capslock said:What is the pink and slightly hairy stuff around the pole piece?

Where you just curious about the construction or was there another reason to take the XT apart?

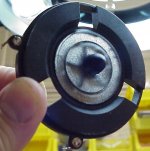

I took it apart because of the lead wire going into the VC burned (see pic) I made a boo-boo changing x-over modules, but I managed to fix it later.

The hairy stuff is a form of Poly-Stuff that fills the sealed rear chamber.

Attachments

.None, the shape of the enclosure is very similar to a sphere where there is no actual baffle to speak of, basically any wave larger than the woofer frame is 4pi, so with an active x-over you just boost the gain to the woofers or cut the gain to the tweeters to balance. I'm sure that some baffle step would help smooth the FR but with a proper shaped baffle the FR is already fairly smooth so very little is needed.

I'm sure many will think I'm nuts for saying this and I don't have any FR plots yet to back it up, but I did many listening tests with many different enclosure shapes and my ears tell me that these kinds of shapes are much smoother than traditional flat baffles

I'm sure many will think I'm nuts for saying this and I don't have any FR plots yet to back it up, but I did many listening tests with many different enclosure shapes and my ears tell me that these kinds of shapes are much smoother than traditional flat baffles

Per Nielsen said:Is there any who has any experince in upgrading this unit?? I have heard it could be done very easily, but I do not now how, any body that have some ideas??

You've got mail!

The instructions are in danish and come from the man that gave Vifa the plan on this tweeter. According to him they didn't do it right!

I haven't come around to do the modifications myself yet, but I'm very interested in the result if you do it.

SvErD said:The instructions are in danish and come from the man that gave Vifa the plan on this tweeter. According to him they didn't do it right!

I'd be interested in seeing an English translation.

dave

Did some listening tests yesterday with a really, really primitive setup. Put a Vifa XT18WO09 and an XT25 on the floor (at equal height) and let them radiate to the ceiling. Let the Woofer run fullrange and used a single capacitor for a 2.5 kHz first order feed to the tweeter. I did the same thing with a BG Neo3PDR ribbon.

Checked in-room frequency response to make sure the tonality was not completely off.

Liked the XT slightly better than the Neo with Gillian Welch, the guitar plucking just sounded a little more dynamic and punchy with the XT.

Switching to the new Tori Amos, which has lots of orchestration, I liked the Neo a tad better.

Going on to Repecca Pidgeon with her immaculate voice and Chesky recording perfection, it was clear the the XT just didn't sound right. It was not the tonality, more like that it gave her voice a rough edge. The Neo blended in a lot better, and the voice was just there in the room, in spite of the highly unconventional setup.

Can't wait to see if those differences persist with a proper baffle and proper LR4 active XO...

Checked in-room frequency response to make sure the tonality was not completely off.

Liked the XT slightly better than the Neo with Gillian Welch, the guitar plucking just sounded a little more dynamic and punchy with the XT.

Switching to the new Tori Amos, which has lots of orchestration, I liked the Neo a tad better.

Going on to Repecca Pidgeon with her immaculate voice and Chesky recording perfection, it was clear the the XT just didn't sound right. It was not the tonality, more like that it gave her voice a rough edge. The Neo blended in a lot better, and the voice was just there in the room, in spite of the highly unconventional setup.

Can't wait to see if those differences persist with a proper baffle and proper LR4 active XO...

planet10 said:

I'd be interested in seeing an English translation.

dave

What he is suggesting is:

1. To contour the inner edge of the front plate, it now has two curves. The front is very thin so care must be taken to not remove too much material.

2. Glue together the voicecoil former. Also glue the former to the membrane at this point. Put a bit of tape on the inside when doing it and glue on the outside. He recomend to use hightemp glue(for breakpads?)

3. Fill all holes on the front plate and make the front smooth and even. How to do this is left to you, one option is epoxy.

This is how I'm interpreting the text

SvErD said:

What he is suggesting is:

1. To contour the inner edge of the front plate, it now has two curves. The front is very thin so care must be taken to not remove too much material.

Looking at Kingdaddy's pics, it is hard to understand what this means. The inner edge, i.e. the rim of the hole seems to have a straight slope (i.e. no curve at all) and then a straight ridge that is parallel to the front surface and acutally holds the membrane.

Assuming the XT is built like other Vifa tweets, there would be a front plate that holds the membrane and a face plate that is screwed onto the front plate. Which one are we talking about here?

SvErD said:

2. Glue together the voicecoil former. Also glue the former to the membrane at this point. Put a bit of tape on the inside when doing it and glue on the outside. He recomend to use hightemp glue(for breakpads?)

Does he mean to fill the gap in the VC former? This gap is there in all speakers with alu VC formers, but it wouldn't hurt to add a little stability.

I am not sure about the "glue the former to the membrane at this point" thing. From shining a bright light on the membrane, I'd say that that membrane and former are joined all the way round, and the glue looks like it bridges the gap in the former already. There also seems to be plenty of glue where the membrane is glued to the faceplate. I'd say about 1/3 of the outer curve are covered with glue, and there is a big variation as to how far the glue extends onto the membrane.

SvErD said:

3. Fill all holes on the front plate and make the front smooth and even. How to do this is left to you, one option is epoxy.

This is how I'm interpreting the text

I can see how this would damp resonances and avoid a few reflections, even if I expect this to be marginal.

ASE, the German Vifa importer, at first sold the XT25 only as a XT300 for 150 Euros. The difference is a faceplate that is made of aluminum (I would suspect that this is the faceplate only, and the front plate would be identical to the one in the XT25).

The German magazine HobbyHifi, probably parroting the importer's babble, claimed the aluminum plate resulted in lower distortion. ASE now also sells the plastic version.

Regards,

Eric

This is a bit off topic, but I'd like to present some more of Steen Duelunds work. I believe he was development engineer at Scan Speak.

Here is an extensive description on how to make a speaker.

http://www.meta-gizmo.com/Tri/speak/STEEN.html

Here is a monster horn he presented in the 70's

http://www.muyiovatki.dk/duelund/duelund.htm

Picktures of a d'appolito speaker and his very special homemade cables and x-over components.

http://www.pinx.dk/duelund/

This is the construction plans for this speaker in danish

http://www.hifisentralen.com/DIY/Hoyt/Duelund/Duelund.html

He is also behind this construction

http://www.gryphon-audio.dk/products/cantata.html

Here is an extensive description on how to make a speaker.

http://www.meta-gizmo.com/Tri/speak/STEEN.html

Here is a monster horn he presented in the 70's

http://www.muyiovatki.dk/duelund/duelund.htm

Picktures of a d'appolito speaker and his very special homemade cables and x-over components.

http://www.pinx.dk/duelund/

This is the construction plans for this speaker in danish

http://www.hifisentralen.com/DIY/Hoyt/Duelund/Duelund.html

He is also behind this construction

http://www.gryphon-audio.dk/products/cantata.html

capslock said:

Looking at Kingdaddy's pics, it is hard to understand what this means. The inner edge, i.e. the rim of the hole seems to have a straight slope (i.e. no curve at all) and then a straight ridge that is parallel to the front surface and acutally holds the membrane.

There is no picture showing the front plate.

capslock said:

Assuming the XT is built like other Vifa tweets, there would be a front plate that holds the membrane and a face plate that is screwed onto the front plate. Which one are we talking about here?

The face plate

capslock said:Does he mean to fill the gap in the VC former? This gap is there in all speakers with alu VC formers, but it wouldn't hurt to add a little stability.

That's the way I read it

capslock said:

I can see how this would damp resonances and avoid a few reflections, even if I expect this to be marginal.

Agreed

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Vifa xt25 tweeter