Doesn't matter, I was in both Rimi and Meny in Oslo and found neither. They just have regular aluminum foil. Would you care to sell me some paperback alu leftovers?

If you are within a company, maybe you can buy it here.

About sending you some leftovers, PM me your address and I´ll send you some.

So you hope to surpass the TPL-150 in HF?

Because I am not at all pleased with the TPL-150 above ~7kHz. From 7kHz I think it is best to use a Transmission Audio 50cm/1" true ribbon or possibly RAAL, or similar.

My aim is a two-way system with an XO somewhere between 200 - 350 Hz.

Are you pleased with the sound down to 200-300Hz and just have better HF left to fix?

I am worry now, before starting, if it is even possible to go down to so low and get clean sound. The concept is based on a tweeter that can't play clean under 1.8kHz.

I am worry now, before starting, if it is even possible to go down to so low and get clean sound. The concept is based on a tweeter that can't play clean under 1.8kHz.

Is 160 mm wide 0,5 mil (that´s 13 um) thermo setting kapton available?Why not 0.5mil kapton?

Yes, I am very pleased.Are you pleased with the sound down to 200-300Hz

In fact, I can live with not being able to solve the hf issue.and just have better HF left to fix?

Still some structural vibrations to fix though. The frame has to be dampened/clamped.

I am worry now, before starting, if it is even possible to go down to so low and get clean sound. The concept is based on a tweeter that can't play clean under 1.8kHz.

It is your choice. Besides, I don´t reckon that I am following the tweeter concept.

Is 160 mm wide 0,5 mil (that´s 13 um) thermo setting kapton available?

Seem to be in China. But you have to ask nicelly, and may have to order for a few hundred dollars for them to bother.

I am not sure if it is Thermosetting.

If Polyester is working for you then why fix something that is not broken. Maybe Kapton is lighter though.

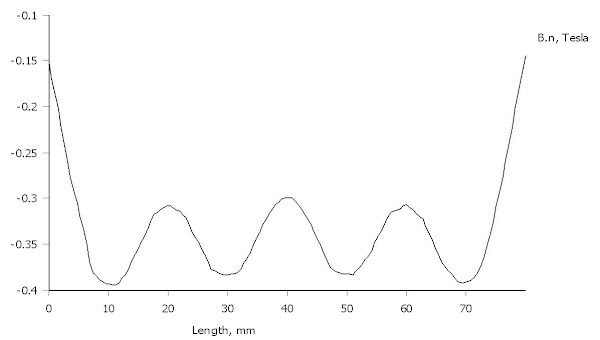

I guess the depth of the folds, 8 mm, turns out to be a Helmholtz resonator.

If that is the case, next try with 6/2 folding ratio (that is, 6 mm deep pocket) and 4/4 alu ratio will show a better hf response.

Found this thread.

Keith Taylor:

"In theory the pleat depth dimension puts a limit on the highest frequency that can be radiated. Output will fall away above a frequency where the depth excedes Lambda/4. If we want to radiate 20kHz where the wavelength (Lambda) is 17mm the depth should not excede around 4mm."

thadman:

"I would assume this effect is a result of destructive interference from the secondary wavefronts generated at the aperture exit (ie helmholtz resonances)."

Keith Taylor:

"In an AMT it is conceivable that a fast pressure pulse may not completely exit the pleat before it is cancelled by a change of motion."

But also

Keith Taylor:

"I think it would make sense to have the pleat depth almost the same as the magnetic gap dimension"

Could be a little tricky to make a 4 mm membrane in a 6 mm gap.

Possible source of the vibrations

thadman:

"Is it possible that turbulence could play a role at high velocities (high SPL)? "

Perhaps a more sparse grid reduces the vibrations. The opposite can actually be tested, just plug every other opening.

The tape from 3m 74 is mylar with thermosetting glue.

It is not the glue that keeps the folds in shape. All mylar can be used.

I have used 25my mylar tape,50my mylar tape ,and mylar sprayed with glue,and it is the same.

Kapton might need higher temperature to keep the folds.

Bernt

It is not the glue that keeps the folds in shape. All mylar can be used.

I have used 25my mylar tape,50my mylar tape ,and mylar sprayed with glue,and it is the same.

Kapton might need higher temperature to keep the folds.

Bernt

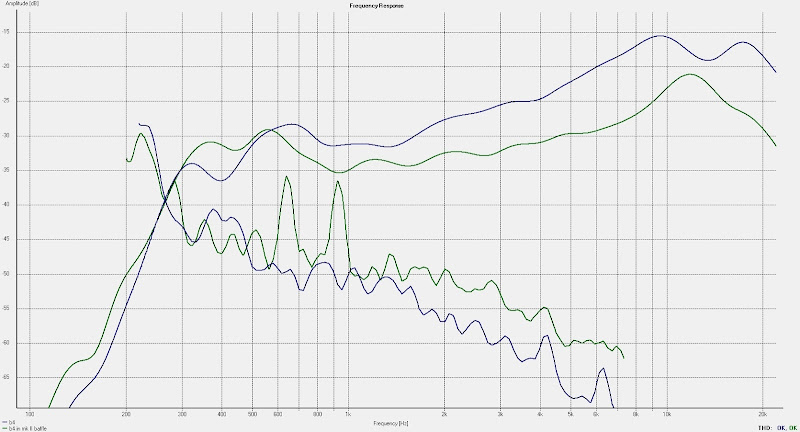

Membrane with 6/2 folding ratio, 4/4 alu. Blue measurement with wave guide. Red is a 8/2-membrane:

Improvements in hf (+20 dB @ 20 kHz) as predicted and higher lf cutoff (+100 Hz) as expected.

Vibrations? Yeah, sure!

Maybe it must be a three way system anyway 😱

Improvements in hf (+20 dB @ 20 kHz) as predicted and higher lf cutoff (+100 Hz) as expected.

Vibrations? Yeah, sure!

Maybe it must be a three way system anyway 😱

Hawthorne have a AMT that plays from 500hz.Dimensions of the diaphragm is mentioned in this post :Hawthorne Audio • View topic - John's Rainier and Little Tahoma Build

Bernt

Bernt

That would be around 160 mm (high?) times 194 mm (wide) with 6,35 mm deep folds.

For sure, that must be the un-folded dimensions, or isn´t it this AMT?

For sure, that must be the un-folded dimensions, or isn´t it this AMT?

An externally hosted image should be here but it was not working when we last tested it.

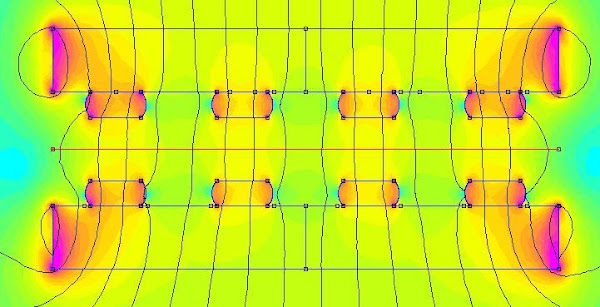

New magnete assembly

I will now try to experiment with a new magnetic structure.

This time it will be designed for a 60 mm wide and 160 mm high membrane.

The field gap is still 10 mm.

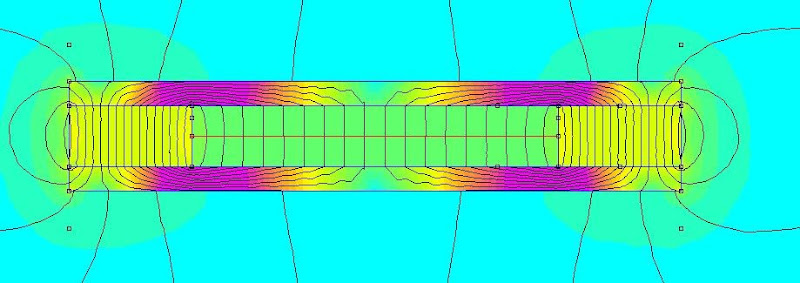

View from above:

Rods will be laying down with a 10 mm spacing will a slighty rounded shape and 4 mm thick.

Here´s a imaginary inverted view from the side:

The membrane will ba a lot easier to build and the grid will affect the sound less.

It will also be easier to make adjustment to the membrane once mounted.

I will now try to experiment with a new magnetic structure.

This time it will be designed for a 60 mm wide and 160 mm high membrane.

The field gap is still 10 mm.

View from above:

Rods will be laying down with a 10 mm spacing will a slighty rounded shape and 4 mm thick.

Here´s a imaginary inverted view from the side:

The membrane will ba a lot easier to build and the grid will affect the sound less.

It will also be easier to make adjustment to the membrane once mounted.

Last edited:

I have no membranes made yet, so I used one I got from båndsei:

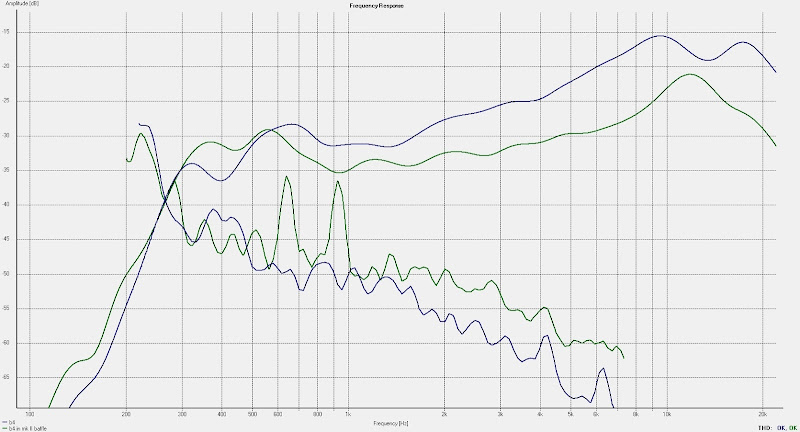

This is how it measured compared to when it was inserted in the old motor:

(blue is the membrane in the old motor, green is the membrane in the "mk II" motor with a simple baffle)

This is how it measured compared to when it was inserted in the old motor:

(blue is the membrane in the old motor, green is the membrane in the "mk II" motor with a simple baffle)

You are right about the dimensions on the Hawthorne AMT .But I dont think it is the unfoldet too.

I found another post with better Pictures:Hawthorne Audio • View topic - Silver Iris Reference AMT official thread

Bernt

I found another post with better Pictures:Hawthorne Audio • View topic - Silver Iris Reference AMT official thread

Bernt

That would be around 160 mm (high?) times 194 mm (wide) with 6,35 mm deep folds.

For sure, that must be the un-folded dimensions, or isn´t it this AMT?

An externally hosted image should be here but it was not working when we last tested it.

Let´s says that the pleat width is 1,5 mm.

194/(1,5+6,35) equals 25 folds.

Looking carefully at the picture, couldn´t that be the case?

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another DIY AMT