Hello from PaulFX!

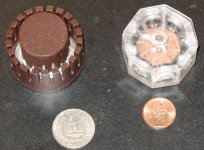

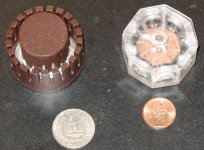

I've recently finished my single Heil AMT driver based on Neil Davis' magnet and pole design and a Great Heil diaphragm:

I was dying to hear it, but I'm out of stuffing so I put rags in and sealed the top and bottom. There is a dip of about 6 dB around 4K, roughly 1/4 wavelengh of which is about the inner diameter, so I'll want to fill it right. Then I hung it on the HF output of my crossover and played some jazz drums. Quick and loud! In its day this must have been unmatchable. Of course in its day they didn't have monster NIB magnets, either.

This is going to go on a center channel MTM speaker. What do you think, Mr. Davis?

I've recently finished my single Heil AMT driver based on Neil Davis' magnet and pole design and a Great Heil diaphragm:

I was dying to hear it, but I'm out of stuffing so I put rags in and sealed the top and bottom. There is a dip of about 6 dB around 4K, roughly 1/4 wavelengh of which is about the inner diameter, so I'll want to fill it right. Then I hung it on the HF output of my crossover and played some jazz drums. Quick and loud! In its day this must have been unmatchable. Of course in its day they didn't have monster NIB magnets, either.

This is going to go on a center channel MTM speaker. What do you think, Mr. Davis?

Here is where Neil Davis shows how he built his Heil:

http://home.comcast.net/~neilandbarbaradavis/DIYHeil/DIY1/index.htm

I copped his design but using the large "great" ESS Heil diaphragm so I would have plenty of overlap for the crossover.

I got the metal online from Metals Depot, 2 feet each for the 2 X 3 rectangular tubing and the 1" square rod, the minimum order. Be sure to get the abolute softest steel, "for cutting, grinding, punching." I used a 10" chop saw to cut it, fitted with a metal cutting blade. I practiced on the one end and set up wooden spacers to get the cuts centered, then used the other end of each for the pole pieces.

I went with half metal, half air in front, sanded and smoothed to minimize diffraction, or at least shift it above what I can hear. The flanges I won't move so I can get the midranges closer.

http://home.comcast.net/~neilandbarbaradavis/DIYHeil/DIY1/index.htm

I copped his design but using the large "great" ESS Heil diaphragm so I would have plenty of overlap for the crossover.

I got the metal online from Metals Depot, 2 feet each for the 2 X 3 rectangular tubing and the 1" square rod, the minimum order. Be sure to get the abolute softest steel, "for cutting, grinding, punching." I used a 10" chop saw to cut it, fitted with a metal cutting blade. I practiced on the one end and set up wooden spacers to get the cuts centered, then used the other end of each for the pole pieces.

I went with half metal, half air in front, sanded and smoothed to minimize diffraction, or at least shift it above what I can hear. The flanges I won't move so I can get the midranges closer.

Attachments

And More Davis Heil

Okay, so that was the outer pole piece, the inner pole piece I sliced and diced using the chop saw with metal cutoff blade. The magnet is a monster Neodymium-Iron-Boron from Forcefield Magnets, 3" X 1 1/2" X 3/4". I found it too dangerous to trial fit, so I cut a block of wood just a millimeter bigger in order to grind down the backside of the pole piece. I used a couple drops of epoxy to bond them. I used 1 hour epoxy, not 5 minute or superglue, in case I had to desperately pry them apart if they snapped together wrong.

Okay, so that was the outer pole piece, the inner pole piece I sliced and diced using the chop saw with metal cutoff blade. The magnet is a monster Neodymium-Iron-Boron from Forcefield Magnets, 3" X 1 1/2" X 3/4". I found it too dangerous to trial fit, so I cut a block of wood just a millimeter bigger in order to grind down the backside of the pole piece. I used a couple drops of epoxy to bond them. I used 1 hour epoxy, not 5 minute or superglue, in case I had to desperately pry them apart if they snapped together wrong.

Attachments

And Still More Davis Heil

So by now, I have a new appreciation for Mr. Davis' ironic comments about the excitement getting to me - - This NIB magnet is so ridiculously strong that I had to cut wooden test jigs for the magnet and the ESS diaphragm to avoid damage and broken fingers. Once everything was ground, filed, fitted, sanded, smoothed, and cleaned, then came pole assembly. Used heavy leather gloves and another couple drops of 1-hour epoxy, then tried to guide the inner pole into the outer. Like hand feeding an alligator!

So by now, I have a new appreciation for Mr. Davis' ironic comments about the excitement getting to me - - This NIB magnet is so ridiculously strong that I had to cut wooden test jigs for the magnet and the ESS diaphragm to avoid damage and broken fingers. Once everything was ground, filed, fitted, sanded, smoothed, and cleaned, then came pole assembly. Used heavy leather gloves and another couple drops of 1-hour epoxy, then tried to guide the inner pole into the outer. Like hand feeding an alligator!

Attachments

Yet More Davis Heil

Having a ball here posting to myself - - this time I'm moving up to three thumnails - - baby steps, as the movie character Bob would say.

I made a a mounting bezel for the diaphragm out of 3M/Scotch VHB two-sided tape. I went from the front plastic frame of the diaphagm outwards, enough to stick to the front inside of the outer pole piece and to cover up the various lengths of hand-cut ridge openings to the left and right. To keep that two-sided tape covering from sticking to anything inside like stuffing, I replaced the red handling film, which is what you can see in the pictures. To keep the assembly from sticking to the inside front before you want it to, place a piece of wax paper inside before sliding in the diaphragm and tape. Sorry, I was so frazelled I forgot to take a picture of the mounting bezel when it was outside!

Concerns:

1) Sounds a little brash - but I still have to seal it, stuff it, and damp it before really listening.

2) The diaphragm came a little warped on one corner, and it has separated from the VHB tape bezel. I'm going to carve 4 dowels that will fit front-to-back as hold-downs, then apply a drop of some kind of contact cement so I can pull everything apart if I fry the diaphragm and have to replace it.

3) Which is the positive lead? I think purple was + from ESS, but I couldn't test this beast of a magnet for polarity with another one (I'd never get them apart!). Besides, you got pleats, vectors, the left-hand-rule (or is it right-hand?). I think I can take a stock Peerless tweeter, play a 2KHz tone into both and pick the loudest sound while reversing polarity on the Heil and then mark the leads.

4) Costs got a little out-of-hand. Metal, blades, magnet, shipping, masks, wrong hardware, & broken stuff came to $250 or so.

Sure I could have gotten a great driver for that and saved a bunch of time, but where would be that 1970's hi-fi exotica mojo? Hope diffraction will be less than with those classic Great Heil AMT tweeters. You wouldn't put a dome tweeter underneath iron prongs and then in a square hole. This should be less diffraction and what there is hopefully is higher in frequency. The penalty, as Davis points out in his Audio Amateur articles, is less output due to less gap flux compared to the Great Heil. I've gotten around that by just bombing it with this wide faced north-south NIB magnet. I think the Great Heils had Alnico's, maybe someone can verify that.

Work safely! This means eye, ear, lung and hand protection. Unless you have a shop with vent ducting, do the cutting and grinding outside, preferably while your neighbors are also running power tools and lawn equipment. I looked up after grinding the vents and found 3 neighborhood kids and their Dad looking at me. And of course, when I explained what I was doing, he smiled and nodded.

Finally, the diaphragm came with a couple stock warning stickers from ESS, "WARNING don't you dare...," so I stuck one on the back.

Having a ball here posting to myself - - this time I'm moving up to three thumnails - - baby steps, as the movie character Bob would say.

I made a a mounting bezel for the diaphragm out of 3M/Scotch VHB two-sided tape. I went from the front plastic frame of the diaphagm outwards, enough to stick to the front inside of the outer pole piece and to cover up the various lengths of hand-cut ridge openings to the left and right. To keep that two-sided tape covering from sticking to anything inside like stuffing, I replaced the red handling film, which is what you can see in the pictures. To keep the assembly from sticking to the inside front before you want it to, place a piece of wax paper inside before sliding in the diaphragm and tape. Sorry, I was so frazelled I forgot to take a picture of the mounting bezel when it was outside!

Concerns:

1) Sounds a little brash - but I still have to seal it, stuff it, and damp it before really listening.

2) The diaphragm came a little warped on one corner, and it has separated from the VHB tape bezel. I'm going to carve 4 dowels that will fit front-to-back as hold-downs, then apply a drop of some kind of contact cement so I can pull everything apart if I fry the diaphragm and have to replace it.

3) Which is the positive lead? I think purple was + from ESS, but I couldn't test this beast of a magnet for polarity with another one (I'd never get them apart!). Besides, you got pleats, vectors, the left-hand-rule (or is it right-hand?). I think I can take a stock Peerless tweeter, play a 2KHz tone into both and pick the loudest sound while reversing polarity on the Heil and then mark the leads.

4) Costs got a little out-of-hand. Metal, blades, magnet, shipping, masks, wrong hardware, & broken stuff came to $250 or so.

Sure I could have gotten a great driver for that and saved a bunch of time, but where would be that 1970's hi-fi exotica mojo? Hope diffraction will be less than with those classic Great Heil AMT tweeters. You wouldn't put a dome tweeter underneath iron prongs and then in a square hole. This should be less diffraction and what there is hopefully is higher in frequency. The penalty, as Davis points out in his Audio Amateur articles, is less output due to less gap flux compared to the Great Heil. I've gotten around that by just bombing it with this wide faced north-south NIB magnet. I think the Great Heils had Alnico's, maybe someone can verify that.

Work safely! This means eye, ear, lung and hand protection. Unless you have a shop with vent ducting, do the cutting and grinding outside, preferably while your neighbors are also running power tools and lawn equipment. I looked up after grinding the vents and found 3 neighborhood kids and their Dad looking at me. And of course, when I explained what I was doing, he smiled and nodded.

Finally, the diaphragm came with a couple stock warning stickers from ESS, "WARNING don't you dare...," so I stuck one on the back.

Attachments

Nice...

Very nice. I'm sure you will be pleased with the results.

I went up in the attic to my retired Heil collection and found one that looks similar. It's got a lot of silicon glue all over it because it was mounted in the wall. This one was made about 20 years ago, back when I was still etching diaphragms. It was crossed over to the small Heil on the right.

Hmm...my wife still wants me to fix the hole in the wall where these speakers used to be, but I figure what's another 10 years?

I've got a set of designs for circular Heils that scale from about 1.5" to 4" in diameter, but I just haven't had time to work on them. I made the magnet structure for the 1.5" Heil--it's in the pictures on the left. I laid out the diaphragm and it's been ready to etch for almost a year now. I even used Frontpanelexpress to make a folding jig, so it shouldn't take that long to develop a prototype.

I still think there is still a lot of untapped potential for the Heil design, and the new magnets open up some possibilities that didn't exist years ago.

It's kinda funny thinking about these drivers. I made my first DIY Heil over 35 years ago. I had just graduated with a degree in philosophy, and didn't know what to do next, so I tried writing two articles for Audio Amateur--one of which was on the DIY Heil. Both articles were accepted, and it was nice getting paid for them, but it became clear rather quickly that I was never going to support myself by writing articles.

--Neil

Hello from PaulFX!

What do you think, Mr. Davis?

Very nice. I'm sure you will be pleased with the results.

I went up in the attic to my retired Heil collection and found one that looks similar. It's got a lot of silicon glue all over it because it was mounted in the wall. This one was made about 20 years ago, back when I was still etching diaphragms. It was crossed over to the small Heil on the right.

Hmm...my wife still wants me to fix the hole in the wall where these speakers used to be, but I figure what's another 10 years?

I've got a set of designs for circular Heils that scale from about 1.5" to 4" in diameter, but I just haven't had time to work on them. I made the magnet structure for the 1.5" Heil--it's in the pictures on the left. I laid out the diaphragm and it's been ready to etch for almost a year now. I even used Frontpanelexpress to make a folding jig, so it shouldn't take that long to develop a prototype.

I still think there is still a lot of untapped potential for the Heil design, and the new magnets open up some possibilities that didn't exist years ago.

It's kinda funny thinking about these drivers. I made my first DIY Heil over 35 years ago. I had just graduated with a degree in philosophy, and didn't know what to do next, so I tried writing two articles for Audio Amateur--one of which was on the DIY Heil. Both articles were accepted, and it was nice getting paid for them, but it became clear rather quickly that I was never going to support myself by writing articles.

--Neil

Thats cool, I been wanting Beyma AMTs, but always

choke on the price...

I've wondered if its possible to make a DIY ESL AMT?

An interdigitation of positive and negatively charged

thin plates, structured as two "combs" with insulated

tips. Hopefully mostly open at front and backbone of

the two combs. Pleated ribbon zigzagged between.

No magnets, just static.... Surely someone has done

this configuration before?

You gonna drive a horn lens with those round ones???

choke on the price...

I've wondered if its possible to make a DIY ESL AMT?

An interdigitation of positive and negatively charged

thin plates, structured as two "combs" with insulated

tips. Hopefully mostly open at front and backbone of

the two combs. Pleated ribbon zigzagged between.

No magnets, just static.... Surely someone has done

this configuration before?

You gonna drive a horn lens with those round ones???

Last edited:

Thats cool, I been wanting Beyma AMTs, but always

choke on the price...

I've wondered if its possible to make a DIY ESL AMT?

An interdigitation of positive and negatively charged

thin plates, structured as two "combs" with insulated

tips. Hopefully mostly open at front and backbone of

the two combs. Pleated ribbon zigzagged between.

No magnets, just static.... Surely someone has done

this configuration before?

You gonna drive a horn lens with those round ones???

Dr. Heil did propose that and ESL AMT could be made by subbing an electrostatic field for the electromagnetic field. I forget if I read that in the original patent or a later one tho.

paulfx - very nice project - congratulations!! I'm looking forward to seeing how this comes along.

Neil - I guess that I'm late to the party as I have always had thoughts about making my own AMT's using the already existing diaphragm (now) available as a replacement part and some big Neo's but never seem to get around to doing it. To many other irons in the fire (excuses, excuses - I know) plus I already have some old stock AMT1's that I'm pretty happy with. I'm with kenpeter's approach on this one - some big Neo's on the sides of the diaphragm and some thin plates running across - maybe some slotted metal - dipole configuration. I think that one of the mistakes being made is trying to use one diaphragm reproduce a broad rage of frequencies when a better approach might be to use larger ones for lower frequencies and small ones for the higher freq's - a mid range and high range AMT so to speak.

I'm with kenpeter's approach on this one - some big Neo's on the sides

My interdigital comb geometry would be entirely wrong for a magnetic field.

Magnet field must pass front to back, so the pleats can move side to side.

Static field(s) need to be parallel to those pleats to coerce similar motion.

We can't be talking of the same thing. Or can we???

I envisioned a comb of plates that intrudes fully into the pleat. One from the

front, oppositely charged one from the back, and double duty as the zigzag

support structure that forms a flat ESL ribbon into AMT pleats.

Last edited:

Neil's Attic

Wow! From the mists, another large Heil, covered with silicon glue and with a custom diaphragm to boot! My wife would just have a stroke if I cut holes in the wall. Neil, I like the way you say "back when I etched diaphragms" as if you've recovered. Modern meds are beautiful...

Neil, I like the way you say "back when I etched diaphragms" as if you've recovered. Modern meds are beautiful...

Viewers to this thread, Neil is the dean of DIY Heils, the philosopher of flux, the prof of pleats. I am merely an NIB buff.

Wow! From the mists, another large Heil, covered with silicon glue and with a custom diaphragm to boot! My wife would just have a stroke if I cut holes in the wall.

Viewers to this thread, Neil is the dean of DIY Heils, the philosopher of flux, the prof of pleats. I am merely an NIB buff.

On second thought, perhaps static combs could intrude from the sides?

Or top and bottom, take your pick....

Would automatically expose the front and back of the pleats to open air!

A pair of aluminum heatsinks is perhaps already in the correct shape???

But wether to insulate the ends of the fins that might touch the ribbon

and form the AMT pleat shape, or physically separate insulating support

structure for the pleats? Then how to assure the combs touch nothing???

Might be better the combs touch the ribbon in a known place than fiddle

with some critical alignment....

Devil is always in the details. Probably a reason if its not been done.

Or top and bottom, take your pick....

Would automatically expose the front and back of the pleats to open air!

A pair of aluminum heatsinks is perhaps already in the correct shape???

But wether to insulate the ends of the fins that might touch the ribbon

and form the AMT pleat shape, or physically separate insulating support

structure for the pleats? Then how to assure the combs touch nothing???

Might be better the combs touch the ribbon in a known place than fiddle

with some critical alignment....

Devil is always in the details. Probably a reason if its not been done.

I was thinking of a electromagnetic arrangement similar to this very basic concept. (Neil is most likely banging his head on the desk or wall and mumbling something like !@$!@$@#%^ didn't you read my stuff??)

This does not show extra iron plates used for shielding the assembly.

This does not show extra iron plates used for shielding the assembly.

Attachments

OK, then the assembly I am describing might look almost like that.

But the comb teeth pushed fully together, and interwoven, but not

touching...

The pleats would have to be running horizontally, as the ribbon

would be folding over the front edge of one plates of one comb,

and behind the rear facing edge of of the other.

Part of the gap between pleats would be taken up by the thickness

of the comb plates, but I don't think this gets in the way of AMT...

I am assuming your plate structure angles inward from both sides like Heil?

Mine would probably be flat faced, as there is no magnetic field to conduct.

And the ribbon will want a flat structure for folding upon anyway...

Thats assuming my idea isn't completely ridiculous to begin with...

But the comb teeth pushed fully together, and interwoven, but not

touching...

The pleats would have to be running horizontally, as the ribbon

would be folding over the front edge of one plates of one comb,

and behind the rear facing edge of of the other.

Part of the gap between pleats would be taken up by the thickness

of the comb plates, but I don't think this gets in the way of AMT...

I am assuming your plate structure angles inward from both sides like Heil?

Mine would probably be flat faced, as there is no magnetic field to conduct.

And the ribbon will want a flat structure for folding upon anyway...

Thats assuming my idea isn't completely ridiculous to begin with...

Forcefield Magnets In Stock

Looks like they're out of stock of the flatside rectangle magnet I used - however there is another tempting model here:

http://www.forcefieldmagnets.com/catalog/product_info.php?cPath=23_37&products_id=87

I would use one for a small diaphragm and two for a 4 inch. The problem is that these are just insanely powerful. Getting two of these in parallel on the inner pole piece instead of the one I used would require finding and marking each nominally North and South on each flat side. Keep them apart as if they were subcritical U235! Maybe a compass you don't mind ruining could find the actual north and south. Or, find attraction and repulsion by keeping one disk inside an unused 3/4" thick speaker box, the 3/4" walls keeping the magnets from sticking forever. Then perhaps glue the first magnet onto your inner pole piece, let it cure, then the next day clamp the assembly such that the second magnet cannot swing around explosively and snap together in a permanent series stack as you are assembling it.

I would cut dummy magnets out of wood and rehearse how I would clamp and glue them so either N-N or S-S was glued to the inner pole. They are that dangerous. You would need these test jigs anyway to grind down the inner pole piece so the components fit inside. When the inner assembly is dry, then you can "feed the alligator," fit it inside the outer pole.

Neil used 4 smaller NIB cubes in series-parallel in each small AMT and saved money. Four of these in a pair of tweeters would be some $120. My single one cost $40.

I feel it's worth it to nail the diaphragm gap with a bunch of flux.

And yes, the Davis design flux goes front to back and then back around to the front.

Looks like they're out of stock of the flatside rectangle magnet I used - however there is another tempting model here:

http://www.forcefieldmagnets.com/catalog/product_info.php?cPath=23_37&products_id=87

I would use one for a small diaphragm and two for a 4 inch. The problem is that these are just insanely powerful. Getting two of these in parallel on the inner pole piece instead of the one I used would require finding and marking each nominally North and South on each flat side. Keep them apart as if they were subcritical U235! Maybe a compass you don't mind ruining could find the actual north and south. Or, find attraction and repulsion by keeping one disk inside an unused 3/4" thick speaker box, the 3/4" walls keeping the magnets from sticking forever. Then perhaps glue the first magnet onto your inner pole piece, let it cure, then the next day clamp the assembly such that the second magnet cannot swing around explosively and snap together in a permanent series stack as you are assembling it.

I would cut dummy magnets out of wood and rehearse how I would clamp and glue them so either N-N or S-S was glued to the inner pole. They are that dangerous. You would need these test jigs anyway to grind down the inner pole piece so the components fit inside. When the inner assembly is dry, then you can "feed the alligator," fit it inside the outer pole.

Neil used 4 smaller NIB cubes in series-parallel in each small AMT and saved money. Four of these in a pair of tweeters would be some $120. My single one cost $40.

I feel it's worth it to nail the diaphragm gap with a bunch of flux.

And yes, the Davis design flux goes front to back and then back around to the front.

Last edited:

Oskar Heil and Julia Child

Went to see "Julie and Julia" with my wife last night - and I couldn't help noticing a parallel with Neil and Oskar. Sure, wrong genders, no "Mastering the Art of German Transducers," and no TV show. And instead of a dish a day, more like a magnet assembly a month.

Has anyone here ever coresponded with Dr. Heil before his death?

Went to see "Julie and Julia" with my wife last night - and I couldn't help noticing a parallel with Neil and Oskar. Sure, wrong genders, no "Mastering the Art of German Transducers," and no TV show. And instead of a dish a day, more like a magnet assembly a month.

Has anyone here ever coresponded with Dr. Heil before his death?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- The Neil Davis Heil AMT