In this design the pleats move closer to each other/away from each other right, not towards you and away from you ?

I am once again in awe of you guys ...

I'll do the magnet motor structure sometime, but that's my limit, the diaphragm is crazy.

I have thought about making it with a bunch of neo-magnets with them facing the diaphragm held in place with a wood or aluminum frame. That eliminates the edge being so close to the magnet ...

Also shiny neos look cool compared to the steel to my eye.

Cool.

Srinath.

I am once again in awe of you guys ...

I'll do the magnet motor structure sometime, but that's my limit, the diaphragm is crazy.

I have thought about making it with a bunch of neo-magnets with them facing the diaphragm held in place with a wood or aluminum frame. That eliminates the edge being so close to the magnet ...

Also shiny neos look cool compared to the steel to my eye.

Cool.

Srinath.

YesIn this design the pleats move closer to each other/away from each other right, not towards you and away from you ?

In my opinion the field will not be linear enough.I have thought about making it with a bunch of neo-magnets with them facing the diaphragm held in place with a wood or aluminum frame. That eliminates the edge being so close to the magnet ...

Also shiny neos look cool compared to the steel to my eye.

Cool.

Srinath.

Yes you're right in the case of the field, unless you put these magnets very very close and they are very very thin ...

That of course means more and more $$$ ...

I have an amt, I am sure its a N8 or something magnet, I wonder what would be the result if I replace em with a 38 or 42 ...

Cool.

Srinath.

That of course means more and more $$$ ...

I have an amt, I am sure its a N8 or something magnet, I wonder what would be the result if I replace em with a 38 or 42 ...

Cool.

Srinath.

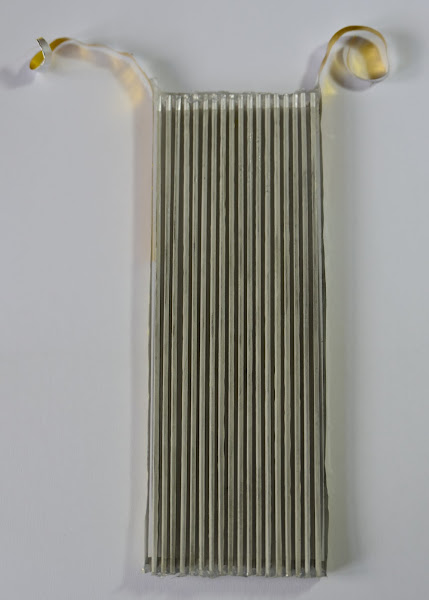

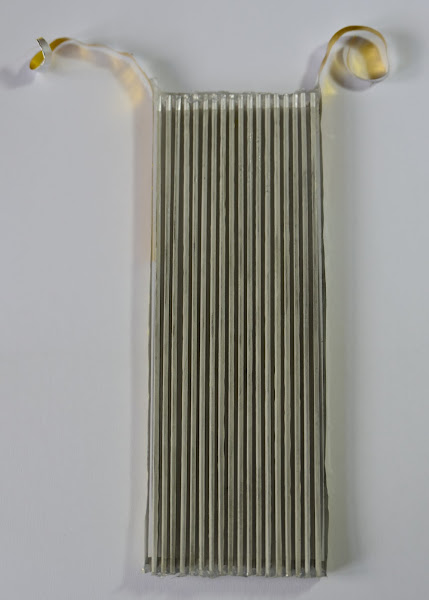

My first membrane for the new motor 60 x 160 mm.

Alu-ratio is 5/3 mm. Resistance 3,8 ohm, weight 2,5 grams:

Membrane is folded as 6,5/1,5 mm:

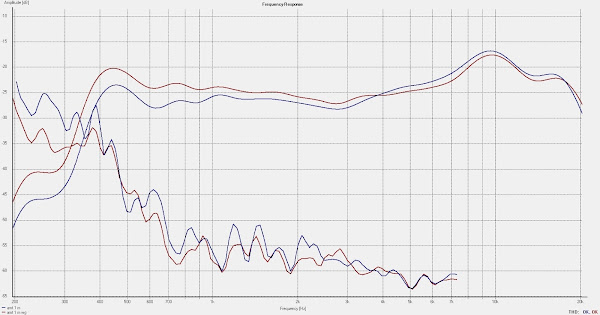

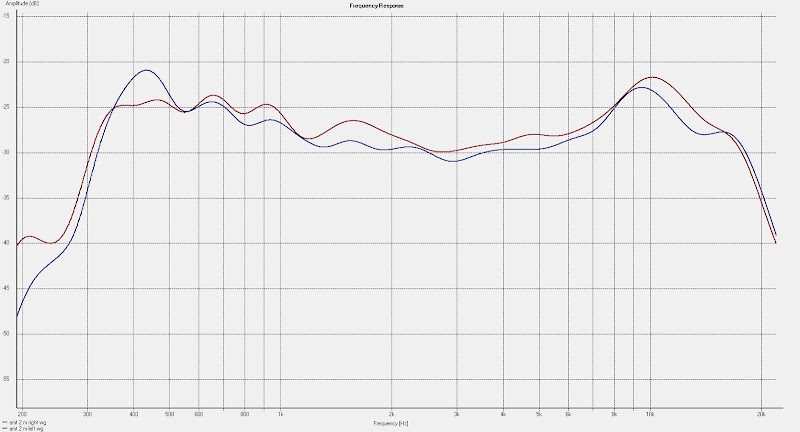

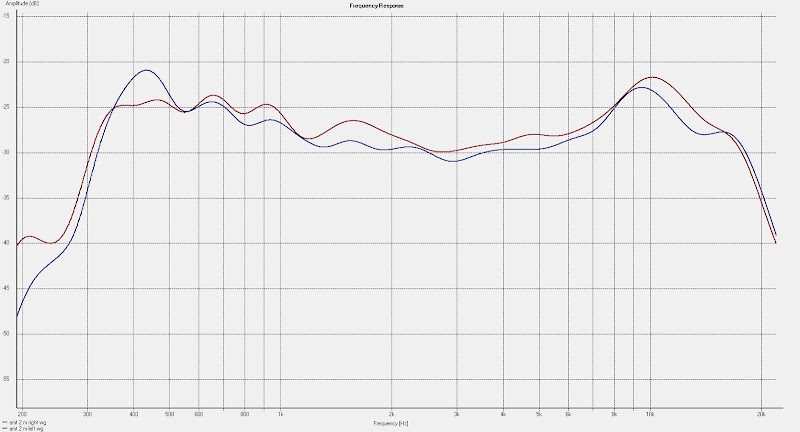

Measurements (red is with a crude waveguide):

Perhaps usable lf response down to 350 Hz can be achieved with some EQ, another thing is of course how it sounds.

Alu-ratio is 5/3 mm. Resistance 3,8 ohm, weight 2,5 grams:

Membrane is folded as 6,5/1,5 mm:

Measurements (red is with a crude waveguide):

Perhaps usable lf response down to 350 Hz can be achieved with some EQ, another thing is of course how it sounds.

I'm impressed that the HF can be so good with wide 6.5 mm traces. That gives a nice width to be able to divide into 2 traces in serial. I've been experimenting with that a little bit but have had very little time due to my wedding last weekend!

One other thing to try is to thin the aluminium chemically after making the traces. Question is whether it's easy to easily etch away the thickness evenly.

With the one decent 1 mil kapton diaphragm that I've managed to make (traces about 6 mm with 2 mil gaps) the HF drops off around 15 kHz or so.

One other thing to try is to thin the aluminium chemically after making the traces. Question is whether it's easy to easily etch away the thickness evenly.

With the one decent 1 mil kapton diaphragm that I've managed to make (traces about 6 mm with 2 mil gaps) the HF drops off around 15 kHz or so.

Good idea with etching away some aluminium after the trace cutting.

If the etchant (Natriumperoxidisulfate) is stired during etching it should be even.

It is also important that the temperature doesn´t rise.

Perhaps one can measure the resistance during etching and just stop (pull out and rinse) when desired resistance is reached?

It should be easy to test with a leftover membrane.

If the etchant (Natriumperoxidisulfate) is stired during etching it should be even.

It is also important that the temperature doesn´t rise.

Perhaps one can measure the resistance during etching and just stop (pull out and rinse) when desired resistance is reached?

It should be easy to test with a leftover membrane.

First serious attempt on making a waveguide

First a skeleton to get the shape:

I used the same foam as sides as in my Cornus (floor dampening XPS):

Quick fastening:

When all four sides are made, the back will get "foam sealed".

First a skeleton to get the shape:

I used the same foam as sides as in my Cornus (floor dampening XPS):

Quick fastening:

When all four sides are made, the back will get "foam sealed".

Last edited:

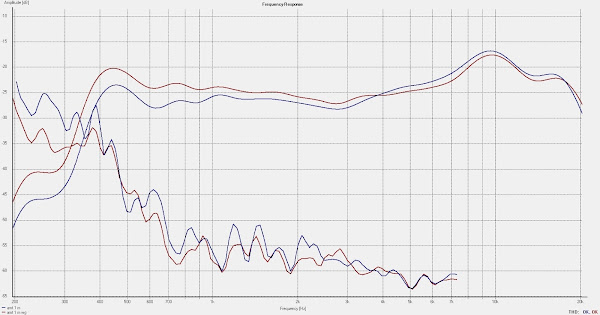

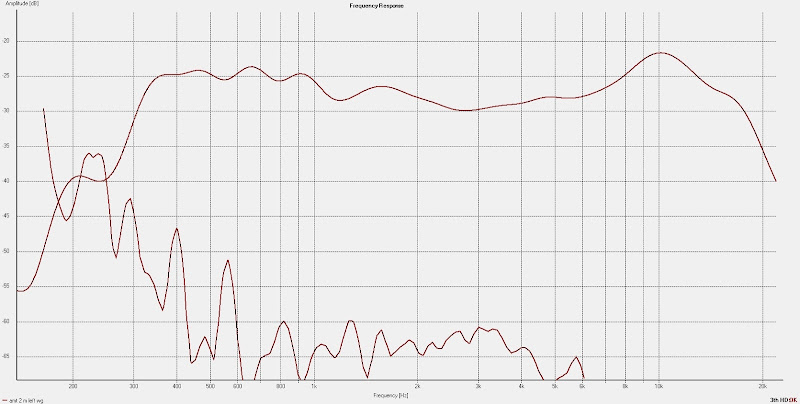

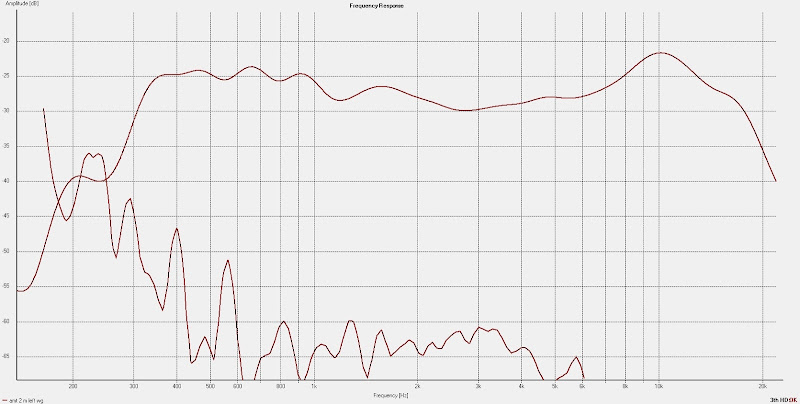

Measurements with waveguides

Measeruments done at listening range, red is with a waveguide made according to above, blue is a previous and inferior attempt:

EQ -6 dB from 300 to 1000 Hz and -6 dB from 5 to 15 kHz.

XO is practically at 300 Hz, but there will be a "DC protection" at 150 Hz or so.

Measeruments done at listening range, red is with a waveguide made according to above, blue is a previous and inferior attempt:

EQ -6 dB from 300 to 1000 Hz and -6 dB from 5 to 15 kHz.

XO is practically at 300 Hz, but there will be a "DC protection" at 150 Hz or so.

It is looking good.

Im a bit worried about distortion below 700 Hz.

I might try to use 4x4x120mm rods,with 4x4x30-40mm in the spacings

Bernt

Im a bit worried about distortion below 700 Hz.

I might try to use 4x4x120mm rods,with 4x4x30-40mm in the spacings

An externally hosted image should be here but it was not working when we last tested it.

Bernt

Last edited:

I meant your distortion ,and that you might try to use 4x4mm rods.

I dont use mine ÁMT's below 800 Hz.

Good to see you still are experimenting for better sound.

Bernt

I dont use mine ÁMT's below 800 Hz.

Good to see you still are experimenting for better sound.

Bernt

Ok, I will spend a couple of days with this setup and then evaluate the distortion between 300 and 700 Hz. It is mainly 2nd harmonic at -45 dB, so perhaps I can live with that.

One good thing about the motor is, as you point out, that it is fairly easy to change the rod size and shape. In fact, it is soo easy that I might as well front load the membrane and then mount the rods.

That opens up for a really long AMT consisting of 2 to 3 60x160 mm membranes.

"Good to see you still are experimenting for better sound."

I´ll never stop.

One good thing about the motor is, as you point out, that it is fairly easy to change the rod size and shape. In fact, it is soo easy that I might as well front load the membrane and then mount the rods.

That opens up for a really long AMT consisting of 2 to 3 60x160 mm membranes.

"Good to see you still are experimenting for better sound."

I´ll never stop.

What´s in the THD measurement?

Looking at the noise levels there are for example peaks at 400 and 556 Hz:

These peaks also shows up in the 2nd harmonic:

And in the 3rd:

So is it distortion or just a effect of not measuring a quiet room?

THD:

Looking at the noise levels there are for example peaks at 400 and 556 Hz:

These peaks also shows up in the 2nd harmonic:

And in the 3rd:

So is it distortion or just a effect of not measuring a quiet room?

THD:

Any ideas on where to obtain that dimension of rods?You might try to use 4x4mm rods.

Bernt

Current setup with somewhat inferior waveguides:

Vibrations? There actually gone at normal listening levels.

Plan forward is to make proper waveguides and one or two AMTs below the top ones.

Then do some tweaking with rods, waveguides and membranes...

Vibrations? There actually gone at normal listening levels.

Plan forward is to make proper waveguides and one or two AMTs below the top ones.

Then do some tweaking with rods, waveguides and membranes...

I can get it from Maskindelen, so no problem.Any ideas on where to obtain that dimension of rods?

New XO

The TD15Hs have phase plugs and are good for well over 1 kHz, so I finally caved in and now XO @ 800 Hz.

Removed the wave guides (I will make a smaller, TDTPL like later) measured and adjusted the EQ accordingly.

And there it was, even without any wave guides 🙂.

Next step will be to add another AMT in a WTWTW configuration (that gives a total height of 170 to 200 cm!). Hopefully can the AMT TDTPL like wave guides be integrated into the OB baffle.

Of course there will be tweaking with the membranes to get even lower distortion and frequency response up to 20 kHz but also the "motor" contraption will be tweaked.

So I actually ended up with making my own TPL150Hs, but there will be four of them so perhaps the hours I have spent equals some kind of wages per hour.

But that is not why we are doing this, right?

It still sounds good @350 Hz, but there are audible problems with the integration with the woofers etcetera and probably with distortion as well; I get tired listening to it. I need to get the AMTs closer to the woofers but the wave guides are then too big. I also suspect that the dispersion patterns @ 350 Hz are not in favour for a good sound stage and it sure doesn´t help that the loudspeaker elements are not in line.I dont use mine AMT's below 800 Hz.

The TD15Hs have phase plugs and are good for well over 1 kHz, so I finally caved in and now XO @ 800 Hz.

Removed the wave guides (I will make a smaller, TDTPL like later) measured and adjusted the EQ accordingly.

And there it was, even without any wave guides 🙂.

Next step will be to add another AMT in a WTWTW configuration (that gives a total height of 170 to 200 cm!). Hopefully can the AMT TDTPL like wave guides be integrated into the OB baffle.

Of course there will be tweaking with the membranes to get even lower distortion and frequency response up to 20 kHz but also the "motor" contraption will be tweaked.

So I actually ended up with making my own TPL150Hs, but there will be four of them so perhaps the hours I have spent equals some kind of wages per hour.

But that is not why we are doing this, right?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT

![URL]](/community/proxy.php?image=http%3A%2F%2F%5BURL%3Dhttp%3A%2F%2Fimg5.imageshack.us%2Fi%2Fa1a0.jpg%2F%5D%5BIMGDEAD%5Dhttp%3A%2F%2Fimg5.imageshack.us%2Fimg5%2F9615%2Fa1a0.jpg%5B%2FIMGDEAD%5D%5B%2FURL%5D&hash=abdb2adbc2ee0392243644b265bdc629)