The nasty bath.

Ok I etched the board in a nitric acid solution (about 17% pv). I use nitric acid because it's fast and requires no agitation. Nasty stuff so a glass lid keeps the fumes in. Takes about 30 minutes, longer on cold nights. Kids!!!....don't try this at home.

Cheers

Ok I etched the board in a nitric acid solution (about 17% pv). I use nitric acid because it's fast and requires no agitation. Nasty stuff so a glass lid keeps the fumes in. Takes about 30 minutes, longer on cold nights. Kids!!!....don't try this at home.

Cheers

Attachments

Re: Ferric chloride

Yes, I used to use ferric cholride and other stuff too.

I like using the nitric because it's clear and quite re-usable. The solution shown in the photo is 2 generations old. I.e. it has already been used to make a couple of large boards.

It is also cheaper to buy (around here anyway) then ferric.

Finally with the nitric, when the bubble stop the boards done.

But while it's clean, it does need to be handled with care.

Cheers

Yes, I used to use ferric cholride and other stuff too.

I like using the nitric because it's clear and quite re-usable. The solution shown in the photo is 2 generations old. I.e. it has already been used to make a couple of large boards.

It is also cheaper to buy (around here anyway) then ferric.

Finally with the nitric, when the bubble stop the boards done.

But while it's clean, it does need to be handled with care.

Cheers

Comparison to Holton's AV800

Hey Angelo;

The AV800's input stage and the one in my design are virtually identical but the rest of the amp is quite different.

It is possible to modify the AV800 by inserting my 3rd stage and output stage after the Vbe multiplier (Q9 in the AV800) and you could swap Q7 & Q8 in my circuit with complimentary FETS just as Holton has done. This would involve re-calculating the values of all the components in the Vbe multiplier.

Another thing, in an all N-channel output stage the positive rail output FETS cannot receive enough voltage drive (this was learned and explained during this thread) to turn on fully, so I have higher voltages driving the input and driver stages.

So it will difficult to do if you were to use Holton's PCB layout.

I hope to finish 2 of my amp modules in a week or so (no sound yet). I'll let you know how it goes and how they sound.

Ciao

Hey Angelo;

The AV800's input stage and the one in my design are virtually identical but the rest of the amp is quite different.

It is possible to modify the AV800 by inserting my 3rd stage and output stage after the Vbe multiplier (Q9 in the AV800) and you could swap Q7 & Q8 in my circuit with complimentary FETS just as Holton has done. This would involve re-calculating the values of all the components in the Vbe multiplier.

Another thing, in an all N-channel output stage the positive rail output FETS cannot receive enough voltage drive (this was learned and explained during this thread) to turn on fully, so I have higher voltages driving the input and driver stages.

So it will difficult to do if you were to use Holton's PCB layout.

I hope to finish 2 of my amp modules in a week or so (no sound yet). I'll let you know how it goes and how they sound.

Ciao

Commentable Experienced Thoughts

Hi Quasi,

Nice PCB ing going!

Well i think ur driver transistors emmiter and collector resistors is too low in value. As the Safe operating area will be crossed and the trannies will be damaged. Try to inc. their value .

Regards

Workhorse Technologies.

Hi Quasi,

Nice PCB ing going!

Well i think ur driver transistors emmiter and collector resistors is too low in value. As the Safe operating area will be crossed and the trannies will be damaged. Try to inc. their value .

Regards

Workhorse Technologies.

SOAR for mje340/350

Worst case conditions are around 120 volts across each of these when the amp is swinging to full opposite rail (near clipping). This voltage and the max. current of around 70 mA for this stage occurs only for a very short time during this part of the waveform half-cycle.

Yes the DC SOAR for the mje350 is around 65mA at 120 volts, but the 1ms SOAR is for 155mA and this is more relevant during the output conditions described above.

If the amp had a bi-polar transistor output where the base current was dependant on the output load then yes they would die. But with FETS I am only charging the gate so the loading on this stage is more constant.

Anyway if I'm wrong I'll post the dead transistors.

Cheers

Worst case conditions are around 120 volts across each of these when the amp is swinging to full opposite rail (near clipping). This voltage and the max. current of around 70 mA for this stage occurs only for a very short time during this part of the waveform half-cycle.

Yes the DC SOAR for the mje350 is around 65mA at 120 volts, but the 1ms SOAR is for 155mA and this is more relevant during the output conditions described above.

If the amp had a bi-polar transistor output where the base current was dependant on the output load then yes they would die. But with FETS I am only charging the gate so the loading on this stage is more constant.

Anyway if I'm wrong I'll post the dead transistors.

Cheers

Attachments

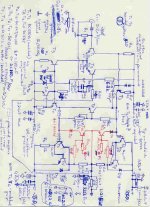

amp under development

I have completely forgot but 25 years ago I designed a quasi-complementary PA from a scratch. It was my first amp I ever designed. I discovered that last weekend when looking through my old audio files. It is 50W into 8 ohms version with a pair of BJTs K503. These were made in Poland or Czechoslovakia and were somewhat better than 3055s. As far as I remember 8 amps were built all for active systems. Later modifications included current mirrors and cascode voltage stage. I still have notes of the calculations. Unregulated supply was +/- 35V nominal used for calculations.

I include the scan of the original sketch. Although it is history but someone may find it interesting as it looks that quasi amps become more popular.

I have completely forgot but 25 years ago I designed a quasi-complementary PA from a scratch. It was my first amp I ever designed. I discovered that last weekend when looking through my old audio files. It is 50W into 8 ohms version with a pair of BJTs K503. These were made in Poland or Czechoslovakia and were somewhat better than 3055s. As far as I remember 8 amps were built all for active systems. Later modifications included current mirrors and cascode voltage stage. I still have notes of the calculations. Unregulated supply was +/- 35V nominal used for calculations.

I include the scan of the original sketch. Although it is history but someone may find it interesting as it looks that quasi amps become more popular.

Attachments

Hey Janusz

Thanks very much for the drawings. Funny how not a lot changes after 25 years. I guess the fundamental design is always there. The circuit is very similar to mine the main difference being my 3rd stage where instead of a darlington output stage I have a voltage drive for the FETS.

The amp works are going slowly. Tonight I just finished cutting heatsinks for the case and I am part way re-winding a 500va toroid transformer to achieve the voltages I require. This amp will be built as cheaply as possible using stuff I already have. So far I have not had to buy anything

Anyway here's a couple of piccies of heatsink cutting.

Cheers

Thanks very much for the drawings. Funny how not a lot changes after 25 years. I guess the fundamental design is always there. The circuit is very similar to mine the main difference being my 3rd stage where instead of a darlington output stage I have a voltage drive for the FETS.

The amp works are going slowly. Tonight I just finished cutting heatsinks for the case and I am part way re-winding a 500va toroid transformer to achieve the voltages I require. This amp will be built as cheaply as possible using stuff I already have. So far I have not had to buy anything

Anyway here's a couple of piccies of heatsink cutting.

Cheers

Attachments

Tidy way of winding a toroid

Hey AndrewT;

A tidy way of winding a toroid?

Probably, but this doesn't apply to my efforts. Here is how I do it. I figure it don't matter as long as the wire is tight. Anyway no-one will know once the tape is replaced.

The winding going on in this pic is over another secondary I wound last night. See, once the tape is on it's hard to see the work quality anyway....

Ok everybody...let me have it!

Cheers

Hey AndrewT;

A tidy way of winding a toroid?

Probably, but this doesn't apply to my efforts. Here is how I do it. I figure it don't matter as long as the wire is tight. Anyway no-one will know once the tape is replaced.

The winding going on in this pic is over another secondary I wound last night. See, once the tape is on it's hard to see the work quality anyway....

Ok everybody...let me have it!

Cheers

Attachments

Hi quasi ,

I do not regularly make pcbs and every time I have to make new solution

of ferric chloride even for one small board and the etching time is the

most boring part ,

I read that you use nitric acid solution (about 17% pv). You have also

written (( I like using the nitric because it's clear and quite re-usable. The

solution shown in the photo is 2 generations old. I.e. it has already been

used to make a couple of large boards. ))

Now I am tempted to use nitric acid for etching in future , please let me

know about the donts while using nitric acid ??? is it dangerous to touch

by hand ??

I do not regularly make pcbs and every time I have to make new solution

of ferric chloride even for one small board and the etching time is the

most boring part ,

I read that you use nitric acid solution (about 17% pv). You have also

written (( I like using the nitric because it's clear and quite re-usable. The

solution shown in the photo is 2 generations old. I.e. it has already been

used to make a couple of large boards. ))

Now I am tempted to use nitric acid for etching in future , please let me

know about the donts while using nitric acid ??? is it dangerous to touch

by hand ??

Hi i purchased a few toroidal tranformers from Kamal @

Tortech Pty Ltd

4/ 31 Wentworth St Greenacre 2190 (02) 9642 6003

or (02) 9742 5812

they were 1500Va and had 2 x secondary windings of 66Vac with about 7% regulation and i never ever found any problems with any of them...I never had any extras put on them(electrostatic and electromagnetic screens) i originally ordered one just bare to see what it was like and never had to buy another with all the screening and stuff...Th e guy i dealt with was Kamal and he was really good.They also to audiophile grade toroidals.My first toroidal took less than 2 weeks to get to me(Perth W.A) and it was custom made as they dont carry that particular one in stock.They also make their own toroidals in house.I also looked at getting them from harbuch and the reason i didnt was due to the fact they took almost a 7 weeks to give me prices on 1,10 & 25

toroidals and i would have had to call them abot 20+ times quite easily and they said they lost the fax i sent to them twice and that is why they couldnt get back to me sooner.

Regards

Bowdown

Tortech Pty Ltd

4/ 31 Wentworth St Greenacre 2190 (02) 9642 6003

or (02) 9742 5812

they were 1500Va and had 2 x secondary windings of 66Vac with about 7% regulation and i never ever found any problems with any of them...I never had any extras put on them(electrostatic and electromagnetic screens) i originally ordered one just bare to see what it was like and never had to buy another with all the screening and stuff...Th e guy i dealt with was Kamal and he was really good.They also to audiophile grade toroidals.My first toroidal took less than 2 weeks to get to me(Perth W.A) and it was custom made as they dont carry that particular one in stock.They also make their own toroidals in house.I also looked at getting them from harbuch and the reason i didnt was due to the fact they took almost a 7 weeks to give me prices on 1,10 & 25

toroidals and i would have had to call them abot 20+ times quite easily and they said they lost the fax i sent to them twice and that is why they couldnt get back to me sooner.

Regards

Bowdown

Using Nitric Acid

Hey Rajeev

Nitric Acid is quite dangerous. If any gets on your skin you must wash it immediately.

I use a deep tub and I keep everything in there. That way if there is a spill it is contained. I also keep a bucket of water handy in case I need it. Nitric acid releases corrosive fumes while it's etching so it needs to be covered. The photo in this thread shows my etching container within a deep tub.

When I etch a board I use just enough acid to cover it by a few millimetres and then cover the etching container with a glass panel to contain the fumes. No agitation is required, in fact it works faster if left alone.

When the etching is finished I use plastic utensils to remove and rinse the board. Then I pour the acid (now a blue colour) back into a bottle to re-use later.

Then I rinse everything including the bottle of acid, all the utensils, etching container and the deep tub.

Sounds dangerous but like all things it is very safe if you are organised and take precautions.

Anyway here is a photo of the half comleted amp module and it's heatsink (no FETS mounted yet).

Cheers

Hey Rajeev

Nitric Acid is quite dangerous. If any gets on your skin you must wash it immediately.

I use a deep tub and I keep everything in there. That way if there is a spill it is contained. I also keep a bucket of water handy in case I need it. Nitric acid releases corrosive fumes while it's etching so it needs to be covered. The photo in this thread shows my etching container within a deep tub.

When I etch a board I use just enough acid to cover it by a few millimetres and then cover the etching container with a glass panel to contain the fumes. No agitation is required, in fact it works faster if left alone.

When the etching is finished I use plastic utensils to remove and rinse the board. Then I pour the acid (now a blue colour) back into a bottle to re-use later.

Then I rinse everything including the bottle of acid, all the utensils, etching container and the deep tub.

Sounds dangerous but like all things it is very safe if you are organised and take precautions.

Anyway here is a photo of the half comleted amp module and it's heatsink (no FETS mounted yet).

Cheers

Attachments

- Home

- Amplifiers

- Solid State

- Power amp under development