£150 - YES !!!

The company that I use is in America. The cost for 2 x boards (their minimum) is approximately £80. Then add P&P and Handling - approximately £30. Then the criminal bit is UPS then add a further UK handling charge of approximately £30 which includes Import Tax.

I appreciate there are cheaper options but these guys are VERY quick, I usually get the boards two to three days after ordering.

Send them to me and maybe we can work out a way to get them to you cheaper.

I never got on with making my own pcbs. It rarely worked was messy and time consuming ending up with a amateur job.

I found a Chinese pcb supplier who turns the pcb's around in 2 weeks to my door. He is very cheapo, about 1/3 of the cost in the UK.

I get great professional looking pcb's and have never had a pcb fault.

Do yo have a link to the pcb supplier?

And what software do you have to use when you send them an order?

Thanks

At long last someone has produced paper specially designed for toner transfer.

PCB "Fab-In-A-Box" ... The 8min circuit board system

The kit is pricey but if you read the blurb you don't need to buy the whole kit, just the TTP (Toner Transfer Paper) and the Green Roll. You should be able to get away with a heavy duty laminator.

PCB "Fab-In-A-Box" ... The 8min circuit board system

The kit is pricey but if you read the blurb you don't need to buy the whole kit, just the TTP (Toner Transfer Paper) and the Green Roll. You should be able to get away with a heavy duty laminator.

Wouldn't the stuff used for t-shirt transfer printing also work for PCBs?

e.g. Printing Instructions for T-Shirt Transfers | HP® Support

e.g. Printing Instructions for T-Shirt Transfers | HP® Support

Toner transfer paper has been around for some time. Most of them will transfer the image very well using a dry iron on low. Make sure the copper is very clean. Scrub it with a Brillo pad to get it nice and shiny. Use latex gloves to avoid finger prints. Works great for silk screening single sided boards as well.

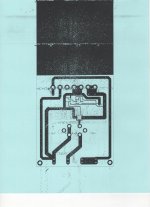

Oh dear another dismal failure

I really thought this might work but NO, another dismal failure.

Now, image 2 was printed on normal 90gsm paper using my Samsung ML1665. The printer is working fine it just doesn't like the TTP (Toner Transfer Paper).

I've got a packet of 8 sheets left if anyone would like to try it. (Call it a £5 incl P&P).

I really thought this might work but NO, another dismal failure.

Now, image 2 was printed on normal 90gsm paper using my Samsung ML1665. The printer is working fine it just doesn't like the TTP (Toner Transfer Paper).

I've got a packet of 8 sheets left if anyone would like to try it. (Call it a £5 incl P&P).

Attachments

Toner transfer works very well. The problem here seems to be the printer. Wouldn't it be best to try your TTP in a different laser printer first or even try to clean it up a bit? You can get very good resolution with the toner transfer method so I wouldn't give up on it yet.

After many weeks of experimenting I have come to the conclusion that any form of toner transfer is a waste of time. The results are unpredictable and the final product is invariably poor. I've tried many many laser printers, even when using the capable HP Laserjet 600, which will print onto the TTP, the image still wont stick to the copper clad board sucessfully. I've tried numerous laminators which all failed, even ironing it with a domestic iron was a failure.

The only repeatable good results are when using photo resist boards.

Now, photo resist board isn't cheap, I'm just trying some photo resist film that our Oriental friends are selling on E-Bay for £0.50p a sheet (only A5 - but that's big enough for most projects).

I've just managed to stick a sheet of it to a bare copper clad board, I'll try exposing it tomorrow with a UV source and I'll let you know how it performs.

This might sound STUPID, but I've spent over £1000 so far trying various printers, medium and techniques. The best so far is using a Ricoh GelJet printer to print an opaque image onto clear acetate film. Buying nude copper clad board from China and then using a laminator to apply photo resist film to the board. (This is far superior to trying to spray photo resist onto the board). Tomorrow - I've already said this above.

The only repeatable good results are when using photo resist boards.

Now, photo resist board isn't cheap, I'm just trying some photo resist film that our Oriental friends are selling on E-Bay for £0.50p a sheet (only A5 - but that's big enough for most projects).

I've just managed to stick a sheet of it to a bare copper clad board, I'll try exposing it tomorrow with a UV source and I'll let you know how it performs.

This might sound STUPID, but I've spent over £1000 so far trying various printers, medium and techniques. The best so far is using a Ricoh GelJet printer to print an opaque image onto clear acetate film. Buying nude copper clad board from China and then using a laminator to apply photo resist film to the board. (This is far superior to trying to spray photo resist onto the board). Tomorrow - I've already said this above.

Last edited:

After many weeks of experimenting I have come to the conclusion that any form of toner transfer is a waste of time. The results are unpredictable and the final product is invariably poor. I've tried many many laser printers, even when using the capable HP Laserjet 600, which will print onto the TTP, the image still wont stick to the copper clad board sucessfully. I've tried numerous laminators which all failed, even ironing it with a domestic iron was a failure.

The only repeatable good results are when using photo resist boards.

Now, photo resist board isn't cheap, I'm just trying some photo resist film that our Oriental friends are selling on E-Bay for £0.50p a sheet (only A5 - but that's big enough for most projects).

I've just managed to stick a sheet of it to a bare copper clad board, I'll try exposing it tomorrow with a UV source and I'll let you know how it performs.

This might sound STUPID, but I've spent over £1000 so far trying various printers, medium and techniques. The best so far is using a Ricoh GelJet printer to print an opaque image onto clear acetate film. Buying nude copper clad board from China and then using a laminator to apply photo resist film to the board. (This is far superior to trying to spray photo resist onto the board). Tomorrow - I've already said this above.

Hi KatieandDad

I use the toner transfer method, and it works very fine. I use a Samsung ML-2165 printer, this is a cheap printer, with results as good as what I could get with the photo resist method on a PCB.

I use a GBC H425 laminator, that works perfectly with it.

What you have to find is the right paper to be used ... I have found in my local super market the pub on a relatively thin paper that makes wonders with my printer (It is used with a white paper below it and adhesive tape to fix both papers together as the thickness of the thin paper is not sufficient for the printer, the thin paper would not do it through the printer. The adhesive tape is the one painters use in your home in order to avoid painting in places not wanted).

I have also tried a lot of different kind of papers ... and I report only bad or insufficient results. The paper IS really the solution. The good new is that pub comes free of charges ... and when you have found the "good pub" for your application, you can get as much paper as you need ... for free

It is a simple method, no chemicals are used else than HCl from the supermarket, and the H2O2 (the good one is sold in your pharmacy, it is the concentrated one, difficult

the right way ... it will come).

the right way ... it will come).It is also very easy to dispose the used (liquid) chemicals as this liquid used with NaHCO3 (sodium acid carbonate) will produce many bubbles (it can be dangerous, pay attention to this part) and a blue solid precipitate that you can throw in the bin.

Don't surrender, find the good paper for free, and ... be happy

Best regards

rephil

What is "pub"?I have found in my local super market the pub on a relatively thin paper that makes wonders with my printer...

... and when you have found the "good pub" for your application, you can get as much paper as you need ... for free.

Same hereWhat is "pub"?

(Expliquez le mot en Français si vous n' avez pas une traduction précise

What is "pub"?

Could be the paper used for "Poster advertising"

pub is in French the short-cut for "publicité"

The biggest issue I have had so far with Toner Transfer was having an iron with not enough heat!!

Used 3 different ones until I found one that worked great!

The one I found that gets hot enough has a mechanical thermostat on it.

The electronic ones I used where just a tad below what I needed to get a good transfer and I got it at the goodwill store for $3!!

Here is my results after a few practice tries in order to get the hang of it,

http://www.diyaudio.com/forums/construction-tips/221683-smd-soldering.html#post3685868

FWIW

jer

Used 3 different ones until I found one that worked great!

The one I found that gets hot enough has a mechanical thermostat on it.

The electronic ones I used where just a tad below what I needed to get a good transfer and I got it at the goodwill store for $3!!

Here is my results after a few practice tries in order to get the hang of it,

http://www.diyaudio.com/forums/construction-tips/221683-smd-soldering.html#post3685868

FWIW

jer

What is "pub"?

Hi Godfrey,

Sorry

Best regards

rephil

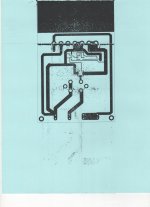

home made pcb

Hi friends.

After many unsuccessful methods i have solved the problem "home made pcb"

Here are all details see post #1152 .http://www.diyaudio.com/forums/solid-state/221741-dx-blame-st-together-dx-super-116.html

All my diy amplifiers built with this method.

Thimios.

Hi friends.

After many unsuccessful methods i have solved the problem "home made pcb"

Here are all details see post #1152 .http://www.diyaudio.com/forums/solid-state/221741-dx-blame-st-together-dx-super-116.html

All my diy amplifiers built with this method.

Thimios.

Last edited:

Well the first attempts were failures.

My fault entirely.

1. I assumed that the ex[posure time would be similar to that of photo resist board (ie 2-3 mins). It isn't it's about 3-6 seconds.

2. I've been using Caustic Soda for developing which may be a bit harsh.

Anyway, I've got the correct developer on the way and I'll try again.

As for toner transfer, I tried all manner of paper, including cheap magazines and none were reliable.

My fault entirely.

1. I assumed that the ex[posure time would be similar to that of photo resist board (ie 2-3 mins). It isn't it's about 3-6 seconds.

2. I've been using Caustic Soda for developing which may be a bit harsh.

Anyway, I've got the correct developer on the way and I'll try again.

As for toner transfer, I tried all manner of paper, including cheap magazines and none were reliable.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Design & Build

- Construction Tips

- Home Brew PCBs