fossil2k said:Sorry, it should be stack film capacitor..and not stack foil..Last few days was going through Farnell book and came across Panasonic ECA series capacitor which claim to be good in audio circuit. Anyone have use this before?

I think stacked film and stacked foil are the same thing, but I maybe wrong with all these new nominations. Both are very good for audio.

Hi,

the use of the descriptors film and foil sometimes get swapped by various manufacturers.

The generally accepted definition is foil is a separate metal foil alternately layered with an insulating di-electric.

Film is usually accepted as meaning a metallised surface applied directly to the surface of the insulating di-electric.

the use of the descriptors film and foil sometimes get swapped by various manufacturers.

The generally accepted definition is foil is a separate metal foil alternately layered with an insulating di-electric.

Film is usually accepted as meaning a metallised surface applied directly to the surface of the insulating di-electric.

fossil2k said:For stack film, I can't find the values that I need from Farnell. Its 220pF.

For that value use polystyrene. In fact always use polystyrene for any values you can get for, at least for audio applications. They are better than polyester, polypropylene and polycarbonate.

Another question on the op-amp, it is running at half of its rated voltage but it becomes hot after 1hr. Could it cause by the 2nd internal op-amp not being grounded?

I have grounded the op-amp and it is still hot..the op-amp is rated 18V max and the power supplied is 18V as well. Most probably it is operating at its max??

I have grounded the op-amp and it is still hot..the op-amp is rated 18V max and the power supplied is 18V as well. Most probably it is operating at its max??

fossil2k said:Another question on the op-amp, it is running at half of its rated voltage but it becomes hot after 1hr. Could it cause by the 2nd internal op-amp not being grounded?

I have grounded the op-amp and it is still hot..the op-amp is rated 18V max and the power supplied is 18V as well. Most probably it is operating at its max??

Yes, it might be. Lower the voltage to +/- 15v.

Heat might be due to oscillation as well.

Can you please tell me which quad chip are you using after all?

How about these caps from the link below??

http://www.octave-electronics.com/Parts/mundorf.shtml

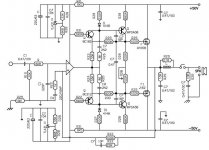

Based on the schematic attached, I've planned to change the caps from the input, 0.47uF, 220pF & 220uF. I have plannedto use 0.47uF from the above, 220uF will be BG and 220pF is an option left open. Any suggestions?

I have wanted to changed the capacitors as recently I've just tested a Creek CAS4040 and it sounded so open. In the catalog from Creek, it is written that they have used "valuable" polystrene & stack film capacitors. I'm really wondering if these are really making the amp sounded better??

http://www.octave-electronics.com/Parts/mundorf.shtml

Based on the schematic attached, I've planned to change the caps from the input, 0.47uF, 220pF & 220uF. I have plannedto use 0.47uF from the above, 220uF will be BG and 220pF is an option left open. Any suggestions?

I have wanted to changed the capacitors as recently I've just tested a Creek CAS4040 and it sounded so open. In the catalog from Creek, it is written that they have used "valuable" polystrene & stack film capacitors. I'm really wondering if these are really making the amp sounded better??

Attachments

fossil2k said:

The caps should be nice, even if a bit expensive. Put your big money on the input cap.

Based on the schematic attached, I've planned to change the caps from the input, 0.47uF, 220pF & 220uF. I have plannedto use 0.47uF from the above, 220uF will be BG and 220pF is an option left open. Any suggestions?

I have wanted to changed the capacitors as recently I've just tested a Creek CAS4040 and it sounded so open. In the catalog from Creek, it is written that they have used "valuable" polystrene & stack film capacitors. I'm really wondering if these are really making the amp sounded better??

The Creek sound may not be only due to the caps, but to whole design.

Best film caps are usually polystyrene, bettered only by teflon caps. The only problem with polystyrenes are values availability.

It wouldn't be a bad idea using a .47uF polystyrene at the input, either by parallelling smaller values or finding one.

The 220pF should definitely be polystyrene.

Thanks for the advise. I can't find stack film for the 220pF. I think I will just stick to the original polystrene or maybe those M Cap if they have this value. In Farnell catalog, Panasonic ECA series is used specifically for audio purpose. Anyone have used those? I'm trying to upgrade a CD52mkII and contemplating to use BG or Panasonic.

fossil2k said:Thanks for the advise. I can't find stack film for the 220pF. I think I will just stick to the original polystrene or maybe those M Cap if they have this value.

If the original is polystyrene, don't replace it. Polystyrenes only have two things against them mostly: larger size which may make them inductive in certain situations, magnetic terminals in some cases. But they have the lowest dissipation factor around, except maybe for teflon caps, which are too expensive.

In Farnell catalog, Panasonic ECA series is used specifically for audio purpose. Anyone have used those? I'm trying to upgrade a CD52mkII and contemplating to use BG or Panasonic.

What are you trying to upgrade? The output cap? Just wire-bypass it.

There are some articles on the web on how to mod a Marantz CD52.

polystyrene has a few more issues:

extremely low temperature tolerance - you need to heatsink the leads while soldering, limit bake out, operating temps to <70 C

solvent sensitivity - incompatable with some pcb "flux cleaners"

and as far as anyone knows cap grade polystyrene isn't made any more - but with low demand and existing stocks this hasn't been a probelm yet

extremely low temperature tolerance - you need to heatsink the leads while soldering, limit bake out, operating temps to <70 C

solvent sensitivity - incompatable with some pcb "flux cleaners"

and as far as anyone knows cap grade polystyrene isn't made any more - but with low demand and existing stocks this hasn't been a probelm yet

jcx said:polystyrene has a few more issues:

extremely low temperature tolerance - you need to heatsink the leads while soldering, limit bake out, operating temps to <70 C

solvent sensitivity - incompatable with some pcb "flux cleaners"

and as far as anyone knows cap grade polystyrene isn't made any more - but with low demand and existing stocks this hasn't been a probelm yet

Good points. You should be careful with these caps indeed.

post51 schematic

Hi,

Polystryrene is reputed to have excellent sound quality.

That 220pF and the 6k8 input certainly will have an effect on the sound quality since the roll-off fequency is lowish in comparason to most other amplifiers. Significant phase angle change starting just above 10kHz with a 1.5uS filter vs 30kHz with a 0.5uS filter.

However, I must ask, if the 6k8 were reduced to around 1k to reduce the input time constant to operate solely as an RF filter rather than an top frequency filter, will polystyrene be the best choice any longer?

Would a lower inductance cap perform as a better RF filter that keeps attenuating the unwanted RF signal way beyond the frequencies that I think the polystyrene is beginning to flatten out? Would the benefit endowed by polystyrene still be audible if the RF filter were moved up and octave or two?

I would suggest that this amp will sound different if the two input filters were moved more towards a wide passband, but I suspect it would no longer sound like the original. My final question becomes:- which version sounds better?

Hi,

Polystryrene is reputed to have excellent sound quality.

That 220pF and the 6k8 input certainly will have an effect on the sound quality since the roll-off fequency is lowish in comparason to most other amplifiers. Significant phase angle change starting just above 10kHz with a 1.5uS filter vs 30kHz with a 0.5uS filter.

However, I must ask, if the 6k8 were reduced to around 1k to reduce the input time constant to operate solely as an RF filter rather than an top frequency filter, will polystyrene be the best choice any longer?

Would a lower inductance cap perform as a better RF filter that keeps attenuating the unwanted RF signal way beyond the frequencies that I think the polystyrene is beginning to flatten out? Would the benefit endowed by polystyrene still be audible if the RF filter were moved up and octave or two?

I would suggest that this amp will sound different if the two input filters were moved more towards a wide passband, but I suspect it would no longer sound like the original. My final question becomes:- which version sounds better?

Hi,

these suggestions WILL change the sound of the amplifier and may also upset it's operation, but probably worth trying. Be prepared to revert to the original values.

Set the two input filter time constants to about 80mS to 100mS and to 0.75uS to 0.3uS.

This could be done retaining the 220pF and the series resistor reduced to 1k5 to 3k. Alternatively parallel the 220pF with a 330pF polypropylene and use ~1k0 as the series resistor. This works best with a low source resistance (Rs) unit preceeding the amplifier, certainly <=300r and preferably ~50r.

The bass/DC block could use the original 20k and a new 4.7uF film cap.

If the source also has a DC blocking capacitor then the pair of capacitors work in series and the usual formula has to be applied to the combination to then calculate the time constant.

The NFB DC blocking time constant does not need altering to match these input modifications. It can remain as 1k0 & 220uF giving 220mS. If you wanted to experiment with a better capacitor here, then do not drop it (or a parallel combination) below 150uF.

these suggestions WILL change the sound of the amplifier and may also upset it's operation, but probably worth trying. Be prepared to revert to the original values.

Set the two input filter time constants to about 80mS to 100mS and to 0.75uS to 0.3uS.

This could be done retaining the 220pF and the series resistor reduced to 1k5 to 3k. Alternatively parallel the 220pF with a 330pF polypropylene and use ~1k0 as the series resistor. This works best with a low source resistance (Rs) unit preceeding the amplifier, certainly <=300r and preferably ~50r.

The bass/DC block could use the original 20k and a new 4.7uF film cap.

If the source also has a DC blocking capacitor then the pair of capacitors work in series and the usual formula has to be applied to the combination to then calculate the time constant.

The NFB DC blocking time constant does not need altering to match these input modifications. It can remain as 1k0 & 220uF giving 220mS. If you wanted to experiment with a better capacitor here, then do not drop it (or a parallel combination) below 150uF.

- Status

- This old topic is closed. If you want to reopen this topic, contact a moderator using the "Report Post" button.

- Home

- Amplifiers

- Solid State

- TL084CN vs AD731