Tony,

A better option is to vacuum impregnate the transformer. This removes all of the air gaps but sucking out the air, and replacing with the varnish. This makes the laminations have a much greater adhesion, decreasing audiable noise, and increases the insulation level between windings. This can be done using a wide mouth glass jar and and a vacuum pump (even a manual vacuum pump will work). You pump down the jar with the transformer submerged until you stop seeing bubbles and before the varnish begins to boil. then remove the vaccum. Repeat this process a couple of times.

A better option is to vacuum impregnate the transformer. This removes all of the air gaps but sucking out the air, and replacing with the varnish. This makes the laminations have a much greater adhesion, decreasing audiable noise, and increases the insulation level between windings. This can be done using a wide mouth glass jar and and a vacuum pump (even a manual vacuum pump will work). You pump down the jar with the transformer submerged until you stop seeing bubbles and before the varnish begins to boil. then remove the vaccum. Repeat this process a couple of times.

Hi TechGuy,

Can you post a simple illustration on how to do this? So readers can have same understanding on how execute correctly the procedure. But thanks anyway for the information. This is great!

Can you post a simple illustration on how to do this? So readers can have same understanding on how execute correctly the procedure. But thanks anyway for the information. This is great!

HI TONY.

one qustion,

when i power on, the power code cable is burned, but before no problem.10a transformer , 220ac, what will be the problem?

in the image the transformer is only for refference .

one qustion,

when i power on, the power code cable is burned, but before no problem.10a transformer , 220ac, what will be the problem?

in the image the transformer is only for refference .

Attachments

Last edited:

^did it happen quick?

1. your cable could be of the dinky type and,

2. possibly your power traffo has developed shorts....

1. your cable could be of the dinky type and,

2. possibly your power traffo has developed shorts....

^did it happen quick?

1. your cable could be of the dinky type and,

2. possibly your power traffo has developed shorts....

hi tony ,

it happen quickly, wthin one second.

but before it works, with that power cord.

if the traffo is short, how to check ?

wire up a 50watt incandescent lamp in series with your traffo's primary, disconnect all secondary loads and keep it an open circuit...

if there is a short in your traffo, the lamp will light up fully brightly, this means a primary coil adjacent wire short...

if the lamp does not light, try to short the secondary leads, the lamp should then be fully on, extinguishing when you let go.....in this case look at your rectifier, or some shorted caps....

it can also be that the leads to the power base has become loose and might have touched the wire to the other line side......

if there is a short in your traffo, the lamp will light up fully brightly, this means a primary coil adjacent wire short...

if the lamp does not light, try to short the secondary leads, the lamp should then be fully on, extinguishing when you let go.....in this case look at your rectifier, or some shorted caps....

it can also be that the leads to the power base has become loose and might have touched the wire to the other line side......

Last edited:

wire up a 50watt incandescent lamp in series with your traffo's primary, disconnect all secondary loads and keep it an open circuit...

if there is a short in your traffo, the lamp will light up fully brightly, this means a primary coil adjacent wire short...

if the lamp does not light, try to short the secondary leads, the lamp should then be fully on, extinguishing when you let go.....in this case look at your rectifier, or some shorted caps....

it can also be that the leads to the power base has become loose and might have touched the wire to the other line side......

thanks tony, i will check.

Tony,

A better option is to vacuum impregnate the transformer. This removes all of the air gaps but sucking out the air, and replacing with the varnish. This makes the laminations have a much greater adhesion, decreasing audiable noise, and increases the insulation level between windings. This can be done using a wide mouth glass jar and and a vacuum pump (even a manual vacuum pump will work). You pump down the jar with the transformer submerged until you stop seeing bubbles and before the varnish begins to boil. then remove the vaccum. Repeat this process a couple of times.

thanks techguy,

i am looking for a suitable vessel to do just that.....

How low does the VAC-VAC pressure have to go to be effective?

1/2 atmosphere absolute, or 1/4 atmosphere absolute, or much lower?

1/2 atmosphere absolute, or 1/4 atmosphere absolute, or much lower?

Depends on several factors:

- viscosity of impregnating fluid;

- coil properties (not neatly wound non-interleaved or neatly wound interleaved);

- time.

- viscosity of impregnating fluid;

- coil properties (not neatly wound non-interleaved or neatly wound interleaved);

- time.

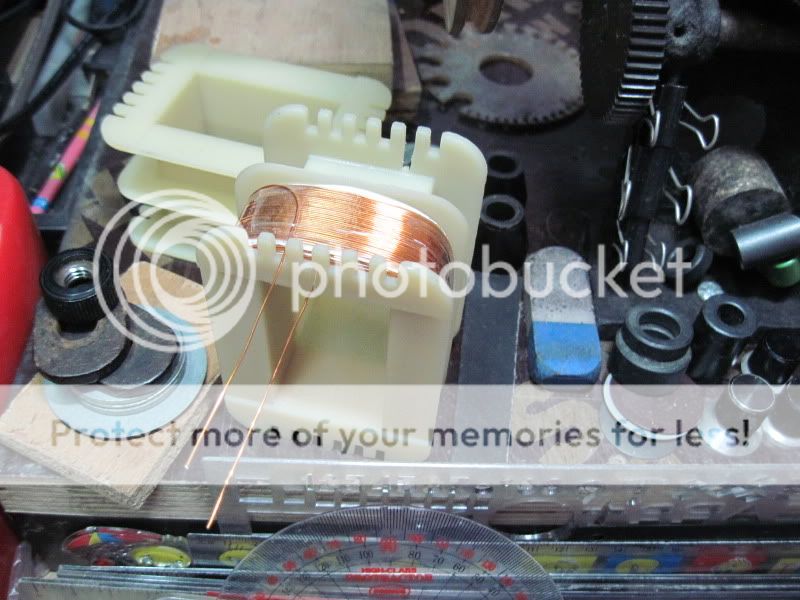

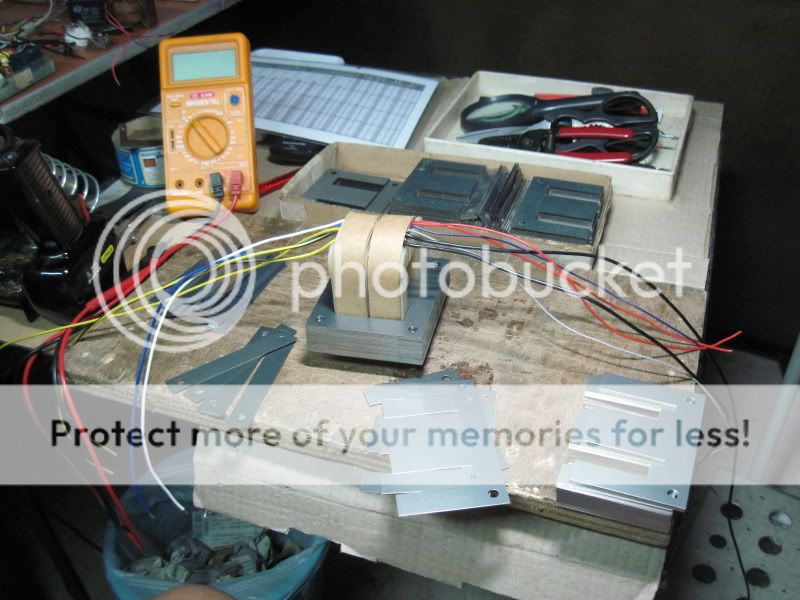

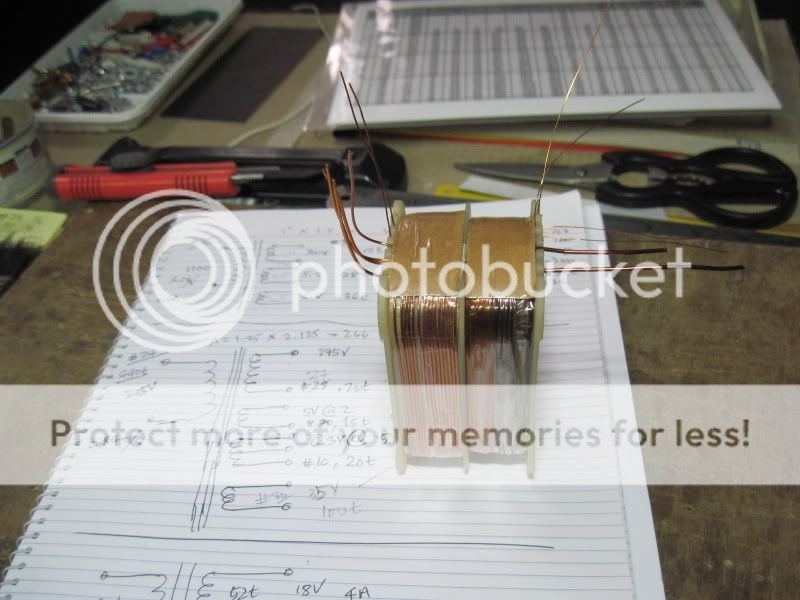

traffo for push-pull 6V6 power amp:

core size is 1 1/4 x 2 1/8, turns per volt is 2.84

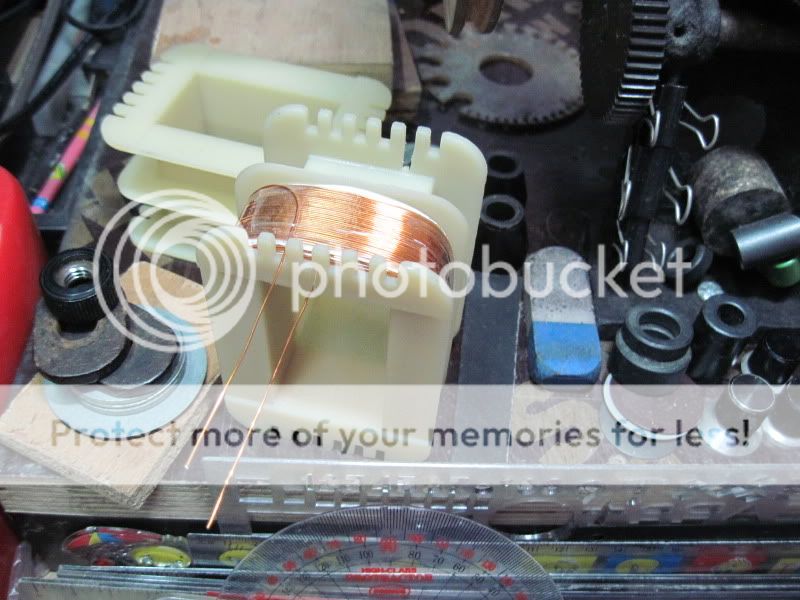

starting the primary coil:

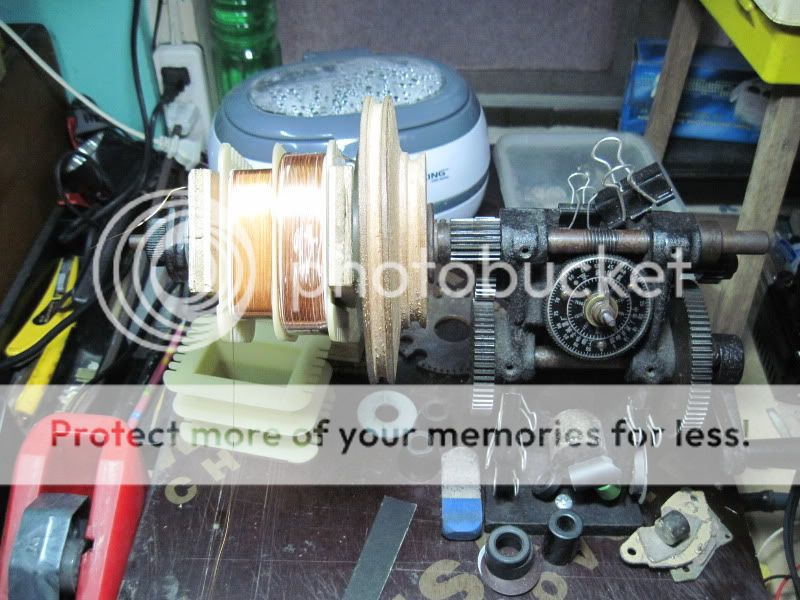

finished winding rpimary:

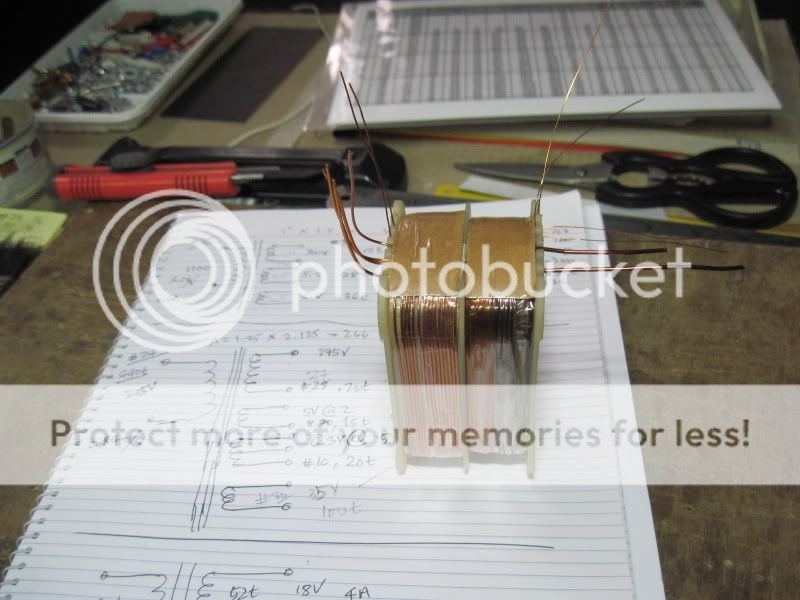

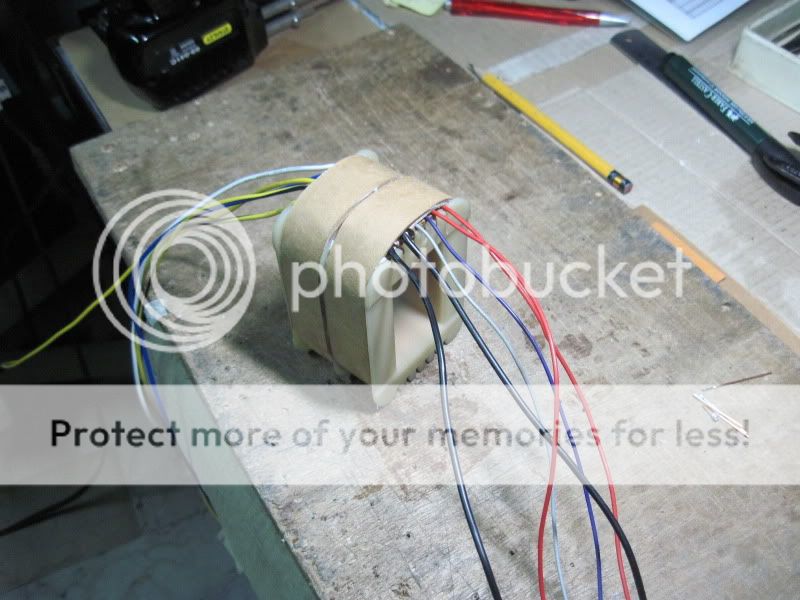

starting the secondary coil:

starting the rectifier fimament winding:

bias and 6.3volt filament winding:

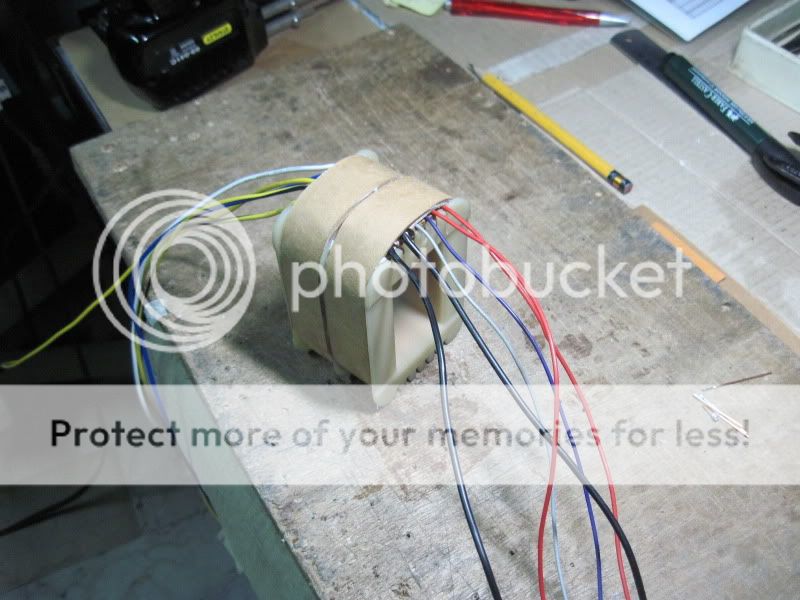

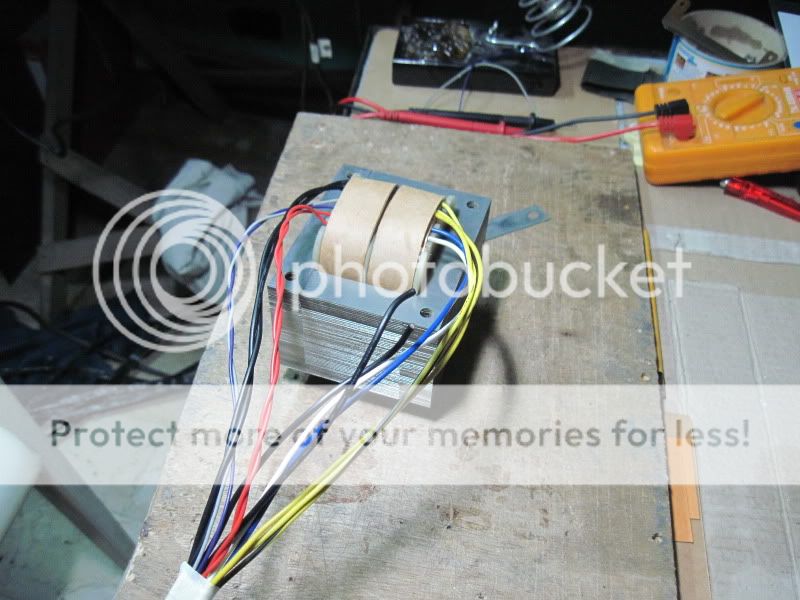

leads terminated and final outer wrap done:

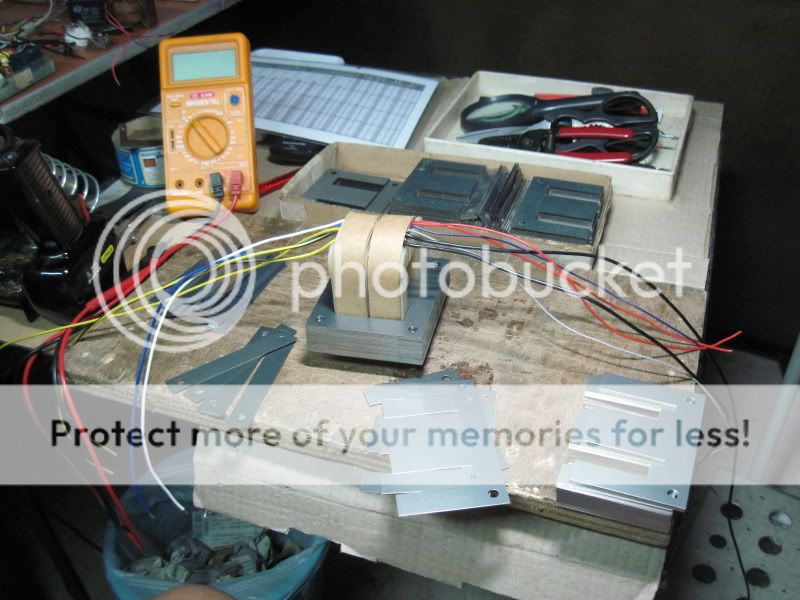

putting in the laminates:

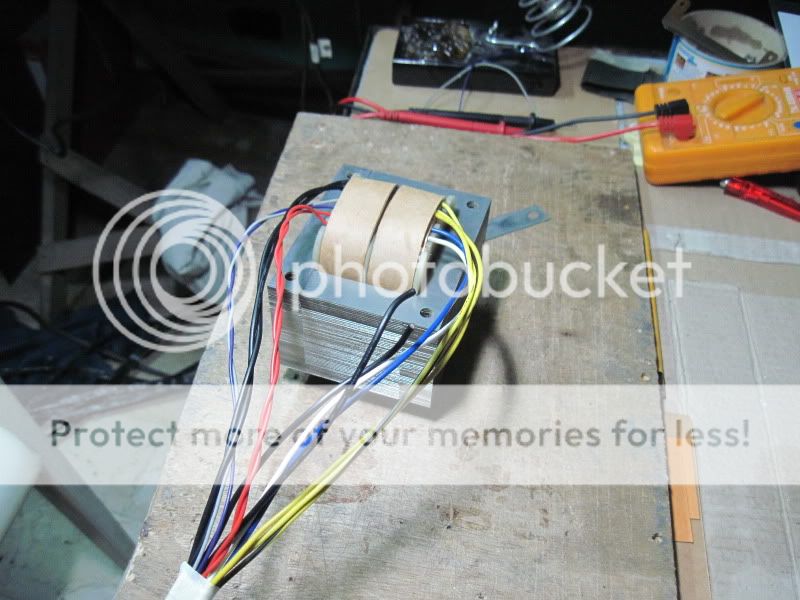

completed traffo:

after dipping in varnish, traffo is placed under sunshine for curing:

core size is 1 1/4 x 2 1/8, turns per volt is 2.84

starting the primary coil:

finished winding rpimary:

starting the secondary coil:

starting the rectifier fimament winding:

bias and 6.3volt filament winding:

leads terminated and final outer wrap done:

putting in the laminates:

completed traffo:

after dipping in varnish, traffo is placed under sunshine for curing:

@ TONY

beautifully done .................. Just have to say ur too good at making these transformers.....

Keep up ur good work.....

regards

sekhar

beautifully done .................. Just have to say ur too good at making these transformers.....

Keep up ur good work.....

regards

sekhar

tony - thats beautiful mate - this is something else i want to learn as well.

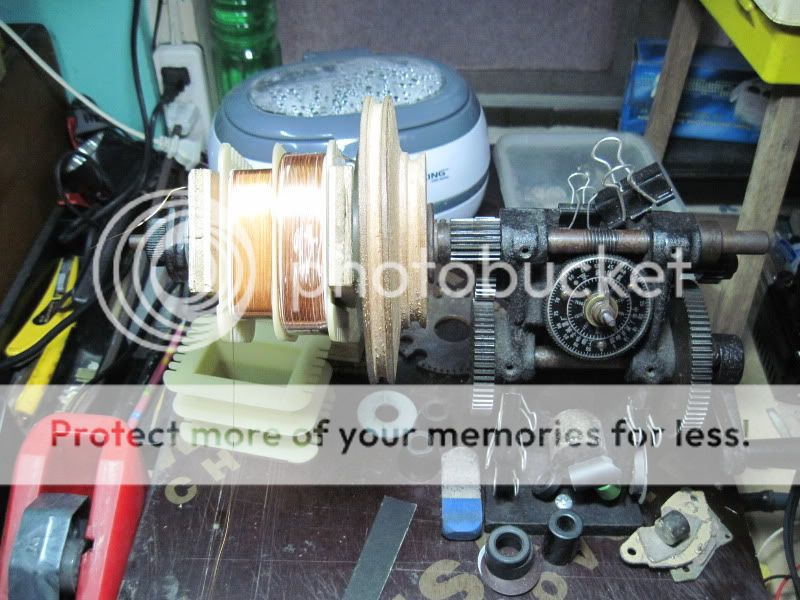

where did you get your winding device or is it something that you made (or inherited if you've been doing this for a few years)

where did you get your winding device or is it something that you made (or inherited if you've been doing this for a few years)

Hi Tony,^Thanks.......i have been doing this for the last 30 years......

that a long time, I'm not 30 years old yet 🙂

You really an expert...

please share your experience to beginner like me

I don't see any "inter layer" insulator on this trafo...

Maybe for small trafo it is no need that inter layer insulating?

Then start on how much VA ratting we need to put the inter layer insulator?

Please guide me

Thanks

Last edited:

hi, that winding machine is an old china job using analog dial counter, i've had it for years...

Hi Tony,

that a long time, I'm not 30 years old yet 🙂

I don't see any "inter layer" insulator on this trafo...

Maybe for small trafo it is no need that inter layer insulating?

Then start on how much VA ratting we need to put the inter layer insulator?

Please guide me

Thanks

inter-layer insulation's are mandatory......regardless of power levels....😎

i used inter-layer insulation, clear cellophane tapes, in several layers, and pvc plastics cut to size......

i used a dual chamber nylon bobbin, the primary and secondaries are well separated....

Oh, i don't see it because it is clearinter-layer insulation's are mandatory......regardless of power levels....😎

i used inter-layer insulation, clear cellophane tapes, in several layers, and pvc plastics cut to size......

I clear now ...

you inspire me 🙂

Thanks

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build