56oval said:Steel plate for speaker cab's ,why shouldn't it work .

Actually, I just bought a pait of TransSonic speakers for the shop that are built like a tank - either cast or steel, I haven't checked with a magnet, but they're really tiny (6" or so high) and weigh nearly as much as my Aura 2-way bookshelf units

I like them 'cause they stay put on the shelf when the tools are shaking the place up

Cheers!

Is £40 a sheet cheap for marine ply? No idea what the sheet price is for less than 20 but I'm having no luck trying to find a UK Baltic Birch plywood supplier online.

What sort of questions should I be asking them before ordering?

Oops...forgot the link

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=390057192016&_trkparms=tab=Watching

What sort of questions should I be asking them before ordering?

Oops...forgot the link

http://cgi.ebay.co.uk/ws/eBayISAPI.dll?ViewItem&item=390057192016&_trkparms=tab=Watching

johnthedoctor said:Is £40 a sheet cheap for marine ply? No idea what the sheet price is for less than 20 but I'm having no luck trying to find a UK Baltic Birch plywood supplier online.

As i understand it, finding any plywood at all in the UK can be a challenge.

dave

planet10 said:

As i understand it, finding any plywood at all in the UK can be a challenge.

dave

I usually get mine from B&Q.

Its not cheap and tends to come in smaller sheets.

I bought some GORGEOUS stuff from Arnold Laver. It's not hard to find at all. The big name DIY stores sell it, but for good stuff it's maybe not so easy.

What I bought was 25mm baltic birch and it was £80 for a sheet. It's very high quality though! Almost finished my open baffles I'm making with it...

What I bought was 25mm baltic birch and it was £80 for a sheet. It's very high quality though! Almost finished my open baffles I'm making with it...

56oval said:Steel plate for speaker cab's ,why shouldn't it work .

Rings like a bellllllllllllll...... I've done it. Try layers of aluminum instead. Two 1/4 sheets atop on another, without damping layer, already sound close to granite on a tap test. Much, much, much easier to damp than steel and no real practical difference in wall flex.

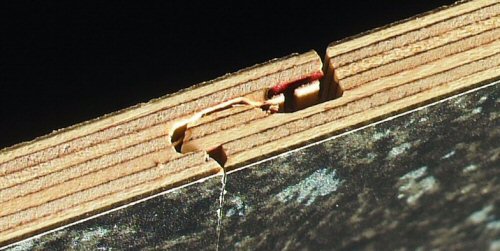

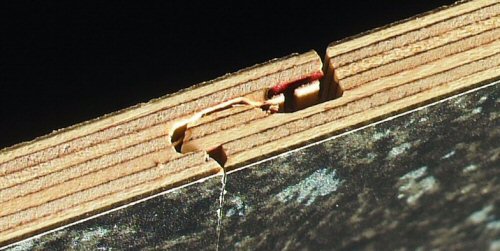

Mine has one or two plugged holes (knot removal) like that, and it looks fine. I think to look at it you can tell if it's good stuff or not. You want baltic birch with many plys - the more the better, and the thicker (overall) the better. Mine wasn't sold as void-free but from cutting and examining edges I'd say it's "nearly void-free".

Hi Guys,

My findings is that using different enclosure materials

for the same cabinet design does equate to slightly

different sound reproduction. One thing for sure is that

stiff & non resonant cabinet is not for me. Many people

or articles have been preaching about cabinets colouring

the sound but another question arises. With so many types

of speakers cone materials available, which type is true to

sound reproduction ? Do the speakers by itself not color the

sound ? Perhaps building cabinets should be done the same

way as building amplifiers. Mix & match parts to aquire the sound

that we're looking for.

My findings is that using different enclosure materials

for the same cabinet design does equate to slightly

different sound reproduction. One thing for sure is that

stiff & non resonant cabinet is not for me. Many people

or articles have been preaching about cabinets colouring

the sound but another question arises. With so many types

of speakers cone materials available, which type is true to

sound reproduction ? Do the speakers by itself not color the

sound ? Perhaps building cabinets should be done the same

way as building amplifiers. Mix & match parts to aquire the sound

that we're looking for.

johnthedoctor said:I think to look at it you can tell if it's good stuff or not

That rules out the ebay listings and picking up the phone and having a merchant deliver if you don't know what the minimum specs should be.

Yeah, sorry I can't be more helpful. I decided based on what I saw. There must be timber merchants in Liverpool.

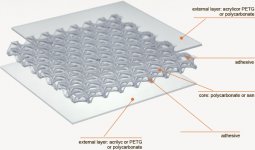

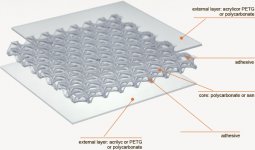

How about using something like this to build a loudspeaker ?

With some luck i may be able to get this material surplus.

Even if it's only "okay" i think it would be a lovely material

to make something that looks totally different from the average

wooden enclosure.

A video demonstrating how strong the stuff is:

Bencore :: Prodotti per Design di interni

Regards,

Klaas

With some luck i may be able to get this material surplus.

Even if it's only "okay" i think it would be a lovely material

to make something that looks totally different from the average

wooden enclosure.

A video demonstrating how strong the stuff is:

Bencore :: Prodotti per Design di interni

Regards,

Klaas

I think for a small enclosure you can use all sorts of materials and still get good results. I recently completed a pair of vented, small enclosures (about 4.5 liters) that I built out of scrap red oak veneered plywood left over from a closet construction. This was not a high quality plywood-it was decent, but had some voids and was, I think, 7 ply. The veneer quality was good (even though red oak is one of my least favorite hardwoods). But it had the virtue of being free.

I think the key was careful construction-the corners, except for the front panel, were all lapped miter joints Lapped Miter Joint Router Bits | Carbide Router Bits. The front panel, also of the same plywood had thick, solid oak edging that I think stiffened it considerably (I used bit 7733 here:MLCS Edge Banding and Roman Ogee Router Bits ). The oak edging had a 3/4" radius rounding. No internal bracing since one of my goals was to make the box as small as possible and still get reasonable bass response. (I did, the 3 db down point was, referenced to 1khz, about 55hz).

I also coated the interior with a goop of my own concoction, consisting of a mixture of an elastomeric latex caulk, joint compound and Epsom salts all thinned with Flotrol and water to a consistency of heavy latex paint. It was a mess to apply with a brush and took five coats to get good results, (I tested it with an accelerometer- although not terribly scientifically-to confirm that I was actually accomplishing something). Someday when I have the time I will perform some more rigorous tests.

The result was better than I had hoped for. I was purposely trying to spend as little money as possible on these and used cheap drivers. I viewed this more as an opportunity to try some different construction techniques to see how they would work. The box passed the "knuckle rap test" -more importantly it actually sounds quite good at moderately loud volumes.

Could it sound better if I used better materials? Probably, but not a lot without using better-more expensive drivers. Would I use the same materials for a larger enclosure (say 60 liters)? Probably not. Would I use the same materials if I had invested more heavily into the drivers? No.

But I think that the construction technique and box design can be just as important as the material selection-in fact from what I have read and seen on diyaudio some people have been very successful using garden variety mdf with non typical design and construction techniques. Automotive engineers have, for example, learned how to build a very stiff chassis using monocoque construction out of relatively thin steel. There are must be some clever mechanical engineers who frequent diyaudio and who might are able to teach me, and others, a thing or two about how to build stiff and low resonance boxes.

I think the key was careful construction-the corners, except for the front panel, were all lapped miter joints Lapped Miter Joint Router Bits | Carbide Router Bits. The front panel, also of the same plywood had thick, solid oak edging that I think stiffened it considerably (I used bit 7733 here:MLCS Edge Banding and Roman Ogee Router Bits ). The oak edging had a 3/4" radius rounding. No internal bracing since one of my goals was to make the box as small as possible and still get reasonable bass response. (I did, the 3 db down point was, referenced to 1khz, about 55hz).

I also coated the interior with a goop of my own concoction, consisting of a mixture of an elastomeric latex caulk, joint compound and Epsom salts all thinned with Flotrol and water to a consistency of heavy latex paint. It was a mess to apply with a brush and took five coats to get good results, (I tested it with an accelerometer- although not terribly scientifically-to confirm that I was actually accomplishing something). Someday when I have the time I will perform some more rigorous tests.

The result was better than I had hoped for. I was purposely trying to spend as little money as possible on these and used cheap drivers. I viewed this more as an opportunity to try some different construction techniques to see how they would work. The box passed the "knuckle rap test" -more importantly it actually sounds quite good at moderately loud volumes.

Could it sound better if I used better materials? Probably, but not a lot without using better-more expensive drivers. Would I use the same materials for a larger enclosure (say 60 liters)? Probably not. Would I use the same materials if I had invested more heavily into the drivers? No.

But I think that the construction technique and box design can be just as important as the material selection-in fact from what I have read and seen on diyaudio some people have been very successful using garden variety mdf with non typical design and construction techniques. Automotive engineers have, for example, learned how to build a very stiff chassis using monocoque construction out of relatively thin steel. There are must be some clever mechanical engineers who frequent diyaudio and who might are able to teach me, and others, a thing or two about how to build stiff and low resonance boxes.

Last edited:

Russian birch ply available from Champions the timber merchants. They will even cut for you on the spot, 2 or 3 cuts for free, then a small charge per cut.

I built some cabs from 9mm ply, with lots of cross bracing internally, fitted with 2 x

15 inch bass drivers. Internal dampening material is natural fibre carpet underlay, available from larger B&Q's, and carpet merchants.

They were built like this because they had to be easily moved by one ordinary person, not superman, (see Australian beach life savers, to whom I'm eternally grateful)

Mid/treble units made from Jelutong (spelling not guaranteed) also from Champoins.

This is a wonderful timber much loved by pattern makers.

All driven by individual amps and an active crossover.

Awesome uncoulored sound quailty

I built some cabs from 9mm ply, with lots of cross bracing internally, fitted with 2 x

15 inch bass drivers. Internal dampening material is natural fibre carpet underlay, available from larger B&Q's, and carpet merchants.

They were built like this because they had to be easily moved by one ordinary person, not superman, (see Australian beach life savers, to whom I'm eternally grateful)

Mid/treble units made from Jelutong (spelling not guaranteed) also from Champoins.

This is a wonderful timber much loved by pattern makers.

All driven by individual amps and an active crossover.

Awesome uncoulored sound quailty

Oiled softwood (pine, spruce, hemlock, fir):

Bernie's Mar-Ken12 . Made from his old fir floor.

dave

where I work we sell a special bathroom board that is a complete solution for bathroom construction (with water and steam protection built in). Is a very high grade birch plywood with a stiff paper backing and a 2mm (or so) high density plastic laminate on the front.

Seems this is the kind of material (high stiffnes solid ply) mostly spoken of in this thread. Its "only" 11mm thick but considering the high quality of it it should be enough with the right bracing.

Byggma - Byggma.se - Byggma - Fibo-Trespo - Våtrumsskiva

Seems this is the kind of material (high stiffnes solid ply) mostly spoken of in this thread. Its "only" 11mm thick but considering the high quality of it it should be enough with the right bracing.

Byggma - Byggma.se - Byggma - Fibo-Trespo - Våtrumsskiva

People get excited about Birch Plywood or other exotic plys because they have high strength to weight ratios. Good stuff if you are making a homebuilt airplane, but I'm not sure they are optimal for loudspeakers.

We want mass and damping rather than light weight strength. Multiple layers with a high proportion of damping material (preferably internal) is the better way to go. Also, to clarify some previous posts, internal means in the middle of the cabinet wall, rather than on the inside surface of the cabinet.

David S.

We want mass and damping rather than light weight strength. Multiple layers with a high proportion of damping material (preferably internal) is the better way to go. Also, to clarify some previous posts, internal means in the middle of the cabinet wall, rather than on the inside surface of the cabinet.

David S.

People get excited about Birch Plywood or other exotic plys because they have high strength to weight ratios.

We want mass and damping rather than light weight strength.

I agree that multiple layers could be a good option, but i can tell that 25 mm beech plywood is not light (100 kg for one Onken). What do you think of double walls filled with sand?

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- What are the characteristics of a better material for enclosure?