Hi,

Fair enough.

Maybe "preferred energy drain pathway" or something along those lines.

Bit of a mouthful though.

Cheers,

You need a better word, a "mechanical diode" is thermo-dynamically impossible.

Fair enough.

Maybe "preferred energy drain pathway" or something along those lines.

Bit of a mouthful though.

Cheers,

Well at least we aren't insulting each other. Lol.

Im going to float the whole turntable. Im going to do it with cheap plentiful glycol and call it " a liquid quartz float".

I sat down to research and saw all sorts of beautiful, crazy and genius solutions for decoupling the turntable.

Wouldn't it be easier to just float the whole thing? A platform floating in a tub of fluid wth a few weak magnets centering it. Thats it.

Time to get to work!

Sent from my TARDIS at the restaurant at the end of the universe while eating Phil.

Im going to float the whole turntable. Im going to do it with cheap plentiful glycol and call it " a liquid quartz float".

I sat down to research and saw all sorts of beautiful, crazy and genius solutions for decoupling the turntable.

Wouldn't it be easier to just float the whole thing? A platform floating in a tub of fluid wth a few weak magnets centering it. Thats it.

Time to get to work!

Sent from my TARDIS at the restaurant at the end of the universe while eating Phil.

Hi,

Fair enough.

Maybe "preferred energy drain pathway" or something along those lines.

Bit of a mouthful though.

Cheers,

That's the idea, think of a mechanical impedance match to something with enough internal loss so no vibrations come back.

Take a long enough piece of RG58 and it doesn't matter if it's terminated, nothing comes back.

A customer makes those for skyscrapers, scary.

I've heard for many years about hologram/optical isolation tables made with a large (massive) plate on top of one or more automotive inner tubes. The best ones are inner tube, plate on top of that, tube on top of that, then another plate on top. The idea is they have different masses and thus different resonant frequencies, so a wide range of frequencies are attenuated.

Here's a (single-layer) commercial product, but just seeing the pic tells you how to make one:

http://www.audio-ideas.com/backiss/winter-2004/rega-tweaks-3.html

Here's a (single-layer) commercial product, but just seeing the pic tells you how to make one:

http://www.audio-ideas.com/backiss/winter-2004/rega-tweaks-3.html

I've been reading this thread, as well as the "Good Turntable" thread with interest, mostly from a theoretical perspective because I have no plans to build a TT at this time (perhaps after I retire, i.e.: a long time from now). I've had an idea for a floating TT for a while, which is supremely simple in theory but probably unworkable in practice, which is probably why I've never seen it before. Or it could be I've just not looked hard enough; I'll admit I don't have much time nor inclination to conduct research.

Anyway, let me float the idea (pun intended) and allow y'all to either trash it or hash it out and perhaps prove it feasible:

Imagine a platter of relatively dense material, ~12" diameter x ~2" thick (any numbers I throw out are at best wild guesses, except perhaps for the ~12" diameter). The sides of the platter are tapered, perhaps 5°, creating an inverted truncated cone. Around the edge of the platter are helical grooves. This platter nestles into a basin that is the negative to the platter.

Fluid of a viscosity somewhere between water and honey is pumped through a hole or holes in the bottom of the basin. Hydraulic pressure raises the platter some small distance, and the fluid flows up around the edge of the platter, engaging the grooves thus causing the platter to rotate. The outflow is collected by a moat around the basin and is channeled back into a fluid reservoir to be recirculated.

Doesn't get much more simple than that: one moving part, no bearings, completely isolated platter.

Speed is set by the geometry of the platter & grooves, with fine adjustment by changing the pressure/velocity of the fluid.

One potentially major obstacle would be wobble/oscillation of the platter. Perhaps this could be overcome with very high machining tolerances, sufficient platter weight, and the right fluid viscosity. It might also be necessary to round over the bottom edge of the platter for a smoother flow of the fluid. But now we're getting into the nitty-gritty that I can't be bothered with . I'll leave it to the engineers among you to work out the details...

. I'll leave it to the engineers among you to work out the details...

PS: If you know of any such beast in existence, please post a link.

Anyway, let me float the idea (pun intended) and allow y'all to either trash it or hash it out and perhaps prove it feasible:

Imagine a platter of relatively dense material, ~12" diameter x ~2" thick (any numbers I throw out are at best wild guesses, except perhaps for the ~12" diameter). The sides of the platter are tapered, perhaps 5°, creating an inverted truncated cone. Around the edge of the platter are helical grooves. This platter nestles into a basin that is the negative to the platter.

Fluid of a viscosity somewhere between water and honey is pumped through a hole or holes in the bottom of the basin. Hydraulic pressure raises the platter some small distance, and the fluid flows up around the edge of the platter, engaging the grooves thus causing the platter to rotate. The outflow is collected by a moat around the basin and is channeled back into a fluid reservoir to be recirculated.

Doesn't get much more simple than that: one moving part, no bearings, completely isolated platter.

Speed is set by the geometry of the platter & grooves, with fine adjustment by changing the pressure/velocity of the fluid.

One potentially major obstacle would be wobble/oscillation of the platter. Perhaps this could be overcome with very high machining tolerances, sufficient platter weight, and the right fluid viscosity. It might also be necessary to round over the bottom edge of the platter for a smoother flow of the fluid. But now we're getting into the nitty-gritty that I can't be bothered with

PS: If you know of any such beast in existence, please post a link.

Last edited:

This jibes with some article I read several decades ago (perhaps it was in Audio Amateur, but I have no real memory of where I read this), that one shouldn't try to "suspend" the arm bearing system, but rather, there should be a solid mechanical path (as solid as can be made through the arm and platter bearings) from the stylus back to the platter and record....

If the platter is isolated but the cartridge and arm are not, there will be some errors of addition occurring. To my way of thinking this is not desirable.

...

If mag-lev is to be used as a means of isolation, consider using it to act on the platter/bearing/sub-chassis/armboard/arm/cartridge system as a whole. Within that system couple the parts together as rigidly as possible.

While this "makes sense," I've read in these forums about successful linear arms based on a large tubular air bearing. Perhaps this bearing is "tight" enough that it emulates a solid mechanical connection.

Hi,

Air is a good transmitter.

Given high enough pressure a tangential air bearing arm will act much like a uni-pivot without the hassle that comes with these.

Cheers,

Perhaps this bearing is "tight" enough that it emulates a solid mechanical connection.

Air is a good transmitter.

Given high enough pressure a tangential air bearing arm will act much like a uni-pivot without the hassle that comes with these.

Cheers,

I can think of no 'isolation' system that could support a tonearm that wouldn't in some way reduce the precision with which the arm base could be held to a fixed accurate distance from the record spindle in 3 planes.

Seems the sensible option is to isolate the motor from the platter/tonearm and then the entire deck from the environment.

Seems the sensible option is to isolate the motor from the platter/tonearm and then the entire deck from the environment.

Exactly what I thought.

How will a floating platter maintain a constant distance between the record surface and the needle?

I mean, any additional weight on the platter would compress the magnetic field.

I'm not an expert but I believe that the main benefit can only be that the reduced forces on the bearing also reduces friction and the noise that comes with that.

So it will act as some kind of pressure-relieve for the bearing, but the bearing will still need some contact points...

How will a floating platter maintain a constant distance between the record surface and the needle?

I mean, any additional weight on the platter would compress the magnetic field.

I'm not an expert but I believe that the main benefit can only be that the reduced forces on the bearing also reduces friction and the noise that comes with that.

So it will act as some kind of pressure-relieve for the bearing, but the bearing will still need some contact points...

Another thought as per ChuckORWC

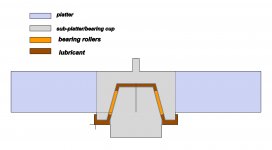

Rather than floating a large Reese's "cup" shaped platter in a well of fluid (shaped as a negative of the cup shaped platter) there are some existing tapered ball bearings that could be used. They come with both a cup and cone and tapered roller needle bearing. I've previously considered trying these as a regular main platter bearing in a turntable, where the taper can be used to self centre.

Following similar lines of thought, the same basic thing could be used to create a magnetic bearing with no contact between the cup and cone. Some experimentation would be needed regarding magnetic strength required to support whatever mass of the platter. The problems concerning the rigidity of the cart/arm/platter/sub-chassis/chassis will remain the same, but the bearing noise could be greatly reduced. Or even submersing the actual bearings in fluid may be enough to damp some noise out of the bearing itself.

Rather than floating a large Reese's "cup" shaped platter in a well of fluid (shaped as a negative of the cup shaped platter) there are some existing tapered ball bearings that could be used. They come with both a cup and cone and tapered roller needle bearing. I've previously considered trying these as a regular main platter bearing in a turntable, where the taper can be used to self centre.

Following similar lines of thought, the same basic thing could be used to create a magnetic bearing with no contact between the cup and cone. Some experimentation would be needed regarding magnetic strength required to support whatever mass of the platter. The problems concerning the rigidity of the cart/arm/platter/sub-chassis/chassis will remain the same, but the bearing noise could be greatly reduced. Or even submersing the actual bearings in fluid may be enough to damp some noise out of the bearing itself.

Attachments

Another idea: Ferrofluid- combines magnet and lubricant...

Thats how I could think of a "magnetically supported bearing":

The attraction of Ferrofluid Bearings | News content from Machine Design

(topmost picture)

Thats how I could think of a "magnetically supported bearing":

The attraction of Ferrofluid Bearings | News content from Machine Design

(topmost picture)

Stew- The tapered needle bearing sounds like a good idea... I'd imagine it could support a quite heavy platter. However, it seems like all those needle bearings could be noisy.

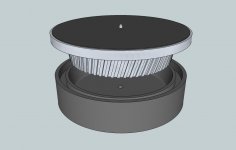

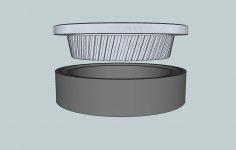

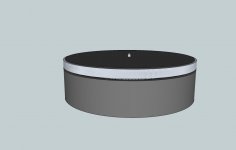

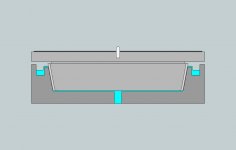

I whipped up a sketchup model of my idea; see the pics. It is essentially a tapered helical gear. My model differs from my earlier description in that there is a demarcation between the "gear" and the platter. The platter and gear could be one machined piece, or they could be an assembly made of two or more pieces.

Again, I know little or nothing about TT design, and this idea obviously bucks the conventional wisdom. I'm just putting it out there as a bit of new thinking (I think), to see if anyone can think of a reason why it wouldn't work.

I whipped up a sketchup model of my idea; see the pics. It is essentially a tapered helical gear. My model differs from my earlier description in that there is a demarcation between the "gear" and the platter. The platter and gear could be one machined piece, or they could be an assembly made of two or more pieces.

Again, I know little or nothing about TT design, and this idea obviously bucks the conventional wisdom. I'm just putting it out there as a bit of new thinking (I think), to see if anyone can think of a reason why it wouldn't work.

Attachments

Forget rolling bearing elements of any kind. Wat to noisy. That's why engineers went to the single spindle on a pad bearing surrounded by a plain bearing sleeve. Look to ultra high precision grinding spindle bearing design to guide you to a good bearing. Think hydrodynamic bearing design. Your car engine is full of them.

BillWojo

BillWojo

Forget the needle bearings...

Guy's. I was forgetting the needle bearings, please read the post (else I forgot to finish my thoughts before I posted). Use the "cup" and the "cone" as a basis of a mag-lev bearing. Don't use the rollers, but use permanent magnets instead. The magnets would have to be substantially stronger, and location (and orientation) would require some experimentation or really good software that could model B fields accurately and the resulting repulsion force...and of course some machining skill would be required.

Guy's. I was forgetting the needle bearings, please read the post (else I forgot to finish my thoughts before I posted). Use the "cup" and the "cone" as a basis of a mag-lev bearing. Don't use the rollers, but use permanent magnets instead. The magnets would have to be substantially stronger, and location (and orientation) would require some experimentation or really good software that could model B fields accurately and the resulting repulsion force...and of course some machining skill would be required.

Hi,

So, this 11 years old thread is trying to tackle what problem exactly ?

Cheers,

Frank, you cut right to the bone on this one.

I would simply ask, what unique problems does a TT present not seen/engineered around in other rotational machinery? The biggest one I can think of is the extremely low speed of operation.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Source & Line

- Analogue Source

- Turntable "floating platter" attempts