Xoc1,

Thanks for pointing me to the post by TundraLTD (nice work there Tundra!). Tundra's model uses 'duct' elements, which I do not believe account for the physical effects of the various folds and turns (which act as inherent fluidic low pass filters). I plan to model the turns as expansions/contractions with a 'waveguide' element where I will include the inertia effect of turns using 'Acoumass', and damping using 'Acouresistance'.

Regards,

X

Well I'd call myself an Akabak novice at best. In the messages I sent back-n-forth with Mr Danley he recommended keeping the models simple, building and measuring as the models tend to produce things that aren't measured in the real world. The model in the link is overcomplicated, the simplified model shows nearly the exact same plot

I usually model full range speakers and all the little physical details like the bends and corners make all the difference - and they show up in the measurements when done properly. It may be that subs are a different game and especially with the low pass and high pass filters applied, this suppresses any of the smaller effects normally present and impacted as a result of the geometry. The AkAbak manual shows examples where very small physical details show up and affect the final simulation's accuracy. I have modeled hundred's of speakers and almost always, in my experience, the small details end up mattering. But like I said, this may be result of a sim that is un filtered.

On the off chance, does anyone know of any suitable Australian drivers for use in this build?

well not a lot really. JBL, Ande, FS-audio, major car audio brands but usually only up to 15"

FS-audio

http://www.vfmaudio.com.au/product.php?id_product=593

ANDE

JDs Sound and Lighting. Speaker Components

We don't get nearly any of the brands you can from say partsexpress and shipping costs are astronomical if ordered from the US. (usually 140% - 200% of actual product price)

Im looking to install 2-4 of these in a very small club (200-300ppl)

FS-audio

http://www.vfmaudio.com.au/product.php?id_product=593

ANDE

JDs Sound and Lighting. Speaker Components

We don't get nearly any of the brands you can from say partsexpress and shipping costs are astronomical if ordered from the US. (usually 140% - 200% of actual product price)

Im looking to install 2-4 of these in a very small club (200-300ppl)

This driver looks good, not sure if it would work though.JDs Sound and Lighting. Ande SB18-5 18" 1000W woofer / driver

Interestingly I just found a dual 18" folded cab for $1300 from JD's. Given it has two 800W drivers in it ($600 worth) and 60KG of birch (not cheap here at all) and trim It seams like this could save me a lot of trouble and time. It seams to be similarly spec to what two th18 would do yet not sure just how good it sounds and how this double folded horn works.

JDs Sound and Lighting. Bob Audio CS218 Dual 18in double folded horn subwoofer 1600W RMS

Interestingly I just found a dual 18" folded cab for $1300 from JD's. Given it has two 800W drivers in it ($600 worth) and 60KG of birch (not cheap here at all) and trim It seams like this could save me a lot of trouble and time. It seams to be similarly spec to what two th18 would do yet not sure just how good it sounds and how this double folded horn works.

JDs Sound and Lighting. Bob Audio CS218 Dual 18in double folded horn subwoofer 1600W RMS

It's a 49x20.5x27.5 cabinet. Or about 16 cubic feet. Vs about 16 cubic feet for the TH-18.

Im betting that it's loud, but the "operating frequency" lower limit of 35hz listed is most likely the -10db point (or even more than -10db)

Just a guess. But if you were looking for sub 40hz output I'm not so sure that's the best cabinet.

Im betting that it's loud, but the "operating frequency" lower limit of 35hz listed is most likely the -10db point (or even more than -10db)

Just a guess. But if you were looking for sub 40hz output I'm not so sure that's the best cabinet.

i doubt it hits 35 with ANY type of authority. Its a FLH, each 18 is crammed into a 700mm x 620mm x 520 mm cabinet (meaning horn length is very small). its probably 10 db down by the time it hits 45.

EDIT* lol mrgsr, we had the same thoughts at exactly the same time.

EDIT* lol mrgsr, we had the same thoughts at exactly the same time.

Last edited:

well not a lot really. JBL, Ande, FS-audio, major car audio brands but usually only up to 15"

FS-audio

PA SPEAKER 18" JB1800 SUBWOOFER 1200W /4 INCH COIL

ANDE

JDs Sound and Lighting. Speaker Components

We don't get nearly any of the brands you can from say partsexpress and shipping costs are astronomical if ordered from the US. (usually 140% - 200% of actual product price)

Im looking to install 2-4 of these in a very small club (200-300ppl)

The JBL driver will work in the design BUT can't say how well it will hold up to the stress of hours of use at a club. I have no idea how strong/well built the cones are

http://www.paudiothailand.com/pdf/products/E-18ELF.pdf

This driver is available in OZ, and is suited for use in a tapped horn.

By the coil overhang plus 1/4 of the gap height method the x-max is 9.5mm

Cannon Sound carries P-Audio, there may be others. P-Audio also makes other suitable drivers that could probably be ordered for you as well.

http://www.paudiothailand.com/pdf/products/IMF-HP18B2.pdf

This driver is available in OZ, and is suited for use in a tapped horn.

By the coil overhang plus 1/4 of the gap height method the x-max is 9.5mm

Cannon Sound carries P-Audio, there may be others. P-Audio also makes other suitable drivers that could probably be ordered for you as well.

http://www.paudiothailand.com/pdf/products/IMF-HP18B2.pdf

Last edited:

Th P-Audio certainly is an option. The JB doesnt look as good but I have used the 15" in some ss15's and have yet to have any issues.

I love deep low frequency subs but the install is probably going to need to be cheap so realistically going down close to 40hz is ok for my needs, so the BOB dual 18 seams like its still a contender but not ideal.

I love deep low frequency subs but the install is probably going to need to be cheap so realistically going down close to 40hz is ok for my needs, so the BOB dual 18 seams like its still a contender but not ideal.

Got em back. Got some nice sub power now woohoo!

Gotta make grills, brace the mouth, put on heavy duty casters and coat with duratex as well as add neutrik connectors. 🙂

Gotta make grills, brace the mouth, put on heavy duty casters and coat with duratex as well as add neutrik connectors. 🙂

Hey guys, I'm a bit late to get onto this thread, so much to read!

I recently picked up some Beyma G550's to replace some cheap Dayton 18's in a simple 186 litre reflex cab, and I'm considering building some tapped horns for them (or possibly new drivers again).

I'm inexperienced with horns, are the G550's a potential candidate?

Cheers 🙂

I recently picked up some Beyma G550's to replace some cheap Dayton 18's in a simple 186 litre reflex cab, and I'm considering building some tapped horns for them (or possibly new drivers again).

I'm inexperienced with horns, are the G550's a potential candidate?

Cheers 🙂

Hey guys, I'm a bit late to get onto this thread, so much to read!

I recently picked up some Beyma G550's to replace some cheap Dayton 18's in a simple 186 litre reflex cab, and I'm considering building some tapped horns for them (or possibly new drivers again).

I'm inexperienced with horns, are the G550's a potential candidate?

Cheers 🙂

Using TundraLTD's Akabak model, the Beyma G550 looks pretty good in a sim with a 30Hz -12dB/oct high pass filter and 120Hz -48dB/oct low pass filter applied.

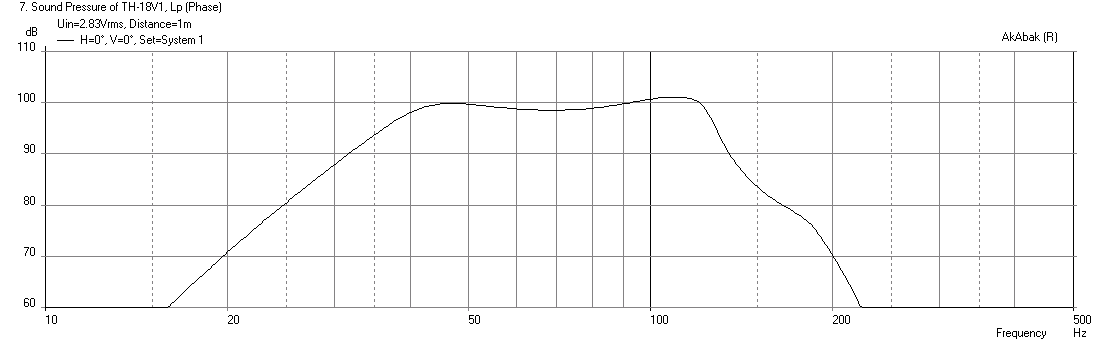

Here is the SPL vs freq at 2.83V for reference

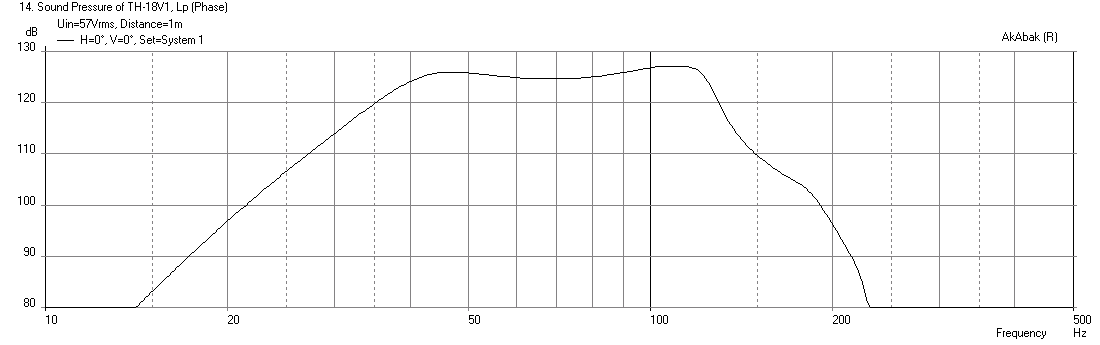

Here is the SPL at xmax which requires 57 volts or 406 watts rms

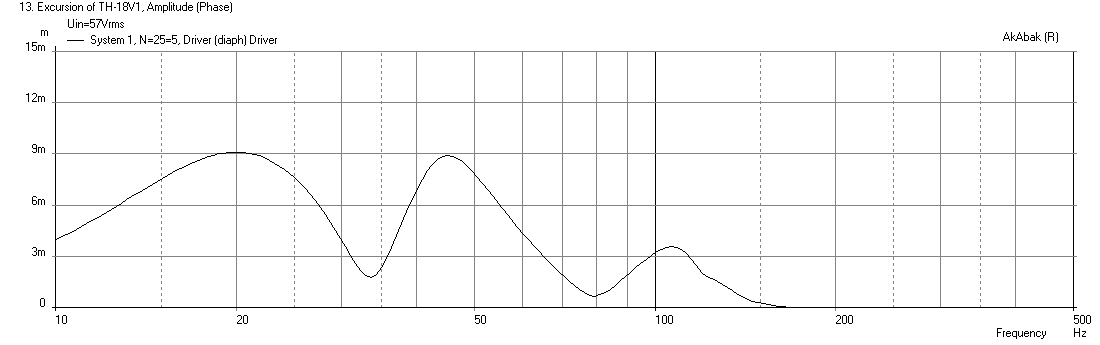

Here is the cone excursion at 57 volts

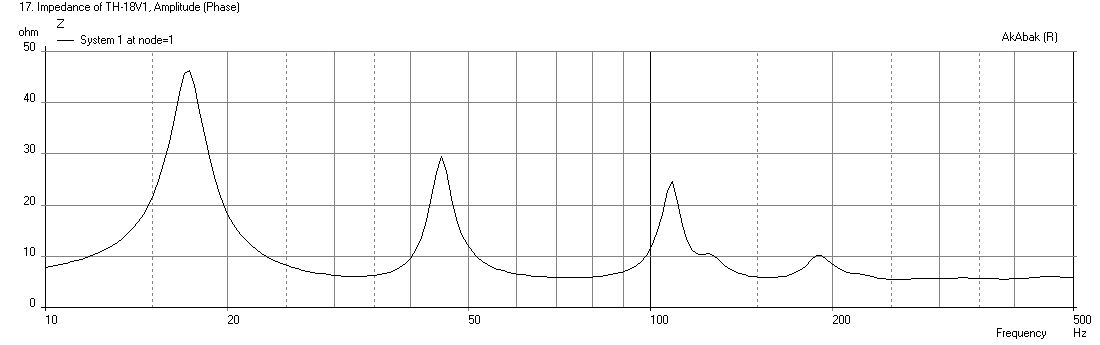

Here is the impedance

Looks like a good performer with good efficiency.

Cheers,

X

Attachments

Wow, thanks so much X! Bit more information than I was expecting and then some 🙂

Is the ~126dB output at 100Hz far off what the quoted drivers achieve? As the beyma is rated to 900w (I think) with close to 9mm xMax), 406 watts is a little conservative...?

I'm not sure how distorted the sound will get in this setup running the driver closer to it's xMech.

More compression inside the horn to limit excursion, or will peak output be vastly greater than the sim?

Is the ~126dB output at 100Hz far off what the quoted drivers achieve? As the beyma is rated to 900w (I think) with close to 9mm xMax), 406 watts is a little conservative...?

I'm not sure how distorted the sound will get in this setup running the driver closer to it's xMech.

More compression inside the horn to limit excursion, or will peak output be vastly greater than the sim?

126 dB at 406 watts is close to the efficiency that the Beymas are capable of - that is why I show the response at 1 watt, it is about 98 dB. You cannot put more power into it as the TH design doesn't control excursion enough - this is common for TH's. 126 dB is no slouch though and will get cops called to your party in a blink if they were used at home. You could high pass at a higher cutoff and limit bass to say 55 to 60 Hz and that will boost max SPL. You could play with tweaking the channel gaps to change compression ratio but that will go off plan and the nice box design provided in this thread will no longer be valid. I will leave tweaking the design up to the OP.

Last edited:

The 406 watts is a theoretical figure it does not include any power compression losses. The Beyma spec sheet for the G550 has a graph for power compression.

http://profesional.beyma.com/pdf/18G550E.pdf

At 406W the power compression is already 2.2dB

At 900W the power compression is 4dB. A 4dB reduction from 900W calculates to a theoretical 358W.

This indicates that the driver will actually require 900W plus to reach X-max.

Regards Xoc1

http://profesional.beyma.com/pdf/18G550E.pdf

At 406W the power compression is already 2.2dB

At 900W the power compression is 4dB. A 4dB reduction from 900W calculates to a theoretical 358W.

This indicates that the driver will actually require 900W plus to reach X-max.

Regards Xoc1

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)