Ok, I had a bit of time to work on the second box today, all it needs is to be sealed up with the top piece of wood. I will hopefully do that after dinner and my QC guy is in bed.

Concerning time, it took about 40 min, maybe a bit less to go from the first photo to the second.

Concerning time, it took about 40 min, maybe a bit less to go from the first photo to the second.

My strips seem to be a little uneven. How precise does the cutting need to be for this project? I'm worried of my front panel appearing "wobbly." Should I go buy a drywall T square to assist the precision of my cuts and try again?

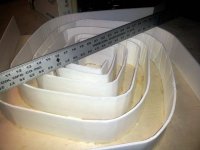

I hate to show my substandard quick build after 6L6s latest posts, but the pics may be helpful. Before gluing the top I placed an aluminum yardstick across the partitions to check uniformity. I found several spots that never would have sealed even with the expansion of Gorilla Glue. Even though I used the same yardstick to cut the strips, just the angle of the blade can make a significant difference.

On the next build I will make a full sized thin wooden template to insure accuracy. I think 6L6 did that. I can fix these but won't have finished cabinets till tomorrow.

Attachments

I hate to show my substandard quick build after 6L6s latest posts, but the pics may be helpful. Before gluing the top I placed an aluminum yardstick across the partitions to check uniformity. I found several spots that never would have sealed even with the expansion of Gorilla Glue. Even though I used the same yardstick to cut the strips, just the angle of the blade can make a significant difference.

On the next build I will make a full sized thin wooden template to insure accuracy. I think 6L6 did that. I can fix these but won't have finished cabinets till tomorrow.

When I see strips that appear too shallow to seal, I lay beads of what else, hot melt, on the channel section in question to 'build it up' to the correct height. Check with straight edge after done. The pva will bond to hot melt bead and make good seal.

What we need to use are one of those graphic art cutting machines they have at framing shops with a razor on a bearing guided rail. Cuts all strips exactly parallel and same size.

Wonder if Michaels craft stores will let me cut if I buy foam core from them?

Thanks. I know there has been some discussion on glue, but are you saying pva (Elmer's, Wellbond etc.) is good enough and the expanding properties of G Glue may be overkill?

Gorilla glue probably works well as it fills gaps. Most of us have used pva with success, probably because we did not have G glue on hand. I personally have never used it so cannot say for sure. Cochleus uses it on all his foam core builds but I don't think he has made the cornu yet. Does anyone have a build of cornu with Gorilla glue?

Today I purchased a drywall t-square to aid in cutting perfectly uniform strips.

Watch the angle of your razor ad that causes variations in thickness too.

Today I purchased a drywall t-square to aid in cutting perfectly uniform strips.

Please make sure you keep the blade at 90 degrees to the foam board as I reported a few posts back.

I hate to show my substandard quick build after 6L6s latest posts

Lol... My first one is very ratty and amateurish. The second one is much better, luckily the learning curve is shallow and short. I learned most of how to do it properly on the first.

Before gluing the top I placed an aluminum yardstick across the partitions to check uniformity. I found several spots that never would have sealed even with the expansion of Gorilla Glue.

That's why I decided to use liquid nails on my first one, because it was very uneven - my gauge wasn't uniform in size and I only noticed too late.

I am now measuring each long cut and it's much, much better.

I also learned that liquid nails isn't the right tool for this job.

Even though I used the same yardstick to cut the strips, just the angle of the blade can make a significant difference.

True

On the next build I will make a full sized thin wooden template to insure accuracy. I think 6L6 did that.

See above about a gauge. Conceptually it's not a bad idea.

chazdrumzalot said:Today I purchased a drywall t-square to aid in cutting perfectly uniform strips.

That's probably the best tool. I wish I thought of that earlier!!!!

Last edited:

Each successive one looks better and better, which is why I would recommend someone new and just starting to try building an all foam core one as first try - just to practice and not waste a plywood panel. If it works, it still sounds good - but stick with the smaller sizes as first build. a Vifa TC9FD or Visaton FRS8 are good starter builds. The best part is that successive builds go very fast as the experience you gain helps enormously.

The white variety works best, drys faster and is white colored. The brown colored gorilla glue works but is slower and is yellowish when dry. The stuff surprised me how much it expands, must be clamped (I used masking tape). Warning: Don't get this stuff on anything valuable, even yourself, and it never washes off clothing.I used acrylic caulking for filling big gaps.

Just wanted to reiterate that

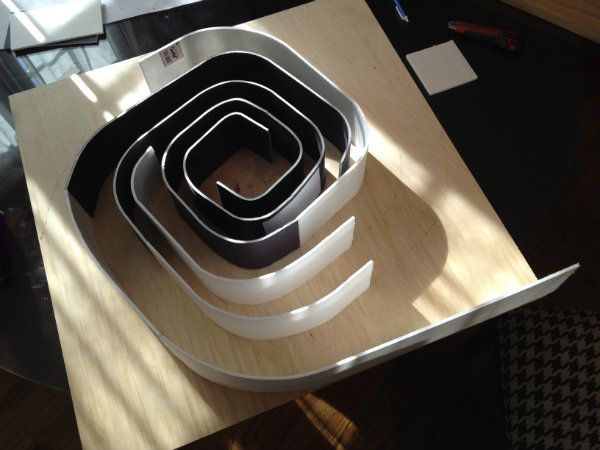

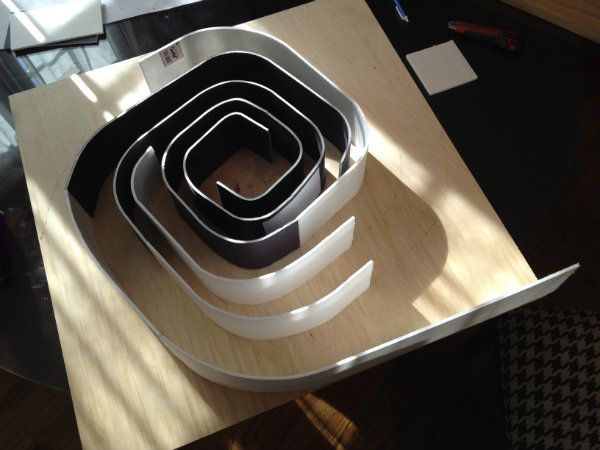

This is the rig I came up with. The three roller idea was just to complicated for possible/probable one time use. In the spirit of "K.I.S.S." I tried to think of materials many might have in the basement or garage.

1. A piece of 1/2' plywood - cut to any size that feels good. This one is ~ 6.5" x 8.5".

2. A 1" dowel glued, countersunk and screwed from the bottom. Could be an old broomstick.

3. Various diameter PVC pipe segments. These are 2" and 3" but there are a lot of choices available all the way up to 6". A trip to the waste bin at your local Home Depot plumbing department might provide what you need free or at little cost.

4. An optional second dowel can be added for stabilization. I say optional because the pipe segments wrap or crawl around the dowel as you shape. Whatever feel best for the user.

The smallest curves can be made using the dowel only. As with all diameters, can be formed by using your hand and/or the use of a flat of wood. In combination with the scores a very accurate and uniform curve is produced.

As a bonus - either cutting the dowel or making a mark to match the width of the desired segments. you have a built-in gauge to verify your cuts.

1. A piece of 1/2' plywood - cut to any size that feels good. This one is ~ 6.5" x 8.5".

2. A 1" dowel glued, countersunk and screwed from the bottom. Could be an old broomstick.

3. Various diameter PVC pipe segments. These are 2" and 3" but there are a lot of choices available all the way up to 6". A trip to the waste bin at your local Home Depot plumbing department might provide what you need free or at little cost.

4. An optional second dowel can be added for stabilization. I say optional because the pipe segments wrap or crawl around the dowel as you shape. Whatever feel best for the user.

The smallest curves can be made using the dowel only. As with all diameters, can be formed by using your hand and/or the use of a flat of wood. In combination with the scores a very accurate and uniform curve is produced.

As a bonus - either cutting the dowel or making a mark to match the width of the desired segments. you have a built-in gauge to verify your cuts.

Attachments

Last edited:

Bob,

Nice work with the channel curvy bendy contraption. If this works well, you can try other materials for the channels. I have thought about using the large blades from a shutter/blind made of thin wood. I think a 3 inch blade is available. I know people return incorrect lengths to HD, maybe they will sell at good deal? You would have to steam the wood with a steam iron or something first, then run through rollers.

Nice work with the channel curvy bendy contraption. If this works well, you can try other materials for the channels. I have thought about using the large blades from a shutter/blind made of thin wood. I think a 3 inch blade is available. I know people return incorrect lengths to HD, maybe they will sell at good deal? You would have to steam the wood with a steam iron or something first, then run through rollers.

Hi Bob, Nice work on your bender but I can't help wonder if that's not overkill. Are you scoring the facer before bending? I found that multiple scores with the box cutter blade set at just the nib showing was so fast, so easy and all it took was rubbing it over the rounded edge of my kitchen counter to end up with a very tight curve.

I think on my next build I will abandon the table saw for cutting the foam and just use a jig with a vertical piece on one side to rest the material up against and a channel in which the knife blade fits. I can use strips of metal on either side so the blade can't wander.

I think on my next build I will abandon the table saw for cutting the foam and just use a jig with a vertical piece on one side to rest the material up against and a channel in which the knife blade fits. I can use strips of metal on either side so the blade can't wander.

I think the channel cutting jig is one of the most important things that will boost both productivity and quality. Good idea Cal. I was thinking of using one of those sliding cutters on a rail that they have at art shops.

What driver will you be using in your next spiral? Are you doing the Daisy perhaps? Or will it be the Hockey Puck?

What driver will you be using in your next spiral? Are you doing the Daisy perhaps? Or will it be the Hockey Puck?

Not sure but there is too much to do before the New year so it gives me plenty of time to think.

Driver is not decided either. I am tempted to use some Foster 10F3's that I have mounted in a box that does them no justice.

Or maybe the RS-1354's Who knows, like I said I have plenty of time and I tend to change my mind as often as a woman.

Driver is not decided either. I am tempted to use some Foster 10F3's that I have mounted in a box that does them no justice.

Or maybe the RS-1354's Who knows, like I said I have plenty of time and I tend to change my mind as often as a woman.

Attachments

Cal,

So that BLH cabinet does not sound as nice as the Cornu? The cabinet actually looks very nice, good thick, heavy birch plywood I can see. That's an interesting magnet yoke, I have never seen one that looks like that. I am thinking of trying the little TB 3 inch aluminum/magnesium driver (315e I think). Has a lower Qts which may help with too much mid bass problem, which I don't actually have a problem with on my build. Might be fact that I made my internal spirals with sharp corners?

The cabinet actually looks very nice, good thick, heavy birch plywood I can see. That's an interesting magnet yoke, I have never seen one that looks like that. I am thinking of trying the little TB 3 inch aluminum/magnesium driver (315e I think). Has a lower Qts which may help with too much mid bass problem, which I don't actually have a problem with on my build. Might be fact that I made my internal spirals with sharp corners?

So that BLH cabinet does not sound as nice as the Cornu?

- Home

- Loudspeakers

- Full Range

- Foam Core Board Speaker Enclosures?