In the data sheet for the LT1033 negative adjustable regulator there is a typical application schematic for a tracking regulator that i am interested in but don't understand. I like the simplicity of the design as all the tracking regulators i am familiar with use opamps.

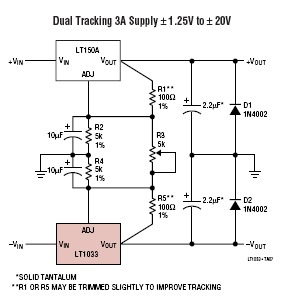

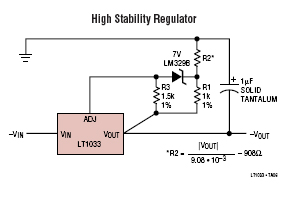

here is the schematic from the data sheet

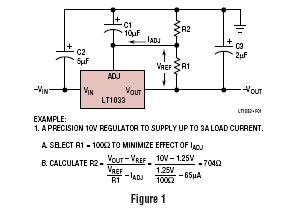

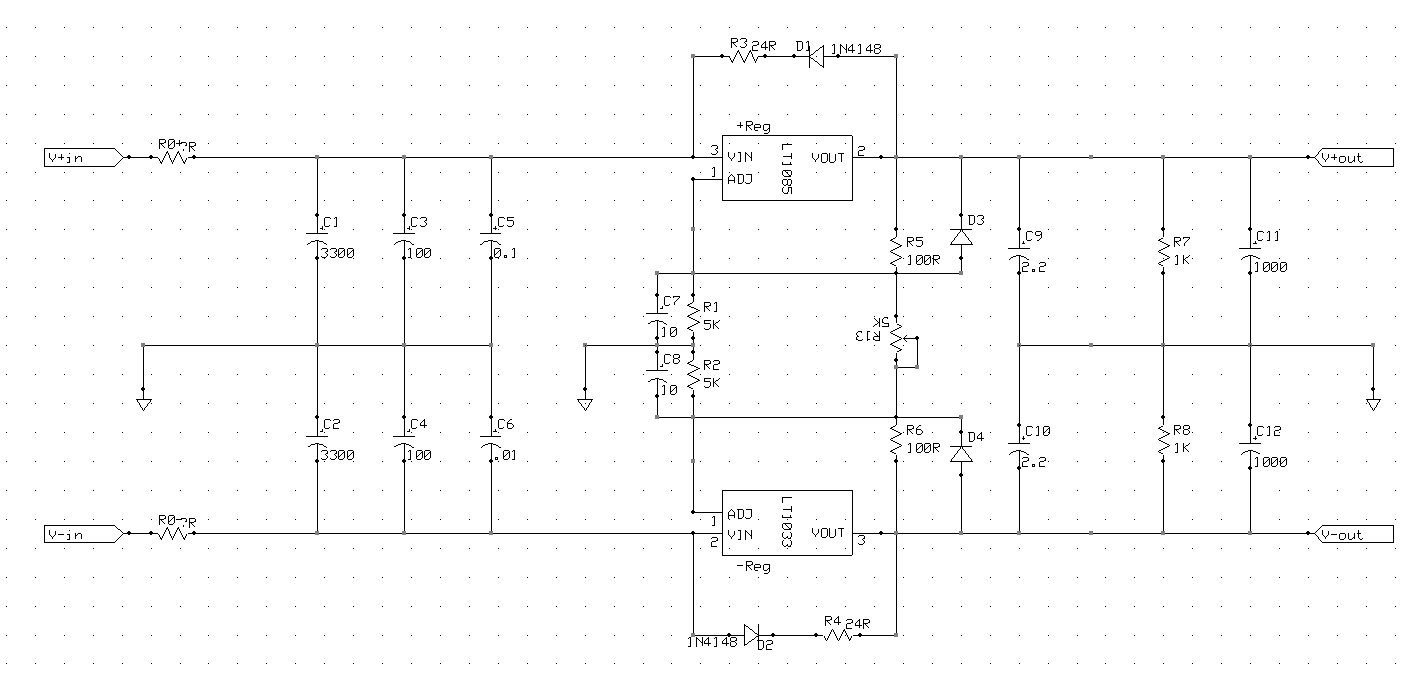

here is the more common implementation as well as the formula for calculating resistor values to set the output voltage.

my two questions are:

1. how do you adapt the formula to calculate resitor values for the tracking regulator?

2. how does the circuit match a voltage change at the output of one regulator in the other regulator?

here is the schematic from the data sheet

here is the more common implementation as well as the formula for calculating resistor values to set the output voltage.

my two questions are:

1. how do you adapt the formula to calculate resitor values for the tracking regulator?

2. how does the circuit match a voltage change at the output of one regulator in the other regulator?

okapi said:1. how do you adapt the formula to calculate resitor values for the tracking regulator?

2. how does the circuit match a voltage change at the output of one regulator in the other regulator?

1) If you want to build the tracking regulator, then use the values in the datasheet, don't recalculate.

2) As you adjust R3, then the resistance between the adj pin and gnd is symmetrically changed for both regulators (look at the resistor network formed by R2 R3 R4).

i believe the resistor values determine the output voltage - it is an adjustable regulator - so i need to at least know what the output voltage is for the resistor values in the schematic.

EDIT:

i think the second resistor in the voltage divider is made up of r4 and r3 in parallel. the effective value of R3 is acutally 2.5K not 5K as i originally thought.

using the above logic i calculate the output to be 22V. Still 2 volts too high so i must still not be accounting for something.

EDIT:

i think the second resistor in the voltage divider is made up of r4 and r3 in parallel. the effective value of R3 is acutally 2.5K not 5K as i originally thought.

using the above logic i calculate the output to be 22V. Still 2 volts too high so i must still not be accounting for something.

I just cannot get my head around what you are trying to say. You do realize that R3 is a potentiometer? When R3 is adjusted to 5K, the voltage is +/- 20V and when it is adjusted to 0 the voltage is +/- 1.25V.

ok - i think.

i do recognize that r3 is a trim pot.

can you run through a calculation for me with r3 set to 5k so i can better understand?

by my (i assume incorrect) calculations i get a voltage output of about 42 V when r3 = 5K

i do recognize that r3 is a trim pot.

can you run through a calculation for me with r3 set to 5k so i can better understand?

by my (i assume incorrect) calculations i get a voltage output of about 42 V when r3 = 5K

okapi,

Essentially, you don't need to change the formulas in the single supply schematic to adjust it for dual tracking. Actually, I think its a really nice application note.... The key is to identify the current flowing through the resistor divider network (R1 - R5).

If R3 = 0, R1 and R5 are tied together and the reference pins are pulled together, putting them to 0V offset through the now parallel connection of R4 and R5.

If you want to fix R3, calculate half its value in parallel R2 and R4.

Bakmeel

Essentially, you don't need to change the formulas in the single supply schematic to adjust it for dual tracking. Actually, I think its a really nice application note.... The key is to identify the current flowing through the resistor divider network (R1 - R5).

If R3 = 0, R1 and R5 are tied together and the reference pins are pulled together, putting them to 0V offset through the now parallel connection of R4 and R5.

If you want to fix R3, calculate half its value in parallel R2 and R4.

Bakmeel

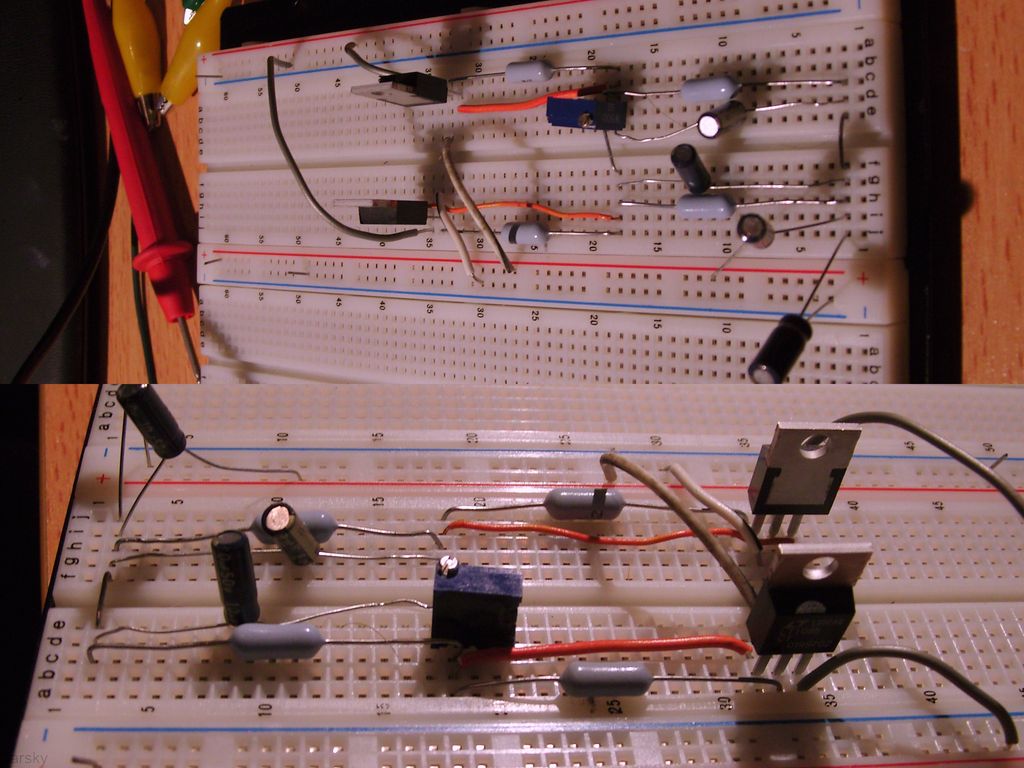

prototype up and running

leadbelly and bakmeel, thank you for your replies.

i now have a working prototype

i have not tested it's tracking but i will do so soon.

i have to admit that i still don't quite understand the circuit but, i do at least know how to calculate the output voltage based on the value of the trim pot.

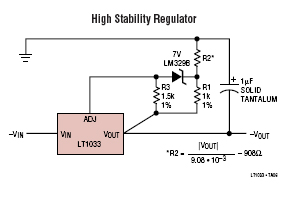

i am planning on increasing the stability of the supply by incorporating the following typical implementation circuit from the data sheet into the tracking regulator circuit.

i don't have the voltage reference in hand yet so it might be a while before i get the chance to try it.

after i build a point to point version i plan on designing and ordering circuit boards. This supply will form the basis for the buffers i have in the works (B1 and a LME49710 based buffer).

if i can find a negative regulator that is pin compatible and can handle higher output amperage it might work for my chip amps as well.

leadbelly and bakmeel, thank you for your replies.

i now have a working prototype

i have not tested it's tracking but i will do so soon.

i have to admit that i still don't quite understand the circuit but, i do at least know how to calculate the output voltage based on the value of the trim pot.

i am planning on increasing the stability of the supply by incorporating the following typical implementation circuit from the data sheet into the tracking regulator circuit.

i don't have the voltage reference in hand yet so it might be a while before i get the chance to try it.

after i build a point to point version i plan on designing and ordering circuit boards. This supply will form the basis for the buffers i have in the works (B1 and a LME49710 based buffer).

if i can find a negative regulator that is pin compatible and can handle higher output amperage it might work for my chip amps as well.

Good work okapi,

Try to approach the regulator as follows: It will work to maintain a voltage difference between OUT and ADJ of 1.25V, based on its internal reference. It will adjust the current passing to the output as a function of the current flowing into the ADJ pin.

Work your way through the resistor network based on the constant 1.25V, and you'll find how the remaining currents flow and why. It's not difficult at all.. 😉

The additional voltage reference is a nice trick to improve stability.

For your benefit: put some ceramic capacitors (typically 100nF) parallel to the output capacitors. Put them physically close to the regulator, and minimise the track distance to the ceramic from the OUT pin and GND. Keep GND close to the input and output (or use a double sided PCB with a ground plane).

The ceramic cap will short high frequency noise generated by the regulator

Try to approach the regulator as follows: It will work to maintain a voltage difference between OUT and ADJ of 1.25V, based on its internal reference. It will adjust the current passing to the output as a function of the current flowing into the ADJ pin.

Work your way through the resistor network based on the constant 1.25V, and you'll find how the remaining currents flow and why. It's not difficult at all.. 😉

The additional voltage reference is a nice trick to improve stability.

For your benefit: put some ceramic capacitors (typically 100nF) parallel to the output capacitors. Put them physically close to the regulator, and minimise the track distance to the ceramic from the OUT pin and GND. Keep GND close to the input and output (or use a double sided PCB with a ground plane).

The ceramic cap will short high frequency noise generated by the regulator

bakmeel -

in regards to your capacitor comment the data sheet for the lt1033 says the following:

"An output capacitor, C3, is required to provide proper frequency compensation of the regulator feedback loop. A 2uF or larger solid tantalum capacitor is generally sufficient for this purpose if the 1MHz impedance of the capacitor is 1W or less. High Q capacitors, such as Mylar, are not recommended because their extremely low ESR (effective series resistance) can drastically reduce phase margin. When these types of capacitors must be used because of other considerations, add a 0.5W carbon resistor in series with 1uF. Aluminum electrolytic capacitors may be used, but the minimum value should be 25uF to ensure a low impedance at 1MHz. The output capacitor should be located within a few inches of the regulator to keep lead impedance to a minimum"

i don't know the what the important differences in specifications are for tantalum and ceramic caps with the same capacitance and voltage ratings.

Should i substitute the ceramic for the tantalums or use the ceramics after the tantalums? I also have hundreds of 0.1 uF polypropylene caps, could i use those?

i also noticed that some power supplies also have much larger caps after the regulators, 1000 uF or more. when is this sort of configuration necessary?

thanks again!

in regards to your capacitor comment the data sheet for the lt1033 says the following:

"An output capacitor, C3, is required to provide proper frequency compensation of the regulator feedback loop. A 2uF or larger solid tantalum capacitor is generally sufficient for this purpose if the 1MHz impedance of the capacitor is 1W or less. High Q capacitors, such as Mylar, are not recommended because their extremely low ESR (effective series resistance) can drastically reduce phase margin. When these types of capacitors must be used because of other considerations, add a 0.5W carbon resistor in series with 1uF. Aluminum electrolytic capacitors may be used, but the minimum value should be 25uF to ensure a low impedance at 1MHz. The output capacitor should be located within a few inches of the regulator to keep lead impedance to a minimum"

i don't know the what the important differences in specifications are for tantalum and ceramic caps with the same capacitance and voltage ratings.

Should i substitute the ceramic for the tantalums or use the ceramics after the tantalums? I also have hundreds of 0.1 uF polypropylene caps, could i use those?

i also noticed that some power supplies also have much larger caps after the regulators, 1000 uF or more. when is this sort of configuration necessary?

thanks again!

Solid Tantalum generally has a poor impedance (high ESR) and works well as buffer capacitance. It is true that in some cases a high Q capacitor can cause loop instability, but a 100nF ceramic is not large enough to make a difference in the loop stability.

You may keep the electrolytics you're using now, or replace them with tantalums. It won't make a difference. Film caps instead of ceramics is no problem either, as long as you keep them small enough.

Power supplies with large capacitances are best when you're expecting large variations in load currents. They are also commonly used in hi-fi audio as an eye-catcher or just to exgagerate 😀

You may keep the electrolytics you're using now, or replace them with tantalums. It won't make a difference. Film caps instead of ceramics is no problem either, as long as you keep them small enough.

Power supplies with large capacitances are best when you're expecting large variations in load currents. They are also commonly used in hi-fi audio as an eye-catcher or just to exgagerate 😀

Okapi, what a cute little circuite. I bet it boils down to the fact

that that 5k pot is acting like a pair of 2.5k pots in paralle with

r2 and r4 as you saw but each of the imaginary 2.5k pot is not

returned to ground like r2 and r4 but to the + & - 1.25v above and below ground this just about solves where that 2 volts

went.

that that 5k pot is acting like a pair of 2.5k pots in paralle with

r2 and r4 as you saw but each of the imaginary 2.5k pot is not

returned to ground like r2 and r4 but to the + & - 1.25v above and below ground this just about solves where that 2 volts

went.

tested the tracking

i had some time this weekend and i designed a pcb for the power supply as well as tested the tracking.

i'll post the pcb later, but i wanted to report that if i unload and load one output rail, the opposite rail moves in parallel, maintaining the voltage difference between rails - just as expected!

i also requested a couple of sample lm329b's from linear so that i can test the high stability circuit.

thanks for everyone's help.

i had some time this weekend and i designed a pcb for the power supply as well as tested the tracking.

i'll post the pcb later, but i wanted to report that if i unload and load one output rail, the opposite rail moves in parallel, maintaining the voltage difference between rails - just as expected!

i also requested a couple of sample lm329b's from linear so that i can test the high stability circuit.

thanks for everyone's help.

How to optimize star grounding

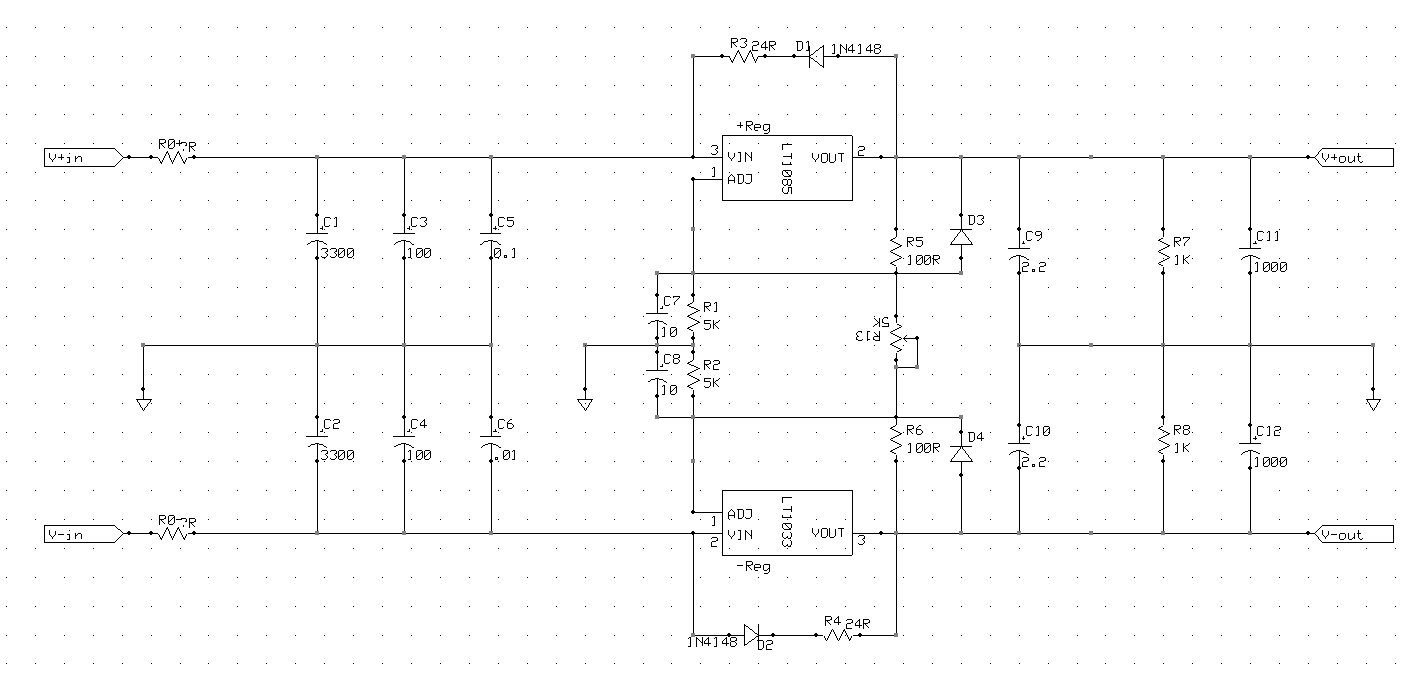

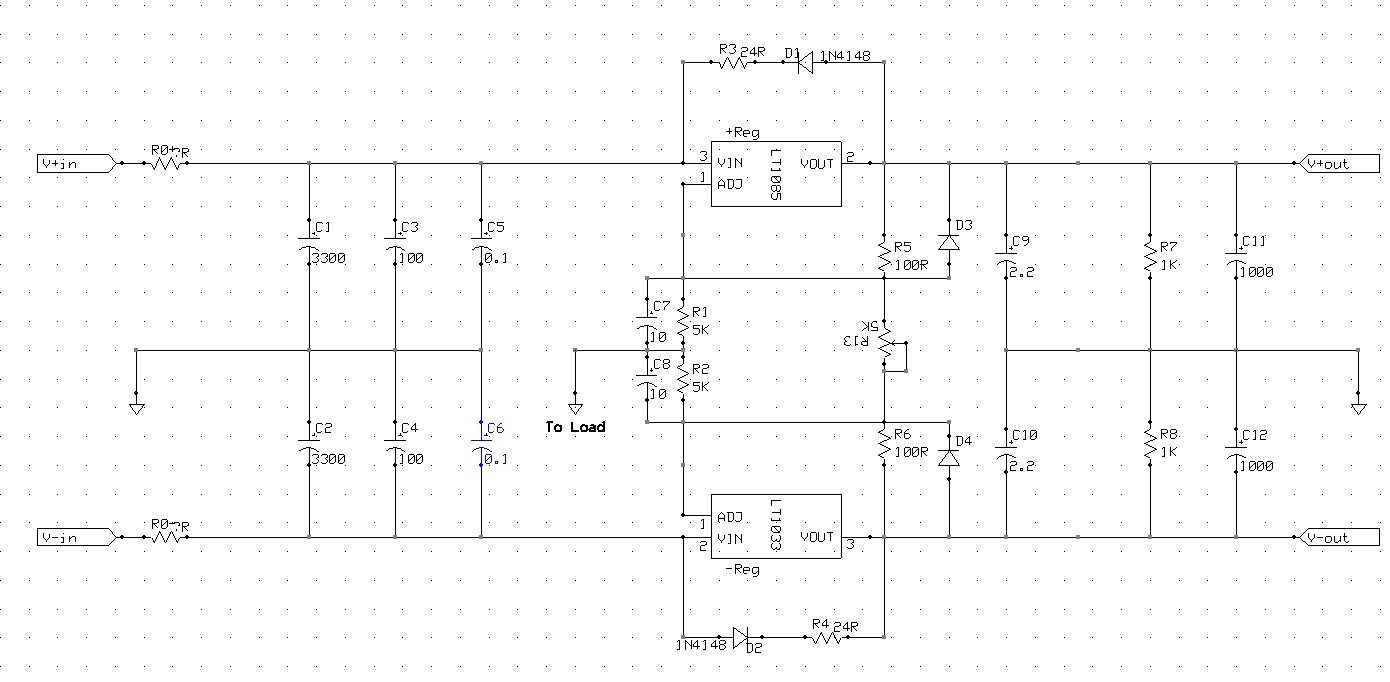

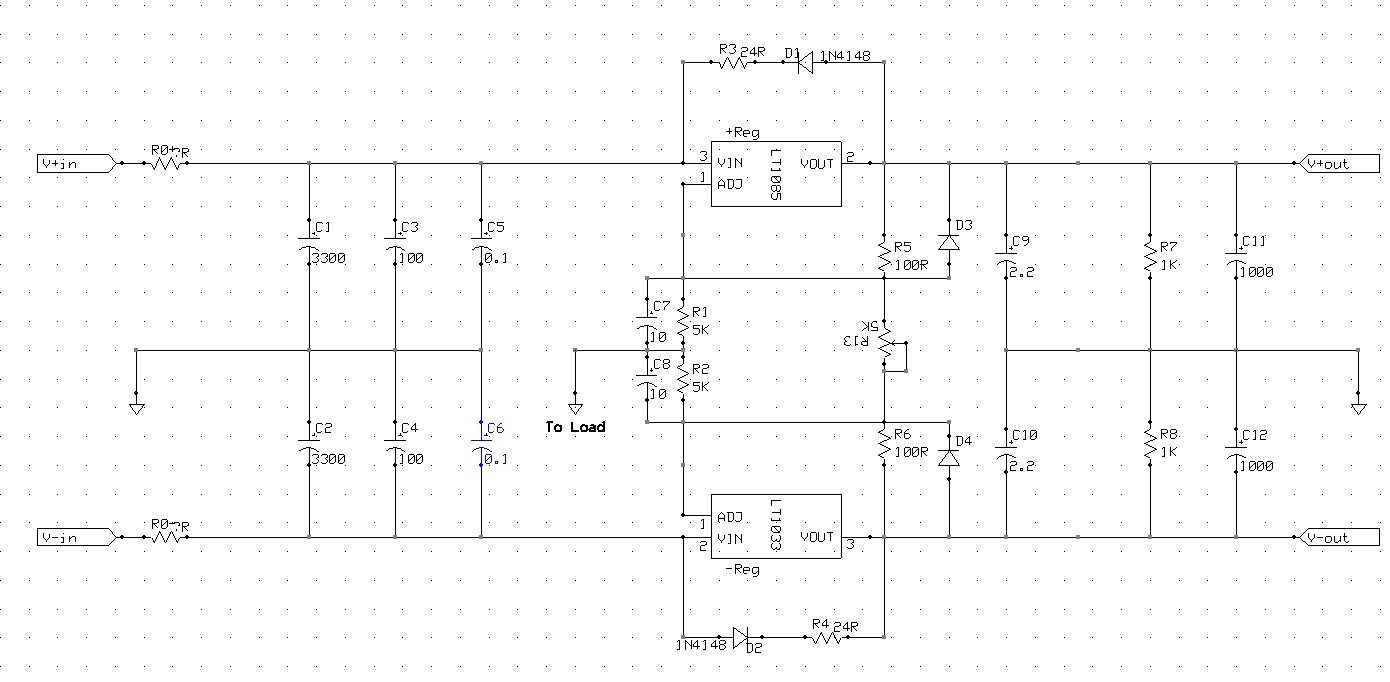

This is the schematic i've come up with for the second stage of my voltage supply. It is essentially the tracking circuit with filter and bypass caps, the necessary protective diodes, and some optional voltage dropping resistors at the input.

Based on my reading about the tri way power supply in audioXpress as well as comments posted here on DIY audio (ex. 1.) it seems that the use of a star ground is preferable to using a ground plane.

Taking this idea to the extreme would require that the ground side of every component be run to a central ground. This would seem to be very difficult to implement.

What is the next best option? How do i decide what grounds to bring together before i run them to a central ground? Where should this central ground be located? Should it be closer to the rectifier bridge or at the load?

thank you for your help.

This is the schematic i've come up with for the second stage of my voltage supply. It is essentially the tracking circuit with filter and bypass caps, the necessary protective diodes, and some optional voltage dropping resistors at the input.

Based on my reading about the tri way power supply in audioXpress as well as comments posted here on DIY audio (ex. 1.) it seems that the use of a star ground is preferable to using a ground plane.

Taking this idea to the extreme would require that the ground side of every component be run to a central ground. This would seem to be very difficult to implement.

What is the next best option? How do i decide what grounds to bring together before i run them to a central ground? Where should this central ground be located? Should it be closer to the rectifier bridge or at the load?

thank you for your help.

Why did you use the combination of a resistor and the 1n4148 ?

wouldn't just a 1n4001 without a resistor be simpler and better ?

wouldn't just a 1n4001 without a resistor be simpler and better ?

Hi Woody,

i copied this idea from the audioXpress article (Tri-Way Low Voltage Supply, Pt. 1, by Paul J. Stamler).

Here is a direct quote from the author: " I followed (Ben) Duncan's suggestion and used 1N4148s as regulator safety diodes, along with current-limiting resistors; these are less likely to conduct high-frequency crud around the regulators"

I think 4148s are much faster than the 4001 family of diodes but can't conduct as much current. I think the resistor acts to protect the diode while at the same time attenuates any "high frequency crud".

do you think this is a reasonable idea?

thanks for following the thread.

i copied this idea from the audioXpress article (Tri-Way Low Voltage Supply, Pt. 1, by Paul J. Stamler).

Here is a direct quote from the author: " I followed (Ben) Duncan's suggestion and used 1N4148s as regulator safety diodes, along with current-limiting resistors; these are less likely to conduct high-frequency crud around the regulators"

I think 4148s are much faster than the 4001 family of diodes but can't conduct as much current. I think the resistor acts to protect the diode while at the same time attenuates any "high frequency crud".

do you think this is a reasonable idea?

thanks for following the thread.

okapi said:

.... do you think this is a reasonable idea?

You understand the diode is there for protecting the regulator when the input voltage is lower than the output. Limiting the current capability of this diode also reduces its capability to protect the regulator. It will only handle small voltage differences. Is that good enough for you? Would you be able to do without diode at all?

I think there's a typo in the value for C5 or C6.

Protection Diodes

by rereading the data sheets it seems like the necessity of the protection diodes is similar for both regulators.

For the LT1033 the data sheet says:

if the output voltage is greater than 6V and an output capacitor greater than 20uF has been used, it is possible to damage the regulator if the input voltage becomes shorted, due to the output capacitor discharging into the regulator. This can be prevented by using diode between the input and the output.

for the adjust pin diode

if the bypass capacitor is larger than 10uF and the output is larger than 25V, a diode should be added between the output and adjustment pins.

For the LT1085 the the data sheet says:

In normal operation, the LT1083 family does not need any protection diodes. Older adjustable regulators required protection diodes between the adjustment pin and the output and from the output to the input to prevent overstressing the die. The internal current paths on the LT1083 adjustment pin are limited by internal resistors. Therefore, even with capacitors on the adjustment pin, no protection diode is needed to ensure device safety under short circuit conditions.

Diodes between input and output are usually not needed. The internal diode between the input and the output pins of the LT1083 family can handle microsecond surge currents of 50A to 100A. Even with large output capacitances, it is very difficult to get those values of surge currents in normal operations. Only with a high value of output capacitors, such as 1000μF to 5000μF and with the input pin instantaneously shorted to ground, can damage occur. A crowbar circuit at the input of the LT1083 can generate those kinds of currents, and a diode from output to input is then recommended. Normal power supply cycling or even plugging and unplugging in the system will not generate current large enough to do any damage.

so it looks like i will need the diode between in and output on the LT1033 and LT1085. But i can drop the diode across the adjust pin on both regulators.

The next question is can i use a 4148 diode with a 24R resistor in series?

My back of the envelope calculation indicates that i can:

The max output voltage of this circuit is 20 volts. 20 Volts across a 24 ohm resistor give 0.83 amps. The 1N4148 IFSM = 1.0 A (Pulse Width = 1 sec), 4.0 A (Pulse Width = 1 uSec) (Non-Repetitive Peak Forward Surge Current).

It seems like the IN4148 can handle the current associated with the maximum possible load it might see with a bit of headroom left over.

by rereading the data sheets it seems like the necessity of the protection diodes is similar for both regulators.

For the LT1033 the data sheet says:

if the output voltage is greater than 6V and an output capacitor greater than 20uF has been used, it is possible to damage the regulator if the input voltage becomes shorted, due to the output capacitor discharging into the regulator. This can be prevented by using diode between the input and the output.

for the adjust pin diode

if the bypass capacitor is larger than 10uF and the output is larger than 25V, a diode should be added between the output and adjustment pins.

For the LT1085 the the data sheet says:

In normal operation, the LT1083 family does not need any protection diodes. Older adjustable regulators required protection diodes between the adjustment pin and the output and from the output to the input to prevent overstressing the die. The internal current paths on the LT1083 adjustment pin are limited by internal resistors. Therefore, even with capacitors on the adjustment pin, no protection diode is needed to ensure device safety under short circuit conditions.

Diodes between input and output are usually not needed. The internal diode between the input and the output pins of the LT1083 family can handle microsecond surge currents of 50A to 100A. Even with large output capacitances, it is very difficult to get those values of surge currents in normal operations. Only with a high value of output capacitors, such as 1000μF to 5000μF and with the input pin instantaneously shorted to ground, can damage occur. A crowbar circuit at the input of the LT1083 can generate those kinds of currents, and a diode from output to input is then recommended. Normal power supply cycling or even plugging and unplugging in the system will not generate current large enough to do any damage.

so it looks like i will need the diode between in and output on the LT1033 and LT1085. But i can drop the diode across the adjust pin on both regulators.

The next question is can i use a 4148 diode with a 24R resistor in series?

My back of the envelope calculation indicates that i can:

The max output voltage of this circuit is 20 volts. 20 Volts across a 24 ohm resistor give 0.83 amps. The 1N4148 IFSM = 1.0 A (Pulse Width = 1 sec), 4.0 A (Pulse Width = 1 uSec) (Non-Repetitive Peak Forward Surge Current).

It seems like the IN4148 can handle the current associated with the maximum possible load it might see with a bit of headroom left over.

Re: How to optimize star grounding

The data sheet also shed some light on the question i posted earlier. It indicates that R2 (the second resistor in the voltage divider) should be connected to the positive side of the load separately from the positive (ground) connection to the raw supply.

i have updated the schematic to reflect this change and correct for the error bakmeel pointed out.

it still remains to be decided where i run the grounds for the input and output capacitor banks?? Should they all meet at the load? That would require 3 or 5 (if i keep the + and - ground rails seperate) individual wires running to the a star ground located at the load. Will this solution lower the noise floor? What are some other good solutions?

okapi said:

What is the next best option? How do i decide what grounds to bring together before i run them to a central ground? Where should this central ground be located? Should it be closer to the rectifier bridge or at the load?

thank you for your help.

The data sheet also shed some light on the question i posted earlier. It indicates that R2 (the second resistor in the voltage divider) should be connected to the positive side of the load separately from the positive (ground) connection to the raw supply.

i have updated the schematic to reflect this change and correct for the error bakmeel pointed out.

it still remains to be decided where i run the grounds for the input and output capacitor banks?? Should they all meet at the load? That would require 3 or 5 (if i keep the + and - ground rails seperate) individual wires running to the a star ground located at the load. Will this solution lower the noise floor? What are some other good solutions?

circuit board

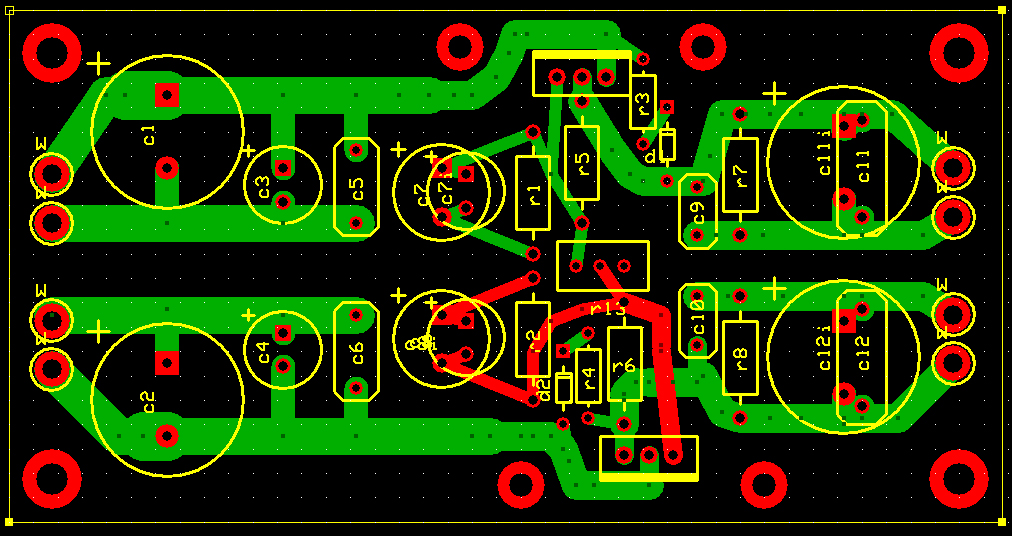

I have come up with a preliminary circuit board design for the tracking regulator. It does not include the high stability circuit but the LM329BZ's arrived today. once i test a prototype circuit i may include the high stability regulator in the final PCB as a optional configuration.

i used expressPCB's proprietary software to make this. Express PCB charges approximately $60 dollars for a single board and each additional board is about $12. If i can shrink the length by about half an inch i can use their MiniBoard and get three boards for $51. But then the width would be about half an inch too large.

this is my first circuit board design so any helpful feedback would be greatly appreciated.

on a side note, from reading a more recent LT application note it seems that bypassing the output with a cap that has a relatively high ESR (the LT1033 application note recommends a tantalum cap) is only necessary when the output voltage is low (less than 5 V) so it looks like ceramics will be the way to go (as bakmeel already kindly pointed out).

red = top layer

green = bottom layer

I have come up with a preliminary circuit board design for the tracking regulator. It does not include the high stability circuit but the LM329BZ's arrived today. once i test a prototype circuit i may include the high stability regulator in the final PCB as a optional configuration.

i used expressPCB's proprietary software to make this. Express PCB charges approximately $60 dollars for a single board and each additional board is about $12. If i can shrink the length by about half an inch i can use their MiniBoard and get three boards for $51. But then the width would be about half an inch too large.

this is my first circuit board design so any helpful feedback would be greatly appreciated.

on a side note, from reading a more recent LT application note it seems that bypassing the output with a cap that has a relatively high ESR (the LT1033 application note recommends a tantalum cap) is only necessary when the output voltage is low (less than 5 V) so it looks like ceramics will be the way to go (as bakmeel already kindly pointed out).

red = top layer

green = bottom layer

update

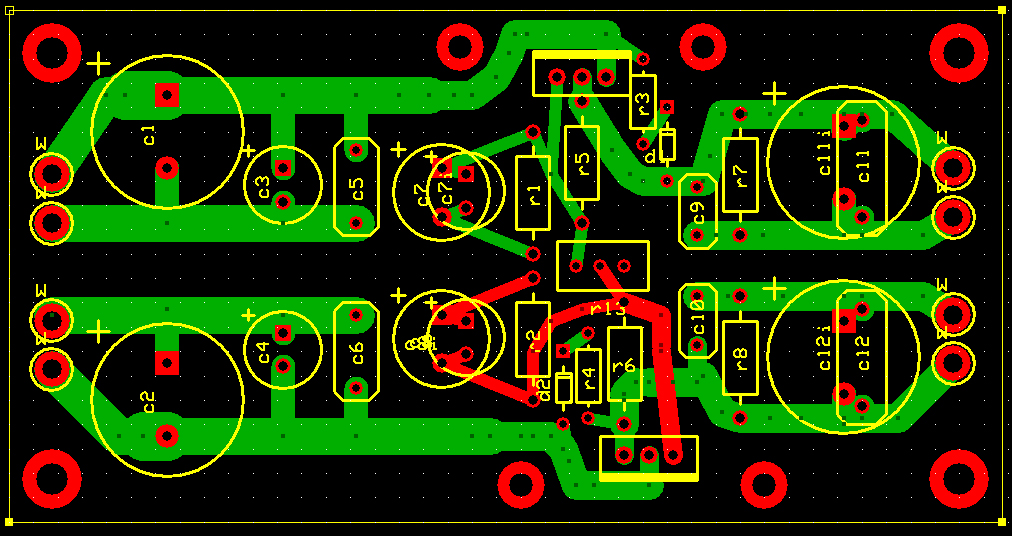

1. i have updated my PCB design for the tracking regulator. The major change is the implementation of a star ground. i have also included the option of running the adjust pin ground to the load or jumping it to the ground on the board. The plan is to run the load ground back to the star ground on this board.

2. i have successfully prototyped the high stability version of the tracking regulator which uses the LM329B voltage reference. I will post the schematic later. Resistor values needed to be tweaked to get it to work correctly.

3. i would like to test the noise level of the regulator, however, my bench supply (agilent E3630A) has about 5 mV peak to peak noise. There may be higher amplitude high frequency noise but my scope only goes to 20 Mhz so i can't see it. The tracking regulator noise is lost in the supply noise. I was thinking of using a bank of 9V batteries instead of my bench supply to get the noise level down.

here is the latest pic of the PCB

1. i have updated my PCB design for the tracking regulator. The major change is the implementation of a star ground. i have also included the option of running the adjust pin ground to the load or jumping it to the ground on the board. The plan is to run the load ground back to the star ground on this board.

2. i have successfully prototyped the high stability version of the tracking regulator which uses the LM329B voltage reference. I will post the schematic later. Resistor values needed to be tweaked to get it to work correctly.

3. i would like to test the noise level of the regulator, however, my bench supply (agilent E3630A) has about 5 mV peak to peak noise. There may be higher amplitude high frequency noise but my scope only goes to 20 Mhz so i can't see it. The tracking regulator noise is lost in the supply noise. I was thinking of using a bank of 9V batteries instead of my bench supply to get the noise level down.

here is the latest pic of the PCB

- Status

- Not open for further replies.

- Home

- Amplifiers

- Power Supplies

- LT Dual Tracking 3A Regulated Power Supply 1.25V to 20V