It compromises Damping Factor. If your voltage source has 0.04 it goes against perfectionism to make it 0.4

But if there is any possibility that the amp is going to face some load with negative angle phase (capacitive) then retain the coil. Again to get 0.4 you need 1.5mH 1mm2 air coil, no way a few turns of an output zobel, Explain exactly what and where you are trying to use or modify.

But if there is any possibility that the amp is going to face some load with negative angle phase (capacitive) then retain the coil. Again to get 0.4 you need 1.5mH 1mm2 air coil, no way a few turns of an output zobel, Explain exactly what and where you are trying to use or modify.

Only Audiobahn can tell us exactly what will happen. From HF spuriae to dangerous levels of quantization noise or, or....If you must absolutely test it by skipping it, use some spare very cheap loudspeaker driver and see if at least does not kill it and that no bad audible distortion comes out. If all goes well enough, then connect your sub and go step by step with the volume listening for distortion. If it still seems ok...well I would not bet on it for prolonged use. Make a spare or get a spare IMHO.

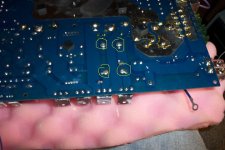

This is a class D amplifier and the big toroid coils are part of the output filter. They are usually in the 10uH to 100uH range. Never power up the amplifier with any of those coils either removed or jumpered, you are likely to blow the switching stage or other components if you do so.

If the magnet wire is damaged, rewind it with same gauge, turns and geometry (be careful not to damage enamel). If the toroid core is damaged, you are in trouble because there are thousands of completely different types looking almost exactly the same and finding a replacement won't be easy at all.

If the magnet wire is damaged, rewind it with same gauge, turns and geometry (be careful not to damage enamel). If the toroid core is damaged, you are in trouble because there are thousands of completely different types looking almost exactly the same and finding a replacement won't be easy at all.

The inductor that failed in your amp is on the secondary side of the power supply before the rail filter caps. The larger diameter inductors to the left are the output filter for the class D section of the amp.

There are lots of amps that don't use secondary inductors. For low power testing, you should be able to jump it out with no problems. You would jump green to green and yellow to yellow. If you jump green to yellow, the amp will likely be damaged.

These inductors fail on a regular basis. They are not well supported by the windings and the insulation wears through. This is a common problem with every wound component in these amps, and all of their clones.

Vibration causes the failure.

An ohm meter that uses DC to measure resistance is not very useful for checking the properties of an inductor (unless you're checking for shorts between windings). If you measured the resistance of the inductors in the output filter, they would essentially read zero ohms to DC but when a high frequency signal is applied to them, they have a very high impedance. If you jumped them out, the amp would fail. This is what happens when they fail (short) and is the reason I suggested that you check them.

There are lots of amps that don't use secondary inductors. For low power testing, you should be able to jump it out with no problems. You would jump green to green and yellow to yellow. If you jump green to yellow, the amp will likely be damaged.

These inductors fail on a regular basis. They are not well supported by the windings and the insulation wears through. This is a common problem with every wound component in these amps, and all of their clones.

Vibration causes the failure.

An ohm meter that uses DC to measure resistance is not very useful for checking the properties of an inductor (unless you're checking for shorts between windings). If you measured the resistance of the inductors in the output filter, they would essentially read zero ohms to DC but when a high frequency signal is applied to them, they have a very high impedance. If you jumped them out, the amp would fail. This is what happens when they fail (short) and is the reason I suggested that you check them.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- Inductor help