Thanks guys. The 80/20 stuff was around $500 not including shipping. And, I already had some short extrusion pieces from leftover projects. Pure Audio wants about twice that for their frame. Another benefit to mine is its adjustability. I can make it wider or narrower if ever needed.

I had Alpha 15A's in for a while. I think the GRS's are a little bit better in this configuration. At least to my ears. This coming from a 15A fan

Thanks,

KC

Ouch! I don't think it is expensive but it is a lot of money. I will give the GRS units a try when I go for such a build.

R.

I like the idea of the 12LTA with a compression tweeter a lot. Godzilla, I know youhave the 1808's as well. A few pages ago I posted my take on the pap speakers. How would you compare the TB vs the 12 lta in this kind of design?

Same question, I've been contemplating on building a version of this as well. Another question regarding this particular speakers' placement, how far should they be from the wall? I have a small room and can only afford to place them 2 feet from the wall.

In their 'normal' position they are about two feet away from the wall with one in the corner. And they still sound great. But when I when I really want to enjoy the music, I take them a bit more away from the wall. And yes, this does sound even better. But they do benefit from some space behind them, as do most speakers btw...

I think the placement issue of OB really is exagerated.

I think the placement issue of OB really is exagerated.

I like the idea of the 12LTA with a compression tweeter a lot. Godzilla, I know youhave the 1808's as well. A few pages ago I posted my take on the pap speakers. How would you compare the TB vs the 12 lta in this kind of design?

Thanks to Godzilla I've had the phase plug modded 12LTA with tweeter as well as the 1808 both with H-frames.

The grand sense of scale is why I still have the 12LTA.

Visaton baffleless

Here is my newest attempt of making a pair of nice OB with minimum effort

I also used industrial erector stuff, this one

Easy-Systemprofile - Profil, Nutprofil, Aluprofil, Aluminiumprofil, Aluprofil 20x40, Aluminiumprofil 20x40

Eventually, accounting for all bits and pieces and import and so on, it was about 150 euros IIRC - I think much cheaper than it used to be. I used M6 threaded rod to attach the woofers, while the fullrange is suspended.

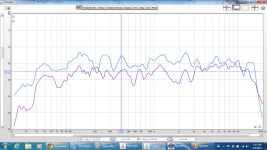

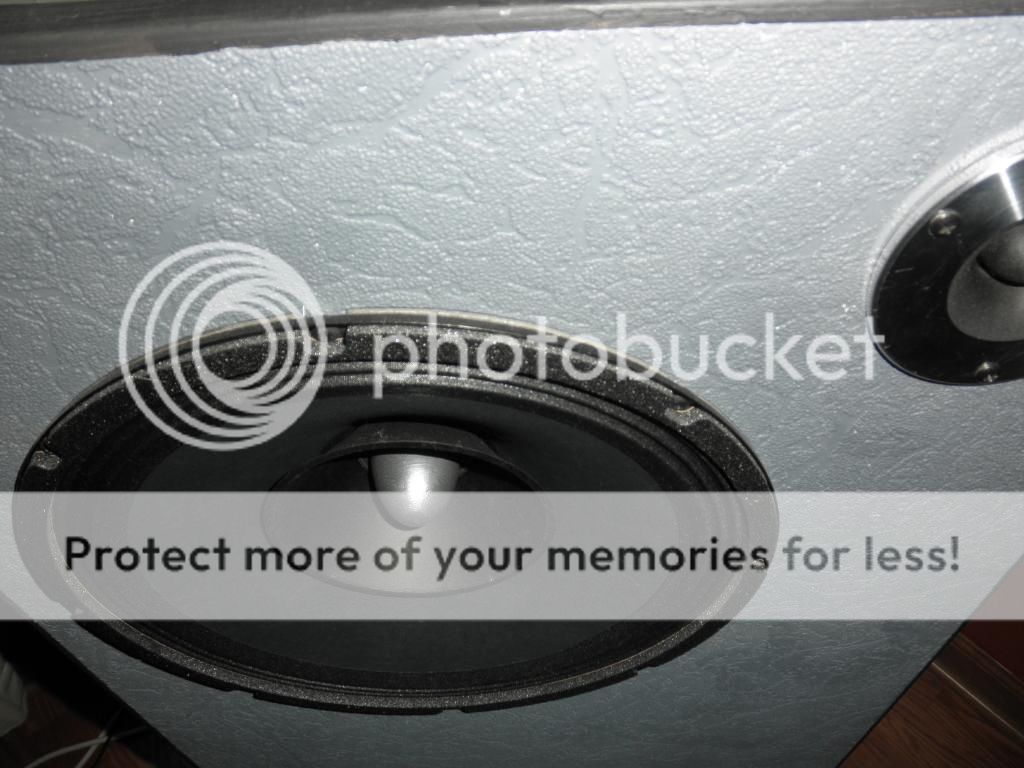

They use 6 Visaton WS25e drivers playing up to 400Hz, and a Visaton B200 for 400Hz and up. Xover and DSP is done with a 2x4 minidsp. For the moment the bass section is powered with a little SS amp, and the B200 with a tube amp - but this is going to change as I spent most of my DIY efforts on amplifiers.

It was also my first attempt in measuring and tuning the speakers performance, using UMIK-1, REW, and the DSP functionality of the 2x4. My wife was asking what I was listening to during all the tests, as according to her the whooooooop testtone always sounded similar SPL level during tests was not very high, I can't play very loud either (this is Switzerland).

SPL level during tests was not very high, I can't play very loud either (this is Switzerland).

I think I am happy with them for the moment. Indeed very little work, no need for machinery and no wood/MDF dust to clean - but still working on their "feet" and covering them. I also just got a package containing 2 NEO10s, which are meant for future upgrades.

The pictures arent really that good, but well, speakers aren't finished either

Here is my newest attempt of making a pair of nice OB with minimum effort

I also used industrial erector stuff, this one

Easy-Systemprofile - Profil, Nutprofil, Aluprofil, Aluminiumprofil, Aluprofil 20x40, Aluminiumprofil 20x40

Eventually, accounting for all bits and pieces and import and so on, it was about 150 euros IIRC - I think much cheaper than it used to be. I used M6 threaded rod to attach the woofers, while the fullrange is suspended.

They use 6 Visaton WS25e drivers playing up to 400Hz, and a Visaton B200 for 400Hz and up. Xover and DSP is done with a 2x4 minidsp. For the moment the bass section is powered with a little SS amp, and the B200 with a tube amp - but this is going to change as I spent most of my DIY efforts on amplifiers.

It was also my first attempt in measuring and tuning the speakers performance, using UMIK-1, REW, and the DSP functionality of the 2x4. My wife was asking what I was listening to during all the tests, as according to her the whooooooop testtone always sounded similar

I think I am happy with them for the moment. Indeed very little work, no need for machinery and no wood/MDF dust to clean - but still working on their "feet" and covering them. I also just got a package containing 2 NEO10s, which are meant for future upgrades.

The pictures arent really that good, but well, speakers aren't finished either

Attachments

Here is my newest attempt of making a pair of nice OB with minimum effort

I also used industrial erector stuff, this one

Easy-Systemprofile - Profil, Nutprofil, Aluprofil, Aluminiumprofil, Aluprofil 20x40, Aluminiumprofil 20x40

Eventually, accounting for all bits and pieces and import and so on, it was about 150 euros IIRC - I think much cheaper than it used to be. I used M6 threaded rod to attach the woofers, while the fullrange is suspended.

They use 6 Visaton WS25e drivers playing up to 400Hz, and a Visaton B200 for 400Hz and up. Xover and DSP is done with a 2x4 minidsp. For the moment the bass section is powered with a little SS amp, and the B200 with a tube amp - but this is going to change as I spent most of my DIY efforts on amplifiers.

It was also my first attempt in measuring and tuning the speakers performance, using UMIK-1, REW, and the DSP functionality of the 2x4. My wife was asking what I was listening to during all the tests, as according to her the whooooooop testtone always sounded similarSPL level during tests was not very high, I can't play very loud either (this is Switzerland).

I think I am happy with them for the moment. Indeed very little work, no need for machinery and no wood/MDF dust to clean - but still working on their "feet" and covering them. I also just got a package containing 2 NEO10s, which are meant for future upgrades.

The pictures arent really that good, but well, speakers aren't finished either

Whoa, that rail and bolt system...genius.

Thanks to Godzilla I've had the phase plug modded 12LTA with tweeter as well as the 1808 both with H-frames.

The grand sense of scale is why I still have the 12LTA.

Been searching the forum for a while now, but can't find much about this modded 12lta. So please, enlighten me on the phase plug and tweeter used...

Been searching the forum for a while now, but can't find much about this modded 12lta. So please, enlighten me on the phase plug and tweeter used...

Beta 12LTA dust cap-ectomy.

An externally hosted image should be here but it was not working when we last tested it.

Beta 12LTA with phase plug paired with the Realistic 40-1310 super tweeter over H-frame Alphas.

What did you use as XO?

dave

PS: the Michael's egg is a good repurpose. Kudos.

What did you use as XO?

dave

PS: the Michael's egg is a good repurpose. Kudos.

Active crossover

AINOgradient Neo83 will be presented at the Finnish DIY convent held at May 23rd.

DIY-messut 2015

More info about the speaker by clicking my signature!

DIY-messut 2015

More info about the speaker by clicking my signature!

Attachments

Finishing advice?

Just about ready to try a home made beeswax and walnut oil polish.

And I've also received some water based aniline dyes, but does anyone have experience with these? I'm wondering if they're going to "break loose" when the oil finish contacts them.

These will be two 10" GRS Polycone woofers below a Neo8 and Neo10 in a separate swap outable baffle.

Thanks for any advice😎

Just about ready to try a home made beeswax and walnut oil polish.

And I've also received some water based aniline dyes, but does anyone have experience with these? I'm wondering if they're going to "break loose" when the oil finish contacts them.

These will be two 10" GRS Polycone woofers below a Neo8 and Neo10 in a separate swap outable baffle.

Thanks for any advice😎

Attachments

First hunch was right, water based dye doesn't bleed when walnut oil is applied.

Will oil up the carcasses and install the drivers tomorrow.

Turns out it's pretty easy to get a near cherry finish over birch with aniline dyes- one coat of orange, a coat of orange- red, then coat of red with just a little blue in it.

I think the walnut oil looks about as good as pure Tung oil, and is a lot easier to find.

Organic section of the grocery store!

Will oil up the carcasses and install the drivers tomorrow.

Turns out it's pretty easy to get a near cherry finish over birch with aniline dyes- one coat of orange, a coat of orange- red, then coat of red with just a little blue in it.

I think the walnut oil looks about as good as pure Tung oil, and is a lot easier to find.

Organic section of the grocery store!

Attachments

- Home

- Loudspeakers

- Multi-Way

- Ultimate Open Baffle Gallery