I don't get why are people so intimidated by SMD, I constantly solder 0603 and 0402 elements on my job every day. I only use tweezers and good light source, for some stuff flux and/or desoldering braid, but that's only for elements with very small leg pitch.

What interests me is how much of the "SMD sounds like sh*t" is snake oil, and how much is actually backed up by science? Somewhere I saw like 2$ SMD resistors, what is that? Normal ones cost like 0.003$. Is 50000% more money justified? Are 0.1$ much better than 0.003$ ones and much worse than 2$ ones?

What interests me is how much of the "SMD sounds like sh*t" is snake oil, and how much is actually backed up by science? Somewhere I saw like 2$ SMD resistors, what is that? Normal ones cost like 0.003$. Is 50000% more money justified? Are 0.1$ much better than 0.003$ ones and much worse than 2$ ones?

I use K series tips from Hakko at work. It is quite easy to solder SMD right down to 0402 size even with lead free solder so when it was time for me to get a soldering station, I had decided which tip to get.

Because of the wide tip, you can heat both sides of a chip part and with a good PCB (with soldermask) the part aligns itself on the lands with surface tension. Because of the wide tnned areas, you can also use it to drag excess solder off chip parts or IC's to remove solder bridges quite easily without the need for solder wicks or suckers.

A recent project of mine was upgrading the op amps of my car headunit which used TSSOP parts. I didn't have to remove the PCB from the bottom chassis to do the entire work.

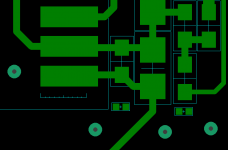

Alpine CDA-9886 Mod

Because of the wide tip, you can heat both sides of a chip part and with a good PCB (with soldermask) the part aligns itself on the lands with surface tension. Because of the wide tnned areas, you can also use it to drag excess solder off chip parts or IC's to remove solder bridges quite easily without the need for solder wicks or suckers.

A recent project of mine was upgrading the op amps of my car headunit which used TSSOP parts. I didn't have to remove the PCB from the bottom chassis to do the entire work.

Alpine CDA-9886 Mod

I don't get why are people so intimidated by SMD, I constantly solder 0603 and 0402 elements on my job every day. I only use tweezers and good light source, for some stuff flux and/or desoldering braid, but that's only for elements with very small leg pitch.

What interests me is how much of the "SMD sounds like sh*t" is snake oil, and how much is actually backed up by science? Somewhere I saw like 2$ SMD resistors, what is that? Normal ones cost like 0.003$. Is 50000% more money justified? Are 0.1$ much better than 0.003$ ones and much worse than 2$ ones?

Some of us are old and can't see. I am going to try building a WEB-CAM microscope, a home made hot air gun and may even try the toaster oven trick. SMT is a pain, but most of the new parts come packaged that way. It is also a pain as it exceeds the kind of board I used to build using a Sharpie for resist.

I don't get why are people so intimidated by SMD, I constantly solder 0603 and 0402 elements on my job every day.

I did it once for a preproduction series (wrong value resistor, 0402 iirc) and before we had our Weller tweezers.

One cup of coffee and you're no use for the rest of the day

And I have very good eyesight, but it's clearly at the limit of what I can handle. The big magnifying glass_with_light doesn't do it for me and the Mantis stereo microscope also doesn't make it easier.

An externally hosted image should be here but it was not working when we last tested it.

An externally hosted image should be here but it was not working when we last tested it.

Last edited:

The large devices are 0402's, the smaller ones 0201'2 and the very tiny little pads are for 008004's...

The grid is a 1mm line.

Murata launches 008004 size (0.25×0.125mm) capacitor-The Industry's smallest-Another "world's first" product offering from Murata | Murata Manufacturing Co., Ltd.

The grid is a 1mm line.

Murata launches 008004 size (0.25×0.125mm) capacitor-The Industry's smallest-Another "world's first" product offering from Murata | Murata Manufacturing Co., Ltd.

Attachments

Absolutely

As a service tech I had that down to a fine art many years ago. Board balanced, solder reel and its solder pre formed to contact the joint in question at the instant required. Iron in one hand, two meter leads held like chop sticks in the other to observe the effect... isolated iron of course, in fact isolated everything.

Soldering parts to audio PCB's is prety tame in comparison

As a service tech I had that down to a fine art many years ago. Board balanced, solder reel and its solder pre formed to contact the joint in question at the instant required. Iron in one hand, two meter leads held like chop sticks in the other to observe the effect... isolated iron of course, in fact isolated everything.

Soldering parts to audio PCB's is prety tame in comparison

Just for renewing this wonderful discussion thread...

These things seem to be very popular now and they can be costly.

Has anyone tried desoldering gear like this?

https://www.amazon.com/dp/B07BFVFMS9?ref=exp_johnriggsriggdgames_dp_vv_d

Video of the item being evaluated

Testing the Hakko FR-301 Desoldering Gun - YouTube

These things seem to be very popular now and they can be costly.

Has anyone tried desoldering gear like this?

https://www.amazon.com/dp/B07BFVFMS9?ref=exp_johnriggsriggdgames_dp_vv_d

Video of the item being evaluated

Testing the Hakko FR-301 Desoldering Gun - YouTube

This seems interesting...

KSGER T12 Review - The Best Cheap Soldering Station Value - YouTube

Desoldering Station reviews

Pro'sKit SS-331 Desolder Station Review - YouTube

KSGER T12 Review - The Best Cheap Soldering Station Value - YouTube

Desoldering Station reviews

Pro'sKit SS-331 Desolder Station Review - YouTube

Last edited:

- Home

- Design & Build

- Parts

- Working with SMD. How to do it without specialised tools.