How did you figure out the shape for the ports......inputs..I guess?

When I went back through the beginning I wondered how you did the ports. Then I saw you had two sort of a weird shapes for the driver to fire into. I wondered why this shape and not a circle or other?

I see you started with the circles then drilled out the rest. Probably noob stuff but I am wondering so I can get my head around things for a future build also.

When I went back through the beginning I wondered how you did the ports. Then I saw you had two sort of a weird shapes for the driver to fire into. I wondered why this shape and not a circle or other?

I see you started with the circles then drilled out the rest. Probably noob stuff but I am wondering so I can get my head around things for a future build also.

jmorken what tool did you use to shape the midrange port?

I drilled the hole first (3/8" inch) then used a dremel for the rest. I started by shaping the frustum (light green) with a sanding band . Then I used a 5/8" diameter grinding stone to carefully create an accurate port length [currently 3mm (orange)] by grinding a flat edge at the bottom of the frustum (light green). I then continued with the sanding band until the angled edges of the frustum matched the flat end where it meets the port.

How did you figure out the shape for the ports......inputs..I guess?

When I went back through the beginning I wondered how you did the ports. Then I saw you had two sort of a weird shapes for the driver to fire into. I wondered why this shape and not a circle or other?

I see you started with the circles then drilled out the rest. Probably noob stuff but I am wondering so I can get my head around things for a future build also.

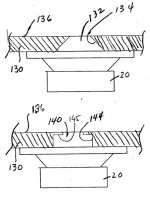

First I determined the desired port width and length (0.95mm wide by 3mm deep). Since the port length is shorter than the depth of my material, I need to "cut away" this depth until I'm left with my desired port. Mr. Danley docuements two ways to achieve this in his patent (see figure). I chose not to terminate the frustum directly to the port because I wanted to create as accurate a port length as possible so it would be easily repeatable. I assume terminating the frustum to the port would cut down on turbulence, but it would also require calculating some sort port end correction for the transitional area. I just didn't want to deal with that.

One added benefit to how I shaped the port entry (which I first saw in others designs) is it allowed the driver to be moved further away from the port (purple arrow) without creating a choke point as the surround of the speaker moves closer to covering the port entry. This creates a longer physical delay as the sound travels from the acoustic center of the cone to the horn entry (red arrows). This delay helps compensate for the distance between the compression driver and the mid range ports.

Attachments

AAHHHH that helps a lot jmorken.

I think soon I will just build a horn and see if I can tackle that. I know it might help me but would placing just a driver on a baffle and make a port like your picture states help me learn more on how to attach the driver to the horn?

Cant quite figure why the ports on the angles of the horn versus more centered.

And what is your horns cutoff freq?

Those 5" drivers seem to be something I should try also and see what I can do.

I think soon I will just build a horn and see if I can tackle that. I know it might help me but would placing just a driver on a baffle and make a port like your picture states help me learn more on how to attach the driver to the horn?

Cant quite figure why the ports on the angles of the horn versus more centered.

And what is your horns cutoff freq?

Those 5" drivers seem to be something I should try also and see what I can do.

One correction, my port width is 9.5mm wide, not 0.95mm.

Mine seem to be holding up just fine. Doing the ports as in the first figure (angled straight to the port opening) would be preferable for strength, but shaping them by hand (as is my case) would make it difficult to do consistently.

On some of Danley's synergy models it appears that he uses a metal plate to create the horn walls. I haven't seen pictures far enough into the horn to know if the mids are mounted to the plate, but it looks like the LF drivers are mounted directly to it. This would allow a very strong and short port configuration.

Mine seem to be holding up just fine. Doing the ports as in the first figure (angled straight to the port opening) would be preferable for strength, but shaping them by hand (as is my case) would make it difficult to do consistently.

On some of Danley's synergy models it appears that he uses a metal plate to create the horn walls. I haven't seen pictures far enough into the horn to know if the mids are mounted to the plate, but it looks like the LF drivers are mounted directly to it. This would allow a very strong and short port configuration.

What insult? What rug? C'mon.....

It would be nice to have a kit for unity horns...FOR us....DIY people....but there is none. Think about that.

Not everybody has the skill to build something like this. Mr Danley makes a few bucks with PA systems, he has no interest in HI-FI. I don't think that bending his patent a little, having as a target the HI-FI and DIY markets will be exactly ....rug steeling. Patent are meant to be broken. And someday, someone will do it.

It would be nice to have a kit for unity horns...FOR us....DIY people....but there is none. Think about that.

Not everybody has the skill to build something like this. Mr Danley makes a few bucks with PA systems, he has no interest in HI-FI. I don't think that bending his patent a little, having as a target the HI-FI and DIY markets will be exactly ....rug steeling. Patent are meant to be broken. And someday, someone will do it.

Respectfully.

It looks as if you are jumping from a few DIY guys to a commercial offering. That ends up being a little more than bending a patent. Tom Danley is as interested in hifi as the rest of us.

As for loosing successful designs to others I have first hand experience. I have designed products since 1989. I refuse to steal other people's work for profit. A one off is totally different case.

As for patent Ming you have a point. Careful examination of prior patents will show that pieces of Danley's concept existed before. But he was one of the first to actually produce a viable product.

It looks as if you are jumping from a few DIY guys to a commercial offering. That ends up being a little more than bending a patent. Tom Danley is as interested in hifi as the rest of us.

As for loosing successful designs to others I have first hand experience. I have designed products since 1989. I refuse to steal other people's work for profit. A one off is totally different case.

As for patent Ming you have a point. Careful examination of prior patents will show that pieces of Danley's concept existed before. But he was one of the first to actually produce a viable product.

DIY synergy..... there is a thread on the avs forum. And clearly everyone is trying to replicate the untity on this thread. SO why do we need to try and bend a patent?

Just take the time and R&D your own design. I am not mad by your suggestion but Tom has been a great help to DIY and I feel anyone that makes a great design and gets their patented should be able to not have their patent "bent," in any way.

PLUS Tom has mentioned before about building some stuff for the HIFI crowd but has been overwhelmed with the larger PA applications.

Just keep at in the shed or basement and ask questions here and I am sure you can come up with anything you want DIY style.

Just take the time and R&D your own design. I am not mad by your suggestion but Tom has been a great help to DIY and I feel anyone that makes a great design and gets their patented should be able to not have their patent "bent," in any way.

PLUS Tom has mentioned before about building some stuff for the HIFI crowd but has been overwhelmed with the larger PA applications.

Just keep at in the shed or basement and ask questions here and I am sure you can come up with anything you want DIY style.

Mr Danley's patent is not original. To be honest i was unawere that both synergy and unity were were both his patents. After some googling i found this http://worldwide.espacenet.com/publicationDetails/biblio?CC=US&NR=5526456&KC=&FT=E&locale=en_EP

I guess you all know about it.

I guess you all know about it.

Last edited:

Do you guys think is possible to build a commercial version avoiding the patents we all know about? I mean....both patents look similar. Why not a third one?

Just go through the paperwork, working with your Patent Attorney and submit your patent application. In the end it will be up to the patent examiners to determine if you have satisfied the requirements.

I agree with the previous comments by others, you come off as a sneaky, underhanded jerk.

TerryO

Last edited:

Did you get my PM?

I didn't

As for the off topic rant

Mr. Danley has been more then generous to the DIY community. It would certainly behoove us to keep from spoiling his good graces by speaking of making commercial copies of his designs. Lets just leave it there.

My sister is getting married this week, so not a lot of time for fiddling. I got my new measurement microphone and started over with much better results. I've found a crossover configuration that I think sounds very nice, but it doesn't have the elusive flat phase response through the crossover region. More fiddling next week.

Last edited:

Let's cut the off-topic!

Sorry to the thread starter!

(i think the economic crisis is omnipresent...i can feel it in all of you) )

rvrazvan,

The economic crisis is one thing that may be on some people's minds, but that's hardly an excuse to steal people's intellectual property. I suppose that you have somehow twisted and rationalized it enough to see yourself as some sort of modern day Robin Hood.

TerryO

It would be nice to have a kit for unity horns...FOR us....DIY people....but there is none. Think about that.

Then pay DSL the royalties necessary to use their patent legitimately for your own profit.

Patent are meant to be broken.

No, they're meant to protect the time and money spent on research and development of something.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Multi-Way

- Unity Horn - budget drivers, active x-over