Capaciti: first let me preface my comment (to all readers) please do not take my remarks personally, I like Acoustats and I have the greatest respect for Jim Strickland. Jim's design is in my opinion the best that has ever gone to market and has enjoyed the longest useful lifespan of any commercial ESL that I know of.

I am not trying to knock Acoustats. Some of the feed back to my suggestion that it is time to start thinking about building replacement panel has bordered upon hostile. Arguments about silly things and comments along the lines of " mine are like new" abound. Yes there are some old Acoustats that have had a good easy life and they are functioning very well. There are lots more that are old and tired because they have been used well and hard and are worse for wear. Then there are units with physically damaged panels that cannot be replaced. If I told everyone that my 35 year old car was as good as new and that I had done next to no maintenance to it over its life span how many out there would believe me? Sure it may be on good condition (for a 35 year old car) but it is not in new condition nor even close. People are taking this personally and it does not make any sense.

The point is that new panels are going to be and are needed soon or now. If you are going to go to the trouble of building new ones (after such a long time) why would you not want to look at options that would make the newly built units better? At the very least it would make sense to review the known issues of the original design and see if those aspects of the design could be adjusted to address those issues.

This is not something that any commercial manufacturer is going to provide for the market as there is not enough money in it and they would rather sell new units of their own design and that's fair. So if people want new Acoustat panels they are going to have to organize to clone their own. Like wise if they want new panels that are better than the stock units they will have to do the same. These are two different project. The person who has one broken panel and only wants one new panel will expect the replacement to be identical to the remaining panels that he has so "better" is not what he wants or needs. I think that there is an interest out there to do both but again I say that this will only happen on a diy basis. So lets get over the hurt feelings because nobody is dissing Acoustats here. I hope that there is a better understanding of where I am coming from regarding this. I have made no attacks I have no agenda and I don't want to build and sell replacement Acoustat panels. I have stated elsewhere that I have in the past attempted to enlist three different people to help them to set up to build Acoustat replacement panels including building the jigs necessary and walking through the procedure to get them up and running but no one has been willing to undertake the project. The owners club needs a parts pool who better to build the parts? Regards.

I am not trying to knock Acoustats. Some of the feed back to my suggestion that it is time to start thinking about building replacement panel has bordered upon hostile. Arguments about silly things and comments along the lines of " mine are like new" abound. Yes there are some old Acoustats that have had a good easy life and they are functioning very well. There are lots more that are old and tired because they have been used well and hard and are worse for wear. Then there are units with physically damaged panels that cannot be replaced. If I told everyone that my 35 year old car was as good as new and that I had done next to no maintenance to it over its life span how many out there would believe me? Sure it may be on good condition (for a 35 year old car) but it is not in new condition nor even close. People are taking this personally and it does not make any sense.

The point is that new panels are going to be and are needed soon or now. If you are going to go to the trouble of building new ones (after such a long time) why would you not want to look at options that would make the newly built units better? At the very least it would make sense to review the known issues of the original design and see if those aspects of the design could be adjusted to address those issues.

This is not something that any commercial manufacturer is going to provide for the market as there is not enough money in it and they would rather sell new units of their own design and that's fair. So if people want new Acoustat panels they are going to have to organize to clone their own. Like wise if they want new panels that are better than the stock units they will have to do the same. These are two different project. The person who has one broken panel and only wants one new panel will expect the replacement to be identical to the remaining panels that he has so "better" is not what he wants or needs. I think that there is an interest out there to do both but again I say that this will only happen on a diy basis. So lets get over the hurt feelings because nobody is dissing Acoustats here. I hope that there is a better understanding of where I am coming from regarding this. I have made no attacks I have no agenda and I don't want to build and sell replacement Acoustat panels. I have stated elsewhere that I have in the past attempted to enlist three different people to help them to set up to build Acoustat replacement panels including building the jigs necessary and walking through the procedure to get them up and running but no one has been willing to undertake the project. The owners club needs a parts pool who better to build the parts? Regards.

Last edited:

I'm part way through separating a 5 wire panel down the long seam. The 65HS is dirty and the wires seem to be cleaner than I'd expect. MJ as you might already have figured I am "Ohifio" Over at AA. I agree there are two different directions on this, but you seem to be suggesting that if a duplicate panel is created that certain issues should be addressed. I think a solid core wire PVC insulated like the stock panel, and of the same diameter as the stock wire could be bonded to a stronger non-styrene version of the Acoustat grid. While we're at it how about clipping the bare wire ends and just join them top and bottom and encapsulate that junction in epoxy? Speaker lead out the bottom and the top and the bias wire for a "killer" 3 wire Acoustat duplicate. Could PVC plumber type cement be used to bond the two haves together as well as affix the mylar to the frame? I have PVC flat stock sign material that is light and strong for the mylar frame.

Speedracer5: yes there are issues that could/should be addressed. I have gone over a number of them as you stated some. The latter Acoustat stators used stranded wire which is easier and better to use and work with from a construction point of view. Those panels used a single length of wire and made connects to the transformer from each of the opposite ends of that stator winding wire. For a stock clone this is the method I would use and I would not change this or there will be significant differences when matching to previous Acoustat panels. Since the exact PVC alloy used on the Acoustat panels is not known it would be wisest to use a currently available PVC dielectric of the same insulation thickness. I have forgotten the gage Acoustat used but it is most likely 26 but that is easy to check for accuracy. For an Acoustat clone standard 1/2 inch thick Styrene louvre would be required to maintain the sonic character (you are making a clone). The encapsulation method using solvent diluted Styrene solids is also the best method to build this panel. Jim already figured that out so there is no need to re invent the wheel for a clone project. Other options do exist for a different project but not for a clone. If you wanted to you could experiment with any number of readily available construction adhesives which would probably work as well as encapsulation but I would imagine that the application would be as much or more work to achieve acceptable results. I think that the easiest way to assemble the two stators would be to use an Acrylic transfer adhesive. You might want to look into adjusting the stator spacing to ensure that the diaphragm to stator wire (in this case the surface of the stator wire) is kept close to Acoustat spec. to maintain compatibility with older panels. What ever material you chose to use for stator spacing would best have a low content of plasticizer. Acoustats used Styrene stator spacers as this is the easiest to solvent weld to the Styrene louvre. Different materials here might make a noticeable difference to the sound of the panel. Lighting supply shop can sell you a wide assortment of louvre material. For an Acoustat clone you need the Styrene. You will also have to hand select the panels to insure the cube pattern mates when sections are meant to be book matched. As I mentioned this is junky material which is all over the place. Jim probably bought panels made on one mould to ensure matching.

For a "Hot Rod" design you will first need to decide what your criteria is and exactly what it is that you want to make. Why not play with the basic Acoustat format and adjust things one at a time and see where that takes you. Such a project is probably going to require a large amount of trial and error to establish successful construction techniques there are no straight answers you will be making something new for the first time.

For a "Hot Rod" design you will first need to decide what your criteria is and exactly what it is that you want to make. Why not play with the basic Acoustat format and adjust things one at a time and see where that takes you. Such a project is probably going to require a large amount of trial and error to establish successful construction techniques there are no straight answers you will be making something new for the first time.

Last edited:

The material at home depot is made of styrene.

As the frequency goes up the capacitive reactance goes down.

The impedance refelcted to the amplifier is determined by the transformation ratio of the transformer.

cacacitve reactance / (ratio*ratio)=reflectd impedeance

This gives you a basic idea as ther are other factors involved also that determine the total impedance.

check out the thread "step-up transformer design".

most all of these factors have been either pionted out, or discussed. jer

As the frequency goes up the capacitive reactance goes down.

The impedance refelcted to the amplifier is determined by the transformation ratio of the transformer.

cacacitve reactance / (ratio*ratio)=reflectd impedeance

This gives you a basic idea as ther are other factors involved also that determine the total impedance.

check out the thread "step-up transformer design".

most all of these factors have been either pionted out, or discussed. jer

Last edited:

Capacitance and Stator wire spacing

The higher the capacitance, the lower the reactance. That is, harder to drive with a high step up ratio. The impedance gets lower with increasing frequency. Note however, that there is a resonance with capacity and leakage reactance of the transformer. This will cause a rise in impedance peaking above the audio range with a decent audio transformer. A low value select resistor in series with the primary will cause a roll -off at a frequency lower than this peak resonance.

The sum of the 2 frequency responses creates a maximally flat response with a smooth roll-off without the peak.

One more thing about stator wires. Doubling the number of wires does not double the capacitance with close spacing. At some point, a wire mesh is nearly equal to a solid surface when it comes to capacitance.

so, increasing wires/inch = more capacitive reactance. This will be an overall higher impedance as seen by the amplifier?

Easier, or harder speaker to drive I guess is my real question.

As this is one of my design goals.

Paul

The higher the capacitance, the lower the reactance. That is, harder to drive with a high step up ratio. The impedance gets lower with increasing frequency. Note however, that there is a resonance with capacity and leakage reactance of the transformer. This will cause a rise in impedance peaking above the audio range with a decent audio transformer. A low value select resistor in series with the primary will cause a roll -off at a frequency lower than this peak resonance.

The sum of the 2 frequency responses creates a maximally flat response with a smooth roll-off without the peak.

One more thing about stator wires. Doubling the number of wires does not double the capacitance with close spacing. At some point, a wire mesh is nearly equal to a solid surface when it comes to capacitance.

Paul more wires per linear inch means you are increasing the density of your electrostatic field which is what is driving your diaphragm. More wires per linear inch means more efficiency, its a good thing. Cube louvres basically come in two materials Styrene (everywhere) and Acrylic (special order).The louvres you see at the home supply shops are going to be Styrene.

Hey Allen would you please email me directly not via the gmail or asylum mail as every time I try to reply to you my mail is bounced back. Perhaps my mail is seen as spam by your machine. We need to connect buddy.

Hey Allen would you please email me directly not via the gmail or asylum mail as every time I try to reply to you my mail is bounced back. Perhaps my mail is seen as spam by your machine. We need to connect buddy.

Is there a way to look at louver panels and tell what they are made of.

At Home Depot their product doesn't say, and the kid obviously doesn't either.

Paul

I have used the standard light fixture screens ( that's what they are ) and have had no issues. To those questioning the design , wired stators IMO are the way to go, more work, absolutely time consuming , but worth it.

If manufacturing it is much easier and cheaper to make perf metal stators, Hence there popularity , if not I'm sure there would be more wired units.....

Hello Moray : What advantage is there in using the acrylic vs the standard Styrene.

regards,

Well the Acrylic material is stronger than Styrene so a 3/8 thick louvre is probably close to the strength of a 1/2 inch Styrene. The Acrylic is also much better damped when compared to the Styrene. The Acrylic is a much higher quality material and does not have the plasticizer issues that the Styrene has and it can be glued or painted with out issues. It is a much nicer material all around. For a lot less money you can work with Styrene if you solvent weld and don't mess with adhesives and you will achieve results equal to Acoustat and they will last a good long time. So Styrene is great for a low cost easily available material to do prototype work or just to build inexpensive yet solid panels with. Acrylic will make a better panel that will last longer with less resonances than Styrene but it does cost more and you will probably have to special order it in. Consider Acrylic louvre the top of the line material choice. A flat perf metal (insulated) bonded to an Acrylic louvre would be the best of both worlds as long as you have the perf metal properly coated. Aside from that it is next to impossible to better an insulated wire stator for all around performance and cost (on a diy level).

I'll have to look into the cost of ordering acrylic panels, but I'm still not sure if the consensus is that pvc coated wire is the best way to go, or to use

magnet wire.

Magnet wire looks to be easier to cut all the loops, and solder at the ends (of the panel)

Also, I have a spray enamel. Could I go over the wires with this after they are tensioned to "improve" them

Paul

magnet wire.

Magnet wire looks to be easier to cut all the loops, and solder at the ends (of the panel)

Also, I have a spray enamel. Could I go over the wires with this after they are tensioned to "improve" them

Paul

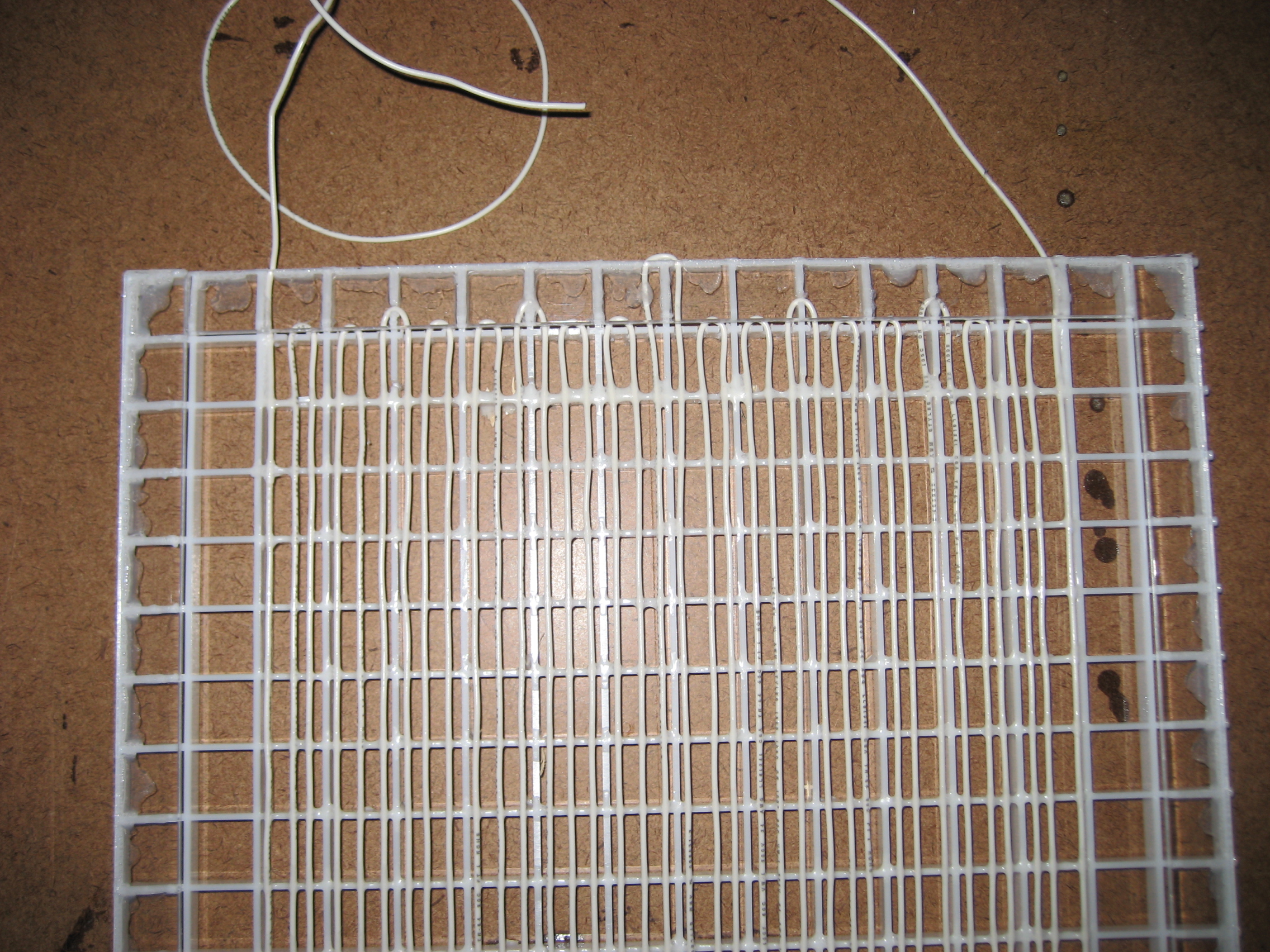

This is how I handle the frame end wires. It is one continuous wire. I used a Dremel to cut slots. The panel is laid with the ends supported to give it a slight concave shape. I have constructed a curved jig for this layup. The wires are pulled back and forth with slight, but equal tension. I then use my styrene syrup to anchor the ends where the wires are in the slots. After a few minutes of drying, the frames are laid flat. The wire tension increases and the wires are now laying against the frame. Then I apply my syrup across all wires. I use the edge of a foam brush. I can do several wires at once this way. You gently touch the surface of the wires and the syrup bleeds out. The solvent in the mixture also melts the wires into the frame slightly.

Note that I am using acrylic spacers along the edge. I solvent weld these and apply syrup fillets to hold them in place. They have been clamped all the way around during the drying process.

Jim

One thing I failed to mention.. I have a rig with a hot-wire and springs on each side. I use a variac and high current filament transformer to cut off the edges of the lighting louvers. I am going to construct a jig for small magnet wire grid to slightly melt the grid wires into the louver. I will then of course have to use thinner spacers.

BTW, my 3 wire per section "Acoustat Clone" panel is about 310pf. Also, I was able to create a paint-on carbon black formula that actually sticks to the mylar. Unfortunately, I don't remember the recipe. I do however remember the ingredients. I am going to make a few test batches and re-learn and report the recipe.

If you will notice, the top center wire loop exits the frame. I did this to make it easy to cut it if one wants a split stator for use with delay lines.

Jim

BTW, my 3 wire per section "Acoustat Clone" panel is about 310pf. Also, I was able to create a paint-on carbon black formula that actually sticks to the mylar. Unfortunately, I don't remember the recipe. I do however remember the ingredients. I am going to make a few test batches and re-learn and report the recipe.

If you will notice, the top center wire loop exits the frame. I did this to make it easy to cut it if one wants a split stator for use with delay lines.

Jim

- Home

- Loudspeakers

- Planars & Exotics

- How to construct a cube louver (Acoustat)