Hello !

I want to use the following weeks to build a new plinth for my Thorens TD124 MkI.

I´ve understood from several sources on net that making a solid plinth for the Thorens TD124 motor noise will be less noticeable.

I will try to install my turntable without mushrooms.

I cannot find any DIY resources on net that has exact drawing on a solid plinth for the TD124...

I´m thinking of building the plinth out of 19mm MDF.

I do not have the opportunity to build this plinth out of slate.

Any other good wood based materials I should consider?

I will need some time to make exact drawings for this plinth.

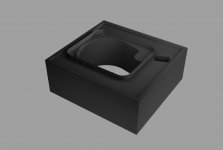

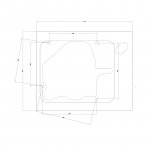

See attached picture for an idea on how I want to build it.

There will be several layers in this plinth with different cutouts.

I want to use the following weeks to build a new plinth for my Thorens TD124 MkI.

I´ve understood from several sources on net that making a solid plinth for the Thorens TD124 motor noise will be less noticeable.

I will try to install my turntable without mushrooms.

I cannot find any DIY resources on net that has exact drawing on a solid plinth for the TD124...

I´m thinking of building the plinth out of 19mm MDF.

I do not have the opportunity to build this plinth out of slate.

Any other good wood based materials I should consider?

I will need some time to make exact drawings for this plinth.

See attached picture for an idea on how I want to build it.

There will be several layers in this plinth with different cutouts.

Attachments

Baltic birch plywood is probably preferable to mdf for this application.

Use the standard template for the top layers, and for the last few layers you just need to clear the linkages and motor.

I have two slate plinths which comprise 4 pieces of 2cm thick slate, top two cut to the template, bottom two are solid under the entire arm board and most of the right side of the table.

I do not have any drawings unfortunately.

Use the standard template for the top layers, and for the last few layers you just need to clear the linkages and motor.

I have two slate plinths which comprise 4 pieces of 2cm thick slate, top two cut to the template, bottom two are solid under the entire arm board and most of the right side of the table.

I do not have any drawings unfortunately.

One more try...

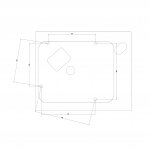

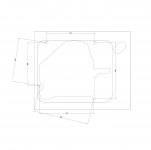

OK- so I printed out the three cutouts I made yesterday.

I´ve done some modifications on the drawings. I need to adjust a new cutout for the SME 3012 tonearm... - and the correct placement of the drilling holes for the cut thread bolts fastened to the Thorens.

I´m guessing I will make a prototype out of MDF tomorrow.

OK- so I printed out the three cutouts I made yesterday.

I´ve done some modifications on the drawings. I need to adjust a new cutout for the SME 3012 tonearm... - and the correct placement of the drilling holes for the cut thread bolts fastened to the Thorens.

I´m guessing I will make a prototype out of MDF tomorrow.

Attachments

Levelling screw layout

A number of years ago, I measured the leveling screw layout of my TD-124.

I am attaching a PDF of same. I hope that this will help you.

Please verify that the dimensions are correct.

Sincerely,

Ralf

A number of years ago, I measured the leveling screw layout of my TD-124.

I am attaching a PDF of same. I hope that this will help you.

Please verify that the dimensions are correct.

Sincerely,

Ralf

Attachments

Last edited:

PROTOTYPE DRAWING

Thank you! - your drawing helped me a lot.

I`m now including one last drawing ( with the help from the drawing made by Straight Tracker; this drawing should be quite accurate).

Will not have time to make a prototype out of MDF today, but quite soon I will post again to verify if the drawing works or not.

________________

I do have one question :

I have to make this plinth with a handheld jigsaw and a handheld router - this is why I wanted to make a prototype of MDF - much more easy to shape as a material than x-finer.

I´ve heard that some people make plinths out of different materials- the different materials used effects the noise from the engine of the turntable differently.

I´ve not seen many plinths like this- has anyone on the forum made a plinth like this?

Thank you! - your drawing helped me a lot.

I`m now including one last drawing ( with the help from the drawing made by Straight Tracker; this drawing should be quite accurate).

Will not have time to make a prototype out of MDF today, but quite soon I will post again to verify if the drawing works or not.

________________

I do have one question :

I have to make this plinth with a handheld jigsaw and a handheld router - this is why I wanted to make a prototype of MDF - much more easy to shape as a material than x-finer.

I´ve heard that some people make plinths out of different materials- the different materials used effects the noise from the engine of the turntable differently.

I´ve not seen many plinths like this- has anyone on the forum made a plinth like this?

Attachments

Hello,

I've started building my new plinth.

Some minor adjustments was needed to get the thorens player in place

- will post new drawings later on.

Attaching one photo of the top plate.

Will make the whole plinth out of 8 layers of 18mm birch x-finer + one top layer out of 4mm x-finer.

I was wondering if the cutout through the whole plinth I'm building is enough for air to move freely around the engine- any thoughts? ( see previously posted drawings...)

I'm also curious if anyone has any suggestions for damping feet / spikes?

All help will be appreciated.... !

I've started building my new plinth.

Some minor adjustments was needed to get the thorens player in place

- will post new drawings later on.

Attaching one photo of the top plate.

Will make the whole plinth out of 8 layers of 18mm birch x-finer + one top layer out of 4mm x-finer.

I was wondering if the cutout through the whole plinth I'm building is enough for air to move freely around the engine- any thoughts? ( see previously posted drawings...)

I'm also curious if anyone has any suggestions for damping feet / spikes?

All help will be appreciated.... !

Attachments

I think if you leave 25mm or more of clearance to the plinth the motor will be sufficiently ventilated - it is cooled solely by natural convection.

I used hard rubber corks to support my 35kg slate plinths, the top of these corks is about 5cm across and the bottom about 4cm. I got these at the local home center. (Lowes)

I used hard rubber corks to support my 35kg slate plinths, the top of these corks is about 5cm across and the bottom about 4cm. I got these at the local home center. (Lowes)

Hi,

Thanks for the input

Now the motor has a 2.5 cm distance to nearest edge.

I´m still in the process of building my plinth.

It´s total weight will be just a little bit under 20 kg.

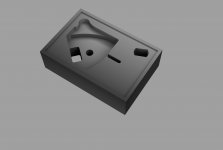

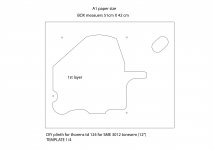

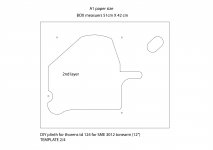

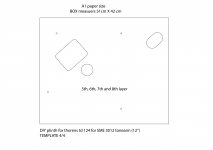

Do have all the templates for the four different layers in place.

See 4 attached files.

I`m hoping that others will find this useful....

Thanks for the help kevinkr and Straight Tracker

Best,

Tralalalala

Thanks for the input

Now the motor has a 2.5 cm distance to nearest edge.

I´m still in the process of building my plinth.

It´s total weight will be just a little bit under 20 kg.

Do have all the templates for the four different layers in place.

See 4 attached files.

I`m hoping that others will find this useful....

Thanks for the help kevinkr and Straight Tracker

Best,

Tralalalala

Attachments

-

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-01.jpg271.5 KB · Views: 449

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-01.jpg271.5 KB · Views: 449 -

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-02.jpg271.5 KB · Views: 584

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-02.jpg271.5 KB · Views: 584 -

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-03.jpg277.4 KB · Views: 241

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-03.jpg277.4 KB · Views: 241 -

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-04.jpg273.1 KB · Views: 325

DIY THORENS TD 124 PLINTH (with cutout for sme 3012 tonearm)-04.jpg273.1 KB · Views: 325

Hello

Was just wondering how your TD-124 plinth worked out for you.

Were you able to finish it and is your TD 124 up and running playing music?

I hope you dont mind, but I have copied the plans you drew

and posted here in this thread.

I plan on using your drawings and I hope to get started soon.

Was wondering if you found the need to modify the plans.

Take care and thanks for documenting your build.

Curt

Was just wondering how your TD-124 plinth worked out for you.

Were you able to finish it and is your TD 124 up and running playing music?

I hope you dont mind, but I have copied the plans you drew

and posted here in this thread.

I plan on using your drawings and I hope to get started soon.

Was wondering if you found the need to modify the plans.

Take care and thanks for documenting your build.

Curt

Hi Curt ,

Yes, it did work out....!

I split the plinth in two parts - for easier mounting and demounting of the fastening bolts for my thorens td 124.. the four top layers together + the four lower layers together.

I also put in one layer of bitumen mat ( roughly 3 mm thick ) between the two parts of the plinth.

Be aware that the placement of the drilling holes are a bit off compared to how the bolts were placed; at least on my Thorens td 124 that is. I would suggest making a prototype out of a cheaper material ; as MDF to see that everything`s in place.

How will you make this plinth?

with CNC or a handheld router? ... something else?

Please let me know if there`s anything you´re wondering about

PS: this plinth is made for 12" tonearms - you have to adjust some things to get it to work with a 9" tonearm...

Yes, it did work out....!

I split the plinth in two parts - for easier mounting and demounting of the fastening bolts for my thorens td 124.. the four top layers together + the four lower layers together.

I also put in one layer of bitumen mat ( roughly 3 mm thick ) between the two parts of the plinth.

Be aware that the placement of the drilling holes are a bit off compared to how the bolts were placed; at least on my Thorens td 124 that is. I would suggest making a prototype out of a cheaper material ; as MDF to see that everything`s in place.

How will you make this plinth?

with CNC or a handheld router? ... something else?

Please let me know if there`s anything you´re wondering about

PS: this plinth is made for 12" tonearms - you have to adjust some things to get it to work with a 9" tonearm...

Pictures

Hi again,

See attached pictures of the plinth.

I did use a 4mm birch plywood on the top layer in addition to the other layers.

The machine I used to sand the edges on the plinth stopped working half through the job, never got around to finish the lower part of my plinth..

Hi again,

See attached pictures of the plinth.

I did use a 4mm birch plywood on the top layer in addition to the other layers.

The machine I used to sand the edges on the plinth stopped working half through the job, never got around to finish the lower part of my plinth..

Attachments

I'm a little late to the party for this thread but I do have something that may be of use to others wanting to build their own TD124 plinth; A scan of a Thorens factory cut template. The scan is not to scale but does show dimensions to critical parts of the plinth, like the stud hole locations and size. Etc.

Here's a link to it in pdf.

http://www.theanalogdept.com/images/spp6_pics/TT%20manuals/Thorens/TD124%20Cut%20Template_not%20to%20scale.pdf

Btw you can find a pdf of this file at The vinyl Engine, or you can find it in the manuals page at my site. I think the contributor for this file to my site was an individual in Russia.

-Steve

Here's a link to it in pdf.

http://www.theanalogdept.com/images/spp6_pics/TT%20manuals/Thorens/TD124%20Cut%20Template_not%20to%20scale.pdf

Btw you can find a pdf of this file at The vinyl Engine, or you can find it in the manuals page at my site. I think the contributor for this file to my site was an individual in Russia.

-Steve

Hello !

I want to use the following weeks to build a new plinth for my Thorens TD124 MkI.

I´ve understood from several sources on net that making a solid plinth for the Thorens TD124 motor noise will be less noticeable.

I will try to install my turntable without mushrooms.

I cannot find any DIY resources on net that has exact drawing on a solid plinth for the TD124...

I´m thinking of building the plinth out of 19mm MDF.

I do not have the opportunity to build this plinth out of slate.

Any other good wood based materials I should consider?

I will need some time to make exact drawings for this plinth.

See attached picture for an idea on how I want to build it.

There will be several layers in this plinth with different cutouts.

updated drawings - correct alignment of holes for fastening bolts.

Hi,

After redrawing my plinth with correct placement of the drilling holes -

INFO: The resource from analog dep. did not work out for me. ( the template was put together in a way where the horizontal alignment did not correspond with the vertical alignment when scaled correctly )

The drawings from vinyl engine was better. But still difficult..

This was the best I could do.

See attached jpeg files (in 1/1 scale in 72dpi ). It is just a few millimeters of at some of the distances. It should be very close to the original template...

Hi,

After redrawing my plinth with correct placement of the drilling holes -

INFO: The resource from analog dep. did not work out for me. ( the template was put together in a way where the horizontal alignment did not correspond with the vertical alignment when scaled correctly )

The drawings from vinyl engine was better. But still difficult..

This was the best I could do.

See attached jpeg files (in 1/1 scale in 72dpi ). It is just a few millimeters of at some of the distances. It should be very close to the original template...

Attachments

Hi,

After redrawing my plinth with correct placement of the drilling holes -

INFO: The resource from analog dep. did not work out for me. ( the template was put together in a way where the horizontal alignment did not correspond with the vertical alignment when scaled correctly )

The drawings from vinyl engine was better. But still difficult..

This was the best I could do.

See attached jpeg files (in 1/1 scale in 72dpi ). It is just a few millimeters of at some of the distances. It should be very close to the original template...

Neither the pdf from VE or The analog Dept is to scale. The scale was lost during the scanning process. Here is a 'print reading basic'; when the drawing is marked "not to scale" you are not supposed to scale it. By your text it appears that that is what you have been trying to do.

All you need to do is use the printed dimensions from either pdf and apply those as nominals to a new "full scale" drawing that you will make.

-Steve

My Thorens TD 124 plinth is already finished.

I did the drawings. I´ve made the plinth.

The guy that asked me answer my own thread - has disappeared into thin air...

The only thing I remarked is that the resources on net are put together on the fly ... missing letters ... ; without taking into concern distances; both the vertical and horizontal.

It has nothing to do with the scale of the drawings.

I did the drawings. I´ve made the plinth.

The guy that asked me answer my own thread - has disappeared into thin air...

The only thing I remarked is that the resources on net are put together on the fly ... missing letters ... ; without taking into concern distances; both the vertical and horizontal.

It has nothing to do with the scale of the drawings.

Attachments

My Thorens TD 124 plinth is already finished.

I did the drawings. I´ve made the plinth.

The guy that asked me answer my own thread - has disappeared into thin air...

The only thing I remarked is that the resources on net are put together on the fly ... missing letters ... ; without taking into concern distances; both the vertical and horizontal.

It has nothing to do with the scale of the drawings.

The error is in expecting to use the scanned document as a template. Its only use is for the printed dimensions on it.

-Steve

OK. Steve.

I get your point!

Anyway; don´t see any point in answering this thread without having anyone asking questions about the drawings or the build of this plinth....

I was merely answering to your thread title. "Can't find any solid diy plinth drawings for TD 124". It is good that you were able to ultimately create your own....which is what we all do.

Nice design, btw.

Very sharp appearance. It will look good in any listening room. The two level design is interesting. And the damping material between the upper and lower levels is also a nice idea.

Getting back to the thread title; when I made my first td124 plinth, the first thing I did was to create a physical template that could be used over and over to trace the interior cut-outs and drilled holes into the top surface of any plinth design. I continue to use that template.

-Steve

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Can`t find any solid DIY plinth drawings for TD 124.