I am thinking of building a subwoofer/seat riser and I have a few questions:

The riser's dimensions will roughly be:

6' wide

4-5' long

6-8" inches high

I was thinking of using (2) 15" subwoofers or alternately using (14) 6.5" Dayton DC160-8. What would sound better of these two options? It's 30 square inches versus 91 in term of possible air movement, obviously. The 14 drivers would be placed along 3 of the 4 sides whereas the 15's would be facing up towards the seats.

How much damping fill should be used?

How much bracing would be required?

This would most likely be a vented design right?

Here's a copy of my room layout:

Thanks in advance!

The riser's dimensions will roughly be:

6' wide

4-5' long

6-8" inches high

I was thinking of using (2) 15" subwoofers or alternately using (14) 6.5" Dayton DC160-8. What would sound better of these two options? It's 30 square inches versus 91 in term of possible air movement, obviously. The 14 drivers would be placed along 3 of the 4 sides whereas the 15's would be facing up towards the seats.

How much damping fill should be used?

How much bracing would be required?

This would most likely be a vented design right?

Here's a copy of my room layout:

Thanks in advance!

Attachments

Actually, the difference in cone area is much less dramatic than you make out - because area is (Pi*Diameter Squared) / 4.

2 15" woofers gives you about 350 square inches of swept area, while 14 6.5" woofers gives you about 460 square inches of swept area.

In reality, both those numbers will be lower, since the actual cone is somewhat smaller than the driver frame.

You've got about 20 cubic feet to work with, so a large ported design is feasible.

2 15" woofers gives you about 350 square inches of swept area, while 14 6.5" woofers gives you about 460 square inches of swept area.

In reality, both those numbers will be lower, since the actual cone is somewhat smaller than the driver frame.

You've got about 20 cubic feet to work with, so a large ported design is feasible.

You have between 15 and 20 cubic feet in your room, just for for subs. No fair!!! I am sooo jealous....

With this much space, it is all about the cabinet. There is no reason not to consider horns or tapped horns.

You could easily do 8 Tang Band W6-1139SI's in a pair of tapped horns with that much space.

I recently built a tapped horn using 4 of these. When placed in the room, it exceeded 125 dB at 30 Hz (+20 dB over the servo-controlled 12 we replaced) . It was less than 1/2 the size you have available.

I can only imagine what two of these would sound like in the same room.

That being said, you might be able to fold up a horn or tapped horn with other drivers.

You could also fold up a horn for some MCM 55-2421 8's. You could use 4 drivers without too much trouble.

You could also horn-load a 15 or a pair of 12's.

What is your frequency range and SPL goal?

Danley makes the SPUD and DTS10, you could use two of something like this

With this much space, it is all about the cabinet. There is no reason not to consider horns or tapped horns.

You could easily do 8 Tang Band W6-1139SI's in a pair of tapped horns with that much space.

I recently built a tapped horn using 4 of these. When placed in the room, it exceeded 125 dB at 30 Hz (+20 dB over the servo-controlled 12 we replaced) . It was less than 1/2 the size you have available.

I can only imagine what two of these would sound like in the same room.

That being said, you might be able to fold up a horn or tapped horn with other drivers.

You could also fold up a horn for some MCM 55-2421 8's. You could use 4 drivers without too much trouble.

You could also horn-load a 15 or a pair of 12's.

What is your frequency range and SPL goal?

Danley makes the SPUD and DTS10, you could use two of something like this

I'll 2nd mike's suggestion. 15's under the couch facing up in a platform cabinet has been done, and has very localized tactile, unnatural feeling to it. I'd personally stay away from that.

TB's or 55-2421's in a very large TH would be ideal, as you can couple the bass to the air and fill the entire room, and not specifically just vibrate a couch cushion or 2.

TB's or 55-2421's in a very large TH would be ideal, as you can couple the bass to the air and fill the entire room, and not specifically just vibrate a couch cushion or 2.

I have no idea how to build a horn cabinet.

I doubt my room will give me much below 30hz, but that's okay. 125db is plenty for me so I'd rather lean towards definition, if that makes sense. I'm assuming the multiple drivers would have to be in a mixed parallel series wiring scheme. And what type of amplification would I need?

I am also planning to build two midbass cabinets to augment my 2-way monitors that would handle 80-500hz so this subwoofer/riser would handle about 80hz and below.

I doubt my room will give me much below 30hz, but that's okay. 125db is plenty for me so I'd rather lean towards definition, if that makes sense. I'm assuming the multiple drivers would have to be in a mixed parallel series wiring scheme. And what type of amplification would I need?

I am also planning to build two midbass cabinets to augment my 2-way monitors that would handle 80-500hz so this subwoofer/riser would handle about 80hz and below.

Last edited:

What is your experience level with speaker building and cabinet construction? What sorts of tools do you have available? With regard to horns and tapped horns, if I can figure it out, anyone can. Everything you need to know is out there. This is speaker building, not rocket science.

I posted lots of details about my build in the Collaborative thread, starting here:

http://www.diyaudio.com/forums/subwoofers/97674-collaborative-tapped-horn-project-299.html#post1765848

I wrapped up this project about here:

http://www.diyaudio.com/forums/subwoofers/97674-collaborative-tapped-horn-project-303.html#post1777897

If I were trying to do what I think you are after, I'd consider a 9.5" high riser with at least 4 MCM 55-2421 drivers in either front-loaded or tapped horns (they are $25 when you have the right coupon code). Wire them series parallel, so you have a 4-ohm load. Build a pair of horns with two drivers in each to suit the space you have (simplest tapped horn box is 7 boards, honest). Run the mouths out the same side or end, horns work better this way. I can help with a simulation of the cabinet, I am very familiar with these woofers.

If that is too tall for you, use the Tang Band W6-1139 I mentioned. That cuts an inch and a half out of the height, but the drivers are a bit more expensive. I can simulate cabinets for these too.

You can use bigger drivers too, just mount them on their side. A simple up and back tapped horn fold will work fine. There are a lot of drivers that will work in a tapped horn. Some of the nicer car audio subs work very well.

Amplification? Whatever you have. I use Dayton and BASH plate amps quite a bit, but also have the big guns when needed, an old QSC and a Behringer EP2500. No need to spend a lot on the amps, 300 to 500 watts will be plenty.

Quality-wise, the tang-bands are a nicer driver, but you'll need at least 4 of them. The MCM is a cheap air-mover, but I would still use a minimum of 4 drivers. In certain cabinets, it is simply amazing. Other drivers I'd consider including are some of the quality pro-sound subs like the high-excursion Eminence models.

Seriously, I'm not trying to talk you into anything here. I have listened to direct radiator subs and tapped horn subs behind a couch. I know which I prefer, which is why I made the recommendation. Read up on horns and tapped horns, there is a ton of info here and on the rest of the web. If you have questions, ask.

I posted lots of details about my build in the Collaborative thread, starting here:

http://www.diyaudio.com/forums/subwoofers/97674-collaborative-tapped-horn-project-299.html#post1765848

I wrapped up this project about here:

http://www.diyaudio.com/forums/subwoofers/97674-collaborative-tapped-horn-project-303.html#post1777897

If I were trying to do what I think you are after, I'd consider a 9.5" high riser with at least 4 MCM 55-2421 drivers in either front-loaded or tapped horns (they are $25 when you have the right coupon code). Wire them series parallel, so you have a 4-ohm load. Build a pair of horns with two drivers in each to suit the space you have (simplest tapped horn box is 7 boards, honest). Run the mouths out the same side or end, horns work better this way. I can help with a simulation of the cabinet, I am very familiar with these woofers.

If that is too tall for you, use the Tang Band W6-1139 I mentioned. That cuts an inch and a half out of the height, but the drivers are a bit more expensive. I can simulate cabinets for these too.

You can use bigger drivers too, just mount them on their side. A simple up and back tapped horn fold will work fine. There are a lot of drivers that will work in a tapped horn. Some of the nicer car audio subs work very well.

Amplification? Whatever you have. I use Dayton and BASH plate amps quite a bit, but also have the big guns when needed, an old QSC and a Behringer EP2500. No need to spend a lot on the amps, 300 to 500 watts will be plenty.

Quality-wise, the tang-bands are a nicer driver, but you'll need at least 4 of them. The MCM is a cheap air-mover, but I would still use a minimum of 4 drivers. In certain cabinets, it is simply amazing. Other drivers I'd consider including are some of the quality pro-sound subs like the high-excursion Eminence models.

Seriously, I'm not trying to talk you into anything here. I have listened to direct radiator subs and tapped horn subs behind a couch. I know which I prefer, which is why I made the recommendation. Read up on horns and tapped horns, there is a ton of info here and on the rest of the web. If you have questions, ask.

Seat raiser ... go for it

Hi MarzZ

I did a similar project for my HT, using 2 x 12" JBL from a JBH HT1 surround set.

Thay are loaded in 2 x 120 l bass reflex ... using same allignment as the originals, but using larger ports.

I would defenetly go for the 2 x 15" instead of a lot of small cones ... the larger sones normally have better Thile-Small parameters for subwoofer use.

I only use 2 x 100 W for the subs, but I really don't need more, and don't get med wrong, I like the room to shake. But the beauty of the seat raiser is the large volume you have for the speakers, which means high effeciency.

Yes a horn would probably also be just great, but it's just much easier to make a reflex enclosure.

I have a 2 pers. sofa on my raiser, and the internal bracing I used is more than enough ... (but I wouldn't go for less either).

The braising needed also depend highly on the topplate thichness. I used 22 mm chipwood.

Take a look at my site:

Building a Home Theater and Listening Room Subwoofer

And also my post on this:

http://www.diyaudio.com/forums/subwoofers/146329-back-row-podium-sub.html

Go for it

Hi MarzZ

I did a similar project for my HT, using 2 x 12" JBL from a JBH HT1 surround set.

Thay are loaded in 2 x 120 l bass reflex ... using same allignment as the originals, but using larger ports.

I would defenetly go for the 2 x 15" instead of a lot of small cones ... the larger sones normally have better Thile-Small parameters for subwoofer use.

I only use 2 x 100 W for the subs, but I really don't need more, and don't get med wrong, I like the room to shake. But the beauty of the seat raiser is the large volume you have for the speakers, which means high effeciency.

Yes a horn would probably also be just great, but it's just much easier to make a reflex enclosure.

I have a 2 pers. sofa on my raiser, and the internal bracing I used is more than enough ... (but I wouldn't go for less either).

The braising needed also depend highly on the topplate thichness. I used 22 mm chipwood.

Take a look at my site:

Building a Home Theater and Listening Room Subwoofer

And also my post on this:

http://www.diyaudio.com/forums/subwoofers/146329-back-row-podium-sub.html

Go for it

Attachments

Thanks for all the input thus far. I would like less tactile/localization and I'd like to keep the step height to 7.5" max. I am interested in the horn design but may not be up to it. I, like everyone else, want loud and clear low frequency response. I would compromise max SPL for accuracy and definition however.

I have all the basic tools to get the job done, such as basic hand/power tools and calibrated Behringer ECM8000 from cross-spectrum and various software.

I have been doing some basic plot with bass box pro and found that two 15's in an isobaric configuration would yield very nice results down to 20hz and below. As I said, I'd be happy with accurate and loud to 30hz in my room. If I went with this config, the top isobaric woofer would be in the middle of the sofa which has a large cavity in that area. Would it be reasonable to mount a top box over the sub, thus sealing it and minimizing the localization? I don't know how to simulate this though.

I don't know how to simulate this though.

I have all the basic tools to get the job done, such as basic hand/power tools and calibrated Behringer ECM8000 from cross-spectrum and various software.

I have been doing some basic plot with bass box pro and found that two 15's in an isobaric configuration would yield very nice results down to 20hz and below. As I said, I'd be happy with accurate and loud to 30hz in my room. If I went with this config, the top isobaric woofer would be in the middle of the sofa which has a large cavity in that area. Would it be reasonable to mount a top box over the sub, thus sealing it and minimizing the localization?

SNIP

If I went with this config, the top isobaric woofer would be in the middle of the sofa which has a large cavity in that area. Would it be reasonable to mount a top box over the sub, thus sealing it and minimizing the localization?I don't know how to simulate this though.

Sounds like a 4th order bandpass box to me.

Isobaric designs seem like a waste of a driver when you have over 10 cubic feet of cabinet. There is simply no need to add the complexity, select a more appropriate driver or reconfigure the cabinet.

BTW - two of the tapped horn subs I put together for my brother would measure out to approximately 4' by 7' by 8.5 inches, when made of 3/4 inch nominal material.

BTW - two of the tapped horn subs I put together for my brother would measure out to approximately 4' by 7' by 8.5 inches, when made of 3/4 inch nominal material.

Hey mike:

since you like to push pixels... can you dream up a way to reorient your drivers 45 degree's on an angled board so you could make the whole thing thinner?

I think a max 7" tall riser approx 4x8 in size would be of great interest to several, especially if a rough sketch was thrown in, along side the hornresp inputs.

Hey mike:

since you like to push pixels... can you dream up a way to reorient your drivers 45 degree's on an angled board so you could make the whole thing thinner?

I think a max 7" tall riser approx 4x8 in size would be of great interest to several, especially if a rough sketch was thrown in, along side the hornresp inputs.

So, Mr. I can build 4 subs in less time that it takes you to check your email, what are you trying to tell me.....

Seriously, I'll have to mock it up, but I think something like this could be done. A 30 degree baffle might be a better fit given the depth of the motor on that driver.

I'll get back to you after I push some pixels.....though I might have to make a little sawdust first....

Mike:

Thanks for my laugh of the day...

Seriously, I think a 7 1/2" tall riser is possible with simple up and back TH's in a dirt simple to build cabinet.

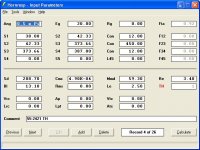

A 4x8 sheet of 3/4" ply top and 1/2" bottom, a 8' long by 6" tall 1/2" thick divider every 12" so there is room for 4 drivers/cabinets that are 8' up and 8' back. Put a 1/2" thick 'up and back' baffle, so there is 1/2" of space at the beginning, and an even 2 3/4" all the way around at the far end. The MCM should just squeak in there at 4.5" mounting depth. Attached is the hornresp for this. (I used .5pi to sim 4 cabinets)

Total height should be 7 1/4" plus carpet, for a finished height of 7.5"

Depending on the room acoustics, you could decide to have 2 firing left, and 2 right. Series-parallel would give a nice 4 ohm load, and a bash amp or equivalent would power it nicely.

This far exceeds THX specs (and you are right on top of the subs) Take into account a little room gain, and this is not bad at all... and can almost be built faster than checking email........ And while not a 'super spud' it should be good enough for the typical couch potato...

Thanks for my laugh of the day...

Seriously, I think a 7 1/2" tall riser is possible with simple up and back TH's in a dirt simple to build cabinet.

A 4x8 sheet of 3/4" ply top and 1/2" bottom, a 8' long by 6" tall 1/2" thick divider every 12" so there is room for 4 drivers/cabinets that are 8' up and 8' back. Put a 1/2" thick 'up and back' baffle, so there is 1/2" of space at the beginning, and an even 2 3/4" all the way around at the far end. The MCM should just squeak in there at 4.5" mounting depth. Attached is the hornresp for this. (I used .5pi to sim 4 cabinets)

Total height should be 7 1/4" plus carpet, for a finished height of 7.5"

Depending on the room acoustics, you could decide to have 2 firing left, and 2 right. Series-parallel would give a nice 4 ohm load, and a bash amp or equivalent would power it nicely.

This far exceeds THX specs (and you are right on top of the subs) Take into account a little room gain, and this is not bad at all... and can almost be built faster than checking email........ And while not a 'super spud' it should be good enough for the typical couch potato...

Attachments

Last edited:

Well, I made a lot of sawdust today, but not that kind.

Had a date with the chainsaw and the wood chipper......

Seriously, the hardest part will be the long bevel rips on the baffle.

Same sort of idea works for the Tang Band W6-1139's, though you'd really want two per cabinet. I'd cut the baffle at 30 degrees on those though, no need to go 45. It will come in just under 7" if you use 1/2" ply.

It may be a challenge to mount the drivers though. Probably will need an access panel to install them.

Had a date with the chainsaw and the wood chipper......

Seriously, the hardest part will be the long bevel rips on the baffle.

Same sort of idea works for the Tang Band W6-1139's, though you'd really want two per cabinet. I'd cut the baffle at 30 degrees on those though, no need to go 45. It will come in just under 7" if you use 1/2" ply.

It may be a challenge to mount the drivers though. Probably will need an access panel to install them.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- Theater Seat Riser Subwoofer