I need a small waveguide for the B&C DE10 from 3khz and up, and ive thought about making one my self out of MDF with inspiration from this thread. Im a quite a newbie when it comes to theory about horn loading and compression drivers, at least compared to some of the guys at this forum

Can I simply make a waveguide like the ones in the link? Just deep enough to support loading down to about 3khz?

Can I simply make a waveguide like the ones in the link? Just deep enough to support loading down to about 3khz?

Ive read that it has a bit of honk to it, but its an alternative for sure

Maybe something like these? Shouldnt be too hard to make... How critical is it to have the "right" expansion in such a small horn/waveguide?

An externally hosted image should be here but it was not working when we last tested it.

Hello Defo, do you have any link for the speaker you posted? What's the size of the woofer? Say, 10" maybe?

Its the top module of the Bastanis Mercury.

What other drive units are you using?The B&C ME10 horn flares are very reasonably priced ,then you can lower the crossover frequency.

The plan is to use the B&C PE32 in an Azura front horn with the DE10 placed a little below halfway "inside" the Azura. So the DE10+waveguide must be small, AND look good

If you use

(t^2+x^2)^1/2 up to where x=15

after this use

19+(-x^2-12.42x-664.1)^1/2

(all in mm.)

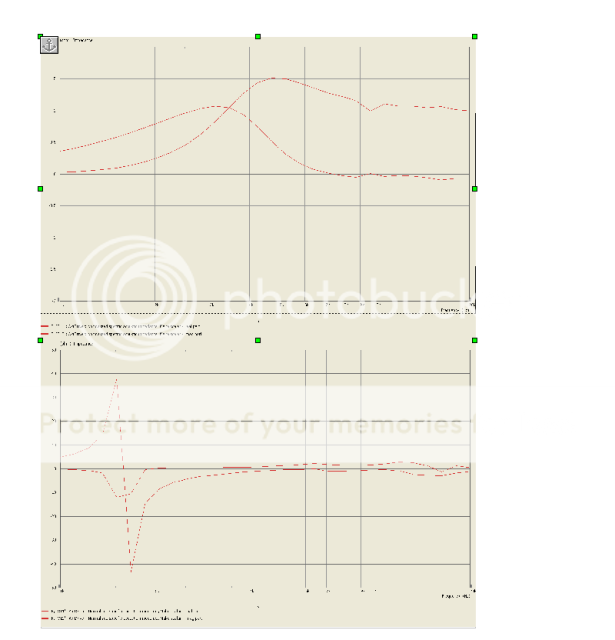

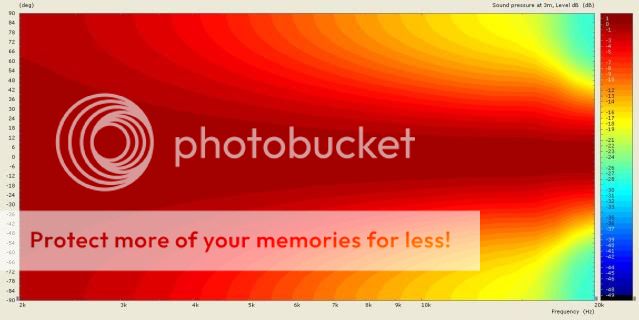

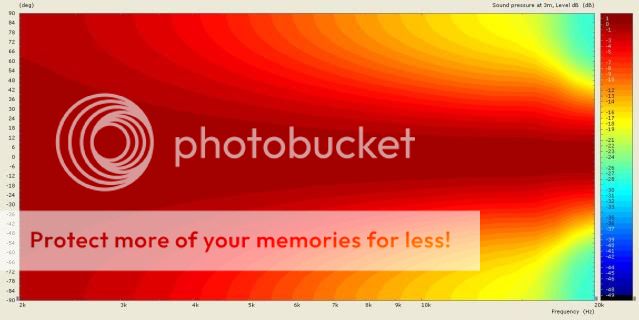

to the mouth, and driven by a flat 25mm. piston you get this sonogram

The mouth at 76mm. is about as big as you can use for a 3kHz. crossover and still get a decent vertical pattern with a five-five and a half inch driver.

rcw.

(t^2+x^2)^1/2 up to where x=15

after this use

19+(-x^2-12.42x-664.1)^1/2

(all in mm.)

to the mouth, and driven by a flat 25mm. piston you get this sonogram

The mouth at 76mm. is about as big as you can use for a 3kHz. crossover and still get a decent vertical pattern with a five-five and a half inch driver.

rcw.

Can't be the DE10 indeedSo the DE10+waveguide must be small, AND look good

The plan is to use the B&C PE32 in an Azura front horn with the DE10 placed a little below halfway "inside" the Azura. So the DE10+waveguide must be small, AND look good

The reason that the tweeter on coaxial speakers is located so close to the woofer cone is that a reflection occurs off the tweeter. The frequency of the reflection is easy to predict - there will be a notch at one quarter wavelength of the distance from tweeter to woofer.

For instance, if you're making a coax with a tweeter that's located half an inch in front of the woofer, a notch in the frequency response appears at 6750hz. (speed of sound / (1/2") / 4)

Does that make sense?

That's why phase plugs are located a fraction of a millimeter from a tweeters diaphragm, and why coaxial speakers sound best when the tweeter is mounted in the neck.

These things push the "notch" to a frequency that's inaudible.

Now lets say we put the tweeter three inches forward of your 12" midrange, in an Azura horn. That will produce a notch at 1125hz, right where it's VERY audible. It will also produce a peak at 2250hz.

(The notch is due to a reflection that's out of phase, the peak is due to a reflection that's in phase.)

Anyways, to make a long story short, if you want to build a pseudo coax, I'd recommend making the tweeter module as diffraction-free as humanly possible. By smoothing the edges of the tweeter module, the reflections off the module will be dispersed, and this will reduce the depth and the height of the peak and the dip.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Hope that makes sense.

Here are some of my "pseudo-coaxial" horns and waveguides. Been doing this for a few years now.

http://www.diymobileaudio.com/forum/diy-mobile-audio/60146-creating-perfect-soundstage.html

http://www.audiogroupforum.com/csforum/showthread.php?t=62789

http://www.diyaudio.com/forums/showthread.php?p=1923359

Last edited:

...snip...

Thanks for great info!

I meant the PE21 8 incher btw, not PE32. My bad.

If you use

(t^2+x^2)^1/2 up to where x=15

after this use

19+(-x^2-12.42x-664.1)^1/2

(all in mm.)

to the mouth, and driven by a flat 25mm. piston you get this sonogram

The mouth at 76mm. is about as big as you can use for a 3kHz. crossover and still get a decent vertical pattern with a five-five and a half inch driver.

rcw.

Didnt quite get all that, but I'll figure it out...

For a coaxial horn type of set up you don't need so much acoustic output in general for domestic use, and you can use a small Neodimium tweeter.

This can be used in a circular arc waveguide and can be made small enough to be incorporated into a phase plug for the other driver.

As Patrick has observed you can fit such a device into a housing that is proportioned such that it has no practicle effect upon the frequency responce, and can improve the wavefront produced by the larger horn.

rcw.

This can be used in a circular arc waveguide and can be made small enough to be incorporated into a phase plug for the other driver.

As Patrick has observed you can fit such a device into a housing that is proportioned such that it has no practicle effect upon the frequency responce, and can improve the wavefront produced by the larger horn.

rcw.

You can find details here.

rcw.

You dont happen to have that in higher resolution?

For a simple straight conical horn with 45 degree expansion rate, how long should it be to load down to 2 khz, 2,5 khz, and 3 khz respectively?

Since you will be EQing, I assume, then don't even worry about "loading", it doesn't matter. Placing something in the mouth of a good horn can do all kinds of bad things. I'd prefer to put them side by side. The DE10 is not my favorite driver, I stepped up to the DE12 because it works a lot better. In waveguides, like speakers in general, bigger is always better. SO the choice is how big do you need to go to get the performance that you want.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Small waveguide for B&C DE10 - diy?