Getting to the end stages of building 10p Pensils and am going to veneer. Question for those who have done this before: am I better off 1) leaving the edges square and veneering the sides and front separately or 2) rounding the edges and veneering the sides and front with one large veneer sheet?

Thank yiu

Thank yiu

arvi,

I have done both; the square edges are easier to do. A big piece of veneer to cover the front baffle and the sides is a bit trickier, but doable, specially if you are using glue and iron on technique for veneering; with contact adhesive it can get very tricky.

But the rounding over on the edges of the baffle has an aesthetic appeal; the small round overs (1/4 inch?) are too small to have any major benefits on diffraction signature of the cabinet through.

One idea is to have small 45 degree chamfers/bevels on the front baffle - you have the aesthetic of a baffle with angled edges, and you can deal with separate pieces of veneer for the sides and the front more easily.

I have done both; the square edges are easier to do. A big piece of veneer to cover the front baffle and the sides is a bit trickier, but doable, specially if you are using glue and iron on technique for veneering; with contact adhesive it can get very tricky.

But the rounding over on the edges of the baffle has an aesthetic appeal; the small round overs (1/4 inch?) are too small to have any major benefits on diffraction signature of the cabinet through.

One idea is to have small 45 degree chamfers/bevels on the front baffle - you have the aesthetic of a baffle with angled edges, and you can deal with separate pieces of veneer for the sides and the front more easily.

arvi,

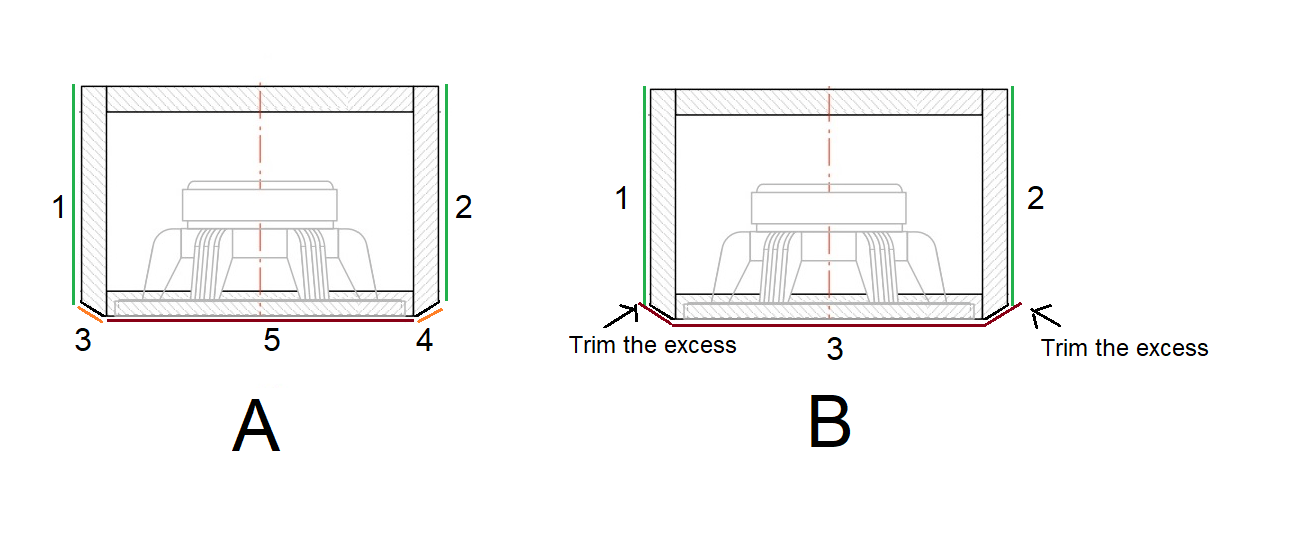

To get real benefits of a chamfer/rounded edges for reducing diffraction signature of the cabinet, the round over would have to be probably around 1.5 inches radius; here we are taking about more cosmetic chamfer, like the one in the image below - maybe a chamfer of 5/8" for a side made with 3/4" plywood (you can also go up to a 3/4" chamfer) . The image also shows how you can:

A. Use 5 pieces of veneer to cover the chamfered baffle and the two sides. 2 pieces cover the 2 sides, 2 thin pieces cover the chamfered edges, and one piece covers the flat part of the front baffle.

B. Use 3 pieces of veneer, with 2 pieces to cover the two sides, and one piece for the baffle that covers the baffle and the chamfered parts.

To get real benefits of a chamfer/rounded edges for reducing diffraction signature of the cabinet, the round over would have to be probably around 1.5 inches radius; here we are taking about more cosmetic chamfer, like the one in the image below - maybe a chamfer of 5/8" for a side made with 3/4" plywood (you can also go up to a 3/4" chamfer) . The image also shows how you can:

A. Use 5 pieces of veneer to cover the chamfered baffle and the two sides. 2 pieces cover the 2 sides, 2 thin pieces cover the chamfered edges, and one piece covers the flat part of the front baffle.

B. Use 3 pieces of veneer, with 2 pieces to cover the two sides, and one piece for the baffle that covers the baffle and the chamfered parts.

Never had major problems with folding the veneer over such chamfers, it just took time running the iron fully along the length, then several passes at increasing angles over the edge until at the 45dg. Make sure to follow the iron with either a veneer roller or solid block of wood to eliminate bubbles that can pop up while glue is cooling. Wait a good half hour before trimming; to avoid tear out both along and across the grain, I sanded along the edge of loose flap with 150G on hard block until almost through the face veneer, then trim with 2”chisel or spare plane iron.

- Home

- Loudspeakers

- Full Range

- Veneering 10p Pensil