Well, Ive decided that the MOSFET 'Mu-Stage' addition to the second gain-stage is well worth the effort....

Power handling at higher levels is improved, as the op-point of the SN7 is more ideal, this stage was going into clipping before the O/P stage, as it was previously...

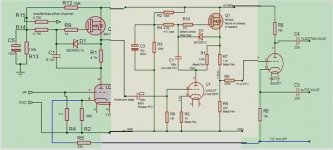

Here is the second stage as I have it now--.

Looks good!

Is IRF710 OK as replacement for 820, also did you use another 100K-100K splitter or just take the 4.7M from the existing source?

C2 now 100n not 220n?

270 carbon comp R10 is this a selection for pref sound or due to stability?

Inductance ect?

Regards

M. Gregg

Finally something to do while waiting for toroids

Are you running single heater or both sides of the 6C33C's...Just some info ..may be useful!

Think cooker element.... If I was to compare heat running, to the heater burn in stage ....think heat X3 when running both sides. Chassis will run at temp of valve sockets ie pos 50C.

I have done a small mod to remove the solid aluminium supports for the top section and replaced with aluminium stand off's.(no change in appearance.) This was a small mod to remove heat transfer to the sub chassis. Works well!

This was linked to: metal will (soak up) heat to temp of local source ie tube sockets...so I have isolated any other metal from the hottest point!

Anything hotter in contact (resistors) may increase the temp!

All just for fun!

Regards

M. Gregg

Yup--710 is fine (better), I just used the 820 as thats what I have loads of!

--(Really need to order some 710, they have a nice low gate-capacitance....)

I made up some small vero-boards with most of the parts on, including duplicates of the 100K pot dividers and the 33uF caps...

You can share the 1/2 potential from the pot. divider you already have, that runs the first stages. As the bias resistors are so high (4.7M) there'll be no interactions...

--Again, the caps I used on the veroboards were what I had around, anything from 1-100uf will prolly be OK if you do double up on the pot divider stages....

The 'Carbon-Compo' is because its a 'Gate-Stopper' and is usually recommended to be a carbon-compo type. TBH Ive used standard resistors in the past with no issues, but recently I ordered a big bag of 270 ohm from R-S Components.....

The value of 'C2' isnt too critical, I'm currently using what was in the amp, I assumed it was 100n, but on checking its 220n as in the earlier diagrams here....

--(Really need to order some 710, they have a nice low gate-capacitance....)

I made up some small vero-boards with most of the parts on, including duplicates of the 100K pot dividers and the 33uF caps...

You can share the 1/2 potential from the pot. divider you already have, that runs the first stages. As the bias resistors are so high (4.7M) there'll be no interactions...

--Again, the caps I used on the veroboards were what I had around, anything from 1-100uf will prolly be OK if you do double up on the pot divider stages....

The 'Carbon-Compo' is because its a 'Gate-Stopper' and is usually recommended to be a carbon-compo type. TBH Ive used standard resistors in the past with no issues, but recently I ordered a big bag of 270 ohm from R-S Components.....

The value of 'C2' isnt too critical, I'm currently using what was in the amp, I assumed it was 100n, but on checking its 220n as in the earlier diagrams here....

Alastair,

I guess stage 2 clippling, do you get higher output before it clips or just softer clipping at the same output level?

Can you post a pic of a vero board you have used? Just looking at layout...

Did you order any 6C33c's?

I will take a look at mod let you know when its in the amp!

Regards

M. Gregg

I guess stage 2 clippling, do you get higher output before it clips or just softer clipping at the same output level?

Can you post a pic of a vero board you have used? Just looking at layout...

Did you order any 6C33c's?

I will take a look at mod let you know when its in the amp!

Regards

M. Gregg

Last edited:

The amp seems o play louder before obvious clipping, which is probably coming from the O/P stage caps charging (blocking distortion)...

Thats something I'm looking at currently. Thinking of a simple clamping circuit set to just a little above the average cathode-bias-voltage of the average 6C33C....

As the cathode-volts rises, the clamp would come into action and prevent it going further into blocking, but still retain the self-bias action as normal....

Prob end up with yet another mosfet and a zener-diode.....

--Summit for me to think about!

I dont think the layout is critical for the upper device, (Veroboard) in fact the layouts are a little different on the two I made....

According to a guy Ive been in contact with, (TubeTVR on here...) he has a set of 6C33C in a Futterman type OTL, biassed at around 200mA that are 10 years old, and still show great performance.

With this in mind, and the number of spare ones I have,(Enough for thirty years by that reckoning!) I havent ordered any more yet!

Thats something I'm looking at currently. Thinking of a simple clamping circuit set to just a little above the average cathode-bias-voltage of the average 6C33C....

As the cathode-volts rises, the clamp would come into action and prevent it going further into blocking, but still retain the self-bias action as normal....

Prob end up with yet another mosfet and a zener-diode.....

--Summit for me to think about!

I dont think the layout is critical for the upper device, (Veroboard) in fact the layouts are a little different on the two I made....

According to a guy Ive been in contact with, (TubeTVR on here...) he has a set of 6C33C in a Futterman type OTL, biassed at around 200mA that are 10 years old, and still show great performance.

With this in mind, and the number of spare ones I have,(Enough for thirty years by that reckoning!) I havent ordered any more yet!

The amp seems o play louder before obvious clipping, which is probably coming from the O/P stage caps charging (blocking distortion)...

Thats something I'm looking at currently. Thinking of a simple clamping circuit set to just a little above the average cathode-bias-voltage of the average 6C33C....

As the cathode-volts rises, the clamp would come into action and prevent it going further into blocking, but still retain the self-bias action as normal....

Prob end up with yet another mosfet and a zener-diode.....

--Summit for me to think about!

I dont think the layout is critical for the upper device, (Veroboard) in fact the layouts are a little different on the two I made....

According to a guy Ive been in contact with, (TubeTVR on here...) he has a set of 6C33C in a Futterman type OTL, biassed at around 200mA that are 10 years old, and still show great performance.

With this in mind, and the number of spare ones I have,(Enough for thirty years by that reckoning!) I havent ordered any more yet!

Sounds good!

I will look at the mod, then decide the best way to implement it in the current set up...Will be interesting..

Well work and all.. catch you laters....

Thank's again...

Regards

M. Gregg

Alastair,

A quick cobble togeather...LOL

I guess this is what we have now with the same feedback Etc.

The pin outs are still not correct for the tubes, however....I will be picking up from the first stage for the second stage CCS.

C2 is still 220N...

Regards

M. Gregg

A quick cobble togeather...LOL

I guess this is what we have now with the same feedback Etc.

The pin outs are still not correct for the tubes, however....I will be picking up from the first stage for the second stage CCS.

C2 is still 220N...

Regards

M. Gregg

Attachments

Last edited:

To keep layout as is i´ll switch my 6j5 to 5692 and rewire the socket.

I like the shape of 6j5 but now it´s history

Still no signs of my toroid

The Murphyfactor always makes me order twice the amount of needed sand so 2 IRF710 in stock

I WANT IT TO MAKE SOME NOICE !!!!!!

GIVE ME SOME IRON !!!!!!!

I like the shape of 6j5 but now it´s history

Still no signs of my toroid

The Murphyfactor always makes me order twice the amount of needed sand so 2 IRF710 in stock

I WANT IT TO MAKE SOME NOICE !!!!!!

GIVE ME SOME IRON !!!!!!!

To keep layout as is i´ll switch my 6j5 to 5692 and rewire the socket.

I like the shape of 6j5 but now it´s history

Still no signs of my toroid

The Murphyfactor always makes me order twice the amount of needed sand so 2 IRF710 in stock

I WANT IT TO MAKE SOME NOICE !!!!!!

GIVE ME SOME IRON !!!!!!!

In all this time I bet its only missing a toroid...

Did you get all the capacitors in the box?

We need more pictures..

Regards

M. Gregg

Last edited:

Managed to pound them in with the big sledgehammer.

It´s now ripped apart again for adding secondstage sand.

I´ll take some pictures when back in one pile again.

I´ll probably test run the small signal/heater regs this weekend.

I´m starting to get dangerous i see pontential transformers everywhere and something is soon going to get ripped apart for iron.

It´s now ripped apart again for adding secondstage sand.

I´ll take some pictures when back in one pile again.

I´ll probably test run the small signal/heater regs this weekend.

I´m starting to get dangerous i see pontential transformers everywhere and something is soon going to get ripped apart for iron.

Managed to pound them in with the big sledgehammer.

It´s now ripped apart again for adding secondstage sand.

I´ll take some pictures when back in one pile again.

I´ll probably test run the small signal/heater regs this weekend.

I´m starting to get dangerous i se pontential transformers everywhere and something is soon going to get ripped apart for iron.

If the pain gets to much bite on a piece of wood...LOL

I know its a real pain isn't it...

I want to see it working as well!

Are you using fans or convection?

Regards

M. Gregg

Last edited:

The bitemarks in the kitchentable is getting deep !!!

I´ll try convection 6mm distance between sockets and topplate same space around the russians.

Have milled a lot of slots in both sides and bottom is filled with holes.

Can always add a fan or two later if it gets to hot.

No 270 CC in the boxes a CF or a 330 is hte choices at hand.

I´ll try convection 6mm distance between sockets and topplate same space around the russians.

Have milled a lot of slots in both sides and bottom is filled with holes.

Can always add a fan or two later if it gets to hot.

No 270 CC in the boxes a CF or a 330 is hte choices at hand.

The bitemarks in the kitchentable is getting deep !!!

I´ll try convection 6mm distance between sockets and topplate same space around the russians.

Have milled a lot of slots in both sides and bottom is filled with holes.

Can always add a fan or two later if it gets to hot.

No 270 CC in the boxes a CF or a 330 is hte choices at hand.

The heat is quite high..I find the ability to switch between one heater or two on each 6c33c very useful. Mains power also drops quite a lot..volume is still OK though.

Perhaps the answer is convection with one heater and fan with two...or switchable fan..with thermostat inside chassis.

I find convection OK.

What coupling caps have you used?

If you get your CCS completed and toroid arrives you will be the first to have it working with the dual CCS..I will be waiting for parts

Regards

M. Gregg

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Tubes / Valves

- Vacuum Tube OTL power amp!!