TMBLACK

i used 740 magnets for a pair. I get my magnets from China it works out cheaper if you buy 1000.All the other sites are dearer. Go to posting 41 for the pictures of my push pull full range planar. The 6mm and 3mm design is no louder than the 3mm 3mm design.So I will build a 6mm 6mm design to see if that is better. Got to cut the MDF glad the weather is better. $2 is very dear compared to China

i used 740 magnets for a pair. I get my magnets from China it works out cheaper if you buy 1000.All the other sites are dearer. Go to posting 41 for the pictures of my push pull full range planar. The 6mm and 3mm design is no louder than the 3mm 3mm design.So I will build a 6mm 6mm design to see if that is better. Got to cut the MDF glad the weather is better. $2 is very dear compared to China

Last edited:

chinese magnets

Send your enquiry to this email address helen@ndmagnets.com She will give you all the details

Send your enquiry to this email address helen@ndmagnets.com She will give you all the details

Last edited:

Hi,

No - have not made much progress yet due to heavy workload.

Did actually spend one hour in the the workshop this evening and got the diaphragm and tape in place

Will try to connect the conductors tomorrow and make it play!

I have not measured the tape. I aquired it by recommendation of an other forum member who have the measurements. But I am more interested in the sound than the resistance

No - have not made much progress yet due to heavy workload.

Did actually spend one hour in the the workshop this evening and got the diaphragm and tape in place

Will try to connect the conductors tomorrow and make it play!

I have not measured the tape. I aquired it by recommendation of an other forum member who have the measurements. But I am more interested in the sound than the resistance

It is app. 30my but seems to have lower resistance than the one i had.

Your Search Results | CPC

The tape is 9mm wide.

For my new speaker i will split it to 3 mm.

Your Search Results | CPC

The tape is 9mm wide.

For my new speaker i will split it to 3 mm.

Finally!!

Ah! Finally some progress!

I actually completed one of my planars tonight and listen to it just now!

I used the CPC tape, 5 lengths of 800mm length. The resistance is 4,3 ohm in total.

I designed the speaker to use 2mm diaphragm-magnet distance, but during the built the distance was increased to 4mm (doubled the layer of VHB tape)

The frame is a mock-up at the moment, it will be precision made and "self bearing" and used as the frame for the grille cloth.

The speaker sounds quite OK, high/middle range is fine but it lacks a bit in the bottom.

I used 6 times 15 neo-magnets 10X10X40 mm

If I am ever to to build a different speaker, I will use magnets that are "flat" so they won´t try to turn when fixing them to the perforated steel plate.

50 mm long, 10mm wide and 3mm thick would be a better solution for building I think

I will try to measure frequency response tomorrow and post on the forum.

Regards

Bent

Ah! Finally some progress!

I actually completed one of my planars tonight and listen to it just now!

I used the CPC tape, 5 lengths of 800mm length. The resistance is 4,3 ohm in total.

I designed the speaker to use 2mm diaphragm-magnet distance, but during the built the distance was increased to 4mm (doubled the layer of VHB tape)

The frame is a mock-up at the moment, it will be precision made and "self bearing" and used as the frame for the grille cloth.

The speaker sounds quite OK, high/middle range is fine but it lacks a bit in the bottom.

I used 6 times 15 neo-magnets 10X10X40 mm

If I am ever to to build a different speaker, I will use magnets that are "flat" so they won´t try to turn when fixing them to the perforated steel plate.

50 mm long, 10mm wide and 3mm thick would be a better solution for building I think

I will try to measure frequency response tomorrow and post on the forum.

Regards

Bent

Hi bonsai

Thanks for the link.

Hi bentl

Looks really good. Congratulations.

Two comments.

1. I think you can get more out of your magnets, and have a more uniform drive on the entire diaphragm. Let the alu foil go over to the middle of the magnets. Either run two alu strips between each pair of magnets, or use more magnets and more strips. This will give higher sensitivity, higher resistance and better drive.

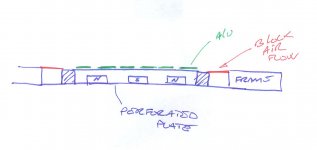

2. To get more and better bass, block the airflow between the outer frame and the diaphragm. You might as well get the most out of the overall size you are using

Thanks for the link.

Hi bentl

Looks really good. Congratulations.

Two comments.

1. I think you can get more out of your magnets, and have a more uniform drive on the entire diaphragm. Let the alu foil go over to the middle of the magnets. Either run two alu strips between each pair of magnets, or use more magnets and more strips. This will give higher sensitivity, higher resistance and better drive.

2. To get more and better bass, block the airflow between the outer frame and the diaphragm. You might as well get the most out of the overall size you are using

Attachments

Here is a way of turning the alufoil. Put tape that is adhedsive on both sides,like tape for fastening carpets,where the turns are.This will help ,that the alufoil do not stik to your fingers to much.The alutape on the pics. is 3 mm.

Did you use the same process as before for splitting the 9mm alu into 3mm (by use of a drill machine, where the roll of alu is mounted and then just cutting into it as it turns)?

How good does the adhesive seems to work. Do you think it is something that will last for years after years?

Kind regards Baldin

It seems to be a very strong adhesive and as it is intended to be used for windows sequrity and beeing washed regulary alongwith the windows,i belive it can last for many years.

I am cutting it as it turns,but i have to use another machine than a regular drillmachine.

I will post some pictures later.

I am cutting it as it turns,but i have to use another machine than a regular drillmachine.

I will post some pictures later.

It seems to be a very strong adhesive and as it is intended to be used for windows sequrity and beeing washed regulary alongwith the windows,i belive it can last for many years.

I am cutting it as it turns,but i have to use another machine than a regular drillmachine.

I will post some pictures later.

Stille dying to see some pictures of the cutting jig.

Would like to get started again with my planars .... it's beeen way too long ...

If it can be cut in sat 2 mm, I think it could also be used in some smalle AMT/Heil unit ....

But I need somewhere to buy the tape first

- Home

- Loudspeakers

- Planars & Exotics

- Planar speaker - first try