It's that time of the year when I get the itch to build more speakers. 🙂 Even though I have TOO many projects already under way, none have the appeal of a new major speaker project.

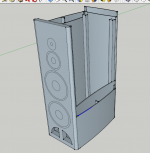

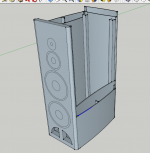

These are to be large speakers, room dominator's - rough initial estimates put the internal volume at around 300 litres, approximately 50" tall, 26" deep and 16" wide. They will have two 12" woofers each, a 7" mid (actually a midwoofer) and a 1" silk dome, horn loaded tweeter.

They will be actively driven using a DCX2496 as the crossover.

The drivers:

Custom 12" woofers from Eminence. Bought from Davygrvy on this forum, measured specs HERE.

The mid is the PL18 from Vifa. I have used this driver a few times before and love the way it sounds. I think it is very hard to beat in the midrange.

The tweeter is the Morel cat378. I haven't heard this driver in person but reviews are very good and it would be perfect for this. I wanted a horn loading on the tweeter and originally I planed to shape the front baffle this way. This tweeter seems to have what I need.

These are to be large speakers, room dominator's - rough initial estimates put the internal volume at around 300 litres, approximately 50" tall, 26" deep and 16" wide. They will have two 12" woofers each, a 7" mid (actually a midwoofer) and a 1" silk dome, horn loaded tweeter.

They will be actively driven using a DCX2496 as the crossover.

The drivers:

Custom 12" woofers from Eminence. Bought from Davygrvy on this forum, measured specs HERE.

The mid is the PL18 from Vifa. I have used this driver a few times before and love the way it sounds. I think it is very hard to beat in the midrange.

The tweeter is the Morel cat378. I haven't heard this driver in person but reviews are very good and it would be perfect for this. I wanted a horn loading on the tweeter and originally I planed to shape the front baffle this way. This tweeter seems to have what I need.

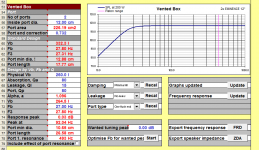

The box will be vented to get the most out of those woofers. Using Unibox and the measured T/S parameters I have come up with what looks to be a pretty good compromise of response, low end extension and size:

I have the box volume at 260 litres, leaving some space for the mid enclosure, ports, etc. There will be 2 ports - 12cm diameter, 27cm long. Box is tuned to 27Hz and F3 is ~28Hz.

It will easily handle 200 watts without running reaching its excursion limit:

So far so good.

🙂

I have the box volume at 260 litres, leaving some space for the mid enclosure, ports, etc. There will be 2 ports - 12cm diameter, 27cm long. Box is tuned to 27Hz and F3 is ~28Hz.

It will easily handle 200 watts without running reaching its excursion limit:

So far so good.

🙂

The mid will be housed in its own sealed enclosure and will have fairly good low end response. It will most likely be driven low pass only through the DCX since it is more than capable down there. Box volume will 15 or 20 litres and deep to reduce the chance of reflection back through the cone.

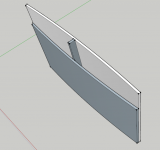

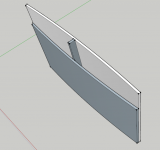

Now for some construction details. I've been wanting to try out an idea I've had for a while - a different way to build the panels of the box. Basically here's the idea:

It is a sandwich but with a twist: the inner and outer skins are joined at the edge and bowed apart in the middle. It is my belief that this will make one hell of a stiff panel, especially when it has been filled with pourable urethane foam. The skins of the panels will be 1/4" hardboard and the idea is to use these panels on 5 sides with a traditional solid front baffle. It will be tricky to put together, especially where the sides meet the bottom and top (compound curves to deal with) but I'm up for the challenge.

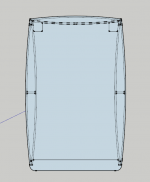

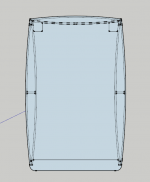

Here's a view of the box from above looking down:

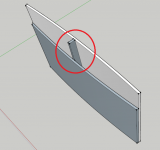

And a view of the overall construction with cut-away view:

I'm not sure yet about what material I'll use for the baffle. I'm considering solid hardwood but this is a risky choice - it would need to be ultra dry to use here to avoid movement.

Now for some construction details. I've been wanting to try out an idea I've had for a while - a different way to build the panels of the box. Basically here's the idea:

It is a sandwich but with a twist: the inner and outer skins are joined at the edge and bowed apart in the middle. It is my belief that this will make one hell of a stiff panel, especially when it has been filled with pourable urethane foam. The skins of the panels will be 1/4" hardboard and the idea is to use these panels on 5 sides with a traditional solid front baffle. It will be tricky to put together, especially where the sides meet the bottom and top (compound curves to deal with) but I'm up for the challenge.

Here's a view of the box from above looking down:

And a view of the overall construction with cut-away view:

I'm not sure yet about what material I'll use for the baffle. I'm considering solid hardwood but this is a risky choice - it would need to be ultra dry to use here to avoid movement.

Last edited:

Hi Andrew,

Hardboard is high density fiberboard and probably has high tensile / compressive strength. Don't forget the curvature and how that will stiffen the panel vertically and transfer the load to the edge. Once filled with 4lb foam, it will be hard to match for stiffness.

I did a bit of a mock-up of the side and back panel sections today:

And a closeup of the vertical corner:

I used 10 degree fillets of softwood at the vertex of the panel to increase gluing surface. The vertical corners will have solid wood cleats (as seen in the pic above) that run from top to bottom to reinforce this joint.

All in all it should be a whole lot of fun to build and I'll post pics along the way showing as much detail as possible.

EDIT: Oops, I guess Andrew deleted his post.

Hardboard is high density fiberboard and probably has high tensile / compressive strength. Don't forget the curvature and how that will stiffen the panel vertically and transfer the load to the edge. Once filled with 4lb foam, it will be hard to match for stiffness.

I did a bit of a mock-up of the side and back panel sections today:

And a closeup of the vertical corner:

I used 10 degree fillets of softwood at the vertex of the panel to increase gluing surface. The vertical corners will have solid wood cleats (as seen in the pic above) that run from top to bottom to reinforce this joint.

All in all it should be a whole lot of fun to build and I'll post pics along the way showing as much detail as possible.

EDIT: Oops, I guess Andrew deleted his post.

Last edited:

Sorry for my bad english.

Such a big enclosure needs a very stiff and dampened structure; you will never achieve this goal by using tight hardboard panels; bending them will largely not enhance their stiffness enough; and pourable urethane foam will only damp tiny part of the fr bandwidth.

You will get a dancing enclosure.

Such a big enclosure needs a very stiff and dampened structure; you will never achieve this goal by using tight hardboard panels; bending them will largely not enhance their stiffness enough; and pourable urethane foam will only damp tiny part of the fr bandwidth.

You will get a dancing enclosure.

You have no faith my friend. 😀

Curving the panel massively increases strength - the way these panels are designed and joined together leaves only one "weak" point: the vertical centre axis of the tallest panels may flex slightly. To help combat this I will use steel flat bar for the divider shown circled here:

Up the side panels and the bottom and top panels will have 1/4" x 1 1/2" flat bar and the back will have 1/4" x 1".

Curving the panel massively increases strength - the way these panels are designed and joined together leaves only one "weak" point: the vertical centre axis of the tallest panels may flex slightly. To help combat this I will use steel flat bar for the divider shown circled here:

Up the side panels and the bottom and top panels will have 1/4" x 1 1/2" flat bar and the back will have 1/4" x 1".

Sorry I deleted my post. I had thought I didn't want to get into this one, but I think you will want to see how little air and how much sand or limestone chip you can wind up casting in-between your panels. Without added mass those panels will become a huge dome midrange.

Without added mass those panels will become a huge dome midrange.

I expect we will see.

I see the structure of these panels and how they tie together as a more effective way to restrict movement. A midrange has a surround that allows the cone (or dome) to move in and out. The "surround" for this is actually the strongest point.

A curve (or arch) will transfer any applied load to its edges - it will by this very nature resist movement. The edges are rigidly tied to the adjacent panel at 90 degrees - how can it move by any significant amount?

Adding mass is not where I want to go with this.

Those will be nice little speakers John.

Tiny compared to some of your gear Cal but big for us common folk...🙂

John you look like you know what you're doing. I don't see why people are doubting your curved panel technique. I'm looking forward to seeing the completed project!

Thank you for the vote of confidence Jason 🙂

It's true that I do have some idea what Im doing but I have been wrong in the past about "sure" things. Like I said: we will see how it turns out. I'll do some accelerometer readings on the panel movement when they are assembled. Worse comes to worst I'm out a few hours work and maybe 30 bux worth of material - I could start again with good ole reliable MDF 4" thick.

😉

It's true that I do have some idea what Im doing but I have been wrong in the past about "sure" things. Like I said: we will see how it turns out. I'll do some accelerometer readings on the panel movement when they are assembled. Worse comes to worst I'm out a few hours work and maybe 30 bux worth of material - I could start again with good ole reliable MDF 4" thick.

😉

Last edited:

At least the experiment will be interesting 🙂. I remember seeing a cabinet design for large phy-hp fullranges which adhered to a lesser degree of stiffness of the walls. Also Nelson Pass 4way with PHY pro drivers has somehow similar principles.

So good luck with this!

So good luck with this!

Thank you for the vote of confidence Jason 🙂

I'll do some accelerometer readings on the panel movement when they are assembled.

😉

Andrew's idea of filling the void with sand sounds like an easy option to try if needs be. (Don't fancy trying to lift them afterward though!) 😱

At least the experiment will be interesting 🙂.

So good luck with this!

I think it will be too. Thanks 🙂

Andrew's idea of filling the void with sand sounds like an easy option to try if needs be. (Don't fancy trying to lift them afterward though!) 😱

Yes, I want these to be relatively lightweight and filling them with sand would not be a direction I'd think about taking. Also the voids will already be full of foam so I'm keeping my fingers crossed.

John,

I think this technique has good potential... the concept is something that hasn't escaped me in the past.

Might take some trial & error to get the tension right, and you do want to worry about the long-term stiffness of the panels -- for instance, i expect MDF would tend to become naturally relax over time.

dave

I think this technique has good potential... the concept is something that hasn't escaped me in the past.

Might take some trial & error to get the tension right, and you do want to worry about the long-term stiffness of the panels -- for instance, i expect MDF would tend to become naturally relax over time.

dave

Hey John. I made a mistake one time trying to build a 20" bass drum from 5-ply maple Keller shells. The shells were high quality but no matter what heads I used the drum sounded like paper. A dirt cheap mass produced basswood bass drum (with shells almost 3 times as thick) were able to kick it's butt in dynamic range and, most embarassingly, tone. I think I understand where you'd like this design to go but I think you will need more material, and unfortunately, mass. There will be flexure and resonance no matter what the construction. More mass and high damping means lower frequency, lower Q resonances.

On the bright side the way you intend to construct could actually help. You don't have a pure tensile load with cabinet pressure modulation unless the panel is a true arc segment. With one divider and converging edges you'd have a funny curve that would probably change with some more non-linear response. That would be good, but I think considerable problems will come from higher order responses and partially longitudinal waves in a hard thin medium.

On the bright side the way you intend to construct could actually help. You don't have a pure tensile load with cabinet pressure modulation unless the panel is a true arc segment. With one divider and converging edges you'd have a funny curve that would probably change with some more non-linear response. That would be good, but I think considerable problems will come from higher order responses and partially longitudinal waves in a hard thin medium.

I like the innovative approach to panel construction - hope it works well

cheers

Thanks Pete 🙂

John,

I think this technique has good potential... the concept is something that hasn't escaped me in the past.

Might take some trial & error to get the tension right, and you do want to worry about the long-term stiffness of the panels -- for instance, i expect MDF would tend to become naturally relax over time.

Thanks Dave,

I want to give this every opportunity to succeed, therefore I'll proceed on the premise the it will work as expected. Filling the voids between the skins with medium density foam will go a long way to locking the structure into a permanent shape. Using a steel "backbone" will (hopefully) address the one potential weakness.

In any case, I'll start soon by cutting all of the parts for the panels. I'll see if there is a local source of the urethane foam I want to use and I'll look through my garage for the steel.

Should be barrels 'o fun.

😉

Hey John. I made a mistake one time trying to build a 20" bass drum from 5-ply maple Keller shells. The shells were high quality but no matter what heads I used the drum sounded like paper. A dirt cheap mass produced basswood bass drum (with shells almost 3 times as thick) were able to kick it's butt in dynamic range and, most embarassingly, tone. I think I understand where you'd like this design to go but I think you will need more material, and unfortunately, mass. There will be flexure and resonance no matter what the construction. More mass and high damping means lower frequency, lower Q resonances.

On the bright side the way you intend to construct could actually help. You don't have a pure tensile load with cabinet pressure modulation unless the panel is a true arc segment. With one divider and converging edges you'd have a funny curve that would probably change with some more non-linear response. That would be good, but I think considerable problems will come from higher order responses and partially longitudinal waves in a hard thin medium.

Hi Andrew,

Each box will have some considerable mass - there is the equivalent of more than 2 full 4' x 8' sheets of 1/4" hardboard involved plus whatever I decide to use for the baffle. Probably a few pounds of foam too. Also the skins are not as thin and frail as you think - 1/4" hardboard is very strong and tough.

I don't see enough internal pressure to be able to change the curvature of the skin, especially once it has been reinforced with foam. If the curve does not change shape, it must transfer all of the load to the rigid edges. A structure like this (shallow arch) will not do well with a point load but it will work well with distributed loads (what we find inside a speaker).

Maybe it sounds like I'm trying to convince myself as much as anyone else...

😀

- Status

- Not open for further replies.

- Home

- Loudspeakers

- Multi-Way

- Large 3-ways design / build