You want pumps?

http://www.sciplus.com/category.cfm?subsection=18&category=176

The submersible fountain pumps are cheap (12.95) and you can just place them in your resivior container. They are made for continuous use in fountains. Just put in an overheat switch in your amp in case whatever pump you use fails.

http://www.sciplus.com/category.cfm?subsection=18&category=176

The submersible fountain pumps are cheap (12.95) and you can just place them in your resivior container. They are made for continuous use in fountains. Just put in an overheat switch in your amp in case whatever pump you use fails.

The cooling capacity of water all depends on temperature difference between the warm and cold tubes and flow.

For a standard Aleph 2 = 600 Watt, and a temperature difference of 5 degrees celcius you need aproximately 105 liters/our.

If the temperature difference doubles, the needed amount of water halves.

As you can see a little amount of water is needed to cool a lot of heat.

The real problem is to cool the heated water with the radiator.

You need a really large surface area, or a high airflow.

Edwin

For a standard Aleph 2 = 600 Watt, and a temperature difference of 5 degrees celcius you need aproximately 105 liters/our.

If the temperature difference doubles, the needed amount of water halves.

As you can see a little amount of water is needed to cool a lot of heat.

The real problem is to cool the heated water with the radiator.

You need a really large surface area, or a high airflow.

Edwin

Hi Edwin-

I am actualy using baseboard pipe, which is 3/4" copper pipe with aluminum fins spaced about every 5mm (see pic). These are used for room heat, and are designed for convection. If you look at the pic, you will see that the sides of the fins are bent into one another, forming a chimney between each fin. They are about 5-6cm square. I plan on buying a 6' piece (or so) of this and cutting up to form a radiator about 18cm (3 rows) x 12cm (2 rows) x 30cm (about 1 ft).

BTW: In the pic, ignore the top pipe: it is a return pipe. I am refering to just the bottom pipe with the fins.

Variac-

The fishtank pumps might work, but they are diaphram pumps generally, and not very quiet. I may use one, as $80 is a bit much, but the iWaki is a different class of pump all together. One of its most common uses is by the PCBoard industry to pump heated etchant. It cannot leak (unless the case wears through) as there are no seals between the impeller and the motor. I would be the last pump I would ever buy for such an application.

I am actualy using baseboard pipe, which is 3/4" copper pipe with aluminum fins spaced about every 5mm (see pic). These are used for room heat, and are designed for convection. If you look at the pic, you will see that the sides of the fins are bent into one another, forming a chimney between each fin. They are about 5-6cm square. I plan on buying a 6' piece (or so) of this and cutting up to form a radiator about 18cm (3 rows) x 12cm (2 rows) x 30cm (about 1 ft).

BTW: In the pic, ignore the top pipe: it is a return pipe. I am refering to just the bottom pipe with the fins.

Variac-

The fishtank pumps might work, but they are diaphram pumps generally, and not very quiet. I may use one, as $80 is a bit much, but the iWaki is a different class of pump all together. One of its most common uses is by the PCBoard industry to pump heated etchant. It cannot leak (unless the case wears through) as there are no seals between the impeller and the motor. I would be the last pump I would ever buy for such an application.

Attachments

Those aren't fishtank pumps but fountain pumps. I doesn't matter if they leak out, as they are in the water tank. Noise- probably some noise, I'd agree..

Of course the pump you are tormented by sounds wonderful- I just thought that the $12 one might get you started to see how the system works for you. Everything else is available almost free!

PS: Were do you buy just the baseboard pipe?

Of course the pump you are tormented by sounds wonderful- I just thought that the $12 one might get you started to see how the system works for you. Everything else is available almost free!

PS: Were do you buy just the baseboard pipe?

PS: Were do you buy just the baseboard pipe?

Good question. I have been looking around. All I can get right now would be a piece of baseboard with the sheet metal baseboard. Pretty expensive. I'll post if I find a source.

BTW: the system I am thinking about will be sealed with no tank.

Clearly the baseboard pipe is best found scavanged at a reclycling store or fronm an old building- Maybe one could call a heating contractor. Leaving it in the housing might actually be attractive enough to have in your room e- possibly mounted as a baseboard.....IMHO the fun of this approach is scavanging stuff, but hightech is  too

too

The baseboard pipe is effective in dissipating heat indeed, but i have to advise against your idea of stacking them on top of eachother.

Three rows next to eachother is a good idea, but dont put another three rows on top of that.

If you do so the efficiency of the total radiator will drop aproximately 30% due to the resistance between the fins.

It is better to make the radiator longer 18cm (3 rows) 1 row high and 60cm long.

This way you can get the maximum capacity out of the baseboard.

Another way of increasing efficiency is to build a case around the baseboard.

Normally the case around these baseboards are aproximately 20cm high.

If you make the height of the case 100cm or more you create a chimney which increases the capacity of the baseboard by two or more.

It is all about creating a weight difference between the cold and warm air just like natural circulation with watersystems.

The higher the chimney the higher the airflow.

Naturally things will ballance out once reached a certain point.

Maybe you can do without fans.

These systems will always work, no things to fail.

Give it a try with an eye on the thermometer.

If it doesnt work well enough you can install fans anyway.

Remember it takes a little water to cool 600Watt but it takes a lot of air to cool the same amount of heat.

End of story is the chimney must be big, but hey were talking about class A here.

Edwin.

Three rows next to eachother is a good idea, but dont put another three rows on top of that.

If you do so the efficiency of the total radiator will drop aproximately 30% due to the resistance between the fins.

It is better to make the radiator longer 18cm (3 rows) 1 row high and 60cm long.

This way you can get the maximum capacity out of the baseboard.

Another way of increasing efficiency is to build a case around the baseboard.

Normally the case around these baseboards are aproximately 20cm high.

If you make the height of the case 100cm or more you create a chimney which increases the capacity of the baseboard by two or more.

It is all about creating a weight difference between the cold and warm air just like natural circulation with watersystems.

The higher the chimney the higher the airflow.

Naturally things will ballance out once reached a certain point.

Maybe you can do without fans.

These systems will always work, no things to fail.

Give it a try with an eye on the thermometer.

If it doesnt work well enough you can install fans anyway.

Remember it takes a little water to cool 600Watt but it takes a lot of air to cool the same amount of heat.

End of story is the chimney must be big, but hey were talking about class A here.

Edwin.

Dont be put off by my post.

It is difficult to estimate the capacity of your radiator.

It it possible it will work verry well with a chimney of 20cm heigh.

It is even possible it will work as you first mentioned by mounting them on top of eachother, but you lose 30% this way.

If the dimentions of the case are a problem you could make a 20cm heigh case of cheap materials just for testing.

If the capacity isn't high enough you can make the case higher, or install fans (noise).

Maybe you can place the radiator in another room.

You must keep in mind that the capacity is less in the summer so it must be designed for these higher environment temperatures.

Edwin

It is difficult to estimate the capacity of your radiator.

It it possible it will work verry well with a chimney of 20cm heigh.

It is even possible it will work as you first mentioned by mounting them on top of eachother, but you lose 30% this way.

If the dimentions of the case are a problem you could make a 20cm heigh case of cheap materials just for testing.

If the capacity isn't high enough you can make the case higher, or install fans (noise).

Maybe you can place the radiator in another room.

You must keep in mind that the capacity is less in the summer so it must be designed for these higher environment temperatures.

Edwin

I have made a little calculation with estimated temperatures to give you the idea of the needed amount of air.

Environment temperature 35 degrees celcius (worst case).

Estimated temperature of air after passed thrue the radiator 45 degrees celcius.

Heat to dissipate 600 Watt.

Mass of air by 45 degrees 1.11kg/m3.

Mass of air by 35 degrees 1.14kg/m3

Specific heat of air 1000J/kg.K

600/(1000*(45-35))=0.06kg/second.

(0.06/1.11)*3600=195m3/h.

Edwin

Environment temperature 35 degrees celcius (worst case).

Estimated temperature of air after passed thrue the radiator 45 degrees celcius.

Heat to dissipate 600 Watt.

Mass of air by 45 degrees 1.11kg/m3.

Mass of air by 35 degrees 1.14kg/m3

Specific heat of air 1000J/kg.K

600/(1000*(45-35))=0.06kg/second.

(0.06/1.11)*3600=195m3/h.

Edwin

Hi all,

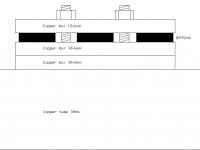

After the faillure of making a heatsink out of sheets and bars of copper i did make the change to watercooling.

This idea was born after a lot of reading on this forum especially the post from Grey who did this before.

I did make the heatsink from copper tubings with copper bars solderd on them just like Grey did.

The tubes are connected with copper fittings.

The heatsink is big becouse it is designed for natural circulation but i think i will be forced do ditch this idea (not enough space to house the tubes), and go for a pump driven system.

I like to thank you all for your inspiring ideas.

Edwin

After the faillure of making a heatsink out of sheets and bars of copper i did make the change to watercooling.

This idea was born after a lot of reading on this forum especially the post from Grey who did this before.

I did make the heatsink from copper tubings with copper bars solderd on them just like Grey did.

The tubes are connected with copper fittings.

The heatsink is big becouse it is designed for natural circulation but i think i will be forced do ditch this idea (not enough space to house the tubes), and go for a pump driven system.

I like to thank you all for your inspiring ideas.

Edwin

Attachments

I mounted my copper bars edge-on to facilitate mounting the devices, but if you can tap those for the proper thread without puncturing the tubing you'll have better heat transfer due to more contact area.

Okay, you've got heat staining. Here's what I did: First, go to the hardware store and buy muriatic acid (aka dilute hydrochloric acid). Tell them you want the stuff they use to clean mortar off of bricks. That will take off the oxide and the red/blue stains. The downside is that it leaves the copper dull. The next step is to use 0000 steel wool to burnish the copper back to brightness. Depending on what sort of chemical copper cleaners you have access to, you might try them in place of either or both of these steps. Finally, when you get a nice, shiny glow on your copper, shoot it with a clear finish to keep it clean and untarnished. I used masking tape to keep the mounting surface from getting lacquer on it; I chose to accept a little dulling with age in that one area in order to increase heat transfer, although the thing is so effective I could probably have coated that surface as well.

I took a small, fine file and removed excess solder from the joints so that all you see is copper with a thin ring of silver where the solder is. It's purely cosmetic and labor intensive. You may not want to go to such lengths.

Keep an eye on the relative temperature of your four sets of devices. You've chosen a different layout than I did and you may find that you don't get equal water flow through each leg of the heat exchanger.

A word to the wise. I put my system together with clamps. It works, but it is a pain to disassemble and reassemble. The next time I break the system down, I'll probably install some sort of quick disconnect in order to make things easier. Something like car folks use to do their pressure lines--not garden hose, which will inevitably leak. If you do it now while your system is apart, you'll thank yourself later.

That said, it looks cool.

Grey

Okay, you've got heat staining. Here's what I did: First, go to the hardware store and buy muriatic acid (aka dilute hydrochloric acid). Tell them you want the stuff they use to clean mortar off of bricks. That will take off the oxide and the red/blue stains. The downside is that it leaves the copper dull. The next step is to use 0000 steel wool to burnish the copper back to brightness. Depending on what sort of chemical copper cleaners you have access to, you might try them in place of either or both of these steps. Finally, when you get a nice, shiny glow on your copper, shoot it with a clear finish to keep it clean and untarnished. I used masking tape to keep the mounting surface from getting lacquer on it; I chose to accept a little dulling with age in that one area in order to increase heat transfer, although the thing is so effective I could probably have coated that surface as well.

I took a small, fine file and removed excess solder from the joints so that all you see is copper with a thin ring of silver where the solder is. It's purely cosmetic and labor intensive. You may not want to go to such lengths.

Keep an eye on the relative temperature of your four sets of devices. You've chosen a different layout than I did and you may find that you don't get equal water flow through each leg of the heat exchanger.

A word to the wise. I put my system together with clamps. It works, but it is a pain to disassemble and reassemble. The next time I break the system down, I'll probably install some sort of quick disconnect in order to make things easier. Something like car folks use to do their pressure lines--not garden hose, which will inevitably leak. If you do it now while your system is apart, you'll thank yourself later.

That said, it looks cool.

Grey

Grey,

I thank you for your advise.

The heatsink is not ready yet.

In order to mount the Fets, i will solder an copper bar on the already mounted bar.

This copper bar will have two thread rods on it so i can clamp the fets (see picture).

Furthermore the heatsink will be provided with a mountingplace for a thermal switch for overtemperature protection in case the natural circulation doesnt start or the pump fails.

The idea of polishing the copper has crossed my mind, and i think it is good looking too.

What kind of lacquer did you use to finish the copper?

About the equal water flow you could be right but ill have to try it in practice to see if it's a problem.

Edwin

I thank you for your advise.

The heatsink is not ready yet.

In order to mount the Fets, i will solder an copper bar on the already mounted bar.

This copper bar will have two thread rods on it so i can clamp the fets (see picture).

Furthermore the heatsink will be provided with a mountingplace for a thermal switch for overtemperature protection in case the natural circulation doesnt start or the pump fails.

The idea of polishing the copper has crossed my mind, and i think it is good looking too.

What kind of lacquer did you use to finish the copper?

About the equal water flow you could be right but ill have to try it in practice to see if it's a problem.

Edwin

Attachments

GRollins said:I'll probably install some sort of quick disconnect in order to make things easier.

Braided hydraulic hoses with pressed-on quick release connectors, works great coupling my automatic tranny to its ATF cooler.

Used the same hoses for watercooling the diesel engine in my boat.

Edwin,

there's a company in "de Spaanse Polder" that presses the connectors on the hoses while you wait. Nice picture.

It's really easy to make waterblocks.

I made one for my graphics card - just get a soft ally block, shape it to whatever size you need, mill out the channel for the water - make sure it's bigger than the diameter of the tube because the water shouldn't flow through too fast. Tap threads for threaded hose tails into the block, use a sheet of alumunium for the top (bottom) sealed with Sikaflex 921 or similar. Easy Maybe attach a copper sheet to the bottom of the waterblock if you are drawing heat from a small contact area.

Maybe attach a copper sheet to the bottom of the waterblock if you are drawing heat from a small contact area.

I think you would need to use a peltier to enough variation in temperature for a decent flow of coolant - I haven't tried myself so I could be wrong.

Moped radiators are pretty cheap on ebay too

I made one for my graphics card - just get a soft ally block, shape it to whatever size you need, mill out the channel for the water - make sure it's bigger than the diameter of the tube because the water shouldn't flow through too fast. Tap threads for threaded hose tails into the block, use a sheet of alumunium for the top (bottom) sealed with Sikaflex 921 or similar. Easy

I think you would need to use a peltier to enough variation in temperature for a decent flow of coolant - I haven't tried myself so I could be wrong.

Moped radiators are pretty cheap on ebay too

We're having some really extreme network problems here, so the picture didn't come up--I'm lucky to have gotten the print portion of the page. The network guys are in and working on the problem, so hopefully things will get back to normal soon.

Granted, when I'm shooting a finish on a bass, I pull out the compressor and use a spray gun. Not for this. I just used a can of cheap stuff from the hardware store. A fairly light coat will do.

Now I get to press the "Submit Reply" button and see if this gets through.

Grey

Granted, when I'm shooting a finish on a bass, I pull out the compressor and use a spray gun. Not for this. I just used a can of cheap stuff from the hardware store. A fairly light coat will do.

Now I get to press the "Submit Reply" button and see if this gets through.

Grey

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Pass Labs

- Water Cooling