Thanks ;-)

The use of a solid template is a really good idea.

I found several sources with the two level plinth on net.

- also the use of the bitumen mat is from the net.

The design reminds me of the "Danish Modern" style that was a popular furnishings style in the seventies and continues to be a choice of style today. I always felt comfortable with it.

-Steve

Hello Again

Coming back to this thread a few days later than I had hoped.

I see there have been some updates.

My thanks to both Tralalala and user510.

I learned something new by this recent exchange.

Im finishing up repairing/restoring an Oracle Delphi and am heading next to the Thorens.

It needs work and has no plinth. The lack of a plinth makes it cumbersome to work on.

So I might start off with the top surface of Tralalala's plinth to support the table and to provide access below at the same time.

Anyway thank you so much for sharing your work. Greatly appreciated.

Curt

Coming back to this thread a few days later than I had hoped.

I see there have been some updates.

My thanks to both Tralalala and user510.

I learned something new by this recent exchange.

Im finishing up repairing/restoring an Oracle Delphi and am heading next to the Thorens.

It needs work and has no plinth. The lack of a plinth makes it cumbersome to work on.

So I might start off with the top surface of Tralalala's plinth to support the table and to provide access below at the same time.

Anyway thank you so much for sharing your work. Greatly appreciated.

Curt

Hi Curt!

Good you`re back.

I googled the Oracle Delphi turntable - that sure is a nice looking turntable.

Which model do you got?

I would suggest doing what user510 talked about; making a template out of a sturdy material ; like MDF , or something..

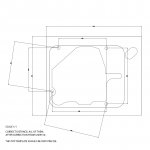

I´m attaching one last template ( top layer ) with exact distances as the original Thorens TD124 template; as the one user510 attached in one of his previous post replies. This template should be very precise.

If you want you can make this one template for me to check that everything works? Then we know this template is for good use for others too !

ABOUT the way I used to make my plinth:

1. I made prototypes of each layer in MDF. - a material that is easy to shape...

I used a jigsaw and sandpaper. I used a sandpaper "thing" ( like this one : Sliperondell Ø50*mm K150 ) to attach to a handheld drill - to smoothen the edges. especially the oval and round edges.

2. Used a handheld router with a wheel bearing attached to the top of the router bit.

3. Started making the parts out of 3/4" birch plywood.

Good you`re back.

I googled the Oracle Delphi turntable - that sure is a nice looking turntable.

Which model do you got?

I would suggest doing what user510 talked about; making a template out of a sturdy material ; like MDF , or something..

I´m attaching one last template ( top layer ) with exact distances as the original Thorens TD124 template; as the one user510 attached in one of his previous post replies. This template should be very precise.

If you want you can make this one template for me to check that everything works? Then we know this template is for good use for others too !

ABOUT the way I used to make my plinth:

1. I made prototypes of each layer in MDF. - a material that is easy to shape...

I used a jigsaw and sandpaper. I used a sandpaper "thing" ( like this one : Sliperondell Ø50*mm K150 ) to attach to a handheld drill - to smoothen the edges. especially the oval and round edges.

2. Used a handheld router with a wheel bearing attached to the top of the router bit.

3. Started making the parts out of 3/4" birch plywood.

Attachments

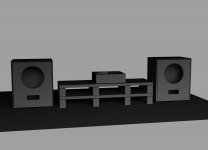

DIY rack system for Thorens TD 124.

Hi !

I just tested my Thorens TD124 in my DIY plinth with a Analogue Productions Test LP.

Track6 on side two is designed for testing table isolation.

It was really bad.

I quess it is because I´m currently using a cabinet with sliding doors and 18mm thick panels. It is a really nice looking cabinet, but the damping of the cabinet is bad.

This all is really silly because I´ve built this large plinth for my TD124 , without taking into concern the damping factor of what it stands on!

Anyway: need a bit of help:

So I have drawn a new hifi rack in my 3D program. ( see attached render )

I was wondering if concrete stands in between a 38mm kitchen solid wood bench top in two layers would do it.

Will I need any other small things - like spikes or similar?

Any help will be really appreciated!

Hi !

I just tested my Thorens TD124 in my DIY plinth with a Analogue Productions Test LP.

Track6 on side two is designed for testing table isolation.

It was really bad.

I quess it is because I´m currently using a cabinet with sliding doors and 18mm thick panels. It is a really nice looking cabinet, but the damping of the cabinet is bad.

This all is really silly because I´ve built this large plinth for my TD124 , without taking into concern the damping factor of what it stands on!

Anyway: need a bit of help:

So I have drawn a new hifi rack in my 3D program. ( see attached render )

I was wondering if concrete stands in between a 38mm kitchen solid wood bench top in two layers would do it.

Will I need any other small things - like spikes or similar?

Any help will be really appreciated!

Attachments

What might help is like the Loricraft plinths use an isolated top 25 mm section. They use squash balls after finding them better than other ideas. I guess an inner tube a nice idea as pressure can be adjusted.

The mass of the plinth or building is read by the stylus, too much mass is like a piano. The isolation helps yet still offers the advantages of that mass. A wall shelf also helps. Sorbothane. I have my doubts about it , it is popular. Springs also, I suspect that would cause as many problems as it solves. The inner tube seems beyond ideal. My instinct is 5 PSI . MDF top, concrete bottom is possible with isolation. Allow the internal cavity to breath. If not it becomes a Helmholtz resonator. The deck bottom open and clear of the shelf is all it needs. If not damp the space with speaker damping fibre. Care with that as things might get hot. Do both perhaps?

If wanting a simple way out squash balls at the plinth bottom. I suspect it will do 90% of the ultimate. Cut holes in a piece of wood slightly smaller than the balls and use that to keep it stable. Yes they do distort quickly. They still seem to work just fine if so. If you can find some holders for them that helps. 38 mm from memory. Paper spacers work fine.

The mass of the plinth or building is read by the stylus, too much mass is like a piano. The isolation helps yet still offers the advantages of that mass. A wall shelf also helps. Sorbothane. I have my doubts about it , it is popular. Springs also, I suspect that would cause as many problems as it solves. The inner tube seems beyond ideal. My instinct is 5 PSI . MDF top, concrete bottom is possible with isolation. Allow the internal cavity to breath. If not it becomes a Helmholtz resonator. The deck bottom open and clear of the shelf is all it needs. If not damp the space with speaker damping fibre. Care with that as things might get hot. Do both perhaps?

If wanting a simple way out squash balls at the plinth bottom. I suspect it will do 90% of the ultimate. Cut holes in a piece of wood slightly smaller than the balls and use that to keep it stable. Yes they do distort quickly. They still seem to work just fine if so. If you can find some holders for them that helps. 38 mm from memory. Paper spacers work fine.

Hello,

I think vinylengine got a plan for the original plinth, but the drawings are not correctly sized, it is not in correct size, nor is the drawing alignments correct - see previous discussion in this thread.

BUT the dimensions on the template from vinylengine is correct !

link:

Thorens TD124 Manual - 4-Speed Belt-Idler-Drive Turntable - Vinyl Engine

- you will need to create an account to download at vinylengine.

( it is free of charge. )

PS : you can also order a template from soundfountain for 11USD ( postage not included )

link:

Thorens TD 124 / TD124 Mk2 and TD-224 Legendary Vintage Turntables

I think vinylengine got a plan for the original plinth, but the drawings are not correctly sized, it is not in correct size, nor is the drawing alignments correct - see previous discussion in this thread.

BUT the dimensions on the template from vinylengine is correct !

link:

Thorens TD124 Manual - 4-Speed Belt-Idler-Drive Turntable - Vinyl Engine

- you will need to create an account to download at vinylengine.

( it is free of charge. )

PS : you can also order a template from soundfountain for 11USD ( postage not included )

link:

Thorens TD 124 / TD124 Mk2 and TD-224 Legendary Vintage Turntables

Hi, Tralalala.

Did you ever solve your damping problems? Is your project complete?

I've started in the opposite direction. Built the stereo rack first.

Last week I sold and TD160 and bought a TD124 on the same day. Ready for complete restoration and a new plinth! Would love to see your completed project.

Did you ever solve your damping problems? Is your project complete?

I've started in the opposite direction. Built the stereo rack first.

Last week I sold and TD160 and bought a TD124 on the same day. Ready for complete restoration and a new plinth! Would love to see your completed project.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Can`t find any solid DIY plinth drawings for TD 124.