actually it's a laser CNC and cuts only Plexiglas and thin aluminumAriyahoor, you could CNC a center ring - yes?

Also any small PVC pipe around, black maybe?

You could cut small "axels".

Is this a full sheet of plywood machine?

btw, if you have a good helper you can wind them quickly and neatly with a battery drill (makeshift arbor). The helper needs to spool the wire with a lot of friction.

I use a generator, resistor, 2-way switch and volt meter to check values, you can measure them with a good deal of accuracy, down to one turn of wire.

yes but winding by hand will lead a more apple-pie order result but it's time-consuming

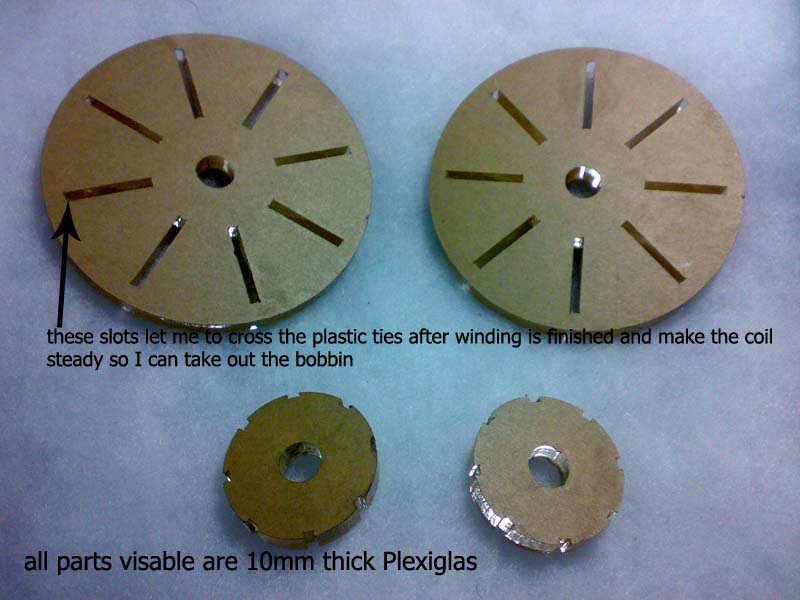

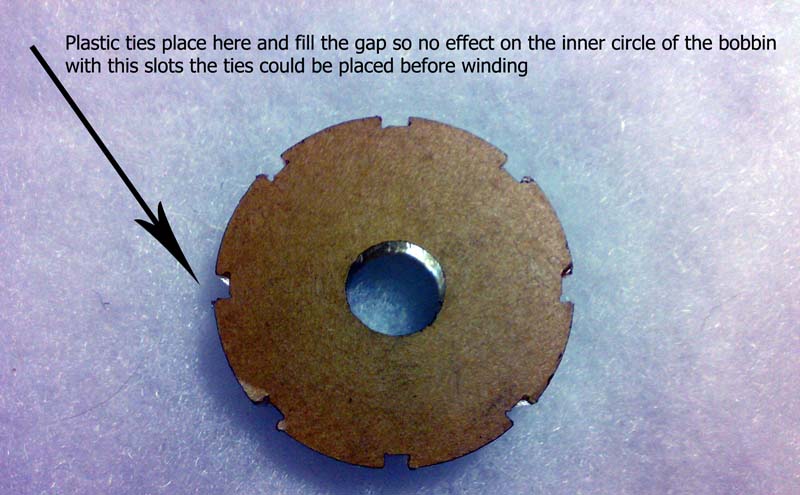

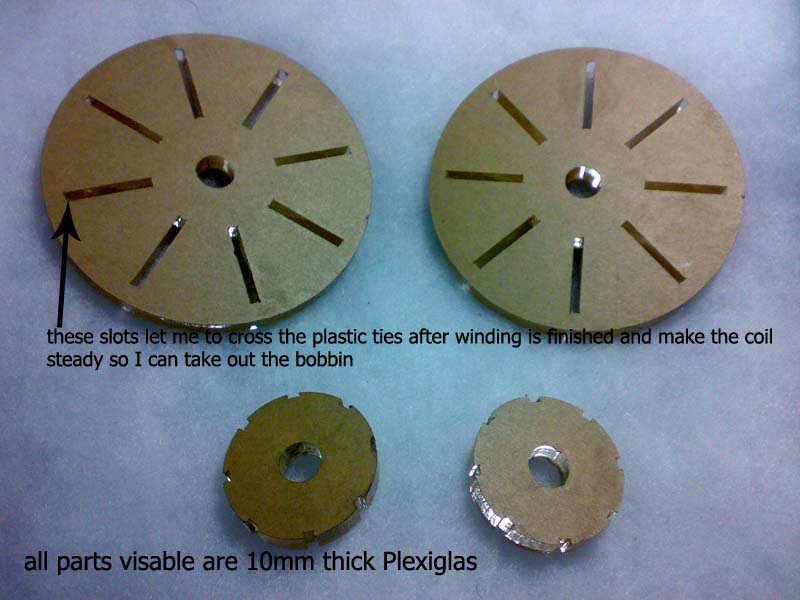

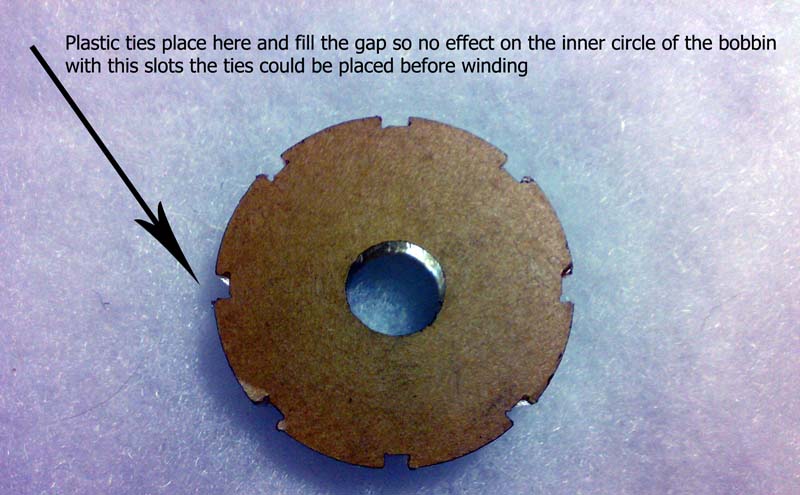

I cut some other bobbin and holder today and I think would be nice for everyone to see what I've done

....I made a similar error "tidily" fitting a capacitor inside a coil, which AllenB put me right about....

That's interesting, I have made the same error in the past, before "knowing better." For sure, a cap laid through the inside of an inductor would effect the value of the inductor. It didn't even occur to me years ago though.

Regards,

Eric

I cut new parts using laser. it worked perfectley  I'm happy with the result... easy way and effective. I hope this will be some kinda orientation

I'm happy with the result... easy way and effective. I hope this will be some kinda orientation

the tricks are:

not using very thick plastic ties because they won't bend well and coil will get loose

lubricate the edges before taking out the bobbin

enjoy it!

pictures talk more than words:

(the inductor in picture is a 0.25 mH using 18# wire)

the tricks are:

not using very thick plastic ties because they won't bend well and coil will get loose

lubricate the edges before taking out the bobbin

enjoy it!

pictures talk more than words:

(the inductor in picture is a 0.25 mH using 18# wire)

Attachments

Last edited:

I'll tell you what, I removed aluminum core and inductance doesn't change even a bit!  I think it's because the aluminum core is an empty pipe with ~1mm thickness

I think it's because the aluminum core is an empty pipe with ~1mm thickness  if the inductance is what should be, so a little bit of aluminum won't effect the sound. castigate me if I'm wrong

if the inductance is what should be, so a little bit of aluminum won't effect the sound. castigate me if I'm wrong

I think that an aluminium pipe used as a coil former will change the inductor characteristics. Without a magnetic core the coupling between the winding and the aluminium isn't great so I guess that's why the inductance measured hasn't changed though it would be interesting to know the measurement frequency used. The other characteristic is the loss or Q and I would expect the aluminium former to have changed that.

I'm not sure how much that will effect the cross over performance or sound though.

I'm not sure how much that will effect the cross over performance or sound though.

I think that an aluminium pipe used as a coil former will change the inductor characteristics. Without a magnetic core the coupling between the winding and the aluminium isn't great so I guess that's why the inductance measured hasn't changed though it would be interesting to know the measurement frequency used. The other characteristic is the loss or Q and I would expect the aluminium former to have changed that.

I'm not sure how much that will effect the cross over performance or sound though.

actually I use an standard LCR meter

Look up "crystal radio" on the web and you will see a lot of hobbyists constructing beautiful hand made coils and aiming for the highest Q possible at RF frequencies. They seem to use a lot of plexiglass, nylon and delrin. Wood as a former is known to give a little lower Q.

This is at more critical RF frequencies.

Nice work!

David S.

This is at more critical RF frequencies.

Nice work!

David S.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- quick question about inductor