Not sure why I'm replying, because I don't know what said part is that you need.

I want to say though: might it be something that could be "3D Printed" for you?

If so it might expand the possibilities of who can help. Search for 3D Print Service. I hear it's becoming less expensive. Antique car folks might hire a job for a car window crank for example.

Best of luck.

I want to say though: might it be something that could be "3D Printed" for you?

If so it might expand the possibilities of who can help. Search for 3D Print Service. I hear it's becoming less expensive. Antique car folks might hire a job for a car window crank for example.

Best of luck.

Making a part

I could do it, depending upon how involved it is. I have my own Bridgeport milling machine but no lathe. I have access to a lathe but I would have to travel to Prescott which is a 40 mile round trip. Can you post a drawing?

There are machine shops all over the place. Have you tried finding one in your neighborhood?

Sincerely,

Ralf

I need to have a part done.

I could do it, depending upon how involved it is. I have my own Bridgeport milling machine but no lathe. I have access to a lathe but I would have to travel to Prescott which is a 40 mile round trip. Can you post a drawing?

There are machine shops all over the place. Have you tried finding one in your neighborhood?

Sincerely,

Ralf

Alex,Not sure why I'm replying, because I don't know what said part is that you need.

I want to say though: might it be something that could be "3D Printed" for you?

If so it might expand the possibilities of who can help. Search for 3D Print Service. I hear it's becoming less expensive. Antique car folks might hire a job for a car window crank for example.

Best of luck.

Thanks for your input!

If I use acrylic, I can do it myself. But I think aluminum makes sound "punchier" and more dynamic, so I chose to use aluminum. I have limited power tools and can't make the part I need with aluminum. 3D printed is plastic, too.

I could do it, depending upon how involved it is. I have my own Bridgeport milling machine but no lathe. I have access to a lathe but I would have to travel to Prescott which is a 40 mile round trip. Can you post a drawing?

There are machine shops all over the place. Have you tried finding one in your neighborhood?

Sincerely,

Ralf

Ralf,

Thank you very much!

I have checked with local machine shops. They simply don't want to do one piece at all. I don't think the part will involve a lathe.

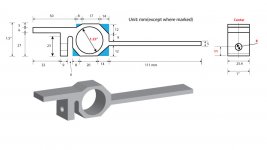

Please see attached drawing. The numbers in red are important. The rest are not. They can be in tolerance +/- 1 mm or even bigger. If it is too much trouble, I can use my band saw to cut the blue areas myself. You don't need do it. These corners are really not important. They can be a little or smaller. I marked the dimensions just for the purpose of communication. You will have rough idea about these corners. I don't have any idea how you set up your milling machine. So, I can revise the design to fit your tooling and milling machine if you need. Material is 2024 aluminum. I can order a 1"x1.5" 1 foot long 2024 aluminum rectangle bar and send it directly to you. Please pm me or email me your shipping address and how much you will charge me.

Again, thanks a lot!

Jim

jimw10001 at gmail dot com

Attachments

Last edited:

Jim

I could do that part for you if Ralf decides not to take it on.

Cheers,

B B

BB,

Thank you! I will let you know.

Jim

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Need Help for Making a Part