You have much more Open area so there will be less pressure to push on the stator.

Low mass is good and means less energy storage for ringing unlike a large massive plate.

As long as the frames are fairly ridgid and with your choice of materails you should have to much of a problem at all, Especially compared the Plate stators.

I had a slight problem with it using my pastic grid and wire mesh system but only when I played them at there maximum level (in which case was way to loud anyhow) but it wasn't a problem at normal listening levels below 95db.

I never did have a chance to properly mount them in a frame before thier demise, but I still very much enjoyed them anyhow at 85-100db at my listening position.

I want to finsh my bigger TIG rod stators this summer and I know that ringing is going to be an issue as it is pretty bad unmounted.

Since they are already one solid panel I will have to segment just the front side, it will be interesting.

Cheers!!!

jer

Low mass is good and means less energy storage for ringing unlike a large massive plate.

As long as the frames are fairly ridgid and with your choice of materails you should have to much of a problem at all, Especially compared the Plate stators.

I had a slight problem with it using my pastic grid and wire mesh system but only when I played them at there maximum level (in which case was way to loud anyhow) but it wasn't a problem at normal listening levels below 95db.

I never did have a chance to properly mount them in a frame before thier demise, but I still very much enjoyed them anyhow at 85-100db at my listening position.

I want to finsh my bigger TIG rod stators this summer and I know that ringing is going to be an issue as it is pretty bad unmounted.

Since they are already one solid panel I will have to segment just the front side, it will be interesting.

Cheers!!!

jer

That's good to hear Jer,

Update 3/24/16:

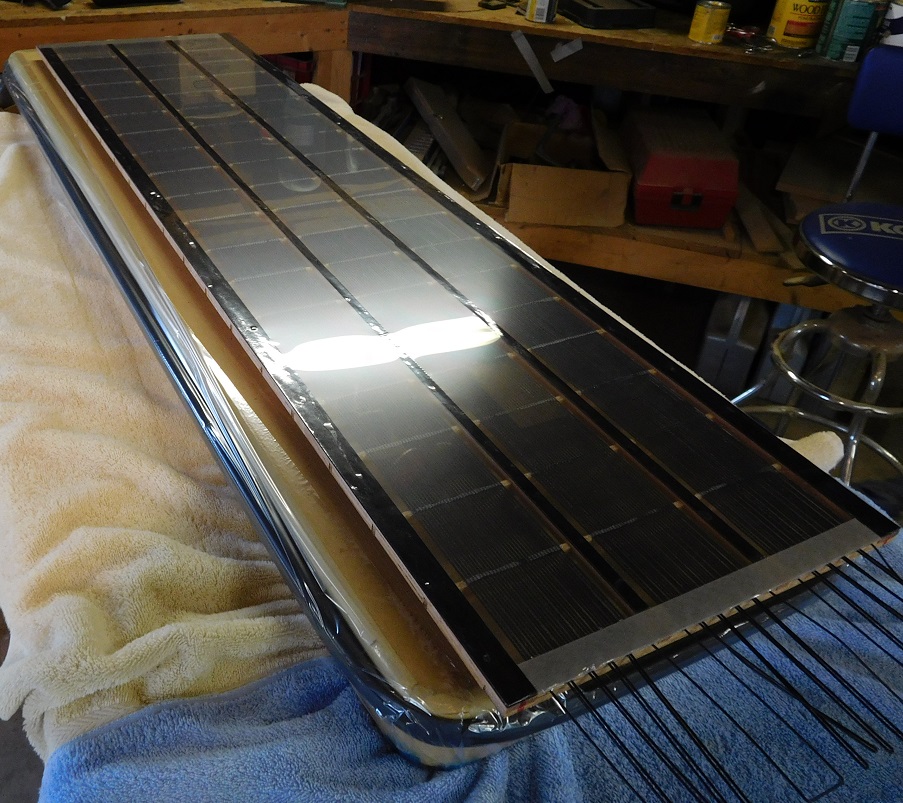

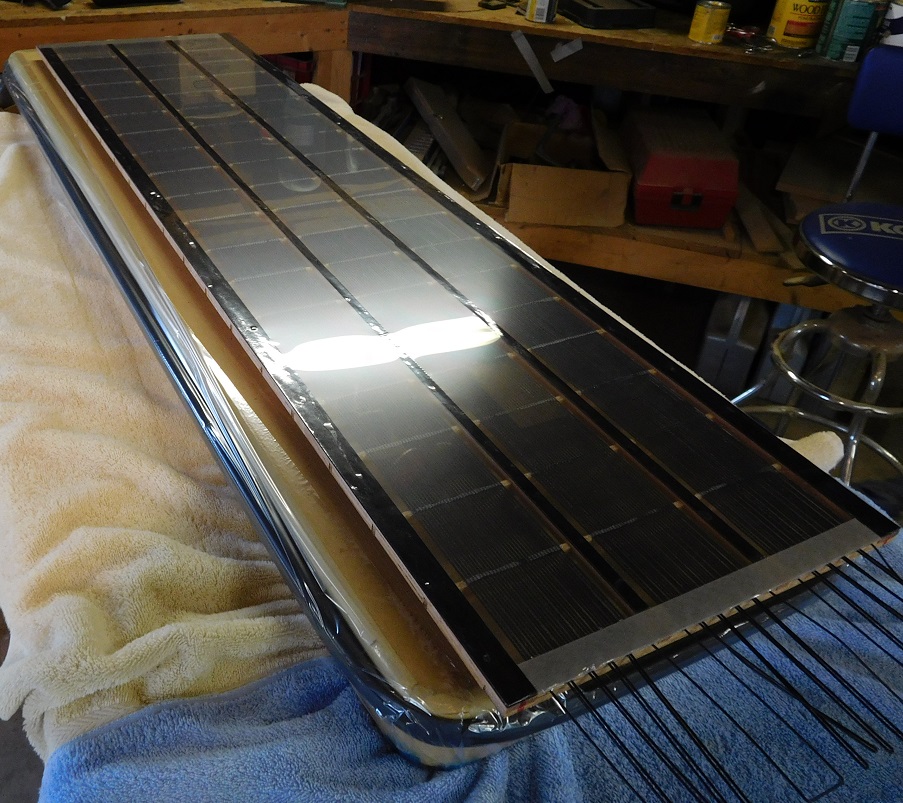

Stators are finished, diaphragms were installed and conductive coatings applied this afternoon. Coatings need twenty four hours to dry and then I can assemble the panels. I ordered the resistors and bread boards for the RC networks today--- still gotta build those. I figure another week to wrap this up.

Photo 1: Bonding stator to the tensioned diaphragm, on my pneumatic (bike tube) tensioning jig. Diaphragms were tensioned to 1.4% elongation.

Photo 2: Diaphram installed

Update 3/24/16:

Stators are finished, diaphragms were installed and conductive coatings applied this afternoon. Coatings need twenty four hours to dry and then I can assemble the panels. I ordered the resistors and bread boards for the RC networks today--- still gotta build those. I figure another week to wrap this up.

Photo 1: Bonding stator to the tensioned diaphragm, on my pneumatic (bike tube) tensioning jig. Diaphragms were tensioned to 1.4% elongation.

Photo 2: Diaphram installed

The panels are now finished. I got first sound from one when I temporarily clamped it together and played it to make sure the diaphragm coating was conducting before sticking it together.

I won't have the feed resistors until Monday so it will probably be next week end before I really get to hear these panels play.

I won't have the feed resistors until Monday so it will probably be next week end before I really get to hear these panels play.

Fellow planar pervs,

Porno:

Charlie,

These look exquisite ! Looking forward to your impressions on firing them up.

Jayant

Hello again Jayant,

These new panels have a dispersion pattern similar to the welding rod panels you heard during your visit. The treble is a bit brighter, which I like. A couple of tunes I played excited the diaphragm resonance so I need to do some fine tuning with the EQ to notch that frequency band-- then the new panels should be exquisite. I'm very pleased with the way they look, which is a whole lot better than the welding rod panels.

Regards,

Charlie

These new panels have a dispersion pattern similar to the welding rod panels you heard during your visit. The treble is a bit brighter, which I like. A couple of tunes I played excited the diaphragm resonance so I need to do some fine tuning with the EQ to notch that frequency band-- then the new panels should be exquisite. I'm very pleased with the way they look, which is a whole lot better than the welding rod panels.

Regards,

Charlie

Hello again Jayant,

These new panels have a dispersion pattern similar to the welding rod panels you heard during your visit. The treble is a bit brighter, which I like. A couple of tunes I played excited the diaphragm resonance so I need to do some fine tuning with the EQ to notch that frequency band-- then the new panels should be exquisite. I'm very pleased with the way they look, which is a whole lot better than the welding rod panels.

Regards,

Charlie

Charlie,

Good to hear from you !

You have made this daunting task look so easy with masterful execution. Should you ever consider changing your occupation, I believe you have one waiting.

Good luck with the tuning of the new Panels and may be I will get to hear them during my next visit to the US.

Jayant

Glad to hear you are pleased with the results of your new wire stators.My new segmented wire stator electrostats are finished. And they sound as good as they look … damned sexy.

Can you describe how you handled the spacers at the ends of the stators?

From the pics on your website it looks like E6000 was used to glue a thin spacer on top of the wires at a level flush with the black VHB tape used on the vertical spacers.

Attachments

Last edited:

Yes, that's right. I glued down .047" thick polycarbonate shims over the wires at the panel ends, and then applied .015" thick UHB tape over the shims to match the height of the .063 foam tape vertical spacers.

Assembling the wood lattice over the wire in the jig worked really well. I put down wax paper on the jig platform before stringing up the wires. When I took the stators out of the jig the glue lines were perfectly flush to the wires.

They sound great and I think they look stunningly good to boot.

Assembling the wood lattice over the wire in the jig worked really well. I put down wax paper on the jig platform before stringing up the wires. When I took the stators out of the jig the glue lines were perfectly flush to the wires.

They sound great and I think they look stunningly good to boot.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Planars & Exotics

- Yet another segmented ESL