TurboFC3S said:

Not to mention it appears your sensitivity is dropping rapidly. The dip there isn't that big a deal since typical BSC will smooth it out somewhat.

Can you apply the coating just on the outside edge of the cone and soften the surround? Or is there a process to only embed fibers in the cone perimeter, and pair that with a softer surround?

The only fiberglass cone mids I've heard have left a lot to be desired, but of course the exact makeup of the fiberglass is what's important. What's special about HSHMPE?

Floor bounce maybe? Try raising your baffle a foot or two and see if the dip moves, or just set the baffle on top of a big stack of pillows

I tried applying the "wet look" or a black damping material on the surround and cone edge and saw minimal effect. The mass of the cone went up when it was made a little bit thicker and the sensitivity took a little bit of a hit

The XG comes to mind as a nice fiberglass cone on a 6.5" and I figure it is worth a shot to try out a curvilinear type fiberglass cone before being forced to move on to even more expensive exotics.

HSHMPE caught my eye as a potentially very high quality fiber since its specific gravity is a very low 0.97 g/cc, it has a high modulus that makes it substantially more rigid per mass than kevlar and some carbon fiber grades and on top of that it has very good vibration damping properties unlike some of the other fibers out there. It is UV and water resistant and a low dielectric constant so you can't see it on radar

It also isn't *that* expensive although getting the process to make woven cones out of it smoothed out I'm sure has the potential to be a pain.

If memory serves correctly the breakup modes for a given cone profile should be about 40-50% higher in frequency than kevlar and be substantially attenuated.

Hopefully I can squeeze a little more sensitivity out of it as well (18-19 grams of mms).

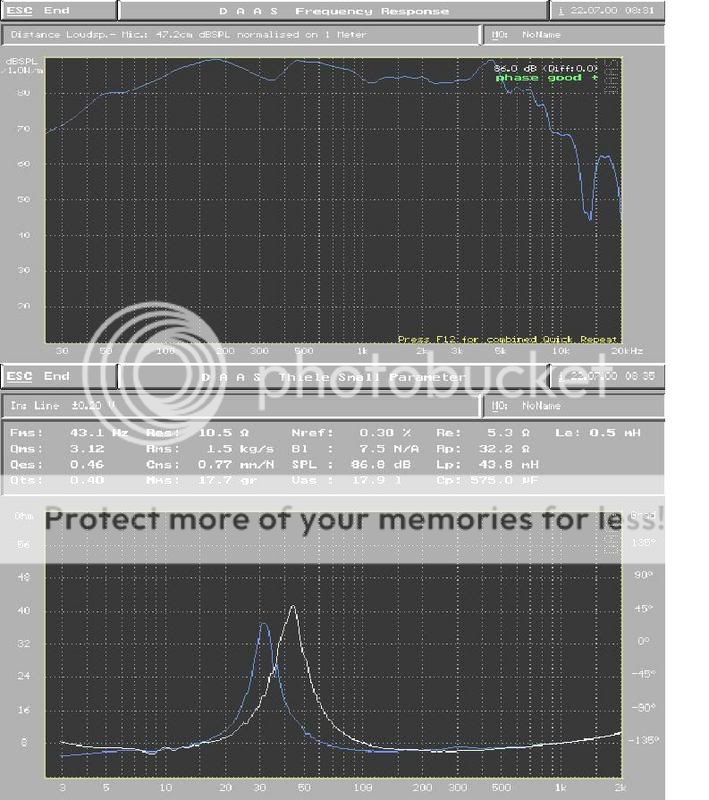

Wool:

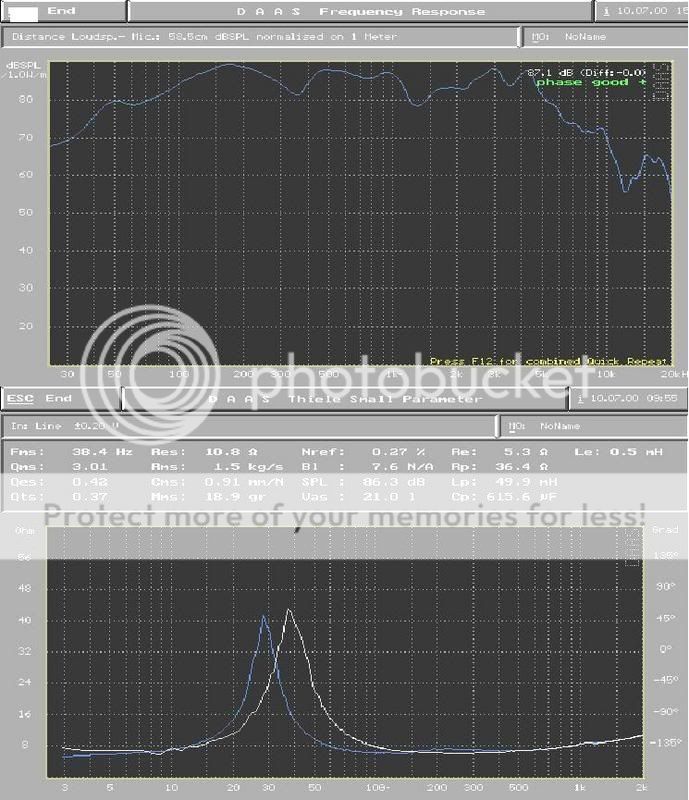

Heavy Wool:

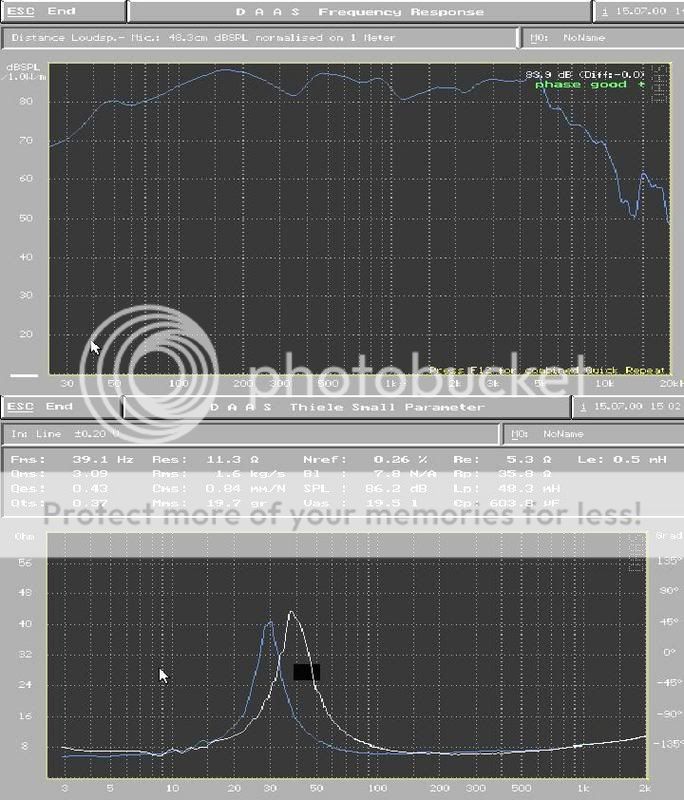

Heavy with coating:

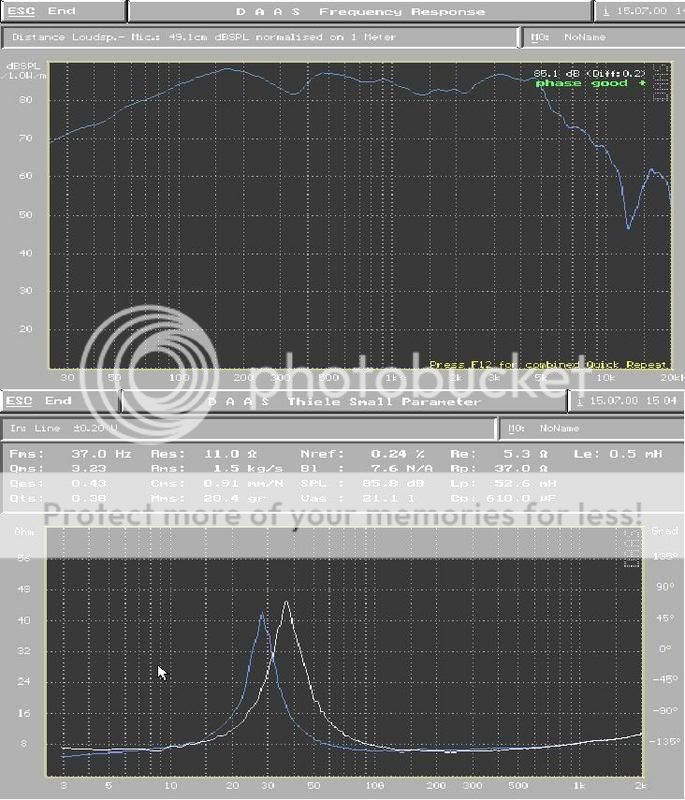

Between the Heavy Wool and the Heavy with Coating, what would you opt for: A slightly more even frequency response under 2khz or slightly more sensitivity? I'm kind of leaning towards the Heavy with Coating, slightly under 86dB/w isn't bad considering the Xmag and power handling due to the fairly long coil. Hopefully that short path is just thick enough to help flatten the Le vs. X and it doesn't end up being a little lower on the negative stroke than on the positive

that wouldn't be good if I made it too thick since it is a little bit lower than I expected at rest...

that wouldn't be good if I made it too thick since it is a little bit lower than I expected at rest...I'll have each of these samples to get distortion measurements on if someone is willing to compare so many samples for me

Oh and if you want to see my dream fiber that has potential for temperature resistant formers, high quality cones and the like...

http://www.richmondcatalyst.com/Issue7_Magellan.asp

I've had my eye on it for quite some time now... It is an amazingly pretty blue fiber

Zylon (great fiber too but humidity eats away at it) on the left, M5 on the right. It is Blue, trust me...

http://www.richmondcatalyst.com/Issue7_Magellan.asp

I've had my eye on it for quite some time now... It is an amazingly pretty blue fiber

An externally hosted image should be here but it was not working when we last tested it.

Zylon (great fiber too but humidity eats away at it) on the left, M5 on the right. It is Blue, trust me...

OlogyAudio said:I tried applying the "wet look" or a black damping material on the surround and cone edge and saw minimal effect. The mass of the cone went up when it was made a little bit thicker and the sensitivity took a little bit of a hit

The XG comes to mind as a nice fiberglass cone on a 6.5" and I figure it is worth a shot to try out a curvilinear type fiberglass cone before being forced to move on to even more expensive exotics.

HSHMPE caught my eye as a potentially very high quality fiber since its specific gravity is a very low 0.97 g/cc, it has a high modulus that makes it substantially more rigid per mass than kevlar and some carbon fiber grades and on top of that it has very good vibration damping properties unlike some of the other fibers out there. It is UV and water resistant and a low dielectric constant so you can't see it on radar

It also isn't *that* expensive although getting the process to make woven cones out of it smoothed out I'm sure has the potential to be a pain.

If memory serves correctly the breakup modes for a given cone profile should be about 40-50% higher in frequency than kevlar and be substantially attenuated.

Hopefully I can squeeze a little more sensitivity out of it as well (18-19 grams of mms).

Between the Heavy Wool and the Heavy with Coating, what would you opt for: A slightly more even frequency response under 2khz or slightly more sensitivity? I'm kind of leaning towards the Heavy with Coating, slightly under 86dB/w isn't bad considering the Xmag and power handling due to the fairly long coil. Hopefully that short path is just thick enough to help flatten the Le vs. X and it doesn't end up being a little lower on the negative stroke than on the positivethat wouldn't be good if I made it too thick since it is a little bit lower than I expected at rest...

I'll have each of these samples to get distortion measurements on if someone is willing to compare so many samples for me

Well, it sounds like you're doing some cool stuff and have resources at your disposal ... so I definately want to do nothing but encourage you to move forward. More driver manufacturers in a good thing! I know trying all these different cones can eat a hole through your bank account real quick, but would love to see something unique come out of it. Maybe the best bet is to produce a known product first, and use the proceeds from that to develop something more exotic. That HSHMPE sound quite interesting though, no doubt.

As far as which one I'd prefer, it all depends on how the coating version sounds. I know how wool typically sounds, and like it quite a bit, especially the heavier/stiffer wool cones I've heard.

I'd be more than willing to help during development, I have all the measurement gear, and could put together designs quickly to give feedback on how they sound.

Honestly, what I wish somebody would produce is a high (90-92 db) sensitive midrange with high-end performance, usable from 100-120hz up to 2800-3000hz or so. There really are an abundance of quality midbass 6.5" and 7" drivers on the market already.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- What do you want in a 6.5... Pick a FR any FR... A few targets inside