HV TO-220 kit

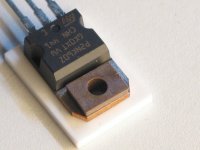

This is actually the Aavid 7721-10PPSG shoulder washer, which has a long insulator that goes through the device tab into the pad (Aavid 4170G) and when mounted with a small head 4-40 screw provides pretty good clearance.

What I use for high voltage TO-220 mounting:

Aavid 7721-8PPSG PPS material shoulder washer .040 x .245 oversized shoulder

Aavid 4170G Al oxide ceramic insulating pad

the ceramic pads are awesome, about .050 thick and reusable

All heat sink mounting is super sensitive to nice flat clean surfaces

PS I don't know if perhaps some of the heatsink compound (arctic silver, etc.) is electrically conductive but I stick to the white stuff.

This is actually the Aavid 7721-10PPSG shoulder washer, which has a long insulator that goes through the device tab into the pad (Aavid 4170G) and when mounted with a small head 4-40 screw provides pretty good clearance.

Attachments

I used the aluminum oxide pads for my "Sic Puppy" Semisouth class A amp, where there were high voltages involved and I wanted to limit signal coupling into the heat sink. I also wanted the extra thermal conductivity of the alumina, as with that design, I push the dissipation limits for the TO-247 package. Ditto the concerns on having a flat mounting surface.

I just picked up an enhanced performance thermal compound put out by MG Chemicals. The usual suspects use Zinc Oxide. The two Arctic formulations I know of use either silver or aluminum oxide. The MG stuff uses boron nitride, so I suspect it's pretty good, and has no conductivity concerns. Basically, it's better than either the ZnO and Al2O3 formulations, and perhaps a bit shy of the performance of the silver-loaded stuff.

I just picked up an enhanced performance thermal compound put out by MG Chemicals. The usual suspects use Zinc Oxide. The two Arctic formulations I know of use either silver or aluminum oxide. The MG stuff uses boron nitride, so I suspect it's pretty good, and has no conductivity concerns. Basically, it's better than either the ZnO and Al2O3 formulations, and perhaps a bit shy of the performance of the silver-loaded stuff.

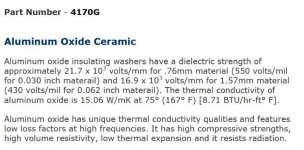

The alumina pads are pretty good. Assuming a TO-220 contact area of about 1.5 cm x 1.0 cm the total would be about 10m for the .062 thickness giving Rtheta of about 10/15 degreesK/W for the pad. So maybe in the range of 1 degree per watt case-to-sink allowing for the interfaces. Not bad given the 26KV breakdown voltage...

By comparison RthetaJC (junction to case) is about 1.67 degrees/W for a 75 watt device. So the 75 watt device rating assumes a 25 degree C contact surface (150 degree C max junction temp typically).

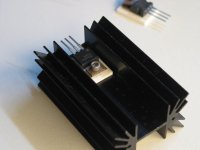

The heatsink I show is optimistically rated at 2.5 degrees per watt (!) in free air. I think it may be a typo! Anyway taken for granted, if the pad is 1 degree and the sink is 2.5 and RthetaJC is 1.67 the total Rtheta is 5.17 degrees per watt allowing almost 25 watts at 25 ambient, with a sink temp of about 87 degrees C. I have run them at 25 W or so but with a fan. Seems like they're happier in the 12-15W range. My guess is the sink is closer to 4-5 degrees per watt when mounted over a surface like a PC board or chassis plate.

By comparison RthetaJC (junction to case) is about 1.67 degrees/W for a 75 watt device. So the 75 watt device rating assumes a 25 degree C contact surface (150 degree C max junction temp typically).

The heatsink I show is optimistically rated at 2.5 degrees per watt (!) in free air. I think it may be a typo! Anyway taken for granted, if the pad is 1 degree and the sink is 2.5 and RthetaJC is 1.67 the total Rtheta is 5.17 degrees per watt allowing almost 25 watts at 25 ambient, with a sink temp of about 87 degrees C. I have run them at 25 W or so but with a fan. Seems like they're happier in the 12-15W range. My guess is the sink is closer to 4-5 degrees per watt when mounted over a surface like a PC board or chassis plate.

Attachments

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.