ROE, if you mean Roederstein (Germany) makes normal industrial quality. We use them at work and they are carefree (we have bought >1000 000 and they never has caused us trouble) but we had some problems the elelctrolytics. But we were to blaim ourselves because we used them beyond their limits and one day they were slightly better than they promised.....before they were MUCH better than they did promise.

Nowadays we use Rubycon (excellent) and RIFA (the best) and Lelon (seems to be good, so far).

Roederstein has absolutely no high-end reputation but this doesn't mean a thing (according to me).

2.5% polypropulene is quite nice, the green polyester not so bad either.

Nowadays we use Rubycon (excellent) and RIFA (the best) and Lelon (seems to be good, so far).

Roederstein has absolutely no high-end reputation but this doesn't mean a thing (according to me).

2.5% polypropulene is quite nice, the green polyester not so bad either.

Attachments

IMHO, Roederstein does have "high end reputation", at least in Germany.

Some manufacturers point out in their brochures that they are using Roederstein electrolytics - in the power supply.

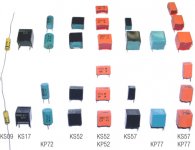

There are many excellent capacitors who have only made it to some local reputation - there is this company EMZ (Elektromanufaktur Zangenstein) which bought the production machines for Styroflex (KS) capacitors from Siemens and continued to make them after Siemens stopped the production...

Now they produce some nice KP capacitors w/ 1% tolerance - I use them quite often.

Some manufacturers point out in their brochures that they are using Roederstein electrolytics - in the power supply.

There are many excellent capacitors who have only made it to some local reputation - there is this company EMZ (Elektromanufaktur Zangenstein) which bought the production machines for Styroflex (KS) capacitors from Siemens and continued to make them after Siemens stopped the production...

Now they produce some nice KP capacitors w/ 1% tolerance - I use them quite often.

AMT-freak said:IMHO, Roederstein does have "high end reputation", at least in Germany.

Some manufacturers point out in their brochures that they are using Roederstein electrolytics - in the power supply.

There are many excellent capacitors who have only made it to some local reputation - there is this company EMZ (Elektromanufaktur Zangenstein) which bought the production machines for Styroflex (KS) capacitors from Siemens and continued to make them after Siemens stopped the production...

Now they produce some nice KP capacitors w/ 1% tolerance - I use them quite often.

I have used these round transparent things but they were soooo sensitive for heat. Hardly possilble to solder at home made pcb's with groundplanes, escpecially those with 70µm (2 oz?)copper.

I think 2.5% is quite enough and if I really want to have an exact value I use my 0.1 % LCR bridge.

But still Roederstein (electrolytics) is worse (if we only talk lifetime) than the other brands we use.

@peranders

I didn't mean those transparent axial Styroflex capacitors... They are available from different sources, mostly 2,5%.

What I meant were the little orange boxes with pins in two opposite corners... They were available as KS and KP, had 1% tolerance and the pin connected to the outer side of the foil was marked - so in your filter, you could connect this pin to GND and you'd have a shielded capacitor

Those were really quality parts!

Here's a picture of the EMZ types

I didn't mean those transparent axial Styroflex capacitors... They are available from different sources, mostly 2,5%.

What I meant were the little orange boxes with pins in two opposite corners... They were available as KS and KP, had 1% tolerance and the pin connected to the outer side of the foil was marked - so in your filter, you could connect this pin to GND and you'd have a shielded capacitor

Those were really quality parts!

Here's a picture of the EMZ types

Attachments

It's dark red with white label and it looks "old". The bottom is yellow and round.

hello.

.......should be elco's with 10uf/40v.........and a plus sign on top (the side of the plus pole).

old parts,e.g. i found them in old b&o receivers and so on..........

greetings

I will have to second Per Anders.

In the past, I have seen blown Roederstein electrolytic caps, I am yet to see a dead Rifa.

Considering that 99% of the electrolytics I use, are Rifa's, and about 0.01% were Roederstein's, the percentage of Roederstein caps in my circuits, has been adjusted to 0%.

Magura

In the past, I have seen blown Roederstein electrolytic caps, I am yet to see a dead Rifa.

Considering that 99% of the electrolytics I use, are Rifa's, and about 0.01% were Roederstein's, the percentage of Roederstein caps in my circuits, has been adjusted to 0%.

Magura

I know this thread is almost 3 years old from last poster. But I happened to have play around with some ROE 2200uf Gold caps. I soldered a pair of these in parallel to the ELNA 6800uf PS filter caps pair of my JLH dual rail class A amp. The sound has definitely sweetened and warmed up a lot. The female vocals have more air and definitely amazing. Acoustic instruments especially guitar sounds real. The improvement is very obvious. Those ROE caps are just NOS and I didn't apply some low voltages across them before I started using them. But the sound improves as I use the amp more. I think the caps started to breaking in. I think they are very good based on my experiment.

no, not that one, but this one:-

http://www.ebay.com/itm/2x-NEW-ROE-GOLD-EGM-2200uF-50V-105C-AUDIO-GRADE-HI-END-CAPS-FOR-AUDIO-/180870975760?pt=Vintage_Electronics_R2&hash=item2a1cc01110

More accurate to say that Roederstein is an industrial manufacturer, which made/makes some parts that qualify as high grade components for audio.

Some of those parts are electrolytics, some are foil caps, a couple of resistor series.

Same goes for Siemens, Valvo, etc.

Good example is Frako.

Most of their manufacture was low-grade stuff, that could be bought at any electronic parts retail store around the corner, cheaper than Siemens or Roederstein.

But an interesting part for audio they came up with in the '80s was the 4-pole lytic capacitor.

(unfortunately, most of the current Jensen aficionados were at that time still wetting their nappies)

Same goes for North American industrial brands, such as Mallory, Cornell Dubilier, Sprague (and it's '80s main competitor, that went to the dogs).

Some of their manufacture series stood out and were used for audio, with good reason.

Back in the 1980s (you know, before the web), the way to hunt parts for audio was by using every possible resource to get your grabby hands on Brand Catalogues, in the Fat and Explicit edition.

The datasheets told if a part/type was good, not the brand label.

Assuming that a brand sucks, based on bad experience with individual types, is just as ignorant as thinking everything is divine if it has the right brand label/logo on it.

(Roederstein EB/EG in the 105C versions were the standard axial caps I used up till the mid '90s, main reason was that they were affordable LL-grades at 100-up wholesale rate. The term Roe-Gold makes me giggle)

Some of those parts are electrolytics, some are foil caps, a couple of resistor series.

Same goes for Siemens, Valvo, etc.

Good example is Frako.

Most of their manufacture was low-grade stuff, that could be bought at any electronic parts retail store around the corner, cheaper than Siemens or Roederstein.

But an interesting part for audio they came up with in the '80s was the 4-pole lytic capacitor.

(unfortunately, most of the current Jensen aficionados were at that time still wetting their nappies)

Same goes for North American industrial brands, such as Mallory, Cornell Dubilier, Sprague (and it's '80s main competitor, that went to the dogs).

Some of their manufacture series stood out and were used for audio, with good reason.

Back in the 1980s (you know, before the web), the way to hunt parts for audio was by using every possible resource to get your grabby hands on Brand Catalogues, in the Fat and Explicit edition.

The datasheets told if a part/type was good, not the brand label.

Assuming that a brand sucks, based on bad experience with individual types, is just as ignorant as thinking everything is divine if it has the right brand label/logo on it.

(Roederstein EB/EG in the 105C versions were the standard axial caps I used up till the mid '90s, main reason was that they were affordable LL-grades at 100-up wholesale rate. The term Roe-Gold makes me giggle)

Attachments

Last edited:

One more (technical) question, folks! Please, it's important!

I have 8 units of 3300uF (rated 100V) Nippon Chemi-com electrolytic caps, fresh new ones and of high ripple current.

And I have an +20 years-old amp in need of replace its power 12,000uF (rated 63V) caps, pretty weak sound.

I don't want to buy another pair of 12,000uF for that. I rather used 4x of these 3300uF 100V caps per rail, making a total of 13,200uF (100V) reservoir of capacitance.

My question now is purely technical: each original 12,000uF 63V have ripple current number of ~5A each. These 3300uF 100V instead have (EACH ONE!) 3,28A of ripple current handling. If I put 4x of them in parallel, will I have 13.12A of ripple current combined in a block of 13,200uF (4x 3300uF) ???

Many thanks!

I have 8 units of 3300uF (rated 100V) Nippon Chemi-com electrolytic caps, fresh new ones and of high ripple current.

And I have an +20 years-old amp in need of replace its power 12,000uF (rated 63V) caps, pretty weak sound.

I don't want to buy another pair of 12,000uF for that. I rather used 4x of these 3300uF 100V caps per rail, making a total of 13,200uF (100V) reservoir of capacitance.

My question now is purely technical: each original 12,000uF 63V have ripple current number of ~5A each. These 3300uF 100V instead have (EACH ONE!) 3,28A of ripple current handling. If I put 4x of them in parallel, will I have 13.12A of ripple current combined in a block of 13,200uF (4x 3300uF) ???

Many thanks!

Last edited:

The main reason to parallel small electrolytic capacitors instead of one biggy.

Which one mainly does with class AB power amps, or e.g. preamps.

In class A power amps, big cans are preferable, as total uF value is the primary target (and large ones have a better/higher uF/volume ratio)

(e.g. Classé, Sphinx, AVM, Swiss Physics, Orpheus)

Which one mainly does with class AB power amps, or e.g. preamps.

In class A power amps, big cans are preferable, as total uF value is the primary target (and large ones have a better/higher uF/volume ratio)

(e.g. Classé, Sphinx, AVM, Swiss Physics, Orpheus)

Last edited:

It's dark red with white label and it looks "old". The bottom is yellow and round.

Be careful with those - they often don't last long. They are in plastic cans, and are usually orange or dark red (photo attached). Some years ago the first job when you got a B&O L or LX TV in for service, was to replace all of them

Frolyt in East Germany made a similar type in white plastic cans - they are terrible also.

Other ROE or Frolyt caps are generally fine - just watch out for the plastic versions.

Just in case other people read through this revived old thread...

Best regards,

Mikkel C. Simonsen

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Parts

- ROE Capacitors