Second try on ebay for the 369 was fine. Try to find some that are on tape. Less likely to be fakes. Out of 10 pieces I managed to find two pairs.

Very nice work though Riccardo!

Are those BL types ?

Can you pm me a link to the correct suppler ?

Thank you

Finally I reached my target. The enhanced simplistic is a true stepup from the "regular" design.

I am allready used to the inherent wide soundstage, fluid mids and highs and total integrity of the simplistic sound and now I got a powerfull detailed bass due certainly to the increased detail provided by the new input stage.

There are no drawbacks... nothing is lost, I only notice an overall improvement in the allready outstanding performance.

Care must be taken to build a good electromagnetic screen over the amp but that is all.

Reaching nearer Nirvana all the time

I am allready used to the inherent wide soundstage, fluid mids and highs and total integrity of the simplistic sound and now I got a powerfull detailed bass due certainly to the increased detail provided by the new input stage.

There are no drawbacks... nothing is lost, I only notice an overall improvement in the allready outstanding performance.

Care must be taken to build a good electromagnetic screen over the amp but that is all.

Reaching nearer Nirvana all the time

Anyway, I never detected differences in noise using 2SK170BL. In my builds I believe the differences in noise come principaly from the value and type of Rs used.

In this case, using two k170 in parallel with much lower Rs really made the difference....

Hi Ricardo

I think you have a realy valid point here IMO.

I have been in the last few weeks, collecting & matching, large quantitys of WIRE-WOUND resistors for a build.

It seems to me the only 'logical' way forward ( Captain ).

There seems to be endless 'rattling on' about noise-performance, of relative Op-Amps & trannys in this forum...

...But when have you ever seen anyone build with WIRE-WOUNDS ?...

...I never have.

You build valve-gear with WW's ( particularly the high-values ), BOOM !!!!

INSTANT better performance...

...I am thinking mostly, microphones & mic-pre's here.

Not so much power-amps; but why not as well...

...particularly again, the 'high-values' that are always needed in valve circuits.

People seem to want to use carbon all the time...

...OK better stability for HT stuff...

...why not just use 'wire' though.

Been looking at resistors a lot this week.

Found in my stock a bunch of 'brand new' carbons...

...ALL drifted UP by as much as 20%; never even been in a circuit.

I also found a large number that were 'open circuit' or of MegOhm type values.

I'm sure people have done this, of course...

...just 'disected' a bunch of WW, carbon & Hi-Stab. glass resistors to see how they are made...

...well...

...it makes any use of 'oxygen-free' & 'silver-wire' seem slightly redundant.

Just 'wire' in the WW's though.

I'd be interested to see what you think of your new 'SUPER-Simplistic' with a FULL compliment of wire-wound resistors ( including ALL power-supply ones as well ).

I know you can do it Ricardo !!!

Cheers.

Si.

Not much noise from me here

Got few things cooking and prety cold in the loft

But came spring I probably have enough savings for ....

Teflon® Film Capacitors | Oil Capacitors by V-Cap

Got few things cooking and prety cold in the loft

But came spring I probably have enough savings for ....

Teflon® Film Capacitors | Oil Capacitors by V-Cap

Guys. what caps would you recommend. I am looking at Multicap RTX vs Auricap XO, although I would consider others.

For the output ?

I would certainly go for the tin foils.

Hi SiI know you can do it Ricardo !!!

Off course it could be done if we could find suitable small and inexpensive WW.

Particularly for the Rs, one could use two WW wired in parallel in reversed directions to minimize any inductance.

For the output ?

I would certainly go for the tin foils.

RIAA caps

Leaaning towards RTX

I have Mundorf SIlver in Oil for output.

Guys. what caps would you recommend. I am looking at Multicap RTX vs Auricap XO, although I would consider others.

RIAA caps

Leaaning towards RTX

I have Mundorf SIlver in Oil for output.

For RIAA caps looks for precision 1% or better, VISHAY-RODERSTEIN MKP-1837 Metalized Polypropylene Film Capacitor is a good an economical choice.

Yes, a different fruits typical case.

Its the transfer function each design conveys, we can't bolt something in judiciously over subjective qualities with any good guess.

The whys are for scientists much above our DIYer heads.

It does not show higher harmonics easily it takes much pushing.

It effects dynamics that shift overall impression though.

So there you have it, but no guarantee because I haven't evaluated it yet.

Have you evaluate?

Last edited:

If parts connection is able to match RTX, I would certainly try those. Tinfoils are really good for the riaa caps.RIAA caps

Leaaning towards RTX

I have Mundorf SIlver in Oil for output.

I use RelCap polystyrenes / tin foil that Michael Percy sends me matched.

Off course the MKP 1837 are a good economical choice.

Sorry Ricardo I don't agree, if the cap is manufacturated with 1% is more accurate than if you match the caps.

That is a strange thought.

If both caps measure exactly the same why do you believe one is more acurate than the other ?

Maybe, but if the caps are matched and exhibit exactly the same value (and they are build with the same materials) they should vary it´s capacitance only due to it´s Temperature Coefficient.

IMO the tolerance is there only to enable the manufacturers to sell caps according to their spec sheets.

Polystyrenes are very stable and do not drift mutch... the only issue is that when we get a lot of 5% styrenes it is fundamental to match them because the same batch brings us 5% variation of specified value.

IMO the tolerance is there only to enable the manufacturers to sell caps according to their spec sheets.

Polystyrenes are very stable and do not drift mutch... the only issue is that when we get a lot of 5% styrenes it is fundamental to match them because the same batch brings us 5% variation of specified value.

Look here: WIMA

"Capacitance Tolerance

Tolerance is the permissible relative deviation of the capacitance from the rated value, expressed in per cent. The tolerance is to be measured at a temperature of +20°C and is only valid at the time of delivery.

After a longer period of storage or use, the tolerance can increase; but, according to standard specification, it may never exceed twice the value measured at the time of delivery.

The following delivery tolerances are usual for wound capacitors:

±1%; ±2.5%; ±5%; ±10%; ±20%.

In the case of electrolytic capacitors for which the largest possible capacitance matters, tolerances of +100/-20% also occur."

"Capacitance Tolerance

Tolerance is the permissible relative deviation of the capacitance from the rated value, expressed in per cent. The tolerance is to be measured at a temperature of +20°C and is only valid at the time of delivery.

After a longer period of storage or use, the tolerance can increase; but, according to standard specification, it may never exceed twice the value measured at the time of delivery.

The following delivery tolerances are usual for wound capacitors:

±1%; ±2.5%; ±5%; ±10%; ±20%.

In the case of electrolytic capacitors for which the largest possible capacitance matters, tolerances of +100/-20% also occur."

- Home

- Source & Line

- Analogue Source

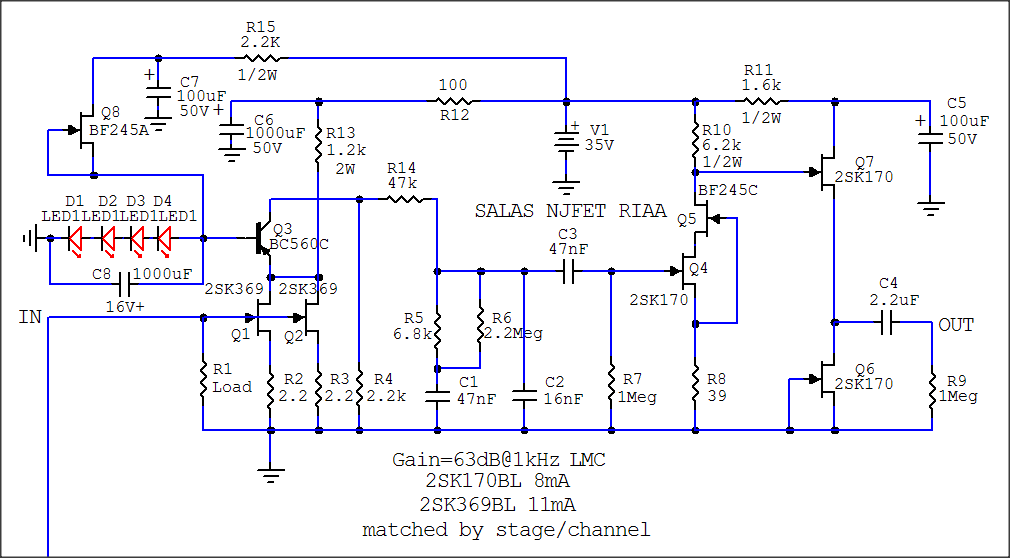

- Simplistic NJFET RIAA