Probably would be a tough thing to tweak up, though, not many knobs (crossover components) to work with. But maybe with some EQ....

I'll bet you'll still have to eq it with some sort of network or active eq to get anything close to flat response due to the falling power response of the driver at high frequencies. You're really just replacing the electrical crossover with a mechanical / acoustical one which is way harder to tune especially since you currently have no model of it. I agree it would be cool if you can get it to work but I'd take the increased sensitivity and increased driver cost any day even for home use.

If the seal is airtight, (like a foam speaker surround) it will dampen the cone, changing it's parameters completely.Basically cut a ring of closed cell foam, epoxy it to the waveguide mouth, and then determine if it causes any kind of rubbing or buzzing. If not, it should seal off the cone 100% from the dust cap of the midrange driver.

Basically we've implemented a mechanical crossover; we've physically seperated the highs from the lows, instead of electrically.

If the seal is not airtight, it will buzz.

Hope you post some on and off axis response curves of what this looks like when you are done!

Art

My "faux-axial" unity horn is looking kinda rough, but it makes music.

The (semi) finished horn

I didn't want to wreck my QSC waveguide, so I used it as a mold. I covered it in candle wax that I heated on the stove to keep the fiberglass from sticking to it.

Here's some detail on the chamber in front of the woofer, which is designed to isolate the edge of the cone from the dustcap.

Here's a video of it playing:

fauxaxial unity horn.mp4 - YouTube

For comparison's sake, here's one of my car audio Unity horns. (Not a good one - or finished.)

johnny cash on unity horn (in a corner).mp4 - YouTube

Here's a JBL array, playing the same song, to give this some context.

3 driver full range-2.mp4 - YouTube

The (semi) finished horn

I didn't want to wreck my QSC waveguide, so I used it as a mold. I covered it in candle wax that I heated on the stove to keep the fiberglass from sticking to it.

Here's some detail on the chamber in front of the woofer, which is designed to isolate the edge of the cone from the dustcap.

Here's a video of it playing:

fauxaxial unity horn.mp4 - YouTube

For comparison's sake, here's one of my car audio Unity horns. (Not a good one - or finished.)

johnny cash on unity horn (in a corner).mp4 - YouTube

Here's a JBL array, playing the same song, to give this some context.

3 driver full range-2.mp4 - YouTube

John,

You might want to try that with one of your cone tweeters. With their extremely low suspension compliance and nonexistent Xmax, you might be able to get tighter spacing for better coupling. Cool concept - I like it!

You might want to try that with one of your cone tweeters. With their extremely low suspension compliance and nonexistent Xmax, you might be able to get tighter spacing for better coupling. Cool concept - I like it!

After a few months of experimentation, I think I'm leaning towards a setup similar to what you are working on. That is, cone tweeters for midrange, and a compression driver at the apex.

I'd hope the faux-axial would be a low cost alternative to a conventional unity horn. But it's Achilles heel seems to be efficiency. In the video* you may notice that it's not as loud as the others, and that's because it isn't! I'd guesstimate that it's limit is about 10dB lower than the others. Even worse, as it gets close to the limit the highs get a little 'shrieky', like any paper cone woofer does. I'm guessing this is the reason that Thiel got a lil' OCD about cone resonances in their fauxaxial.

In my video with the cone tweeters**, it's surprising how smooth they sound, considering the horn has no mouth termination, the hole size was a guess, and I'm only using two midranges. With four midranges, a compression driver, and better engineering, I think this horn could shine.

Last but not least, here's a video of a comparably sized Unity horn, but with phase plugs! I'd mentioned this one a few months back, basically using phase plugs to extend the high frequency response of the midranges. I think this one is audibly superior to the others. In fact, this one could be the basis for a decent Unity horn as well. I guess I'm leaning towards the cone tweeters because the footprint is smaller.

unity with phase plugs-1.mp4 - YouTube

Here's the video with the faux-axial Unity horn:

fauxaxial unity horn.mp4 - YouTube

** Here's the video with the cone tweeters:

unity horn with cone tweeters - YouTube

[/font]

I'd hope the faux-axial would be a low cost alternative to a conventional unity horn. But it's Achilles heel seems to be efficiency. In the video* you may notice that it's not as loud as the others, and that's because it isn't! I'd guesstimate that it's limit is about 10dB lower than the others. Even worse, as it gets close to the limit the highs get a little 'shrieky', like any paper cone woofer does. I'm guessing this is the reason that Thiel got a lil' OCD about cone resonances in their fauxaxial.

In my video with the cone tweeters**, it's surprising how smooth they sound, considering the horn has no mouth termination, the hole size was a guess, and I'm only using two midranges. With four midranges, a compression driver, and better engineering, I think this horn could shine.

Last but not least, here's a video of a comparably sized Unity horn, but with phase plugs! I'd mentioned this one a few months back, basically using phase plugs to extend the high frequency response of the midranges. I think this one is audibly superior to the others. In fact, this one could be the basis for a decent Unity horn as well. I guess I'm leaning towards the cone tweeters because the footprint is smaller.

unity with phase plugs-1.mp4 - YouTube

Here's the video with the faux-axial Unity horn:

fauxaxial unity horn.mp4 - YouTube

** Here's the video with the cone tweeters:

unity horn with cone tweeters - YouTube

[/font]

I knew about you trying the phase plugs, but had not actually seen it until now. I love the look of the Lowther light bulb style phase plugs. In my mind I kept thinking about a more conventional compression driver style phase plug - SURPRISE!

Sometimes I wish I could throw things together like you do. I'm just too analytical and can't bring myself to do it. Only if I could half-a$$ things half as good as you. 😀 I commend you on your abilities to knock out quick prototypes for testing. Its more efficient than making it all nice and pretty then have it fail anyway.

I keep coming back to the Misco RDC3T-A. It just works so damn well in a Unity. For the longest time I was fighting it because I couldn't get the thing to turn off in the high frequencies. This was messing up the frequency response of the compression driver and the overall phase response. Finally, I made a breakthrough in my Akabak script and found a rather simple solution. I ended up inserting a series resonance attenuation circuit across the RDC3T-As and it fixed it. It is a 3.3 ohm resistor, 14uF cap, and 0.15mH coil in series placed across the RDC3T-As which are wired for series parallel to maintain 8 ohms. A few more tweaks and I'll be satisfied enough to make a little bit more sawdust. Yeah, I know I'm slow as molasses, but that's the way I'm wired.

Sometimes I wish I could throw things together like you do. I'm just too analytical and can't bring myself to do it. Only if I could half-a$$ things half as good as you. 😀 I commend you on your abilities to knock out quick prototypes for testing. Its more efficient than making it all nice and pretty then have it fail anyway.

I keep coming back to the Misco RDC3T-A. It just works so damn well in a Unity. For the longest time I was fighting it because I couldn't get the thing to turn off in the high frequencies. This was messing up the frequency response of the compression driver and the overall phase response. Finally, I made a breakthrough in my Akabak script and found a rather simple solution. I ended up inserting a series resonance attenuation circuit across the RDC3T-As and it fixed it. It is a 3.3 ohm resistor, 14uF cap, and 0.15mH coil in series placed across the RDC3T-As which are wired for series parallel to maintain 8 ohms. A few more tweaks and I'll be satisfied enough to make a little bit more sawdust. Yeah, I know I'm slow as molasses, but that's the way I'm wired.

IA few more tweaks and I'll be satisfied enough to make a little bit more sawdust. Yeah, I know I'm slow as molasses, but that's the way I'm wired.

Join the club... I've got all these great drivers sitting around that just need some horns made for them, but it takes me forever to get around to making them anymore. Currently I'm rationalizing this as just needing a better dust collector and enclosure on my cnc router so it doesn't coat my garage in saw dust when I use it, but that's yet another project. It's a vicious cycle.

Sometimes I wish I could throw things together like you do. I'm just too analytical and can't bring myself to do it. Only if I could half-a$$ things half as good as you. 😀 I commend you on your abilities to knock out quick prototypes for testing. Its more efficient than making it all nice and pretty then have it fail anyway.

Thanks!

One thing that's absolutely KILLING my progress lately is the lack of a good way to do measurements. I used to have a PC running 24x7 in the garage, and that gave me the ability to do measurements in a matter of seconds. Literally turn on the monitor, hit the button on Arta, and *voila*, I was done.

The stupid PC crashed though - all the dust is murder on the moving parts.

I keep telling myself that I'll figure out a faster way to do measurements; but I'll probably just have to break down and build another dedicated PC for it.

It's such a p.i.t.a, because it seems completely wasteful to dedicate an entire PC to something so trivial.

But the alternative is to use my laptop, and that means I'd have to spend 30 minutes plugging in cables, setting levels, double checking, etc... Just to make a measurement that takes less than a minute.

You could have me make your horns for far less money than a better dust collector and enclosure for your cnc router, I don't mind sawdust in my shop.Join the club... I've got all these great drivers sitting around that just need some horns made for them, but it takes me forever to get around to making them anymore. Currently I'm rationalizing this as just needing a better dust collector and enclosure on my cnc router so it doesn't coat my garage in saw dust when I use it, but that's yet another project. It's a vicious cycle.

I could even lighten your driver load in trade for horns 😉.

Seriously, if any one has a design they want to pursue, but for whatever reason can't DIY, I'm available to prototype, measure and do the tweaking needed for a relatively low cost.

Art

Thanks for the offer, but I just need to suck it up and make some horns. I've actually had a pair of LeCleac'h horns cut for several years now and just need to finish sanding them. I've been working on a cabinet for a JBL 2245 to sit one of them on top of, but I've got too many other projects going at the same time. Eventually I'd like to do another unity horn as well to take advantage of some of the better drivers everybody's finding here.

Since I couldn't get that Celestion 4", I went for the Misco RDC3T-A. It works damn well from what I've done with them so far. The best thing about them is that they were originally designed as a tweeter so once horn loaded they present a nearly resistive impedance. This makes it easier to use in a Synergy horn because you don't have to worry about its resonance screwing up the lower end frequency response. Its low end response is then purely controlled by the local area of expansion (i.e. local flare rate). I ordered a half case of them (30) and tested them all after breaking them in for 48 hours. Below are the overall average T/S parameters. The only way to come up with Vas was to use the sensitivity method with Smith & Larson Speaker Tester.

Fs = 1240Hz

Re = 7.76 ohms

Qes = 6.5631

Qms = 4.9345

Qts = 2.7557

Le = 0.4587 mH

Vas = 0.0559 L

Bl = 3.36

Cms = 3.36E-05

Rms = 0.77

Sd = 34.21 sq cm

My woofer tester wouldn't give me a proper measurement of the Goldwood GT-25, so I had to chop one up to figure out it's parameters. If you use my parameters in hornresp, be sure to add a back chamber, which will raise the FS and QTS to match the sealed back parameters.

Fs = 448Hz

Re = 7.19 ohms

Qes = 8.02

Qms = 8.51

Qts = 4.13(!)

Le = 0.38 mH

Vas = 0.06 L (guesstimate based on JLH's measurements of the similar Misco)

Sd = 39.59 sq cm[/QUOTE]

I'm making dust, just not wood dust...plenty of fiberglass and bondo dust though. 20 something years of custom car audio fabrication coming into play.

Gotta order another gallon of resin and some 8oz 2x2 twill fiberglass cloth...which is badassed since I can drape it over the mold in one piece and only need 2 layers to get the thickness I need. Two single piece layers giving me the thickness of about 10 layers of mat in a very easy and non messy lay up. Wet both pieces out together, cover the mold, work the bubbles out, and done...5 minutes.

Gotta order another gallon of resin and some 8oz 2x2 twill fiberglass cloth...which is badassed since I can drape it over the mold in one piece and only need 2 layers to get the thickness I need. Two single piece layers giving me the thickness of about 10 layers of mat in a very easy and non messy lay up. Wet both pieces out together, cover the mold, work the bubbles out, and done...5 minutes.

Runs off to see what John's filer does on the Miscos...

They are pretty cute little speakers...🙂

They are pretty cute little speakers...🙂

Member

Joined 2009

Patrick, please let me send you a can of Partall Paste wax...killing me with the mold release stuff. Or you can have the rest of my can of Meguiars #8 mold release wax.

If you had some way to spray it, I would send you some of my Partall PVA mold release. Put that on top of the wax, and nothing is sticking.

If you had some way to spray it, I would send you some of my Partall PVA mold release. Put that on top of the wax, and nothing is sticking.

Member

Joined 2009

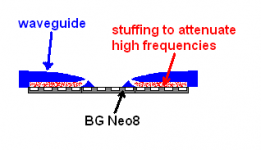

What do you guys think about building a faux-axial waveguide for the BG Neo8?

The high sensitivity, low distortion and extended response make it a great candidate.

View attachment 272349

my thoughts here

Taming the NEO8 - DIYMA.com - Scientific Car Audio - Truth in Sound Quality

- Home

- Loudspeakers

- Multi-Way

- Suitable midrange cone, for bandpass mid in Unity horn