carlosfm said:Why should a chip's datasheet be the heatsink's encyclopedia?

The datasheets never say it all.

If the thickness of the heatsink was important to their products being used sucessfully, they would say so. In fact, the three pages on heat/power issues, coupled with the two or three preceding pages of graphs, is the most comprehensive (should I say encyclopedic?) treatment of these issues I've ever seen in a spec sheet.

carlosfm said:I'm not willing to discuss this, as I'm just sharing my experience.

Take it or leave it.

Yes, I can see this clearly.

There are diyers that make it.

There are other ones that just theorize and never make anything.

Of course your implication is that I just theorize and never make anything. I've probably built more in my 20 years of being a DIYer than most people. Some of us look for reasons, look to theory, to explain those things that we're just learning about. Others just make it up as they go along.

I never thought that a good advice could turn into a big discussion.

But I should know better by now...

I'm sorry that you cannot provide any rationale for "thickness". I was hoping to learn something from you. At least I have from others.

budweiser,

sorry for having helped to turn this into an off-topic discussion...

Wanna describe what exactly you had, and what you did to it (e.g. which values, pictures)?

Cheers,

Sebastian.

PS: Eric,

Rth is the common symbol for thermal resistance, [Rth] = 1 K/W.

It's commonly also noted RTH, but I was lazy

You need a good book on the topic, not a diy forum to find the answer... sometimes in life it's not sufficent to yell at others for not answering a question.

Philosophical question for you: does thickness not matter just because noone here can satisfy you with an answer?

Can you say Texas?...

sorry for having helped to turn this into an off-topic discussion...

I do notice more punch and amybe more low end with this new PS.

Wanna describe what exactly you had, and what you did to it (e.g. which values, pictures)?

Cheers,

Sebastian.

PS: Eric,

Rth is the common symbol for thermal resistance, [Rth] = 1 K/W.

It's commonly also noted RTH, but I was lazy

You need a good book on the topic, not a diy forum to find the answer... sometimes in life it's not sufficent to yell at others for not answering a question.

Philosophical question for you: does thickness not matter just because noone here can satisfy you with an answer?

Can you say Texas?...

Eric Weitzman said:Of course your implication is that I just theorize and never make anything. I've probably built more in my 20 years of being a DIYer than most people. Some of us look for reasons, look to theory, to explain those things that we're just learning about. Others just make it up as they go along.

Let me put it this way:

Are the heatsinks on the pics fine for an LM3886 working at +/- 37V?

Eric Weitzman said:I'm sorry that you cannot provide any rationale for "thickness".

I did, but you didn't understand, or don't want to.

Or you don't understand my english, which is not as good as yours.

Eric Weitzman said:I was hoping to learn something from you. At least I have from others.

I did my part on this thread, helping a diyer to make a better amp.

You didn't help.

I do not intend to teach you anything.

I don't know how to explain better than what I did.

Sorry to disappoint you.

sek said:Philosophical question for you: does thickness not matter just because noone here can satisfy you with an answer?

That's a question one should make to a woman, not us.

Eric:

You may be right, those of us who consider that the heatsink thickness is a factor must be wrong. It may not be a three dimensional consideration at all. Heat must only travel on the surface, i.e it is only a 2 dimensional phenomenom.

You are so very sure thickness matters not at all.

Therefore you should make all your heat sinks out of aluminum foil!

Think of the money you could save, make them as large as you want.

Pick up your heat sinks at the grocery store!

You may be right, those of us who consider that the heatsink thickness is a factor must be wrong. It may not be a three dimensional consideration at all. Heat must only travel on the surface, i.e it is only a 2 dimensional phenomenom.

You are so very sure thickness matters not at all.

Therefore you should make all your heat sinks out of aluminum foil!

Think of the money you could save, make them as large as you want.

Pick up your heat sinks at the grocery store!

sek said:Rth is the common symbol for thermal resistance, [Rth] = 1 K/W.

It's commonly also noted RTH, but I was lazy

I see, common in Germany perhaps... Here it's θ (theta), as in θjs or θsc.

You need a good book on the topic, not a diy forum to find the answer... sometimes in life it's not sufficent to yell at others for not answering a question.

First, a "good book" on the subject would probably be at 3rd year mechanical engineering level. I don't have the spare time to engage in such a study. A forum is just the right place for experts like yourself to provide novices like me with design equations, or at least references to them. [Note: I'm still waiting for you to provide a lesson, see end of your post #37 and my reply post #39]

Second, I only responded appropriately when carlosfm started to yell at me. Please review the posts in the thread more carefully. I asked carlosfm very politely to if he could provide a reference to support his assertion. His first answer was a snotty "Yes. See my post ..." Most other posts have been civil.

Realistic answer: It appears to NOT matter because spec sheet writes never mention it and none of my textbooks mention it. Philosophical answer: In my state of little knowledge, I put more faith in National Semiconductor than carlosfm.Philosophical question for you: does thickness not matter just because noone here can satisfy you with an answer?

Can you say Texas?...[/B]

I don't get this. Can you explain this to me?

carlosfm said:Let me put it this way:

Are the heatsinks on the pics fine for an LM3886 working at +/- 37V?

That would depend on knowing the materials and dimensions, data that I do not have available to me right now.

I did my part on this thread, helping a diyer to make a better amp.

You didn't help.

Further demonstration of your .... ? I have been helping budwiser with his problem via email.

I really appreciate everyones input. Based on the dimensions for the current heat sinks for the LM3875 running off +/- 37v in my amp. I think I need to look closer at replacing them. The c/w came to 2.8.

Thanks,

Pete

The amp really sounds good, but I have not used it since the tread started. Maybe being over cautious.

Pete (budwiser)

Thanks,

Pete

The amp really sounds good, but I have not used it since the tread started. Maybe being over cautious.

Pete (budwiser)

SheldonD said:You may be right, those of us who consider that the heatsink thickness is a factor must be wrong.

....snip...

You are so very sure thickness matters not at all.

...snip...

Think of the money you could save, make them as large as you want. Pick up your heat sinks at the grocery store!

You're saying that "[I am] so very sure thickness matters not at all." I am not sure of that. I have asked for a credible explanation of why thickness matters, or for at least a reference to an explanation. None of the explanations have been conclusive, some have been easily refuted, many ideas have been interesting, and no references have answered the question (except for the amazon index of a text that omits heat transfer in three dimensions?) I'm very open to the possibility that it does matter, it seems intuitively so, so please show me why.

Perhaps you're just upset that I observed that gaincloners have a penchant for thick blocky heatsinks. I agree that they look cool, but a simple analysis of a 3" x 3" x 1/2" piece of aluminum (as I've seen recommended) shows that it's not a very good heatsink. The surface area of a medium size case may be good for some applications, but the thickness, AFAIK (and which so far hasn't been disproved) has nothing to do with it.

You really should look under the hood of your car to see just how much resemblence your car radiator bears to aluminum foil.

I just had a good idea.  Just have a look at the commercially available heatsinks. All the hi efficiency heatsinks I'm familiar with have have reasonable mass (width, thickness etc) with a large surface area (fins).

Just have a look at the commercially available heatsinks. All the hi efficiency heatsinks I'm familiar with have have reasonable mass (width, thickness etc) with a large surface area (fins).

I think you need the mass for conduction and large surface area for convection. BTW, I failed thermodynamics.

budwiser,

Don't stop using you amp, just make sure you monitor the temperature. You learn more when you experiment and maybe blow a few things up. I just use aluminium angle for heatsinks on my GCs and have found it sufficient for my requirements.

I just use aluminium angle for heatsinks on my GCs and have found it sufficient for my requirements.

I think you need the mass for conduction and large surface area for convection. BTW, I failed thermodynamics.

budwiser,

Don't stop using you amp, just make sure you monitor the temperature. You learn more when you experiment and maybe blow a few things up.

How long are the 'fins' in a car radiator? Not much more than a couple of cm away from the heat source (water). This is an important factor, since the thermal resistance of a lump of material is proportional to area and inversely proportional to length.Eric Weitzman said:...You really should look under the hood of your car to see just how much resemblence your car radiator bears to aluminum foil.

In a heatsink for an amp the lengths involved are greater, and thus the thickness must also be greater to maintain the same overall thermal resistance.

If this were not so then a huge sheet of aluminium foil would be sufficient, as suggested earlier. However even an infinite sheet of foil would have a high thermal resistance.

A forum is just the right place for experts like yourself

To my understanding this is a DIY forum and I am no expert.

It's of course true that a forum is the right place to ask. But if noone knows it, noone knows it...

Realistic answer: It appears to NOT matter because spec sheet writes never mention it and none of my textbooks mention it.

Do you see the contradiction?

First, you say that noone here can be right, because everyone refuses to deliver proof.

Then, you say that the datasheets must be right, because not a single one mentions it?

The key in understanding this discussion is: We are not speaking about missing facts in datasheets, we speak about the limit of the thermal resistance model theory. Or more specifically: it's applicability to transistor heat sinking under all circumstances.

Put a transistor on a thick heat sink with a too low thermal resistance specification and load it with only short but large power peaks. It will very likely survive. Power it with a constantaneous load that is too high for the heat sink capability and the transistor will fail (after a significant amount of time).

Put a transistor on a (too) thin heat sink with a high (enough) thermal resistance specification and again load it with a constantaneous load as high as the constantaneous load above. It will very likely survive, too. Power it, again, with short but large power peaks and it will very likely overheat.

Even if nobody here can prove why this is possible, some claim that they have experienced such a phenomenon, including me. So it obviously appears to matter for some, does it?

This is the reason why you never see heat sinks with low thermal resistance and thin mounting plates (or high-theta sinks with a waste of material in plate thickness, for that matter).

Practical calculations with thermal resistances work because the manufacturers care for the numbers. But for their validity, the mounting considerations are of importance.

Philosophical answer: In my state of little knowledge, I put more faith in National Semiconductor than carlosfm.

So far, Carlos did not contradict with any datasheet. He just said that they are usually far from complete and somtimes provide biased data.

As for his explanations: I liked the analogy of taking a kitchen roll of aluminium foil, making it infinitely large, and then claim it to be a suitable heatsink... It won't be, thickness does matter in this case. One could now argue that if it was ideally flat and void free, in theory it should. But is a thin mounting plate ideal?

I don't get this.

It's a running gag on the forum(s), nothing of importance...

Sebastian.

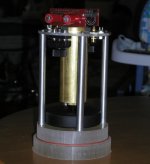

Here's the picture of my current amp. It's using 2" brass rod (about 6" long) as the heatsink (it also serves as a chassis). I expected it to be quite enough for heat dissipation, as the surface of the rod is about the same as other plates I was using successfuly for heatsinking. However, it's no the case.

Even if amp is idle, the rod is always warm, (normally it should be cold), and when amp is pushed, it gets much warmer than usually, sometimes in excess of 50 deg, which not comparable with my other amps.

I expect that a 1/8 plate of similar surface area would be more efficient in heat dissipating.

Even if amp is idle, the rod is always warm, (normally it should be cold), and when amp is pushed, it gets much warmer than usually, sometimes in excess of 50 deg, which not comparable with my other amps.

I expect that a 1/8 plate of similar surface area would be more efficient in heat dissipating.

Attachments

sek said:Do you see the contradiction?

First, you say that noone here can be right, because everyone refuses to deliver proof.

Then, you say that the datasheets must be right, because not a single one mentions it?

Either you're backing you "contradiction" by distortion, pure and simple, or you're skipping over the literal meaning of the words I choose. I have never said nobody is right, I have never said I am right. I am debating the issue and asking those making strong assertions to back them up. I offer what I've read in spec sheets as support for my doubt that thickness matters, not as proof that everyone else is wrong. I have even conceded that some of the intuitive arguments are appealing several times.

The key in understanding this discussion is: We are not speaking about missing facts in datasheets, we speak about the limit of the thermal resistance model theory. Or more specifically: it's applicability to transistor heat sinking under all circumstances.

It seems that you've been in a different conversation that I have been. Nobody has presented any formal model of thermal resistance, let alone discussed the limitations of the model. Maybe this is where your thinking is at, but not your posting.

Anyways, nothing has been proven either way. We only have several more datapoints to consider now, especially those presented by Peter.

- Eric

Peter Daniel said:Here's the picture of my current amp. It's using 2" brass rod (about 6" long) as the heatsink (it also serves as a chassis). I expected it to be quite enough for heat dissipation, as the surface of the rod is about the same as other plates I was using successfuly for heatsinking. However, it's no the case.

Peter,

I'd suggest two reasons for the higher temperature:

1. the smooth surface and curved shape severely limits turbulent air flow, limiting heat transfer to the air

2. shiny surfaces (like your brass has) have terrible emissivity (0.07 for polished copper compared to 0.9 for anodized aluminum)

- Eric

Peter Daniel said:I will try to mill out the grooves on the length; this might help in dissipation.

Just put it in the baby walker and let your kid walk it around...

Peter Daniel said:I will try to mill out the grooves on the length; this might help in dissipation.

Besides being inefficient, this type of heatsink arrangement has certain advantages not only for the sound, but also building a chassis gets pretty simple.

Peter have you ever determined if there is a relationship between chip temperature and sound quality. It seems to me that there is a lot of GCs with inefficient heatsinks so maybe running the chips warmer has an advantage. Heat is the only way I can think of to influence the internal circuitry.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Chip Amps

- Legacy GC with new snubber PS