Dominick, sealing your boxes, whether they be ported, or acoustic suspension, is a good idea, regardless of how accurate the joints are in your construction. You would be suprised how many joints that appear to be tight and leak free, actually do develope leaks, if not initially, but as time passes. I use silicone sealant, the clear kind. GE their 'best' version, but at around 5 bucks a tube, its certainly worth the peace of mind you will get. I run a bead along the joints and then use my finger to smooth it into the corners. I also use it to mount drivers, as it effectively decouples the drivers from the box, eliminating unwanted vibration, that is inherent with good bass response, regardless of how strong your box is built...... One caveat though: Silicone has, as its solvent, acetic acid. This takes several hours, or even a few days to evaporate. I have found after taking apart an enclosure that I used silicone with that some metal parts on the backs of my drivers showed evidence of corrosion, basically due to the acetic acid. So if you use silicon, allow a few days for it to fully cure, to allow the acetic acid to evaporate, before you seal the rest of the enclosure with your baffle. It is very strong with a viscosity which assuredly will get into any hidden voids, and it stays flexible, even after 20 years, so it will do the job. Respectfully.......Omni

Hi Cal,

I've had problems with it on anything but clean MDF, yes. But since that's all I use for the main box, I never thought of including that warning.

Cheers!

Cal Weldon said:Hi Gregg,

I recommend against the use of any silicone based caulk including the paintable version mixed with latex.

Silicones require a good a mount of prep work before application and this is something I've rarely seen on the inside of a box.

I've had problems with it on anything but clean MDF, yes. But since that's all I use for the main box, I never thought of including that warning.

Cheers!

Cal Weldon said:

The man wants to know what caulk to use not that

you guys are so good you don't have to use it.

Hi Cal,

You are missing the point, the man shouldn't need to use caulk.

All we are saying is that mechanically sound joints by default

will be sealed, even if this is not obviously apparent from the

inside of the enclosure. If a person wants the inside corners

to obviously look sealed a bead of PVA will usually do the job.

sreten said:You are missing the point, the man shouldn't need to use caulk.

The point being that the man asked about caulking not how to make a perfect joint. C'mon sreten we were all there at one point.

If a person wants the inside corners to obviously look sealed a bead of PVA will usually do the job.[/B]

PVA is not, and never was intended as a caulk. It is a bonding agent not a gap filler.

Having said that, I confess to tooling the excess glue into the corners to act as a sealant also. Often with no further sealant added, but this is because my joints are tight to begin with.

I was trying to give the man a serious answer. Suggesting butyl or urethane based caulks for boxes is sage advice.

Danger; Will Robinson!

Many of the sealants/caulks mentioned here outgas strong solvents. Strong solvents are not good for your fancy expensive drivers. They will attack the glues or even the cone materials.

Smell the stuff, if it makes your head spin don't use it (ps. remember to stop smelling)

There are a number of clay like sealants that never harden (well almost never) the ones used to mount drivers seem fine to me, Why not?

A big question, will you ever need to open the box? On your home made speakers you will say no, but you are lying, they will be opened many times because you will keep making them better.

Many of the sealants/caulks mentioned here outgas strong solvents. Strong solvents are not good for your fancy expensive drivers. They will attack the glues or even the cone materials.

Smell the stuff, if it makes your head spin don't use it (ps. remember to stop smelling)

There are a number of clay like sealants that never harden (well almost never) the ones used to mount drivers seem fine to me, Why not?

A big question, will you ever need to open the box? On your home made speakers you will say no, but you are lying, they will be opened many times because you will keep making them better.

I'm using Polyurethane Liquid Adhesive, from the manufacturer, Lepage (in Canada):

See: http://www.lepageproducts.com/products/detail.asp?catid=20&subid=180&plid=688

-A super strong polyurethane adhesive that is highly waterproof and weatherproof

-100% Waterproof - can be used outdoors and withstand harsh environments

-Fast Setting, Clamp-free after 1 hour

-Bonds wood, foam, metal, stone, concrete, leather, marble, glass, many plastics, chipboard, laminate and more

-Flexible

-Low odour & Paintable

It cures with humidity in the air. Very liquid at time of the application, it fills all joints perfectly, then it will expand (without force, not forcing the joints) but filling them even more. Then it will hardened but will stay slightly flexible. You will have a perfectly sealed box with this adhesive. It is also a very strong adhesive, and will increase the box joints strenght.

See: http://www.lepageproducts.com/products/detail.asp?catid=20&subid=180&plid=688

-A super strong polyurethane adhesive that is highly waterproof and weatherproof

-100% Waterproof - can be used outdoors and withstand harsh environments

-Fast Setting, Clamp-free after 1 hour

-Bonds wood, foam, metal, stone, concrete, leather, marble, glass, many plastics, chipboard, laminate and more

-Flexible

-Low odour & Paintable

It cures with humidity in the air. Very liquid at time of the application, it fills all joints perfectly, then it will expand (without force, not forcing the joints) but filling them even more. Then it will hardened but will stay slightly flexible. You will have a perfectly sealed box with this adhesive. It is also a very strong adhesive, and will increase the box joints strenght.

Dominick22 said:re-opening...or the ant to do so is something that I am pretty worried about. Once it is sealed, that is it. It feels so final...like I am marrying the project as it is forever.

Shoe Goo will provide a perfectly airtight albeit potentially messy seal for any driver regardless of what it's screwed on; wood, metal or synthetic materials.

And trust me it will definitely be permanent, divorce won't be an option. Officially it's semi-liquid rubber in a tube but the adhesive properties of the stuff is of an alien nature if you ask me, must be why NASA uses it, makes superglue look like scotch tape.

I don't recommend doing this but if you really want to make sure you'll never itch to remove the drivers again...

On a side note Shoe Goo is unsurpassable as an adhesive for Xover parts once the final design is achieved. It will make a 10-lb coil stand upright on its board forever even if said board is upside down and subjected to massive vibrations.

I think there may have been a lack of clarity in my original post. I suppose if you are just building a kit and plan to make no changes then the whole thing can be built more or less permanently the first time.

Me, I think I can make it better and sometimes I can. I say glue the box and let it set up. And depending on the design, all except either the front baffle or back plate for access.

After that, here's my opinion.

1. Do not use any sealants that outgasses strong solvents on the loose panel or drivers (Shoe Goo) they might damage your drivers.

2. During development the box must be correctly sealed or you will get the wrong acoustic answers.

3. If you use a sealant that doesn't set up, and doesn't outgas during development, why them switch to a permanent glue later?

Years later, I still think of experiments (wow, would that capacitor sound better in the crossover?)

Enjoy, building this stuff is a great way to save on products you can't afford. 'Course you'll spend ten times over on time, but it's a hobby, right?

Me, I think I can make it better and sometimes I can. I say glue the box and let it set up. And depending on the design, all except either the front baffle or back plate for access.

After that, here's my opinion.

1. Do not use any sealants that outgasses strong solvents on the loose panel or drivers (Shoe Goo) they might damage your drivers.

2. During development the box must be correctly sealed or you will get the wrong acoustic answers.

3. If you use a sealant that doesn't set up, and doesn't outgas during development, why them switch to a permanent glue later?

Years later, I still think of experiments (wow, would that capacitor sound better in the crossover?)

Enjoy, building this stuff is a great way to save on products you can't afford. 'Course you'll spend ten times over on time, but it's a hobby, right?

«What should I use to make sure that the seams where the wood meets is seemless?»

Well, yeah, nobody mentioned how to check the box's impermeability. In my case I had a port, so I could blow throw it and have another guy listen/feel if somewhere the air is leaking out.

Another method mentioned in an old Soviet book is the following:

Slightly press the woofer inside the box and wait for a couple of minutes. Then release it. If it returns to its initial potion quickly then you have a leak. In a well-sealed enclosure the woofer will crawl back slowly because the lack of significant leaks won't let the air be sucked in rapidly.

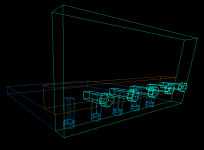

I used 12m plywood sheets fastened with wood screws through additional wooden bars laid along the inside corners, as shown on the picture. The bars were glued to the plywood. After all that I had to smear the inside corners with a sealing compound that has a good adhesion to wood and never fully hardens.

«why do you think you want to seal a speaker box? - look up atmospheric pressure variations - room pressure changes from storm fronts, maybe even wind gusts could move a truely "sealed box" driver beyond its Xmax»

Hah, it's imposible to seal it that good!

Well, yeah, nobody mentioned how to check the box's impermeability. In my case I had a port, so I could blow throw it and have another guy listen/feel if somewhere the air is leaking out.

Another method mentioned in an old Soviet book is the following:

Slightly press the woofer inside the box and wait for a couple of minutes. Then release it. If it returns to its initial potion quickly then you have a leak. In a well-sealed enclosure the woofer will crawl back slowly because the lack of significant leaks won't let the air be sucked in rapidly.

I used 12m plywood sheets fastened with wood screws through additional wooden bars laid along the inside corners, as shown on the picture. The bars were glued to the plywood. After all that I had to smear the inside corners with a sealing compound that has a good adhesion to wood and never fully hardens.

«why do you think you want to seal a speaker box? - look up atmospheric pressure variations - room pressure changes from storm fronts, maybe even wind gusts could move a truely "sealed box" driver beyond its Xmax»

Hah, it's imposible to seal it that good!

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Best Caulking for speaker box building?