Although I understand the desire to have a nice chassis, I confess to feeling that a DIY circuit should live in a DIY chassis. I sometimes make exceptions for circuits that have died, leaving behind shells that are empty and waiting for another circuit...in much the same way that Hermit crabs find new homes.

It took me five "dead" Hafler DH-200s before I found one that was truly dead. The first four were victims of horrendously botched "upgrades." I couldn't bear to kill an honorable amp whose only problem was a bad solder joint. So the first three went into my AV system. The fourth was in the lab for a while, now in the living room system because it's easier for my wife to live with. The fifth one was the charm. Dead. Totally. I've got an idea or two about what I want to do there, but don't have time at the moment. Oh, well.

Grey

It took me five "dead" Hafler DH-200s before I found one that was truly dead. The first four were victims of horrendously botched "upgrades." I couldn't bear to kill an honorable amp whose only problem was a bad solder joint. So the first three went into my AV system. The fourth was in the lab for a while, now in the living room system because it's easier for my wife to live with. The fifth one was the charm. Dead. Totally. I've got an idea or two about what I want to do there, but don't have time at the moment. Oh, well.

Grey

GRollins said:Although I understand the desire to have a nice chassis, I confess to feeling that a DIY circuit should live in a DIY chassis.

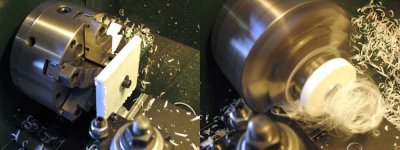

It is great feeling finishing good amp. It is equally rewarding making nice job on the case. Case is the biggest obstacle to many people. It is hard to make a good case without proper equipment. Because of the very reason, last year I have been learning machining.

It took me five "dead" Hafler DH-200s before I found one that was truly dead.

Grey [/QUOTE]

This is really funny statement.

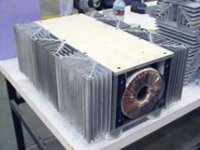

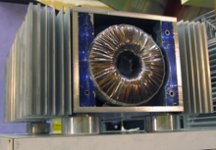

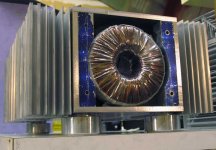

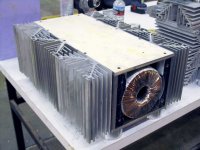

Here is the proof that I do not just destroy great amps. This is the case that I am working on right now, with my newly acquired knowledge. Even do I am not very patient person, I decided to do it slowly with attention to details, such as feet and special work on the front plate, beveled edges for the cooling openings... It is work in progress.

Attachments

Yes, exactly 10mm aluminum.Boettgenstone said:Looks really great your "shell"

what is it made of? 10 mm aluminum?

christoph

roddyama said:Hmm,... let me guess. Cardas RCA's with Rhodium plated binding posts?!?

Ha, ha, How do you know - are you looking into the future.

You forgot on the Cardas solder. I still have it and keep it for the best projects. Did you make any more of the anual GBs?

roddyama said:I'm Physic.No Cardas GB's since '05

You need a photo editing software to enlarge the pic and save it as a low "quality" jpg file.

I refuse to do it as low quality.

AR2,

It looks as if you have a machine shop at your disposal. Maybe you have a smallish granite surface plate too, maybe 12"sq or 18"sq. If you do, when you sand the surface of the heatsinks, put the sandpaper on the plate in a laundry sink and move the heatsink over the paper while running water over it. This will give u a better finish and hold the paper to the plate too.

BTW, The amp is looking great.

It looks as if you have a machine shop at your disposal. Maybe you have a smallish granite surface plate too, maybe 12"sq or 18"sq. If you do, when you sand the surface of the heatsinks, put the sandpaper on the plate in a laundry sink and move the heatsink over the paper while running water over it. This will give u a better finish and hold the paper to the plate too.

BTW, The amp is looking great.

Thank you Rodd. Yes I do have big granite slab (compliments from Grizzli Industrial) and a small one for the purpose you described.

I have been experimenting with various grits and I completely agree with you. Finishes are much better with water, and wet sending is must with those fine grits. Water prevents loading of the sand paper as well, that otherwise would be wasted in no time.

I have been experimenting with various grits and I completely agree with you. Finishes are much better with water, and wet sending is must with those fine grits. Water prevents loading of the sand paper as well, that otherwise would be wasted in no time.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Treshold Stasis S300 Vs Aleph 30