Hi jencelo,

It probably needs a new transformer as CSA did not allow 220/240 volt windings for a while. At least that was what I was told. But check for two primary windings in parallel. If you can see that, just wire the windings in series.

IMPORTANT: Use a variac to start powering it up very slowly. If the windings are out of phase, the transformer will draw destructive amounts of current. You can test this by running the rewired transformer as at very low voltage to limit the fault energy. You must test any rewired transformer carefully before just plugging it in to try.

-Chris

It probably needs a new transformer as CSA did not allow 220/240 volt windings for a while. At least that was what I was told. But check for two primary windings in parallel. If you can see that, just wire the windings in series.

IMPORTANT: Use a variac to start powering it up very slowly. If the windings are out of phase, the transformer will draw destructive amounts of current. You can test this by running the rewired transformer as at very low voltage to limit the fault energy. You must test any rewired transformer carefully before just plugging it in to try.

-Chris

Thanks! There is one for sale on the used market. I wanted to see if it was an easy rewiring. In one of the photos of the listing, it shows 120V and 50/60Hz. I wonder if this means anything since it was printed both 50 & 60 Hz?

With my limited knowledge, I am GUESSING 120V is always (or is it?) 60Hz. Since it is also compatible with 50Hz, it can be rewired???

With my limited knowledge, I am GUESSING 120V is always (or is it?) 60Hz. Since it is also compatible with 50Hz, it can be rewired???

If it's older than 15 years replace the power supply caps with ones

comparable to the originals. Panasonic or Nichicon is plenty good enough.

Arrange to get the amplifier some serious ventilation and then raise the

bias until the heat sinks run at 50 deg C after an hour of operation.

Serious ventilation is what you think it is - a fan is not out of the question.

I realize this is an a old post, but I'm still using the PA-5 along with my other Nakamichi components. I've had one repair done and it looks like now I need another one. I'm getting loud distortion periodically and I have to shut it down immediately so I can't tell if it's one channel, which one or both. I'm interested in what you have to say about bias and heat! Mine is in a cabinet but because we live in an apartment now we never really crank it up, so wasn't too worried about heat (especially given the large heat sinks on the sides). Should I still be concerned about heat? Is that possibly my issue?

Hi Gary,

I did warranty for those in the Toronto, Ontario area for years. You really can't restrict airflow on a Stasis product, they dissipate a fair amount of heat normally. So what you are doing is ill-advised. The owner's manual is very clear on this.

Having said that, I've also seen work done by others and it normally isn't done well - or completely. There are some changes I make in these for reliability that does not involve changing the circuit or cutting traces. It is necessary to match components that need changing to maintain performance. Also, the set procedure for bias assumes an open, free air environment. Your bias currents will be incorrect where you have your amplifier installed.

Your Nakamichi products are excellent, and I did warranty on all the top brands. However, allowing them to run hot is very destructive over time. The failure rate on components doubles for every 10 °C rise in temperature. That means every single brand and piece of equipment no matter what they are or what the manufacturer claims. I would HIGHLY recommend you change the location of housing for your equipment, it's up to you but why invite trouble?

I know this isn't what you wanted to hear, but it is the truth and I am hoping to avoid trouble for you in years to come. I am seeing them need service finally. Not bad given how old they are. I normally didn't see them for anything but stupidity or hacks "improving" them. THe components are so good in these amps that there is no improvements to be made. I have studied them when requested to make improvements and I've always said, they are already at the top level. So, I just do required service and that is all. Ther area couple minor things I can do that was impossible in a mass assembly situation, like hand matching specific parts. Tiny improvements, nothing you would likely hear.

-Chris

I did warranty for those in the Toronto, Ontario area for years. You really can't restrict airflow on a Stasis product, they dissipate a fair amount of heat normally. So what you are doing is ill-advised. The owner's manual is very clear on this.

Having said that, I've also seen work done by others and it normally isn't done well - or completely. There are some changes I make in these for reliability that does not involve changing the circuit or cutting traces. It is necessary to match components that need changing to maintain performance. Also, the set procedure for bias assumes an open, free air environment. Your bias currents will be incorrect where you have your amplifier installed.

Your Nakamichi products are excellent, and I did warranty on all the top brands. However, allowing them to run hot is very destructive over time. The failure rate on components doubles for every 10 °C rise in temperature. That means every single brand and piece of equipment no matter what they are or what the manufacturer claims. I would HIGHLY recommend you change the location of housing for your equipment, it's up to you but why invite trouble?

I know this isn't what you wanted to hear, but it is the truth and I am hoping to avoid trouble for you in years to come. I am seeing them need service finally. Not bad given how old they are. I normally didn't see them for anything but stupidity or hacks "improving" them. THe components are so good in these amps that there is no improvements to be made. I have studied them when requested to make improvements and I've always said, they are already at the top level. So, I just do required service and that is all. Ther area couple minor things I can do that was impossible in a mass assembly situation, like hand matching specific parts. Tiny improvements, nothing you would likely hear.

-Chris

Thanks very much Chris. I should have known better. I’m actually CET who majored in Audio but it’s been many years. The amp didn’t seem to get too hot because we can’t crank it in an apartment but none the less, Nelson Pass agrees with you, so I’ll have to figure something out.Hi Gary,

I did warranty for those in the Toronto, Ontario area for years. You really can't restrict airflow on a Stasis product, they dissipate a fair amount of heat normally. So what you are doing is ill-advised. The owner's manual is very clear on this.

Having said that, I've also seen work done by others and it normally isn't done well - or completely. There are some changes I make in these for reliability that does not involve changing the circuit or cutting traces. It is necessary to match components that need changing to maintain performance. Also, the set procedure for bias assumes an open, free air environment. Your bias currents will be incorrect where you have your amplifier installed.

Your Nakamichi products are excellent, and I did warranty on all the top brands. However, allowing them to run hot is very destructive over time. The failure rate on components doubles for every 10 °C rise in temperature. That means every single brand and piece of equipment no matter what they are or what the manufacturer claims. I would HIGHLY recommend you change the location of housing for your equipment, it's up to you but why invite trouble?

I know this isn't what you wanted to hear, but it is the truth and I am hoping to avoid trouble for you in years to come. I am seeing them need service finally. Not bad given how old they are. I normally didn't see them for anything but stupidity or hacks "improving" them. THe components are so good in these amps that there is no improvements to be made. I have studied them when requested to make improvements and I've always said, they are already at the top level. So, I just do required service and that is all. Ther area couple minor things I can do that was impossible in a mass assembly situation, like hand matching specific parts. Tiny improvements, nothing you would likely hear.

-Chris

Good to hear you're going to modify the installation location.

If the amp wasn't getting hot in there, the bias current is not where it should be. Being a CET, you know that. You also know that transistors are extremely temperature sensitive and that affects beta a great deal. You match on beta, not Vbe! The only way to match transistors for signal applications is to mount them together in a diff pair configuration with a CCS tail current generator. Using precision resistors in the collectors (I use 100R0 0.1% selected using a Keysight 34465A or 3457A) in the collectors, you simply compare the collector voltages using a good meter as a null detector. A cheap meter simply will not do. You must block external air and a box (or whatever) to block air currents from the pair under test. It takes a few minutes for each pair to settle at 3 mA tail current, longer at lower currents. Aim for approx 10 VDC Vce.

- Best, Chris

If the amp wasn't getting hot in there, the bias current is not where it should be. Being a CET, you know that. You also know that transistors are extremely temperature sensitive and that affects beta a great deal. You match on beta, not Vbe! The only way to match transistors for signal applications is to mount them together in a diff pair configuration with a CCS tail current generator. Using precision resistors in the collectors (I use 100R0 0.1% selected using a Keysight 34465A or 3457A) in the collectors, you simply compare the collector voltages using a good meter as a null detector. A cheap meter simply will not do. You must block external air and a box (or whatever) to block air currents from the pair under test. It takes a few minutes for each pair to settle at 3 mA tail current, longer at lower currents. Aim for approx 10 VDC Vce.

- Best, Chris

Thanks Chris. I guess it’s been a little too long. The funny thing is I went to great lengths to cool my older 27” iMac when running Garageband and Final Cut Pro, but have neglected my Audio system. I now have an M1 MAC mini so heat is no longer and issue there. So the focus will now be on the Nakamichi system.

Thanks so much Nelson. Taking your advice I have installed 2 x 80mm USB fans into the side of my Stereo cabinet. One for each RH section of the cabinet ( the lower section contains PA-5, upper sect contains CA- 7 Control / pre amp ). I am still measuring 85 F on top of the PA-5 power amp, after an hour, playing reasonably load music. I have not yet performed the bias adjustment you recommended, but I can’t imagine the amp running at 122 C inside this ( internal cabinet ) after the 50C bias setting? your design Power Amp sounds really good to me now, so I’m hesitant to adjust it!If it's older than 15 years replace the power supply caps with ones

comparable to the originals. Panasonic or Nichicon is plenty good enough.

Arrange to get the amplifier some serious ventilation and then raise the

bias until the heat sinks run at 50 deg C after an hour of operation.

Serious ventilation is what you think it is - a fan is not out of the question.

Last edited:

I hate to disagree with Nelson on this, but I do. Strongly. I have to upmost of respect for Nelson, but I do have technical reasons for disagreeing with him. What I have seen in practice doesn't support his suggestions either.

Most main filter capacitors remain in excellent condition well beyond 15 years. I check them with an oscilloscope under load in the amp. Rare to see these bad, but the latest fad is to replace them.

High bias is not always good. Nelson does like to run stuff hot. Failure rate doubles for every 10°C rise in temperature. Very little to no sonic benefits except in poorly designed amplifiers - some times.

-Chris

Most main filter capacitors remain in excellent condition well beyond 15 years. I check them with an oscilloscope under load in the amp. Rare to see these bad, but the latest fad is to replace them.

High bias is not always good. Nelson does like to run stuff hot. Failure rate doubles for every 10°C rise in temperature. Very little to no sonic benefits except in poorly designed amplifiers - some times.

-Chris

Thanks Chris. I appreciate your comments and advice.Thanks very much Chris. I should have known better. I’m actually CET who majored in Audio but it’s been many years. The amp didn’t seem to get too hot because we can’t crank it in an apartment but none the less, Nelson Pass agrees with you, so I’ll have to figure something out.

Thanks Chris. I appreciate your comments and advice.I hate to disagree with Nelson on this, but I do. Strongly. I have to upmost of respect for Nelson, but I do have technical reasons for disagreeing with him. What I have seen in practice doesn't support his suggestions either.

Most main filter capacitors remain in excellent condition well beyond 15 years. I check them with an oscilloscope under load in the amp. Rare to see these bad, but the latest fad is to replace them.

High bias is not always good. Nelson does like to run stuff hot. Failure rate doubles for every 10°C rise in temperature. Very little to no sonic benefits except in poorly designed amplifiers - some times.

-Chris

https://www.firstwatt.com/pdf/art_leave_classa.pdf nice reading ...I hate to disagree with Nelson on this, but I do. Strongly. I have to upmost of respect for Nelson, but I do have technical reasons for disagreeing with him. What I have seen in practice doesn't support his suggestions either.

Most main filter capacitors remain in excellent condition well beyond 15 years. I check them with an oscilloscope under load in the amp. Rare to see these bad, but the latest fad is to replace them.

High bias is not always good. Nelson does like to run stuff hot. Failure rate doubles for every 10°C rise in temperature. Very little to no sonic benefits except in poorly designed amplifiers - some times.

-Chris

Attachments

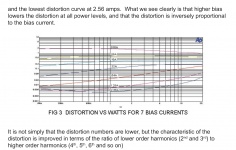

From the above pdf...

The bias is generally set at a level suited to the heat dissipation capacity of the hardware. At Pass Labs the bias is set to the value which raises the heat sinks 25 – 30 degrees C. above ambient temperature. The result is a heat sink which you can put your hand on for about 10 seconds or so.

I think I'd be replacing parts every other year if my bias was set that high on my 30+ year old PA-7A MKII. As Chris said NP likes to bias on the high side; stasis Thresholds from the same era as my NAK are usually set at 100mA, 2.5X more than the NAK

The bias is generally set at a level suited to the heat dissipation capacity of the hardware. At Pass Labs the bias is set to the value which raises the heat sinks 25 – 30 degrees C. above ambient temperature. The result is a heat sink which you can put your hand on for about 10 seconds or so.

I think I'd be replacing parts every other year if my bias was set that high on my 30+ year old PA-7A MKII. As Chris said NP likes to bias on the high side; stasis Thresholds from the same era as my NAK are usually set at 100mA, 2.5X more than the NAK

Hi UncleAng,

You do not need to do that. Just run the poor things at the recommended bias levels. Higher bias is not buying you anything at all. There are enough parallel out[put devices so your output impedance is low enough already.

Reality check time. What is the distortion from your speakers? Compare that to the amp. It comes down to the type of distortion where the PA-7 actually performs well. Other amps with the similar numbers may not sound as good. But cranking the bias 2.5X is not helping you at all.

-Chris

You do not need to do that. Just run the poor things at the recommended bias levels. Higher bias is not buying you anything at all. There are enough parallel out[put devices so your output impedance is low enough already.

Reality check time. What is the distortion from your speakers? Compare that to the amp. It comes down to the type of distortion where the PA-7 actually performs well. Other amps with the similar numbers may not sound as good. But cranking the bias 2.5X is not helping you at all.

-Chris

- Home

- Amplifiers

- Pass Labs

- Nakamichi PA-5 upgrades