price as of yet. That being said I was going to be buying some 18 Sound 18 LW2400's for my TH18 build. And now 18 Sound is coming out with their 2500 model. Works great in the TH18 has more Xmax and hopefully will be around the same price point as the 2400. Give or take 75 dollars and I would be happy.

The 2500 is less sensitive compared to the 2400. BUT I figured that compared to the 2500's 294g MMs compared to the 2400's 192. SO that makes it 95db verse 98(2400).

The 2500 is less sensitive compared to the 2400. BUT I figured that compared to the 2500's 294g MMs compared to the 2400's 192. SO that makes it 95db verse 98(2400).

I am always searching for value and dont know the price as of yet. That being said I was going to be buying some 18 Sound 18 LW2400's for my TH18 build. And now 18 Sound is coming out with their 2500 model. Works great in the TH18 has more Xmax and hopefully will be around the same price point as the 2400. Give or take 75 dollars and I would be happy.

The 2500 is less sensitive compared to the 2400. BUT I figured that compared to the 2500's 294g MMs compared to the 2400's 192. SO that makes it 95db verse 98(2400).

An externally hosted image should be here but it was not working when we last tested it.An externally hosted image should be here but it was not working when we last tested it.

You forgot something...😀

Very interesting if cheaper alternatives are available for premium drivers. Parts express has somehow made their freight to Australia a viable option (especially when I have to add internal freight on top of seafreight). Therefore the B&C 18SW115 is now a viable option compared to the 18NLW9601 at four for $2600au delivered ($2,032us plus $321us for airfreight, not bad!).

Looks like if this driver is also comparable it may be even better value.

Looks like if this driver is also comparable it may be even better value.

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)