Hi i could do with some advise on my 1st diy speaker project and realised this is the best place. Ive built a pair of 20 litre 18mm mdf cabinets with 4mm bitumen pads and 8mm felt material on walls except the baffle, two 'picture frame' braces above and below the woofers, using Seas U18RNX/P woofers and Seas 27TBFC/G tweeters with external bi-wired crossovers using ClarityCap ESA throughout crossed over at 2.2kHz, QED XT Silver Anniversary cables throughout. They have had plenty of run-in time and they sound great but i think the tweeter is a little bright ive not finished the cosmetics yet and plan on rounding the baffle edges to help diffraction and flush mounting the tweeter, will this help with the brightness? It sounds like the phase is out the tweeter sounds louder than the woofer, do i unwind the inductors or try a 0.2 ohm increase on the tweeter resistors? Or is it the QED cabling? I can also move the tweeter closer to the woofer if that may help. Thanks in advance!

Last edited:

the caps and cabling aren't the problem. Crossover design or implementation is. Which brand of cap is far far less important than the right value of cap!

Can you post crossover details? Did you design yourself? If so - did you take measurements or can you post the crossover simulation you did?

Can you post crossover details? Did you design yourself? If so - did you take measurements or can you post the crossover simulation you did?

Thanks for the reply and i will invest in some measuring gear soon as and try a few different resistors.

at the very least, make sure you always multimeter measure DC resistance across the speaker terminals before you hook it up to your amp for a test.

Ideally using measuring gear, you'd be able to do an impedance sweep which will a) confirm your crossover is wired correctly and b) check for impedance minimums which will stress an amplifier.

If you are simply looking to tweak (ie. increase) series tweeter resistance to pad it down a bit - that is quite safe to do (but depending on amount, you *will* affect phase and tracking through the crossover region and without the ability to measure, you could introduce other sound quality problems). In speaker design, a change to fix one problem rarely affects only one problem!

the caps and cabling aren't the problem. Crossover design or implementation is. Which brand of cap is far far less important than the right value of cap!

Can you post crossover details? Did you design yourself? If so - did you take measurements or can you post the crossover simulation you did?

cheers dave ive read about the design being more important and can understand now (leanings dam exspensive ha) I just chose the crossover frequency the guy at a uk supplier designed it, sorry cant seem to upload the pic the tweeter has a 1.5 ohm in series and 18 ohm in parallel x3 1.5 ohm and x2 15 ohm

at the very least, make sure you always multimeter measure DC resistance across the speaker terminals before you hook it up to your amp for a test.

Ideally using measuring gear, you'd be able to do an impedance sweep which will a) confirm your crossover is wired correctly and b) check for impedance minimums which will stress an amplifier.

If you are simply looking to tweak (ie. increase) series tweeter resistance to pad it down a bit - that is quite safe to do (but depending on amount, you *will* affect phase and tracking through the crossover region and without the ability to measure, you could introduce other sound quality problems). In speaker design, a change to fix one problem rarely affects only one problem!

great advice dave i've done the multimetre test on xovers gonna invest in some measuring gear sharpish

yeah think i'll try some resistors i did change the polarity which helped

Have a read of this, assuming you haven't already - Link

wow great link...wish i'd seen this before i did my x-overs thanks again

great advice dave i've done the multimetre test on xovers gonna invest in some measuring gear sharpish

yeah think i'll try some resistors i did change the polarity which helped

A basic measurement setup need not be expensive.

I run a windows 98 PC, 16-bit soundcard and speakerworkshop - with a claudio negro cable jig.

the most expensive part was buying a measurement microphone (behringer ECM8000), mic preamp with phantom power (since my sound card cannot power the mic) and an XLR cable to connect the mic to the pre-amp.

There are more choices now with free measurement software. There are also more comprehensive software packages.

you can do very well with simulation techniques (as per link above). But I think a lot of variables are removed when you can actually measure your own drivers in their own cabinet with actual phase to accurately model crossovers. It also gives you the ability to confirm your design by measuring on completion and tweaking with confidence.

A basic measurement setup need not be expensive.

I run a windows 98 PC, 16-bit soundcard and speakerworkshop - with a claudio negro cable jig.

the most expensive part was buying a measurement microphone (behringer ECM8000), mic preamp with phantom power (since my sound card cannot power the mic) and an XLR cable to connect the mic to the pre-amp.

There are more choices now with free measurement software. There are also more comprehensive software packages.

you can do very well with simulation techniques (as per link above). But I think a lot of variables are removed when you can actually measure your own drivers in their own cabinet with actual phase to accurately model crossovers. It also gives you the ability to confirm your design by measuring on completion and tweaking with confidence.

am familiar and impressed with the behringer mics and their other equipment i was gonna ask if the quality of mic would help i've got a good shure one about

am familiar and impressed with the behringer mics and their other equipment i was gonna ask if the quality of mic would help i've got a good shure one about

Any omnidirectional mic should be fine.

From memory - my ECM8000 is reasonably flat between about 100Hz and 10Khz. good enough for 2 or 3 way designs.

I compared it with a calibrated AKG and the ECM was almost identical except the peaking above 10KHz.

I created my own calibration file by setting up a test baffle the same and using the same tweeter (known to measure consistently) and did a delta between my measurement and the reference measurement. This seems to work well.

The sure should be fine - but you could use the above technique to validate calibration

Here's the Seas design Idunn that uses the same drivers.

Is it this design that you used ?

You can easily adjust the L-pad of the tweeter, instead of 1 and 10, try 1.5 and 6.8 ohm.

Is it this design that you used ?

You can easily adjust the L-pad of the tweeter, instead of 1 and 10, try 1.5 and 6.8 ohm.

Last edited:

i will try that technique with the mic thanks my friend has has the same issues with his 2-ways with smaller seas woofers dxt tweeters same design x-overs with different values and Jantzen caps.

We will take it one step further with measurement equipment and really get tweaking.

What material would be best for the baffle rubberised paint, leather etc?

We will take it one step further with measurement equipment and really get tweaking.

What material would be best for the baffle rubberised paint, leather etc?

Here's the Seas design Idunn that uses the same drivers.

Is it this design that you used ?

You can easily adjust the L-pad of the tweeter, instead of 1 and 10, try 1.2 and 6.8 ohm.

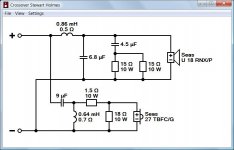

Similar design as on your link w/o L-Pad woofer has resistors and no C2

C1 9uF L1 0.64 R1 1.5 Ohm R2 18 Ohm

C3 6.8uF L2 0.86 HAS 4.5uF and x2 15 Ohm resistors is parallel before the woofer

Last edited:

Hi,

The only problem with the diyaudio link on designing crossovers

using software is that there is far too much emphasis on zobels.

Go with the Idunn x/o and minor treble tweaking to R1 IMO.

rgds, sreten.

Better is :

http://audio.claub.net/Simple Loudspeaker Design ver2.pdf

FRD Consortium tools guide

Designing Crossovers with Software Only

The only problem with the diyaudio link on designing crossovers

using software is that there is far too much emphasis on zobels.

Go with the Idunn x/o and minor treble tweaking to R1 IMO.

rgds, sreten.

Better is :

http://audio.claub.net/Simple Loudspeaker Design ver2.pdf

FRD Consortium tools guide

Designing Crossovers with Software Only

Last edited:

For what is that needed ??? It will attenuate the woofer a lot.x2 15 Ohm resistors is parallel before the woofer

That's a completely different crossover.

If the cabinet has the same dimensions (width) you could try the Idunn crossover.

Last edited:

Hi,

The only problem with the diyaudio link on designing crossovers

using software is that there is far too much emphasis on zobels.

Go with the Idunn x/o and minor treble tweaking to R1 IMO.

rgds, sreten.

Better is :

http://audio.claub.net/Simple Loudspeaker Design ver2.pdf

FRD Consortium tools guide

Designing Crossovers with Software Only

My tweeters are different to the Idunn

H1212-06 27TBFC/G

It has a different resonance frequency, does that matter?

For what is that needed ??? It will attenuate the woofer a lot.

That's a completely different crossover.

If the cabinet has the same dimensions (width) you could try the Idunn crossover.

its the same width but different tweeter

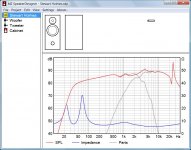

The crossover obviously is a theoretical design with a zobel on the woofer and two second order filters at 2.1 kHz. Unfortunately it doesn't consider baffle step and actual driver frequency response, thus the acoustic result is not that great.

For the attached simulation I assumed the same cabinet and vent as Seas Idunn. I hope the crossover is right, otherwise correct me please.

For the attached simulation I assumed the same cabinet and vent as Seas Idunn. I hope the crossover is right, otherwise correct me please.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Help with my 1st project a 2-way with Seas drivers