The eddy current losses are reduced by using thin laminations that are insulated from each other.

It appears that welding across the laminations does not substantially affect the eddy current losses, if the Weld Area is kept very small in proportion to the lamination area.

What effect does damage to the insulating layers on the laminations have on the eddy current losses?

I am concerned with the scratching of the oxide surface when I slide the Es and Is in from opposite sides.

Does the scratching through the insulation matter?

Should we take steps to minmise this?

Should we "repair" damaged oxide that is evident when we take apart an old transformer?

It appears that welding across the laminations does not substantially affect the eddy current losses, if the Weld Area is kept very small in proportion to the lamination area.

What effect does damage to the insulating layers on the laminations have on the eddy current losses?

I am concerned with the scratching of the oxide surface when I slide the Es and Is in from opposite sides.

Does the scratching through the insulation matter?

Should we take steps to minmise this?

Should we "repair" damaged oxide that is evident when we take apart an old transformer?

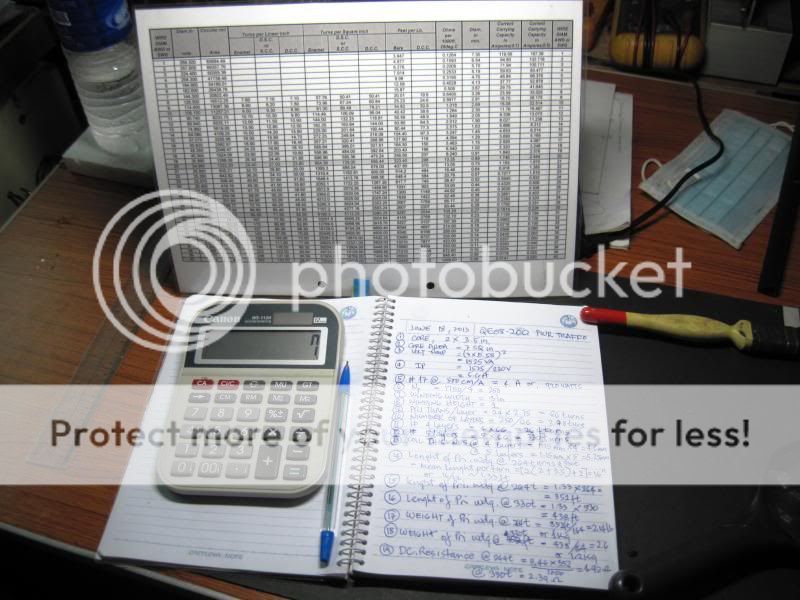

Hi Sir Tony,

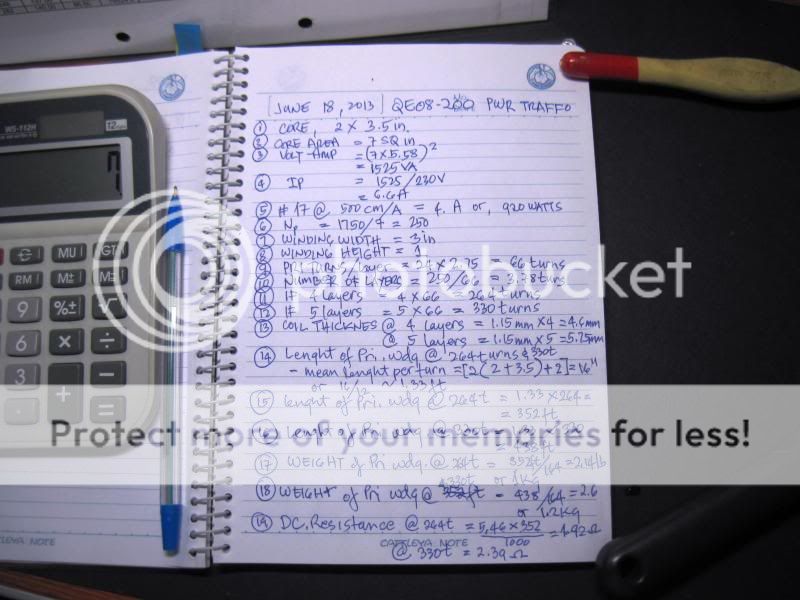

Nice one sir, 3.5 is a good balance for its L X W size.

This spec. for me is a keeper.

Looking at step#1-4 - seems like squeezing bigger wire for primary winding does not yield higher primary current/VA rating, is this true?

Is bigger core area the only factor? Could you help me understand what is 5.58 multiplier?

regards,

Roland

Nice one sir, 3.5 is a good balance for its L X W size.

This spec. for me is a keeper.

Looking at step#1-4 - seems like squeezing bigger wire for primary winding does not yield higher primary current/VA rating, is this true?

Is bigger core area the only factor? Could you help me understand what is 5.58 multiplier?

regards,

Roland

Last edited:

the 5.58 is a constant picked up in RDH4, http://www.tubebooks.org/Books/RDH4.pdf

you can download it in the web...

the core ratings are just a guide, more often than not,

the core ratings are not used up 100%

and most of it is due to winding window not big enought

capacity is determined by the wire size used in the primary,

naturally if you can squeeze in a bigger wire,

then you will get a higher primary coil rating

in another application, i will have used #16, but since

the secondary contemplates many windings at

different voltage and insulation requirements,

then i have to make more space...

you can download it in the web...

the core ratings are just a guide, more often than not,

the core ratings are not used up 100%

and most of it is due to winding window not big enought

capacity is determined by the wire size used in the primary,

naturally if you can squeeze in a bigger wire,

then you will get a higher primary coil rating

in another application, i will have used #16, but since

the secondary contemplates many windings at

different voltage and insulation requirements,

then i have to make more space...

It's not big deal, not only because "the area is small" but because there is very little magnetic flux in tyhe corners, if any at allThe eddy current losses are reduced by using thin laminations that are insulated from each other.

It appears that welding across the laminations does not substantially affect the eddy current losses, if the Weld Area is kept very small in proportion to the lamination area.

We use rectangular cut laminations (so called "EI") because they are cut from a flat sheet, and we try to minimize scrap, but magnetic flux lines try to follow the shortest path.

Imagine a horse racing track , set in a rectangular field, and seen from above.

Now imagine lots of horses running there.

What path will they follow?

Will you find many horses in the corners?

That's why high performance audio transformer cores are "C" shaped.

More adapted to the actual magnetic flux path, they don't miss the 90º corners at all

So soldering in the corners has very little or nil effect.

It increases losses, but you should grind them to bare metal to cause significative damage; small nicks and scratches don't matter.What effect does damage to the insulating layers on the laminations have on the eddy current losses?

It's incredibly tough.I am concerned with the scratching of the oxide surface when I slide the Es and Is in from opposite sides.

**Old** laminations (think 30's and 40's) had some kind of lacquer or paint which could scratch, but oxide or baked in surfaces are tough.

Just don't be Terminator or Hulk when stacking them.Does the scratching through the insulation matter?

Should we take steps to minmise this?

No big deal.Should we "repair" damaged oxide that is evident when we take apart an old transformer?

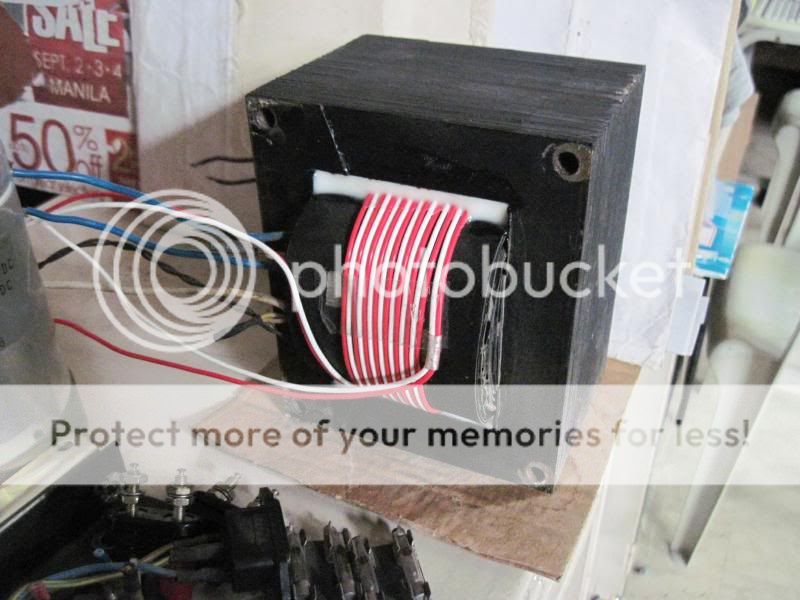

EDIT: @ rolandong: congratulations on your transformer , it looks very good and very carefully made and finished

Last edited:

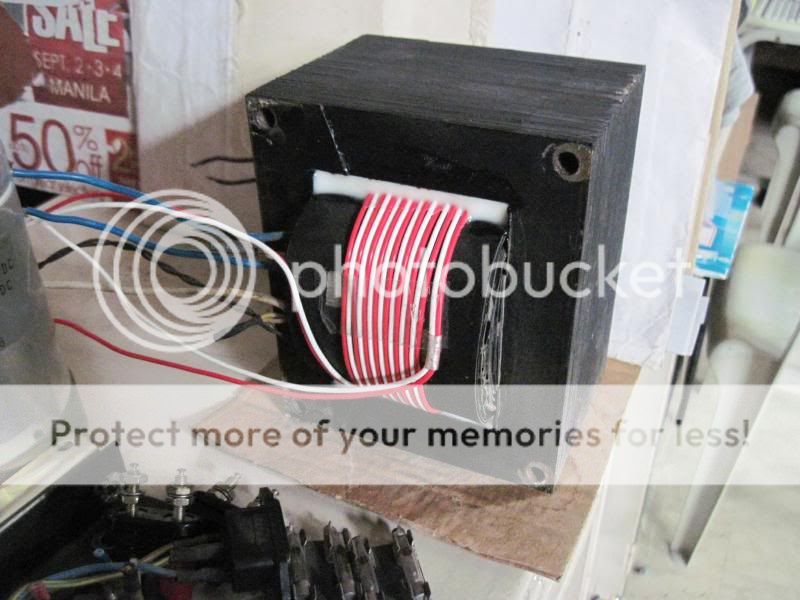

i added 8 bifilar turns to up the voltage from 2 x 55v to 2 x 65 volts....

i used teflon coated #14 wire for the added turns,

good thing that 20 years ago, i did not use the full winding window,

so today i was able to squeeze in more turns

since endbells are not available for 2inch cores,

i decided to use "FulaTite" automotive putty to form one.

angle grinders used to shape the "masilya", then fine grit sandpaper prior to painting...

gray hamertone painting...

left out to dry for several days...

i used teflon coated #14 wire for the added turns,

good thing that 20 years ago, i did not use the full winding window,

so today i was able to squeeze in more turns

since endbells are not available for 2inch cores,

i decided to use "FulaTite" automotive putty to form one.

angle grinders used to shape the "masilya", then fine grit sandpaper prior to painting...

gray hamertone painting...

left out to dry for several days...

hi ajt,

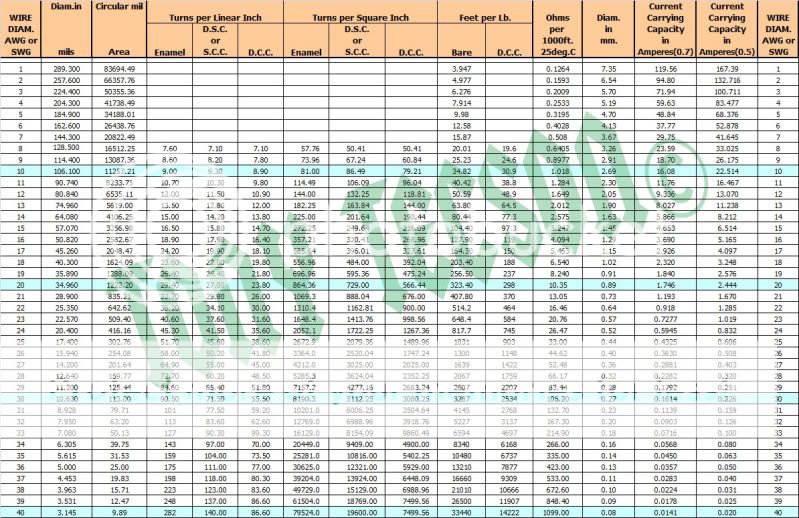

can i parallel 4*.5mm gauge wire to wind instead 1*2.05 gauge wire?.

the thing is, it is the cross section area that counts...

take a look at the table below

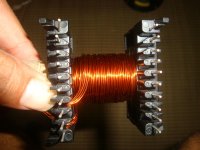

newly completed and ready for dipping in varnish, traffos intended for phono stage and tone controls...

An externally hosted image should be here but it was not working when we last tested it.

- Home

- Amplifiers

- Power Supplies

- Tony's latest traffo DIY build