The fine pitch was a success.

That corrugation looks almost identical in pleat size to my Apogee Scintilla ribbons. Nice work!

However even 0.6um thick foil has resonances and needs damping.

0.6 µm sounds unrealistic to me. Maybe you meant 6 µm?

0.6um alu foil can be bought as "Imitation silver leaf foil".

At first it felt really thin, but when I started experimenting with leaf gold (0.2um)... oh man that's thin.

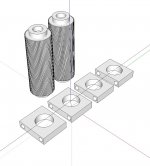

I used Sketchup for modelling the corrugator. A gear drawing plugin is available on the web.

Trimble SketchUp

Shapeways material called "Frosted ultra detail" is good for fine detail printing.

3D Printing in Frosted Detail Plastic on Shapeways

At first it felt really thin, but when I started experimenting with leaf gold (0.2um)... oh man that's thin.

I used Sketchup for modelling the corrugator. A gear drawing plugin is available on the web.

Trimble SketchUp

Shapeways material called "Frosted ultra detail" is good for fine detail printing.

3D Printing in Frosted Detail Plastic on Shapeways

Attachments

Hi all,

I haven't had any luck in finding thinner than 6.5um foil.

so I started thinning down my foil with simple etching process (I used a strong alkali solution). See pic..

The results are as expected. Thinner foil has less resonances in 2 - 8kHz range.

Regardless of foil thickness, embossing seems to be more effective way of killing 2 - 8kHz resonances in pure alu tweeter ribbon than corrugation.

I wouldn't like to repeat the etching, and I woudn't recommend anyone to try it.

So a hint or a tip of thinner foil source would be very welcome, thanks.

I haven't had any luck in finding thinner than 6.5um foil.

so I started thinning down my foil with simple etching process (I used a strong alkali solution). See pic..

The results are as expected. Thinner foil has less resonances in 2 - 8kHz range.

Regardless of foil thickness, embossing seems to be more effective way of killing 2 - 8kHz resonances in pure alu tweeter ribbon than corrugation.

I wouldn't like to repeat the etching, and I woudn't recommend anyone to try it.

So a hint or a tip of thinner foil source would be very welcome, thanks.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.