Hello Gents.

I post a newly designed and constructed horn loaded subwoofer. It uses the CSS TRIO8 driver and a meager 4 sheets of material to make a horn solid down to 18hz. Tell me what you think.

The pics are here: Horn Subwoofer pictures by mwmkravchenko - Photobucket

Mark

I post a newly designed and constructed horn loaded subwoofer. It uses the CSS TRIO8 driver and a meager 4 sheets of material to make a horn solid down to 18hz. Tell me what you think.

The pics are here: Horn Subwoofer pictures by mwmkravchenko - Photobucket

Mark

Attachments

An externally hosted image should be here but it was not working when we last tested it.

Wow! Thats some high compression!

Not really. 4.73 to 1. So it is actually quite gentle.

Hold up ... when did 5:1 compression in a horn-sub get labeled as gentle? We're not talking about engines here.

:/

I suppose if the motor can drive it and the cone can take it ... why not.

I always thought 3:1 and under was gentle.

The rule of thumb for pro work is 3 to 1. This motor and the cone are very well behaved at this compression ratio of more or less 5 to 1. Just back in from the shop doin some testing. I'm using a flea power amp at the moment and it is indeed a beast. You can count the beats on a 32 ft low C on a pipe organ! And that is in the middle of my shop off of the floor. Very poor boundary loading at the moment. But it still speaks with great authority.

The trade off in compression ratio is that the larger you make the throat the larger the horn must be overall to support a clean wave front. This horn is just under Half wavelength of 16hz at 23 feet long. !/2 wavelength is 32 feet for 16 hz. So it is already big enough. This is a permanet installation type of an enclosure. One you hide away and scare the guests with!

Mark

Oooh, my kind of horn!  Yeah, for relatively low power apps, I experimented with up to ~10:1 CR using an accordion surround driver that was stiffened up with a spray epoxy coating. I figured if WE/Altec's small format compression driver's paper thin aluminum diaphragm could handle 30 W continuous it seemed reasonable to me that a 75 W rated point source mid-bass driver could too when horn loaded. Don't know if it could or not, at ~108 dB efficient/100 Hz it was loud enough hooked to an old AM tabletop radio that I called it a success without bothering to hook it up to a high power amp.

Yeah, for relatively low power apps, I experimented with up to ~10:1 CR using an accordion surround driver that was stiffened up with a spray epoxy coating. I figured if WE/Altec's small format compression driver's paper thin aluminum diaphragm could handle 30 W continuous it seemed reasonable to me that a 75 W rated point source mid-bass driver could too when horn loaded. Don't know if it could or not, at ~108 dB efficient/100 Hz it was loud enough hooked to an old AM tabletop radio that I called it a success without bothering to hook it up to a high power amp.

So, you planning on doing a TH to see if it can compete/best it in less bulk?

GM

So, you planning on doing a TH to see if it can compete/best it in less bulk?

GM

Hello Gents.

I post a newly designed and constructed horn loaded subwoofer. It uses the CSS TRIO8 driver and a meager 4 sheets of material to make a horn solid down to 18hz. Tell me what you think.

The pics are here: Horn Subwoofer pictures by mwmkravchenko - Photobucket

Mark

Nice work. What do you think of the Trio12 driver btw? It's high up on my "drivers I'd like to try" list...

Hi GM

Yep this is a killer sub. But a TRIO12 and a tapped horn do not work together. Not the right application for that driver. If I find the right driver it would be an interesting design competition. But so far I have found drivers that model well in a true tapped horn that fill up fewer than 5 fingers! Most of the tapped horns are just tappered quarter wavelength jobs that the designer thinks is a tapped horn.

Hey Brian

Thanks for the complement. It was a exercise in cheapness. I spent more money on the 5 tubes of Pl Premium adhesive than I did on the 4 sheets of 7/16" OSB! But it proves a concept.

The TRIO 12 is an excellent driver if you know how to load it properly. Well made and a pretty good price to performance ratio.

I do have a few kinks to iron out of the box but other than that I'm quite happy.

Mark

Yep this is a killer sub. But a TRIO12 and a tapped horn do not work together. Not the right application for that driver. If I find the right driver it would be an interesting design competition. But so far I have found drivers that model well in a true tapped horn that fill up fewer than 5 fingers! Most of the tapped horns are just tappered quarter wavelength jobs that the designer thinks is a tapped horn.

Hey Brian

Thanks for the complement. It was a exercise in cheapness. I spent more money on the 5 tubes of Pl Premium adhesive than I did on the 4 sheets of 7/16" OSB! But it proves a concept.

The TRIO 12 is an excellent driver if you know how to load it properly. Well made and a pretty good price to performance ratio.

I do have a few kinks to iron out of the box but other than that I'm quite happy.

Mark

Oooh, my kind of horn!Yeah, for relatively low power apps, I experimented with up to ~10:1 CR using an accordion surround driver that was stiffened up with a spray epoxy coating. I figured if WE/Altec's small format compression driver's paper thin aluminum diaphragm could handle 30 W continuous it seemed reasonable to me that a 75 W rated point source mid-bass driver could too when horn loaded. Don't know if it could or not, at ~108 dB efficient/100 Hz it was loud enough hooked to an old AM tabletop radio that I called it a success without bothering to hook it up to a high power amp.

So, you planning on doing a TH to see if it can compete/best it in less bulk?

GM

If I'm not mistaken, hornresp and Akabak can't model the change in Thiele Small parameters that occurs at high compression ratios. For instance, I took a Trio8 and measured the Thiele Small when the woofer is slot loaded in a 1/2" slot, and the Thiele Small changed considerably. I posted the results over on diymobileaudio, I'm too lazy to look up the thread right not.

Just something to consider if one uses a very high compression. If you're clever, you can really use it to your advantage, since the drop in FS can lower your F3. But the bump in QTS can change the response of the entire horn.

In comparison to my dual MCM 55-2421 horns at 8:1.... under 5 IS gentle.

The cone of the MCM is kinda flimsy, and my "Triple 8" tapped horn uses a high compression. While trying to find a leak in my horn, I decided to seal off the cone of the MCM. (The magnet of the woofer was vented, and I was worried that minute amounts of air might be leaking through the cone and the surround; they're very lightweight.) I used Titebond II wood glue. It worked out really well; the change in Thiele Small was negligible, but the cone is noticeably stiffer now. I applied it to about half of the surround - it might prevent foam rot too. Who knows?

Hi GM

Yep this is a killer sub. But a TRIO12 and a tapped horn do not work together. Not the right application for that driver. If I find the right driver it would be an interesting design competition. But so far I have found drivers that model well in a true tapped horn that fill up fewer than 5 fingers! Most of the tapped horns are just tappered quarter wavelength jobs that the designer thinks is a tapped horn.

Greets!

Long time no hear!

Hmm, it looks pretty good to me, but it's so small, ergo lower efficiency, it will take four drivers to get near its efficiency/bulk.

Well, they are tapped horns since they expand, just not ideal tapped horns.

True, the vast majority I've posted are tapped 'BIB' pipe horns since I wanted them to perform well and ~as predicted while not giving away any of the finer points of DSL's designs in any more detail than TD already has. This assumes of course that I have a clue, which remains to be seen until I can build/measure a few.

Yeah, I've found some that it takes two/horn to make them big enough to mount the drivers.

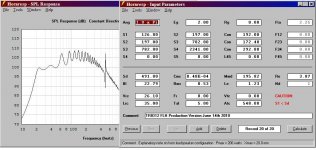

Anyway, the driver specs for your design are so far from what's published that to call it a TRIO12 is a gross misnomer at best, so what gives?

GM

If I'm not mistaken, hornresp and Akabak can't model the change in Thiele Small parameters that occurs at high compression ratios.

If you're clever, you can really use it to your advantage........

Dunno about AkAbak, but HR does for compression horns as shown in its impedance plots, though not for THs.

This is a truism.

GM

Hi GM

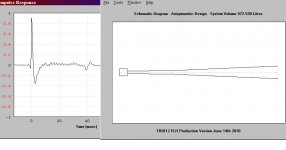

WHat gives for the specs is mee posting the wrong screen. I did some work on the same box with an RCF driver. So attached is the right screen. The bottom end is a bit more wavy but not that much different. To many jobs to do and not enough time to do it! I wanted to see the difference between a high efficiency driver and the TRIO 12. Not that much actually.

Agree on the tapped horn's posted. And further agree on the right of Tom Danley to make a living without anyone undermining him.

Two true horn designs have been posted. One was a direct drawing from DSL and the first one was an actual derivation from the DTS 20 I believe the Tower of Power one. Again you need the driver. Without the driver the speaker will not perform properly.

Now I have to cchase down a glue block that failed to bond properly. Haste makes waste! Now I have to remove one side of an enclosure that was never made to be removed! Chainsaw time!

Mark

WHat gives for the specs is mee posting the wrong screen. I did some work on the same box with an RCF driver. So attached is the right screen. The bottom end is a bit more wavy but not that much different. To many jobs to do and not enough time to do it! I wanted to see the difference between a high efficiency driver and the TRIO 12. Not that much actually.

Agree on the tapped horn's posted. And further agree on the right of Tom Danley to make a living without anyone undermining him.

Two true horn designs have been posted. One was a direct drawing from DSL and the first one was an actual derivation from the DTS 20 I believe the Tower of Power one. Again you need the driver. Without the driver the speaker will not perform properly.

Now I have to cchase down a glue block that failed to bond properly. Haste makes waste! Now I have to remove one side of an enclosure that was never made to be removed! Chainsaw time!

Mark

Attachments

Greets!

Dang! I was hoping it was a prototype Bob was considering offering. Oh well....... which RCF is it? Anyway, glad you've plenty of business, it's an increasing rarity around here unless you're willing to work for minimum wage (or less in some cases).

Oh well....... which RCF is it? Anyway, glad you've plenty of business, it's an increasing rarity around here unless you're willing to work for minimum wage (or less in some cases).

There's been a sim of at least one other......... Right on, though if I understand the physics of the situation correctly, for LF reproduction one can relatively easily create a 'close enough' right one from an available driver, it just probably won't allow as cost/space effective a design as the custom made ideal, but for DIY HIFI/HT apps it's a small price to pay to get closer to what you want size/performance wise since it doesn't need to hit a prosound unit's 130-140 dB/m and meet a specific stacking/storing layout.

Right on, though if I understand the physics of the situation correctly, for LF reproduction one can relatively easily create a 'close enough' right one from an available driver, it just probably won't allow as cost/space effective a design as the custom made ideal, but for DIY HIFI/HT apps it's a small price to pay to get closer to what you want size/performance wise since it doesn't need to hit a prosound unit's 130-140 dB/m and meet a specific stacking/storing layout.

Bummer, I hate it when that happens.

GM

Dang! I was hoping it was a prototype Bob was considering offering.

There's been a sim of at least one other.........

Bummer, I hate it when that happens.

GM

Oh there are prototypes coming. But this is an existing driver.

What happens with most drivers and tapped horns is a very large box and almost no gain over a conventional enclosure. There are but few drivers that can be massaged into a true tapped horn and actually have proper gain of 7 to 8 db.

130 to 140db for home use! Ouch! This would be interesting. Break windows but hey glass is cheap.

Have to do the chainsaw surgery after I write this.

RCF driver was LF12N401

Not a bad driver if you don't mind the price.

Mark

What happens with most drivers and tapped horns is a very large box and almost no gain over a conventional enclosure. There are but few drivers that can be massaged into a true tapped horn and actually have proper gain of 7 to 8 db.

130 to 140db for home use! Ouch! This would be interesting. Break windows but hey glass is cheap.

Have to do the chainsaw surgery after I write this.

RCF driver was LF12N401

Not a bad driver if you don't mind the price.

Mark

Nice folding, good work!

I didn't see in pics but I supose the first portion of the flare (those two panels close to each other) is well braced like the rest. I said this because there is expected to be the most high dynamic presure load of the entire structure.

Regards,

Dorin

I didn't see in pics but I supose the first portion of the flare (those two panels close to each other) is well braced like the rest. I said this because there is expected to be the most high dynamic presure load of the entire structure.

Regards,

Dorin

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Loudspeakers

- Subwoofers

- TRIO 12 Front loaded Horn Subwoofer