Zen Mod babysitter solve all problem , is really non sense use on this macho man power amp a sissies bias .....

ps drill under some holes too

I respect the position of Anatech as official repair .....but here we are at performance racing club with just a simple fan we cure longevity too

ps drill under some holes too

I respect the position of Anatech as official repair .....but here we are at performance racing club with just a simple fan we cure longevity too

Last edited:

if you are in US and the trafo have dual primary 120v you can put in series to have half B+ to crank bias for class A

place a bet that some circ areas would be voltage starved?

Anatech is having it completely right - Nak isn't made to elevate temps inside

it is doable, depending on your speakers you'll hear difference or not, but one thing is sure - if you want bigger (hotter) amp - either buy one, or build it

leave Nak as is ( recap if needed, change what is needed, set by factory specs)

Anatech is having it completely right - Nak isn't made to elevate temps inside

it is doable, depending on your speakers you'll hear difference or not, but one thing is sure - if you want bigger (hotter) amp - either buy one, or build it

leave Nak as is ( recap if needed, change what is needed, set by factory specs)

sissies amp at 50°?place a bet that some circ areas would be voltage starved?

Anatech is having it completely right - Nak isn't made to elevate temps inside

it is doable, depending on your speakers you'll hear difference or not, but one thing is sure - if you want bigger (hotter) amp - either buy one, or build it

leave Nak as is ( recap if needed, change what is needed, set by factory specs)

quite happy with ACAminiyou can always buy fancy ones, with copper heaatsinks, chimney drilled

I hear these are the best nowadays

or Mc, with nice leds below toobz

Hi nicoch58,

A "sissy" amp based on the temperature it runs at?

Okay, you've just defined yourself rather clearly as someone who has zero knowledge of electronics or sound quality.

All,

Engineering is the science based on intelligent compromise. It is also based on facts and empirical measurements (reality check opposed to simulator drivers). Striving for perfection in performance is a very simplistic pursuit that ignores practical limits. When you engineer something, you have opposing characteristics. The very basic ones are performance, cost and reliability. A simple trio that is responsible for the quality of the product being made. These days cost is the prime motivator (greed), so not surprisingly products don't really perform well, or last. Sound familiar?

One low tech way to create a more linear circuit is to run it at higher current levels than advisable. The higher current reduces the delta I in the circuit with signal level, and charges / discharges capacitance more quickly (higher frequency response). Ignoring practical performance limits encourages a designer to tread into that high current area. The cost of this is higher part dissipation will will, and always does, result in higher failure rates as stated earlier.

Another way to reduce cost in a circuit is to reduce component count, as Nelson does. Simple is not always better, not by a long shot! We can make the operation of a circuit more linear by arranging it so the voltage variation is restricted or held constant, and that goes a long way to dropping distortion. We can do this at much lower currents, lowering part temperature. Gee, guess what? The device will now last longer and may generate lower system noise as well. Increasing the component cout (circuit complexity) beyond this point tends to increase failure rate and may also negatively impact sound quality. So there is actually a sweet spot, depending on basic circuit design, where the complexity, performance and cost are all maximized in relation to each other.

For example, what is the possible benefit of having circuit performance greatly beyond our ability to perceive any improvement? Well, there isn't except for advertising. There is a cost benefit to having increased reliability to the manufacturer in that the warranty program (which they killed off) is less expensive to maintain, and it also translates directly into a higher confidence in quality from buyers of that product. That drives sales. Don't forget the cost of shipping defective products back and forth for service or replacement. Outside warranty the customer pays directly for reliability issues and transportation - plus the cost of not having the product to use. Okay, nothing but positive things from increased reliability. Lower cost? Okay, people who don't understand the product they are buying go for this as a primary motivator. So you're dealing with a less well informed market segment that tends to misuse products causing failures and driving up the cost of the warranty program, and generating negative press. All very negative factors. Okay, let's introduce greed from the manufacturer. They bank on higher cost being seen as an indicator of quality. (Linn is a great example, Pioneer also). Now customers make the wrong choice, over pay and are saddled with service costs greater than normal for that product type. That's pretty negative in my view.

This era of Nakamichi product was very well engineered. Customers received a well engineered product with very good performance at a fair price level that lasted longer than average for these products. This is a claim supported by the history of these amplifiers.

The engineering that went into these amplifiers go beyond the schematic. Output transistors were more linear, thermal path to the heat sink much shorter to the radiators with lower thermal resistance. Hmmm, more efficient in getting rid of heat. In general the parts were better and operating points well chosen. They did have a listening lab in the USA by the way. So people far less skilled in design, and even assessing sound quality want to come in behind and critique / redesign a product put together by a skilled design team?? Note I said team, it was a group of engineers, not any one person.

What I said holds for any well designed product, not just these amps. I find that single people who declare a design produced by a team of competent engineers defective in performance typically do not have good design chops themselves. But they seem to always possess one hell of an inflated ego! Now to be clear, I would never say this about Nelson as he is about the opposite in character, but most other design engineers who work on their own are extremely arrogant. This is even more the case with people who do not do this as a profession or work in teams. This arrogance blinds them to the reality of a better way to do things.

Anyone who wants to listen to and follow these people? Have at it! I know exactly where you'll end up as I have been fixing these engineering mistakes for decades. All I am going to say is, use your head for something more than a hat rack people!

-Chris

A "sissy" amp based on the temperature it runs at?

Okay, you've just defined yourself rather clearly as someone who has zero knowledge of electronics or sound quality.

All,

Engineering is the science based on intelligent compromise. It is also based on facts and empirical measurements (reality check opposed to simulator drivers). Striving for perfection in performance is a very simplistic pursuit that ignores practical limits. When you engineer something, you have opposing characteristics. The very basic ones are performance, cost and reliability. A simple trio that is responsible for the quality of the product being made. These days cost is the prime motivator (greed), so not surprisingly products don't really perform well, or last. Sound familiar?

One low tech way to create a more linear circuit is to run it at higher current levels than advisable. The higher current reduces the delta I in the circuit with signal level, and charges / discharges capacitance more quickly (higher frequency response). Ignoring practical performance limits encourages a designer to tread into that high current area. The cost of this is higher part dissipation will will, and always does, result in higher failure rates as stated earlier.

Another way to reduce cost in a circuit is to reduce component count, as Nelson does. Simple is not always better, not by a long shot! We can make the operation of a circuit more linear by arranging it so the voltage variation is restricted or held constant, and that goes a long way to dropping distortion. We can do this at much lower currents, lowering part temperature. Gee, guess what? The device will now last longer and may generate lower system noise as well. Increasing the component cout (circuit complexity) beyond this point tends to increase failure rate and may also negatively impact sound quality. So there is actually a sweet spot, depending on basic circuit design, where the complexity, performance and cost are all maximized in relation to each other.

For example, what is the possible benefit of having circuit performance greatly beyond our ability to perceive any improvement? Well, there isn't except for advertising. There is a cost benefit to having increased reliability to the manufacturer in that the warranty program (which they killed off) is less expensive to maintain, and it also translates directly into a higher confidence in quality from buyers of that product. That drives sales. Don't forget the cost of shipping defective products back and forth for service or replacement. Outside warranty the customer pays directly for reliability issues and transportation - plus the cost of not having the product to use. Okay, nothing but positive things from increased reliability. Lower cost? Okay, people who don't understand the product they are buying go for this as a primary motivator. So you're dealing with a less well informed market segment that tends to misuse products causing failures and driving up the cost of the warranty program, and generating negative press. All very negative factors. Okay, let's introduce greed from the manufacturer. They bank on higher cost being seen as an indicator of quality. (Linn is a great example, Pioneer also). Now customers make the wrong choice, over pay and are saddled with service costs greater than normal for that product type. That's pretty negative in my view.

This era of Nakamichi product was very well engineered. Customers received a well engineered product with very good performance at a fair price level that lasted longer than average for these products. This is a claim supported by the history of these amplifiers.

The engineering that went into these amplifiers go beyond the schematic. Output transistors were more linear, thermal path to the heat sink much shorter to the radiators with lower thermal resistance. Hmmm, more efficient in getting rid of heat. In general the parts were better and operating points well chosen. They did have a listening lab in the USA by the way. So people far less skilled in design, and even assessing sound quality want to come in behind and critique / redesign a product put together by a skilled design team?? Note I said team, it was a group of engineers, not any one person.

What I said holds for any well designed product, not just these amps. I find that single people who declare a design produced by a team of competent engineers defective in performance typically do not have good design chops themselves. But they seem to always possess one hell of an inflated ego! Now to be clear, I would never say this about Nelson as he is about the opposite in character, but most other design engineers who work on their own are extremely arrogant. This is even more the case with people who do not do this as a profession or work in teams. This arrogance blinds them to the reality of a better way to do things.

Anyone who wants to listen to and follow these people? Have at it! I know exactly where you'll end up as I have been fixing these engineering mistakes for decades. All I am going to say is, use your head for something more than a hat rack people!

-Chris

this is really BS and free insult !!!Hi nicoch58,

A "sissy" amp based on the temperature it runs at?

Okay, you've just defined yourself rather clearly as someone who has zero knowledge of electronics or sound quality.

-Chris

On sound quality I owened a speaker firm from 1991 go figure , i'm elettronic tech ,I build a lot amp from smd Tripath , tube amp of my , erno borbley phono and power amp ,plus two pass amp ,some pre and some dac You cannot give a lesson to me on sound please

I have naka sr3 and the pa7 are cheaper copy of S300 work the same! fan solve all temp problem and affidability

The problem you have as in caps section, that you think that caps don't have a sound and hi bias cannot sound better !!

end of story

Whatever you say ...

Don't advise people to do silly things. You are in fact dead wrong on a number of things. I also come from a test and measurement lab background with design experience. I don't talk about anything I don't know about.

A fan is a failure point, makes equipment into vacuum machines (dust collectors) and they are simply loud, especially when the bearings begin to wear.

I can most certainly offer you information, but you are fixed on myths so no, no one can give you any lessons on sound.

Don't advise people to do silly things. You are in fact dead wrong on a number of things. I also come from a test and measurement lab background with design experience. I don't talk about anything I don't know about.

A fan is a failure point, makes equipment into vacuum machines (dust collectors) and they are simply loud, especially when the bearings begin to wear.

I can most certainly offer you information, but you are fixed on myths so no, no one can give you any lessons on sound.

This is like adding a turbo to a 2.5 or so liter Mustang and expecting the thing to work like a 5 liter Mustang.

Like above, use a good design, use the best parts, and run it well within its safe operating area.

It will last decades, without any major issues.

You (nicoch) also have experience, so there is little for me to say, except that our perceptions differ about a souped up amp.....or the need to do so.

Like above, use a good design, use the best parts, and run it well within its safe operating area.

It will last decades, without any major issues.

You (nicoch) also have experience, so there is little for me to say, except that our perceptions differ about a souped up amp.....or the need to do so.

Not a fan of piggybacking, but here I am

I’d like input on the best replacement mains caps for a PA-5. Best meaning quality and fit. Perhaps also best bets for the bridge rectifier.

the amp works, but it is exhibiting some hum and I know NP suggests the mains cans be replaced. The smaller caps are already replaced last year.

I’d like input on the best replacement mains caps for a PA-5. Best meaning quality and fit. Perhaps also best bets for the bridge rectifier.

the amp works, but it is exhibiting some hum and I know NP suggests the mains cans be replaced. The smaller caps are already replaced last year.

You aren't "piggybacking" (I hate that term). You are continuing a useful conversation.

Okay, let's use some intelligence here. Don't blindly follow what anyone says, use common sense and some science to figure it out.

Nelson is a very smart guy, but he designs equipment that runs at high current levels and also - HOT. The filter capacitors in his equipment will not last as long as the ones in a Nakamichi PA-5/7 type amplifier, or a normal class A-B amplifier. It is about ripple current in the capacitor and ambient temperature. I have yet to find bad main filter capacitors in these amplifiers. I have found other issues I repair when inside, but not filter caps yet. I have in other amplifier brands. I have also replaced perfectly good filter capacitors in equipment and measured before and after (no difference). They also sounded the same. We commonly measure to levels well beyond what any human being can hear by using a sensitive spectrum analyzer designed for audio.

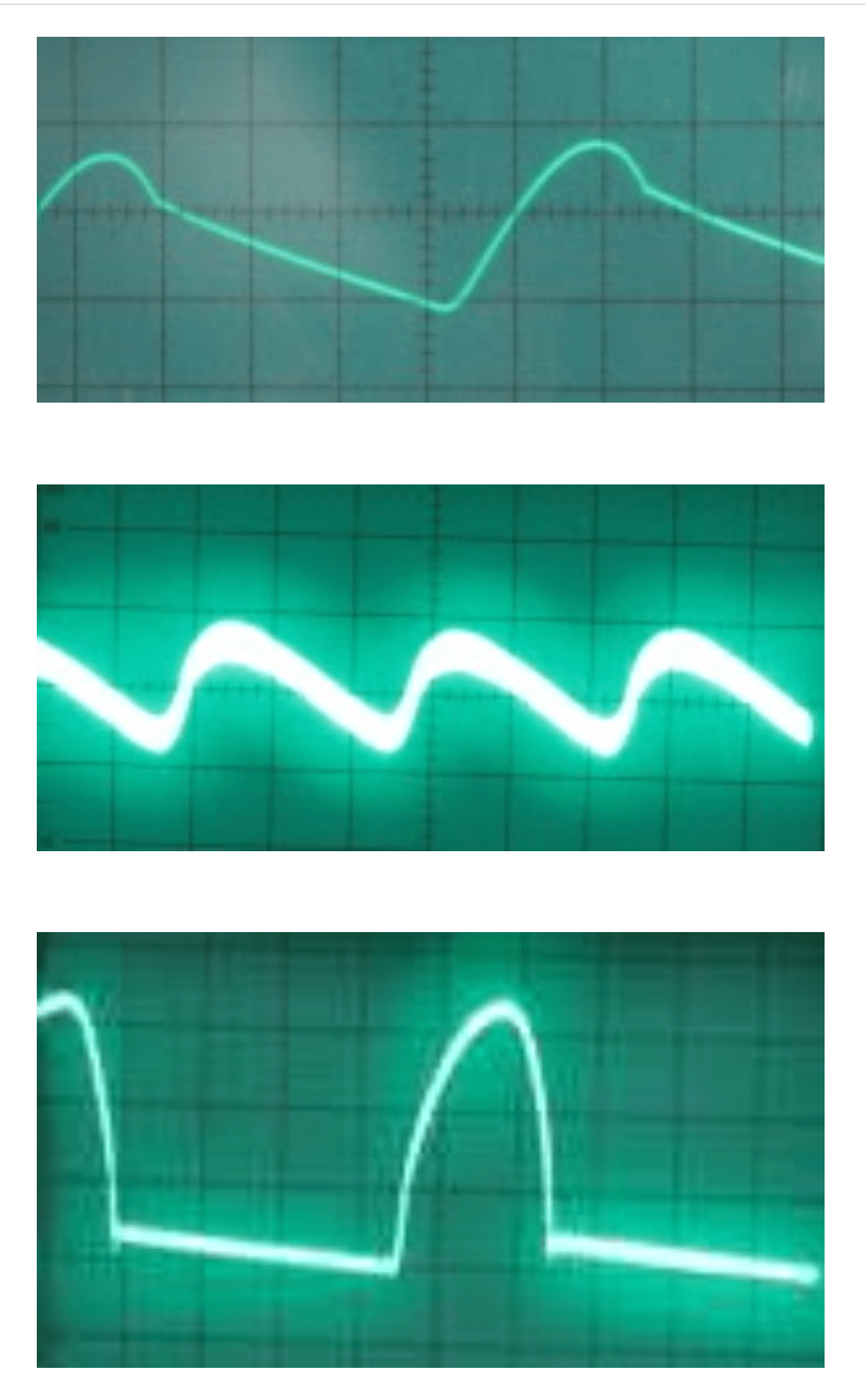

Take a good oscilloscope and have a look at the ripple across the filter capacitors. That tells the entire story. Filter capacitors are better sealed than other types, and there is more electrolyte inside too. They rarely go bad unless over-heated and then they typically vent. That's a clear sign you need to replace them. Better techs know what types of waveforms are normal, and which indicate a capacitor is aging. Do not install higher capacitance values.

On the other capacitors ... If you didn't properly size them, or bend the leads carefully without placing stress on the leads going into he can, you may as well just yank them and replace them, doing the job properly this time. I do have different capacitors I use in certain locations, and as long as you use good brands they will sound the same. There are some tricks to this the better techs know about.

-Chris

Okay, let's use some intelligence here. Don't blindly follow what anyone says, use common sense and some science to figure it out.

Nelson is a very smart guy, but he designs equipment that runs at high current levels and also - HOT. The filter capacitors in his equipment will not last as long as the ones in a Nakamichi PA-5/7 type amplifier, or a normal class A-B amplifier. It is about ripple current in the capacitor and ambient temperature. I have yet to find bad main filter capacitors in these amplifiers. I have found other issues I repair when inside, but not filter caps yet. I have in other amplifier brands. I have also replaced perfectly good filter capacitors in equipment and measured before and after (no difference). They also sounded the same. We commonly measure to levels well beyond what any human being can hear by using a sensitive spectrum analyzer designed for audio.

Take a good oscilloscope and have a look at the ripple across the filter capacitors. That tells the entire story. Filter capacitors are better sealed than other types, and there is more electrolyte inside too. They rarely go bad unless over-heated and then they typically vent. That's a clear sign you need to replace them. Better techs know what types of waveforms are normal, and which indicate a capacitor is aging. Do not install higher capacitance values.

On the other capacitors ... If you didn't properly size them, or bend the leads carefully without placing stress on the leads going into he can, you may as well just yank them and replace them, doing the job properly this time. I do have different capacitors I use in certain locations, and as long as you use good brands they will sound the same. There are some tricks to this the better techs know about.

-Chris

You mentioned the type of ripple on good versus bad capacitors. I stole the below information from Eric's Aleph X page:

https://sites.google.com/bucknell.edu/ericshometheater/erics-home-theater/aleph-x-clone-amp

https://sites.google.com/bucknell.edu/ericshometheater/erics-home-theater/aleph-x-clone-amp

Well, what happens is the less good condition a capacitor is in, it develops a "pip" on the leading edge which increases as the capacitor degrades. You will see this long before changes are measured on an ESR meter. However, the dissipation reading on a good capacitance meter (ie a real one like a 4263B from HP / Agilent / Keysight or similar) will increase before an ESR meter can show changes. Once you see that the charge doesn't hold well, that capacitor is really bad. Far beyond the changes you'll see on the leading edge or dissipation reading change.

I guess the important point is that you can see the condition of a filter capacitor while it is in-circuit and operating. Ripple will depend greatly on load current (so internal ripple current). The leading edge "pip" will always show you the health of the capacitor.

-Chris

I guess the important point is that you can see the condition of a filter capacitor while it is in-circuit and operating. Ripple will depend greatly on load current (so internal ripple current). The leading edge "pip" will always show you the health of the capacitor.

-Chris

Thank you for the reply. The other caps were properly spaced and I would never up the capacitance value. Maybe the voltage and temperature rating though. It is my friends amp, and he uses it a LOT, so it does get warm for an extended period of time and often.You aren't "piggybacking" (I hate that term). You are continuing a useful conversation.

Okay, let's use some intelligence here. Don't blindly follow what anyone says, use common sense and some science to figure it out.

Nelson is a very smart guy, but he designs equipment that runs at high current levels and also - HOT. The filter capacitors in his equipment will not last as long as the ones in a Nakamichi PA-5/7 type amplifier, or a normal class A-B amplifier. It is about ripple current in the capacitor and ambient temperature. I have yet to find bad main filter capacitors in these amplifiers. I have found other issues I repair when inside, but not filter caps yet. I have in other amplifier brands. I have also replaced perfectly good filter capacitors in equipment and measured before and after (no difference). They also sounded the same. We commonly measure to levels well beyond what any human being can hear by using a sensitive spectrum analyzer designed for audio.

Take a good oscilloscope and have a look at the ripple across the filter capacitors. That tells the entire story. Filter capacitors are better sealed than other types, and there is more electrolyte inside too. They rarely go bad unless over-heated and then they typically vent. That's a clear sign you need to replace them. Better techs know what types of waveforms are normal, and which indicate a capacitor is aging. Do not install higher capacitance values.

On the other capacitors ... If you didn't properly size them, or bend the leads carefully without placing stress on the leads going into he can, you may as well just yank them and replace them, doing the job properly this time. I do have different capacitors I use in certain locations, and as long as you use good brands they will sound the same. There are some tricks to this the better techs know about.

-Chris

Over time, it has developed a mild hum. That’s the main symptom which has me staring at the filter caps.

Another thread here has mentioned a low value resistor in between the ground and the input jack. Curious cure there.

The transformer, if it hums more at high output, has to be dunked in varnish, there is a gap in the laminations, the filler does dry out over time.

The curious cure is simply grounding the inputs in such a way that current from the rest of the circuit does not enter the inputs, which are very sensitive, the loss from the rest of the circuit to ground would be amplified, resulting in overload on the outputs.

The resistor reduces or eliminates this problem, so at least noise is removed, if not totally eliminated.

It is a well known remedy.

Another thing, keep the amp in a location where it has room for air to circulate, for ventilation.

For example, it should not have the rest of the equipment on top, vents should be exposed, and so on.

I have seen lacy cloth, and even (shudder) vases with flowers on top of electrically operated equipment, which is frankly dangerous.

And do check up for dried out heat sink compound and loose fasteners on the devices attached to the heat sink, those can happen over time as well.

Another source of hum can be corrosion in the RCA cables, check for continuity, and put something that prevents corrosion, such products are sold in jelly / cream form, useful if you are in a damp and humid location.

Also, check for continuity to physical Earth from the chassis, another source of problems at times.

The curious cure is simply grounding the inputs in such a way that current from the rest of the circuit does not enter the inputs, which are very sensitive, the loss from the rest of the circuit to ground would be amplified, resulting in overload on the outputs.

The resistor reduces or eliminates this problem, so at least noise is removed, if not totally eliminated.

It is a well known remedy.

Another thing, keep the amp in a location where it has room for air to circulate, for ventilation.

For example, it should not have the rest of the equipment on top, vents should be exposed, and so on.

I have seen lacy cloth, and even (shudder) vases with flowers on top of electrically operated equipment, which is frankly dangerous.

And do check up for dried out heat sink compound and loose fasteners on the devices attached to the heat sink, those can happen over time as well.

Another source of hum can be corrosion in the RCA cables, check for continuity, and put something that prevents corrosion, such products are sold in jelly / cream form, useful if you are in a damp and humid location.

Also, check for continuity to physical Earth from the chassis, another source of problems at times.

Last edited:

- Home

- Amplifiers

- Pass Labs

- Nakamichi PA-5 upgrades