Hi TundraLTD,

I think that would work just fine w/ 1/4-20 flat head screws from the outside through the wood, even 1/2" angle iron would do it as the grill material is very strong. We have been using this type of expanded metal mesh on walkways, and it is very strong once the edges are held in place.

Regards,

I think that would work just fine w/ 1/4-20 flat head screws from the outside through the wood, even 1/2" angle iron would do it as the grill material is very strong. We have been using this type of expanded metal mesh on walkways, and it is very strong once the edges are held in place.

Regards,

yeahh i think i can manage a little tack weld.... 😉

An externally hosted image should be here but it was not working when we last tested it.

Good to see that you have metalworking skills!

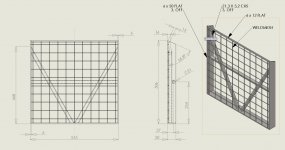

I have put together a proposal for making a grille.

Main points are 6mm (1/4") X 50 (2")flat outer frame - no inner flange to restrict the opening.

Tie bars integrated into the grille frame - I used 22.3 x 3.2 CHS tube.

Weldmesh for least crossectional area. Weight as drawn with 2" x 2" X 1/8" weldmesh is 6.6 Kg.

The Stress calc shows minimum movement where it is needed.

Have a think about it.

I,m off out to see Primal Scream in Concert😀

Regards

Martin

I have put together a proposal for making a grille.

Main points are 6mm (1/4") X 50 (2")flat outer frame - no inner flange to restrict the opening.

Tie bars integrated into the grille frame - I used 22.3 x 3.2 CHS tube.

Weldmesh for least crossectional area. Weight as drawn with 2" x 2" X 1/8" weldmesh is 6.6 Kg.

The Stress calc shows minimum movement where it is needed.

Have a think about it.

I,m off out to see Primal Scream in Concert😀

Regards

Martin

Attachments

The stress charts presented bring to mind prior experience with stress analysis using acrylic models with polarized light.

The bracing I chose for a horn was quite similar to the triangular truss style in the models shown.

The bracing I chose for a horn was quite similar to the triangular truss style in the models shown.

Didn't know they had a life after "Loaded" 😛 (watch out for the horror show 😉)I,m off out to see Primal Scream in Concert😀

Hi Xoc1,

"...no inner flange to restrict the opening."

I doubt that a 1/2" wide by 1/8" thick flange will have a major effect on the SPL, same for the extruded mesh. Maybe somebody can figure out how to model this in AkAbak (?can one add acoustic resistance to the radiator, with a very short reduced cross-sectional area duct?), and see if it makes a difference? Maybe it'll make it better 🙂.

Regards,

"...no inner flange to restrict the opening."

I doubt that a 1/2" wide by 1/8" thick flange will have a major effect on the SPL, same for the extruded mesh. Maybe somebody can figure out how to model this in AkAbak (?can one add acoustic resistance to the radiator, with a very short reduced cross-sectional area duct?), and see if it makes a difference? Maybe it'll make it better 🙂.

Regards,

It's definitely possible to model, I've got to go be a sound engineer tonight but I'll work on it when I get back

Hi Xoc1,

"...no inner flange to restrict the opening."

I doubt that a 1/2" wide by 1/8" thick flange will have a major effect on the SPL, same for the extruded mesh. Maybe somebody can figure out how to model this in AkAbak (?can one add acoustic resistance to the radiator, with a very short reduced cross-sectional area duct?), and see if it makes a difference? Maybe it'll make it better 🙂.

Regards,

Akabak is going to have to wait til tomorrow after work.

I just ordered myself a pair of B&C 18SW115

I just ordered myself a pair of B&C 18SW115

Nice! Let's get these projects rolling the way the ss15 has taken off! (although these boxes are much more expensive)

Right now I've got 2 Crest CA9's and 5 QSC CX502's. Power isn't going to be an issue, finding a place to store them... 🙄

Good choice, any ideas about the amps yet?

Each one of the crest bridged should provide enough power for the sw115's, but i don't think the qsc's will put out enough to really drive the sub....

I'm probably going to have to grab another xti 4000 and run each one bridged to each cabinet :/

I'm probably going to have to grab another xti 4000 and run each one bridged to each cabinet :/

i think factory floor stuff would be as stiff .... as anithing 😛I know, so don't use perforated steel. Look in the industry for weaving-wire. It is used in filter technique a lot. Here in the Netherlands we have Averinox in Haarlem.

Another option is concrete mesh with small openings (10x10cm). On the ends you iron rings for attachments. It's very cheap and very strong.

An externally hosted image should be here but it was not working when we last tested it.

As a third option, at gardening shops they sell steel plant-holders for wall attachment. It doesn't have the relief on the steel like concrete mesh but it is more expensive.

An externally hosted image should be here but it was not working when we last tested it.

this is what i mean.

An externally hosted image should be here but it was not working when we last tested it.

you can get them in varius thicknesis and size's

Epa, we used the same stuff from aluminium once that we took out "ouwe postbank hokjes" it was claimed 'hufterproof' and served as safety screen above the bullit glass windows. But 'sjonges' that stuff is expensive if you want to buy it new (over 100ballen per vierkante meter).i think factory floor stuff would be as stiff .... as anithing 😛

this is what i mean.You can get them in varius thicknesis and size's

The QSC's are actually for my Tannoy V series cabs: 7 - V8's, 1 - V12, 2 - V15's also have 2 Power V15's. I do some small production stuff and also use it for a semi-portable outdoor theater with a Integra THX Ultra2 XLR output receiver and Media Matrix X-Frame88 processor. It only started as a hobby HAHAHA

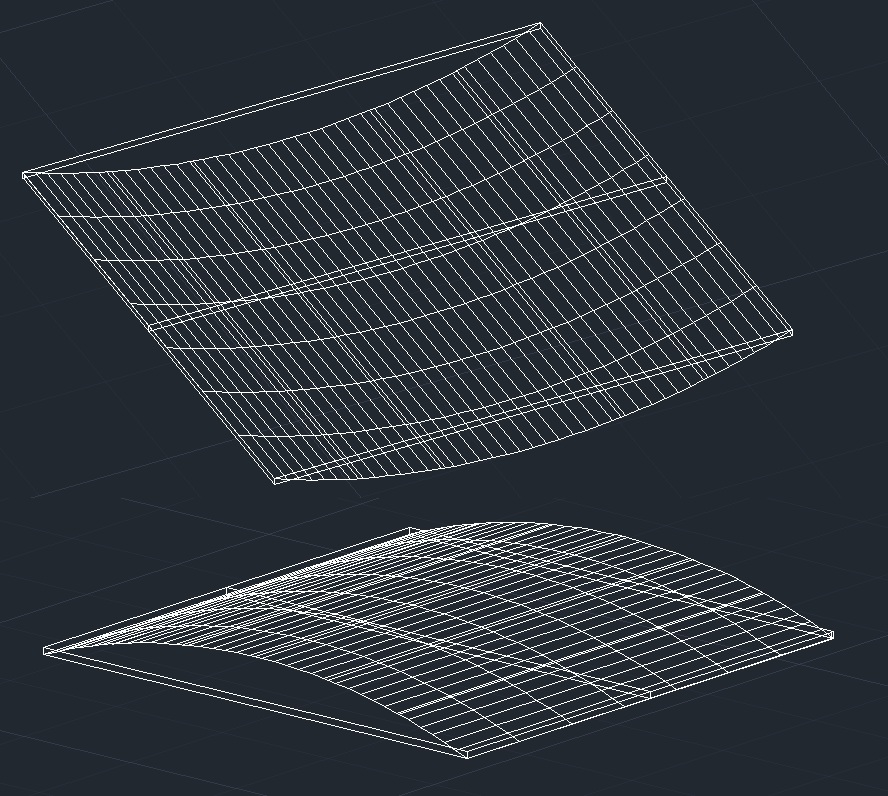

OK now to the point. The grill if going over the outside edge of the mouth only obstruct it 1/4" on three sides, Akabak shows only a MAX 0.13dB drop and I can live with that for the added rigidity. Another thought is that vibration looses you some SPL so you may make up that minimal loss and then some in reality

Each one of the crest bridged should provide enough power for the sw115's, but i don't think the qsc's will put out enough to really drive the sub....

I'm probably going to have to grab another xti 4000 and run each one bridged to each cabinet :/

OK now to the point. The grill if going over the outside edge of the mouth only obstruct it 1/4" on three sides, Akabak shows only a MAX 0.13dB drop and I can live with that for the added rigidity. Another thought is that vibration looses you some SPL so you may make up that minimal loss and then some in reality

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

yes expencive for alu or heavy in steel,maybe a scrap jard?Epa, we used the same stuff from aluminium once that we took out "ouwe postbank hokjes" it was claimed 'hufterproof' and served as safety screen above the bullit glass windows. But 'sjonges' that stuff is expensive if you want to buy it new (over 100ballen per vierkante meter).

maybe its an ideer to curve mesh/perfed alu, horizontal and and put 1 or 2 bars in vertical.it would stiffen the grill by a lot , and stops it ratling /fibrating.

OK now to the point. The grill if going over the outside edge of the mouth only obstruct it 1/4" on three sides, Akabak shows only a MAX 0.13dB drop and I can live with that for the added rigidity. Another thought is that vibration looses you some SPL so you may make up that minimal loss and then some in reality

I had concidered mounting the angle framed grill on the external face of the box by rebating the edge but see two practical issues.

1: How to finish the top edge of the grille where you have a rough open edge?

2 : The external edges of the box would be fairly square and sharp - with no way of rounding them off. This won't be a problem untill the first time you trap your fingers between the steel and a door frame.

I know from experience what happens when moving a heavy bass bin and trapping my hand on a square edge. A 90deg edge will cut through the skin with enough inertia behind it😱

Anyway the information on the dB drop with the mesh is very interesting.

What was the percentage open area that you calculated this with?

Regards

Martin.

I don't know if this makes a difference or not, but didn't I read that akbak does NOT factor in the "bubble" around the horn mouth, and hornresp does? I'm not sure what equations go along with the "bubble" calculation, but maybe that makes a difference.

I just ran a sim with only 50% open area at the mouth and it still only drops 0.51dB @100Hz. As far as the 'Bubble' I believe that is because Akabak only calculates as if it were in a 2Pi environment

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Loudspeakers

- Subwoofers

- TH-18 Flat to 35hz! (Xoc1's design)