I know that metal provide some degree of shielding from EM radiation, etc. but could one just as well build an amplifier enclosure using wood, e.g. some nice hardwood? By "could" I mean without suffering terrible consequences in performance of the amplifier compared to an all metal enclosure.

The reason I ask is that I will be putting together a few amplifiers in the near future and while I have heatsinks a plenty I am really hesitant to drop several hundred dollars (at a minimum) on chassis!

The reason I ask is that I will be putting together a few amplifiers in the near future and while I have heatsinks a plenty I am really hesitant to drop several hundred dollars (at a minimum) on chassis!

In the realm of RF interference, my amp andor preamp plus cables has picked up:

The AM radio station 5 miles away.

The police and fire trucks driving down the street.

A CB radio in a yellow pickup that continually transmitted Dixie yelped by dogs when the owner wasn't blathering in person.

The lamp dimmer in the next room.

The computer in the synthesizer.

The Ultra low frequency (audio) submarine communication transmitter in Maine.

I suggest you look at dead VCR's, other dead amps, metal file boxes for sale at charity resale shops. Metal tool boxes. Not pretty, but keep the noise out. I cut square holes for heat sinks by drilling 4 holes and connecting the dots with a stanley carbide hacksaw blade. Sabre saws can do the square hole job if you can stand the noise. Use a vise & safety glasses.

You can make holes for ventilation with mesh for sale in the concrete section of home stores. ~$10 a sheet. It bends so easy I make box shaped covers by cuting squares out of the corners and bending over a sharp edge of a concrete step.

You filter the inputs with parallel caps to analog ground, and series chokes. Dead switcher power supplies like in dead TV's are full of them.

Have fun.

The AM radio station 5 miles away.

The police and fire trucks driving down the street.

A CB radio in a yellow pickup that continually transmitted Dixie yelped by dogs when the owner wasn't blathering in person.

The lamp dimmer in the next room.

The computer in the synthesizer.

The Ultra low frequency (audio) submarine communication transmitter in Maine.

I suggest you look at dead VCR's, other dead amps, metal file boxes for sale at charity resale shops. Metal tool boxes. Not pretty, but keep the noise out. I cut square holes for heat sinks by drilling 4 holes and connecting the dots with a stanley carbide hacksaw blade. Sabre saws can do the square hole job if you can stand the noise. Use a vise & safety glasses.

You can make holes for ventilation with mesh for sale in the concrete section of home stores. ~$10 a sheet. It bends so easy I make box shaped covers by cuting squares out of the corners and bending over a sharp edge of a concrete step.

You filter the inputs with parallel caps to analog ground, and series chokes. Dead switcher power supplies like in dead TV's are full of them.

Have fun.

Nothing wrong with using wood, but it seems you have a table saw already. As do I.

I bought an 80 tooth, 10" blade and bought a bunch of sheet, flat and angle aluminum stock at Metal Supermarkets | Steel, Aluminum, Stainless, Hot-Rolled, Cold-Rolled, Alloy, Carbon, Galvanized, Brass, Bronze, Copper and build my own chassis.

Getting it right with aluminum on a table saw takes some time (easy does it, with many exclamation marks).

Once you master the technique, chassis and enclosures have no limit! E

I bought an 80 tooth, 10" blade and bought a bunch of sheet, flat and angle aluminum stock at Metal Supermarkets | Steel, Aluminum, Stainless, Hot-Rolled, Cold-Rolled, Alloy, Carbon, Galvanized, Brass, Bronze, Copper and build my own chassis.

Getting it right with aluminum on a table saw takes some time (easy does it, with many exclamation marks).

Once you master the technique, chassis and enclosures have no limit! E

Hi Charlie,

Because ... Wood is an effective insulator compared to metal.

Most people don't install cooling vents in wood.

Wood moves with humidity.

It burns well.

In truth, wood is best used as an accent if you really must. We have seen stone, man-made stone and all kinds of other materials. In almost every case, the alternative case material is a lot heavier than the steel or aluminium is. They are also thicker and in most cases have less structural strength on top of everything else.

The point about shielding, very important especially these days with all the electronic noise we have.

Your case is what holds everything together and protects you and your loved ones (as it is conductive and tied to ground with your three wire cord). It defines how much care you put into the project to others and is a good tip-off as to how the internal construction might be.

You really need to spend on the chassis. You can buy plain ones and dress them up, or buy a ready made chassis that is attractive and put your own holes in it. You can also design and have professionally made a front panel. It's all up to you, but I really can't recommend you go with a wood chassis.

-Chris

Because ... Wood is an effective insulator compared to metal.

Most people don't install cooling vents in wood.

Wood moves with humidity.

It burns well.

In truth, wood is best used as an accent if you really must. We have seen stone, man-made stone and all kinds of other materials. In almost every case, the alternative case material is a lot heavier than the steel or aluminium is. They are also thicker and in most cases have less structural strength on top of everything else.

The point about shielding, very important especially these days with all the electronic noise we have.

Your case is what holds everything together and protects you and your loved ones (as it is conductive and tied to ground with your three wire cord). It defines how much care you put into the project to others and is a good tip-off as to how the internal construction might be.

You really need to spend on the chassis. You can buy plain ones and dress them up, or buy a ready made chassis that is attractive and put your own holes in it. You can also design and have professionally made a front panel. It's all up to you, but I really can't recommend you go with a wood chassis.

-Chris

Hi Charlie,

Because ... Wood is an effective insulator compared to metal.

Most people don't install cooling vents in wood.

Wood moves with humidity.

It burns well.

I would (no pun intended) mount the heat sinks on the exterior of the chassis.

For the burning, there is always Burning Amp...

> my amp andor preamp plus cables has picked up:.... The Ultra low frequency (audio) submarine communication transmitter in Maine.

You are welcome.

FWIW: while it is near-audio it does not send speech/music. Low-rate data with modem-like FSK.

It sucks big power. A plan to run a new power line raised objections from scallop fishermen.

You are welcome.

FWIW: while it is near-audio it does not send speech/music. Low-rate data with modem-like FSK.

It sucks big power. A plan to run a new power line raised objections from scallop fishermen.

I am plagued by Marine Radar in fishing vessels, being repaired less than 100 meters from my home (I live in the old Buenos Aires Port, surrounded by ship repair and fitting shops)

An externally hosted image should be here but it was not working when we last tested it.

The concern that I would probably put most interest into is the flammability aspect. Many types also have questionable dielectric properties.

RF insulation definitely makes metal enclosures favourable, however whether it's necessary is really down to the environment and design and build. My early veroboard builds picked up a lot but more recent PCB based layouts are much more refined and the days where the mobile phone modulation would trigger a digital horse race are by and large gone.

RF insulation definitely makes metal enclosures favourable, however whether it's necessary is really down to the environment and design and build. My early veroboard builds picked up a lot but more recent PCB based layouts are much more refined and the days where the mobile phone modulation would trigger a digital horse race are by and large gone.

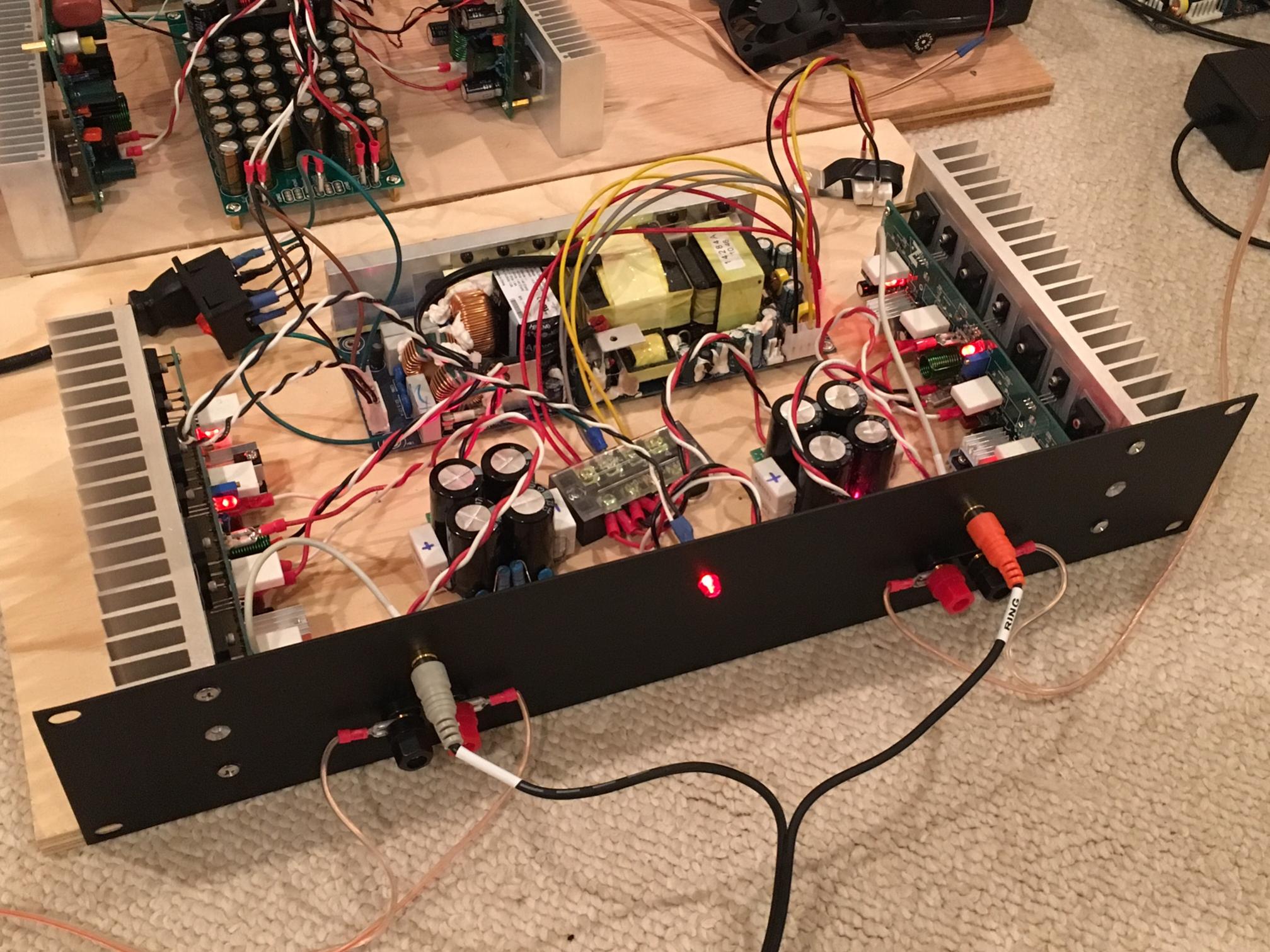

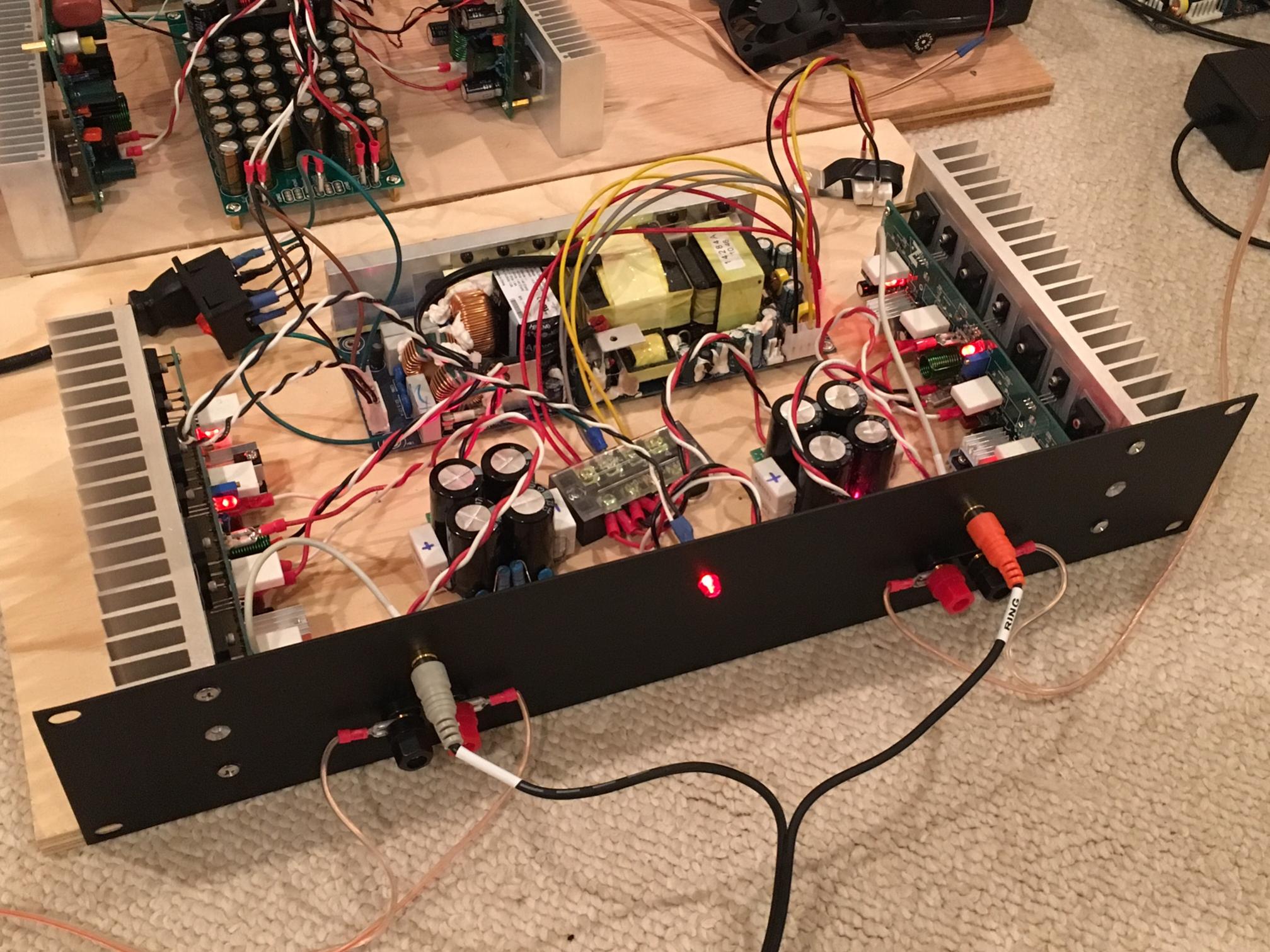

You can make the "Un-Case" - use heatsinks for sidewalls and a 2U or 3U blank 17in rack mount panel to mount heatsinks to. Then a plywood base and something else for top and back. But all you need to mount in a rack enclosure is the front panel and bottom panel. Open top leaves room for air flow. You could add concrete mesh like Indianajo suggests. I am lucky as the RF interference here is not too bad. But small SMT circuit boards seem to pick up less stray noise?

So, shielding is a concern... is this mostly a need to shield the amplifier PCB and other internal components do not need shielding? How about a "box" of metal around the amp PCB and everything else (e.g. PS) unshielded, possible using a CRC type PS with the last RC inside the shielding?

Honestly, it seems the chassis is the most expensive part of an amp build!

Honestly, it seems the chassis is the most expensive part of an amp build!

The chassis of an amplifier is the largest amount of work and makes or breaks the finished product of the amplifier. It is also what people see and give someone a first impression of an amplifier. If someone sees an amplifier that looks poorly assembled, chances are they will assume it's not a good amplifier no matter how good it sounds. It is also what protects anyone or anything around the amplifier. This is not an area to go cheaply.

As for shielding, the input section of the amplifier and the input wiring are the most critical areas. Some amplifier designs are more resistant to induced noises than others. The one xrk971 shows in post 11 (the VHex+) is the best I've seen at rejecting noise or external influence.

As for shielding, the input section of the amplifier and the input wiring are the most critical areas. Some amplifier designs are more resistant to induced noises than others. The one xrk971 shows in post 11 (the VHex+) is the best I've seen at rejecting noise or external influence.

Yes, a Faraday cage around the sensitive portions of the circuit would do the trick, as would ensuring that your attention to connections/grounding are spot on (that's regardless the case material!). Driven guard rings around sensitive parts of your circuits, etc, if you need them.

No need to line with copper, either, aluminum will work just as well for RF. Steel obviously has its benefits when it comes to LF shielding.

No need to line with copper, either, aluminum will work just as well for RF. Steel obviously has its benefits when it comes to LF shielding.

Check out Nebraska Surplus. I just picked up one of their Nabu cases for $16 plus shipping. I expected an empty case, but this thing had a transformer, nice aluminum heat sink, power supply and some other goodies. Just finished building an amp using this case and couldn't be happier.

Attachments

I like to be able and ground the case, you know, just in case.

I think the insurance company would like that too...

Also my hafler will buzz a bit with the lid off, picking up stray stuff.

I have my headphone amp in a recycled steel enclosure, inside a metal file cabinet.

I like the arrangement using the heatsinks as sides.

I think the insurance company would like that too...

Also my hafler will buzz a bit with the lid off, picking up stray stuff.

I have my headphone amp in a recycled steel enclosure, inside a metal file cabinet.

I like the arrangement using the heatsinks as sides.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- materials for amplifier enclosures: why not wood?