Hi direct driver

You're the courageous soul here.

I wouldn't have become aware of most of the tonearms posted to your thread.

Thank you very much.

Sincerely,

Ralf

Could not have done it without you courageous souls here

You're the courageous soul here.

I wouldn't have become aware of most of the tonearms posted to your thread.

Thank you very much.

Sincerely,

Ralf

For a linear tonearm, how about ball less plastic bearing like this ? Igus drylin bearing Link. A short video of its working here. Link. Since cartridge and arm would not be too much load for such bearing, we can shave off few slots inside the bearing to give even less friction. We can make arms like these (beautiful workmanship 🙂) with even more tighter tolerance and without ball bearings.

Regards.

Regards.

I've been looking for a simplified mechanical ellipse follower and I thought something like this ellipse trammel might work, but it doesn't.

I CAD out the point cloud from excel and the most accurate simplistic ellipse has a 17.319 mm minor axis and a 47.692 mm major axis, for a 200 mm arm

Deviation from the simple ellipse to the tangential point cloud data is 0.07 Deg

A normal tangential tonearm can have a 0.5 Deg deviation off tangent, so still very good.

I'll keep looking though.

I CAD out the point cloud from excel and the most accurate simplistic ellipse has a 17.319 mm minor axis and a 47.692 mm major axis, for a 200 mm arm

Deviation from the simple ellipse to the tangential point cloud data is 0.07 Deg

A normal tangential tonearm can have a 0.5 Deg deviation off tangent, so still very good.

I'll keep looking though.

Attachments

A short pause in the DIYer's quest for historical aids in arm design

A recent update to the encyclopedic treatment of tonearm tracking by Graeme Dennes is more than a little interesting. Mr. Dennes has published links to Klaus Rampelmann's translations (special praise!) of the works of Erik Lofgren (1938) and Bela Harsanyi (1908). Aside from (1) the interference of a World War in this 30-year period, (2) Lofgren's need to publish in German (he was Swedish), (3) and Harsanyi's need to publish in French (he was Hungarian), these entries use the same observations and almost the same equations to comment on the problems of tracking a radially-cut disc with a tonearm that swings in an arc. The remarkable third paragraph in Harsanyi's patent reads as follows:

“ To avoid this inconvenient situation, various devices have been proposed which automatically change the position of the sound box, being mounted in an articulated manner, relative to the arm so that the tangential direction of the needle plane was achieved in any arm position. These devices have not, however, become accepted because of their complicated structure. Yet it has been recognized that a virtually exact tangential direction of the needle plane in any position of the sound arm can be obtained, even without moving the sound box, if the sound box is mounted relative to the arm b such that …...”.

The remainder of the sentence is the usual patent scribe's laborious way of saying that the arm should swing across the radius instead of merely underhanging it.

What I found remarkable are the words “articulated”, and those following; “Yet it has been recognized that a virtually exact tangential direction of the needle plane in any position of the sound arm can be obtained....”. It means

1. Articulated arms were considered from the start!

2. Use of overhang and offset were known from the start!!

3. It took another 16 years for Percy Wilson to virtually repeat Harsanyi's methods, but without any attribution!

4. It took another 12 years for Lofgren to add some obvious information (the inverse nature of tracking and its effect on error and distortion), promising to use it (but not doing so completely) and not really solving the problem;

5. Baerwald gave the subject the full academic treatment (calling in every mathematician from Newton to Kepler to Tchebycheff, mainly for bragging rights (he gave some credit to Lofgren) but also not solving the problems), hence the protractor brigade,

6. and then on to Bauer, Seagrave, Stevenson, Pisha, et al.

In between, we went from single 78s to broadcast-diameter discs to changers to microgroove to stereo to the elimination of 7” and 10” discs. But realize that the earliest writers seemed to espouse better fidelity, when their main agenda was keeping the 78s and their styli from each being ground up during playback!

I am not ready to praise or condemn any of the above writers, since we don't know what or who preceded Harsanyi. They clearly borrowed from each other or from an as-yet-unknown original source. Only patents ask for sources, and not consistently.

Back then, the only way to get yourself or your company or university into print was to publish, at least in the technical journals of the times. All the writings have some usefulness, even if only to try to “clarify” someone else's previous work. Notice the different pubs: Technical Journals, Audio, Wireless World, Stereo Review, Hi-Fi News & Record Review, The Gramophone. Whether you wrote and what you wrote was often decreed by an advertising department or magazine editor.

Additional real problems, such as treating only conical styli, ignoring vertical alignment issues (changers don't care), and giving no help for the possibly larger problem, i.e. skating force, are among their added sins.

No one is an outstanding figure, here. As Newton said, "I have stood on the shoulders of giants."

Andy

A recent update to the encyclopedic treatment of tonearm tracking by Graeme Dennes is more than a little interesting. Mr. Dennes has published links to Klaus Rampelmann's translations (special praise!) of the works of Erik Lofgren (1938) and Bela Harsanyi (1908). Aside from (1) the interference of a World War in this 30-year period, (2) Lofgren's need to publish in German (he was Swedish), (3) and Harsanyi's need to publish in French (he was Hungarian), these entries use the same observations and almost the same equations to comment on the problems of tracking a radially-cut disc with a tonearm that swings in an arc. The remarkable third paragraph in Harsanyi's patent reads as follows:

“ To avoid this inconvenient situation, various devices have been proposed which automatically change the position of the sound box, being mounted in an articulated manner, relative to the arm so that the tangential direction of the needle plane was achieved in any arm position. These devices have not, however, become accepted because of their complicated structure. Yet it has been recognized that a virtually exact tangential direction of the needle plane in any position of the sound arm can be obtained, even without moving the sound box, if the sound box is mounted relative to the arm b such that …...”.

The remainder of the sentence is the usual patent scribe's laborious way of saying that the arm should swing across the radius instead of merely underhanging it.

What I found remarkable are the words “articulated”, and those following; “Yet it has been recognized that a virtually exact tangential direction of the needle plane in any position of the sound arm can be obtained....”. It means

1. Articulated arms were considered from the start!

2. Use of overhang and offset were known from the start!!

3. It took another 16 years for Percy Wilson to virtually repeat Harsanyi's methods, but without any attribution!

4. It took another 12 years for Lofgren to add some obvious information (the inverse nature of tracking and its effect on error and distortion), promising to use it (but not doing so completely) and not really solving the problem;

5. Baerwald gave the subject the full academic treatment (calling in every mathematician from Newton to Kepler to Tchebycheff, mainly for bragging rights (he gave some credit to Lofgren) but also not solving the problems), hence the protractor brigade,

6. and then on to Bauer, Seagrave, Stevenson, Pisha, et al.

In between, we went from single 78s to broadcast-diameter discs to changers to microgroove to stereo to the elimination of 7” and 10” discs. But realize that the earliest writers seemed to espouse better fidelity, when their main agenda was keeping the 78s and their styli from each being ground up during playback!

I am not ready to praise or condemn any of the above writers, since we don't know what or who preceded Harsanyi. They clearly borrowed from each other or from an as-yet-unknown original source. Only patents ask for sources, and not consistently.

Back then, the only way to get yourself or your company or university into print was to publish, at least in the technical journals of the times. All the writings have some usefulness, even if only to try to “clarify” someone else's previous work. Notice the different pubs: Technical Journals, Audio, Wireless World, Stereo Review, Hi-Fi News & Record Review, The Gramophone. Whether you wrote and what you wrote was often decreed by an advertising department or magazine editor.

Additional real problems, such as treating only conical styli, ignoring vertical alignment issues (changers don't care), and giving no help for the possibly larger problem, i.e. skating force, are among their added sins.

No one is an outstanding figure, here. As Newton said, "I have stood on the shoulders of giants."

Andy

Last edited:

Trying to find the right first inventor, or originator of a scientific idea, always feels like a faintly mean-spirited pursuit and somehow ends in acrimony. I like to think that they all, together, form a school that has benefited mankind in some small way.

Hi, Tnargs

I agree with you 100%. Graeme Dennes did us all a wonderful service by unravelling the works of the various writers on the subject of tonearm tracking.

In his revision, after over 35 years, Dennes came to see Lofgren as being slighted in the profusion of references to the work of Baerwald (on the same subject, and only a few years later) when protractors came to be used in cartridge set-up. The word "plagiarism" surfaced. And another writer wrote that he now saw the "truth" about Lofgren.

My letter takes a broader perspective and echoes your sentiments about quibbling over originators and instead focuses on their contributions as a whole (the Newton quote).

Andy

I agree with you 100%. Graeme Dennes did us all a wonderful service by unravelling the works of the various writers on the subject of tonearm tracking.

In his revision, after over 35 years, Dennes came to see Lofgren as being slighted in the profusion of references to the work of Baerwald (on the same subject, and only a few years later) when protractors came to be used in cartridge set-up. The word "plagiarism" surfaced. And another writer wrote that he now saw the "truth" about Lofgren.

My letter takes a broader perspective and echoes your sentiments about quibbling over originators and instead focuses on their contributions as a whole (the Newton quote).

Andy

Last edited:

DIY experiments

Van Eps tonearm reincarnate.

https://www.youtube.com/watch?v=N_DjmJwevj8

Check out his other videos:

https://www.youtube.com/channel/UC0H9NjsWm26IFDuaKdiHKkw/videos?view=0&sort=dd

Van Eps tonearm reincarnate.

https://www.youtube.com/watch?v=N_DjmJwevj8

Check out his other videos:

https://www.youtube.com/channel/UC0H9NjsWm26IFDuaKdiHKkw/videos?view=0&sort=dd

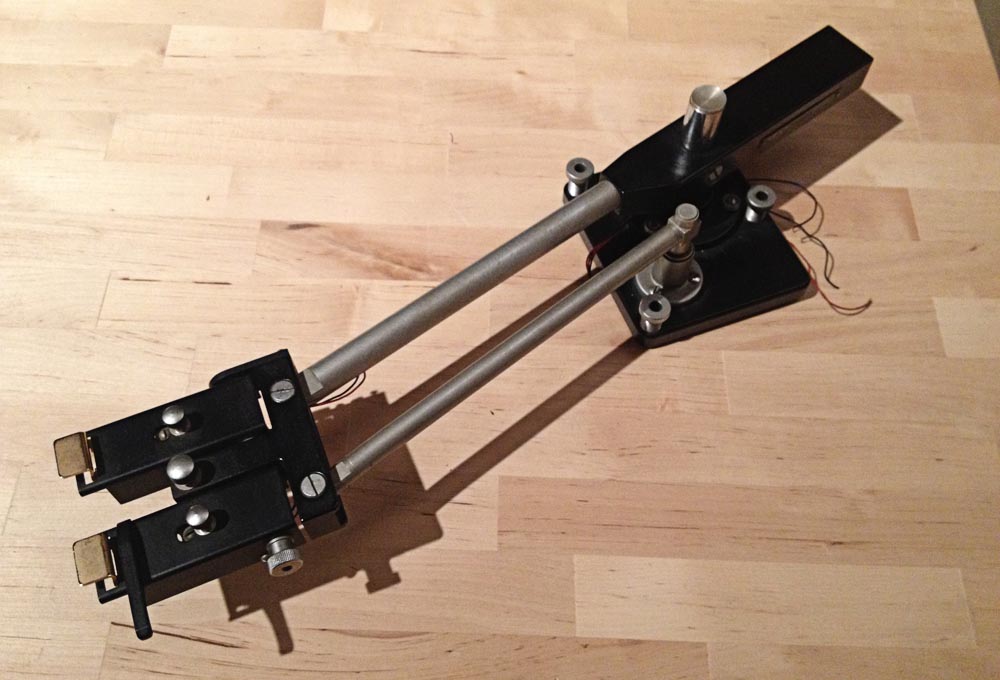

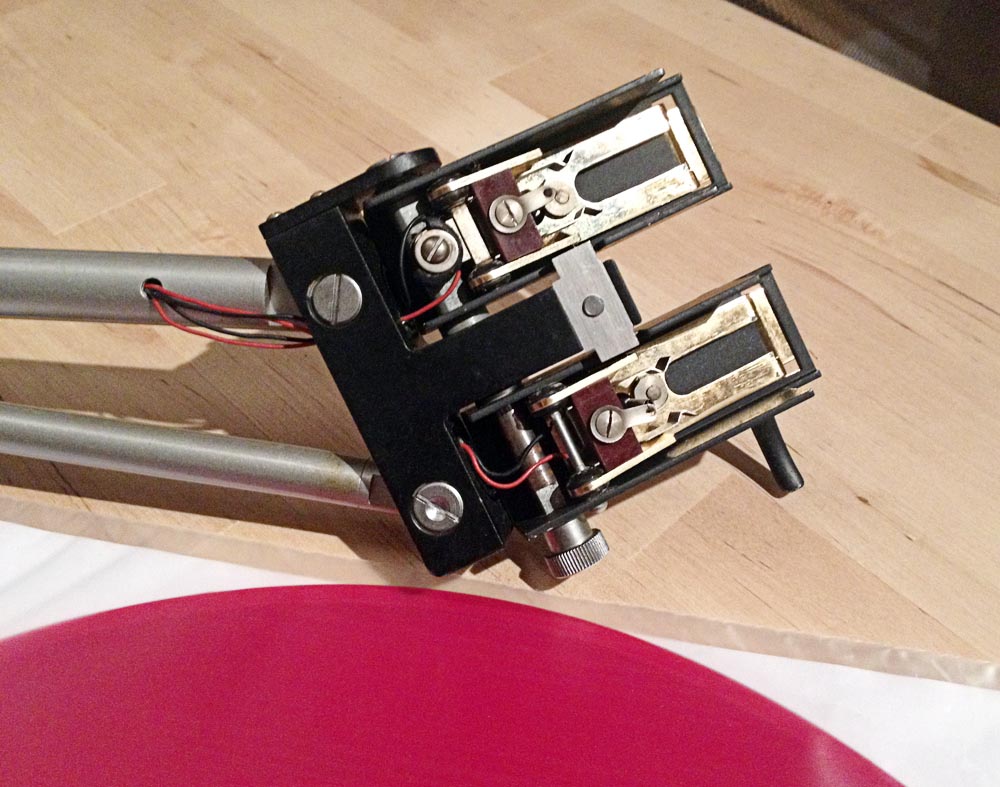

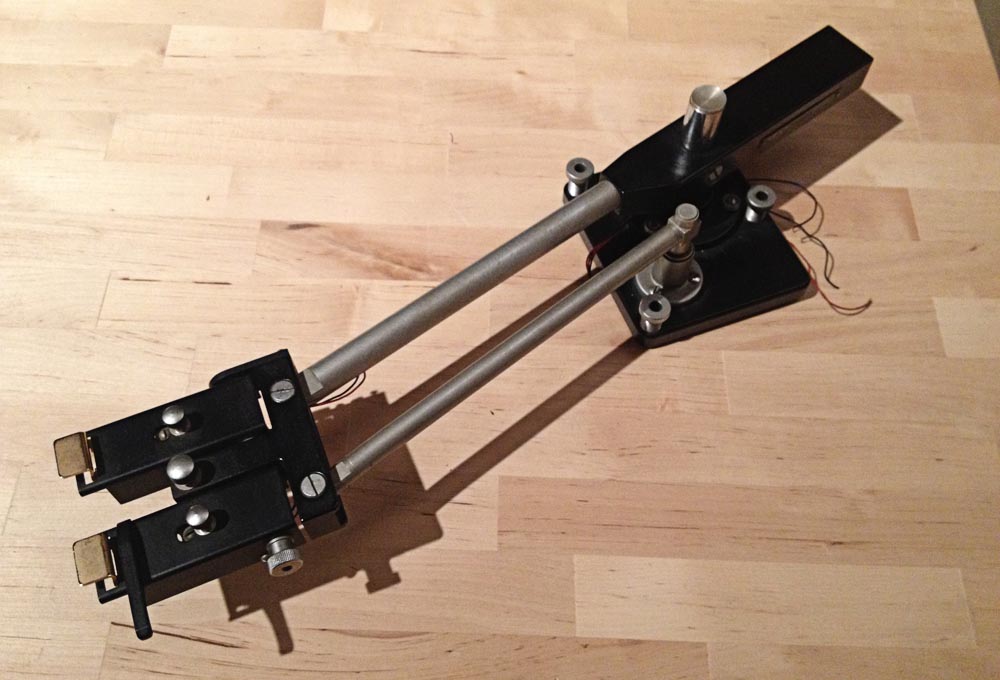

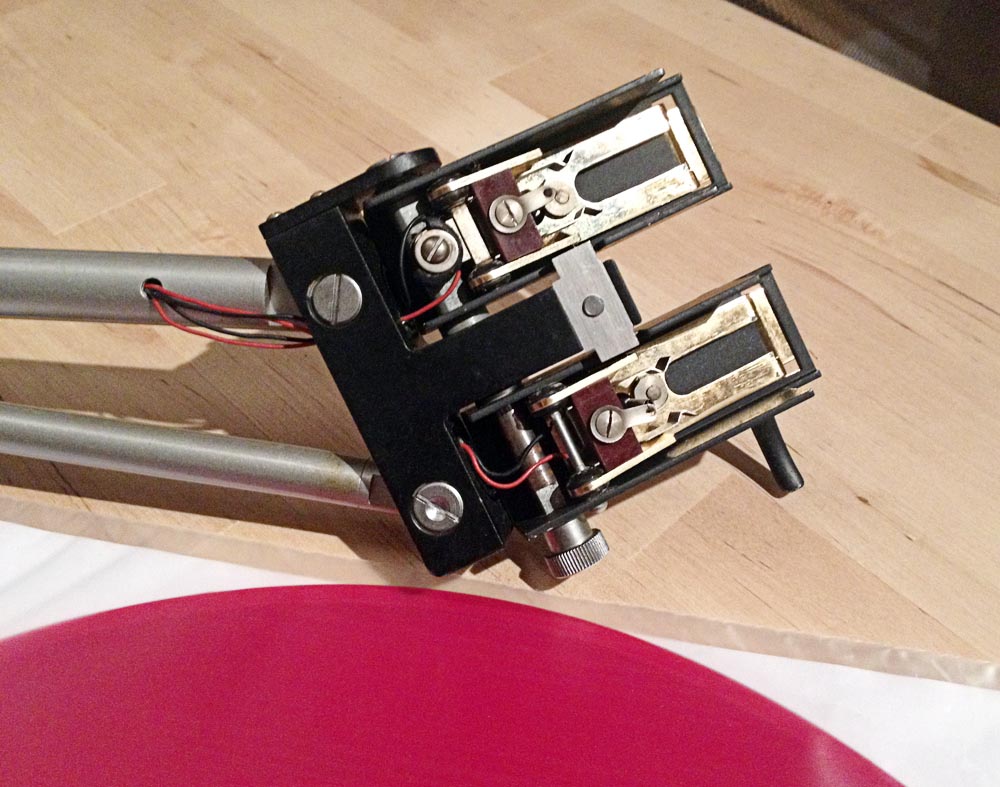

binaural and tangential

I thought I exhausted history. Nope, there's always something to discover!

More information HERE... also check out the video in the link and watch it in action!

I thought I exhausted history. Nope, there's always something to discover!

More information HERE... also check out the video in the link and watch it in action!

An externally hosted image should be here but it was not working when we last tested it.

Here's a lot more on Emery Cook and his somewhat short-lives early foray into 2 channel vinyl replay. A friend of mine has all the records and all associated gear, incl. a conventional linear tracker(carrying two carts off course):

https://en.wikipedia.org/wiki/Cook_Records

Cheers,

Frank

https://en.wikipedia.org/wiki/Cook_Records

Cheers,

Frank

Last edited:

That's an impassive looking piece of machinery. Thanks for posting the photos. Are there any of the back end?

KLAudio linear tangential tonearm

Check out this video and this video.

More pictures of KLAudio arm:

Check out this video and this video.

More pictures of KLAudio arm:

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Hello guys!

I urge you to help!

Maybe someone has mounting template for the arm (Burne Jones) BJ super 90 tangential tonearm?

If possible, send me a photo with dimensions or scan a copy of mounting template!

Thank you in advance for any help on this!

Yuriy

I urge you to help!

Maybe someone has mounting template for the arm (Burne Jones) BJ super 90 tangential tonearm?

If possible, send me a photo with dimensions or scan a copy of mounting template!

Thank you in advance for any help on this!

Yuriy

- Home

- Source & Line

- Analogue Source

- Angling for 90° - tangential pivot tonearms